Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82 results about "Inorganic Syntheses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inorganic Syntheses is a book series which aims to publish "detailed and foolproof" procedures for the synthesis of inorganic compounds. Although this series of books are edited, they usually are referenced like a journal, without mentioning the names of the checkers (referees) or the editor. A similar format is usually followed for the series Organic Syntheses.

Synthetic method of carbon quantum dot material

The invention relates to the technical field of inorganic synthesis, and aims to provide a synthetic method of a carbon quantum dot material. The method is characterized in that a reducing agent and a reaction substrate are put in a solvent and react at 100-200DEG C for 2-72h to synthesize the carbon quantum dot material; the molar ratio of the reducing agent to the reaction substrate is 1-100; and the mass ratio of the solvent to the reaction substrate is 20-1000. The method is simple and effective, adopts a solvothermal synthesis process to substitute traditional tedious synthetic processes, adopts an organic matter to substitute traditional expensive substances as a carbon precursor and adopts L-ascorbic acid and its analogues as the reducing agent. The whole process of the method has the advantages of high efficiency, environmental protection and low cost.

Owner:ZHEJIANG UNIV

Method for inorganically synthesizing organized mesoporous alumina

InactiveCN101993102ALow costLarge specific surface areaOther chemical processesCatalyst activation/preparationAluminium chlorideNano structuring

The invention belongs to the field of inorganic nano structure materials, in particular to a method for inorganically synthesizing organized mesoporous alumina, which is characterized in that inorganic matters of sodium aluminate and aluminum chloride are in acid-base pairing to prepare mesoporous alumina which has large specific surface area, narrow pore-size distribution, organized pore channel and high hydrothermal stability; and methyl cellulose which is used as a template agent in a synthesizing process has thermosensitivity and is beneficial to recycle. The method for inorganically synthesizing organized mesoporous alumina has the characteristics that raw materials have low cost, the template agent can be recycled, the technology is simple and easy to control, and the like. The method for inorganically synthesizing organized mesoporous alumina is easy to realize industrial production, and the obtained organized mesoporous alumina has wide application prospect in the fields of catalytic reaction, adsorption, separation, and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Core-shell structural dibasic composite zeolite and preparation method thereof

InactiveCN101177276AEmission reductionSave raw materialsMolecular sieve catalystsMordenite aluminosilicate zeoliteHydrogenMordenite

A binary composite zeolite with a core-shell structure and a preparation method thereof, which belong to the field of inorganic synthesis and catalyst preparation, specifically relate to a binary composite zeolite with a Beta core and a mordenite shell structure and a preparation method thereof. The material will contain two phases of Beta zeolite and mordenite at the same time, and the ratio of the two phases and the surface L / B acid can be adjusted. Directly add aluminum, organic template agent tetraethylammonium bromide and alkali, and use Beta zeolite as the silicon source for mordenite synthesis to prepare a binary composite zeolite material with a double microporous core-shell structure, which is transformed by amine exchange After forming hydrogen form, it is used as a catalyst for the conversion of methanol to prepare dimethyl ether. At a weight space velocity of 2.26 (g / g) h-1, a partial pressure of methanol of 11.4Kpa and a reaction temperature of 300°C, after 72 hours of reaction, methanol The conversion rate still remains above 80%, and the selectivity of dimethyl ether is above 99%.

Owner:TAIYUAN UNIV OF TECH

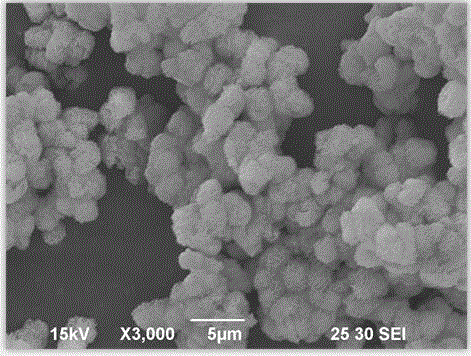

Method for preparing nano powder material

InactiveCN101962168ASmall grain sizeNarrow particle size distributionNanostructure manufactureRare earth metal compoundsSolventParticle-size distribution

The invention relates to a method for preparing a nano powder material, and belongs to the field of inorganic synthesis and material chemistry. In the method, a crystalline hydrate of nitrate is taken as a raw material, anhydrous C2 to C4 alcohols are taken as a solvent, ethanolamine is taken as a precipitator; and the nano powder material, such as zirconium oxide, cerium oxide and the like, is prepared by a coprecipitation method. The method overcomes the defects of nonuniform precipitation, easy aggregation, need of special drying method and equipment, and the like in the conventional coprecipitation method in which water is taken as the solvent, and an inorganic base or an inorganic salt is taken as the precipitator; and the prepared nano powder material, such as zirconium oxide and cerium oxide has the advantages of small grain size (the grain size is 6 to 20nm), small particle size, narrow particle size distribution range (the particle size distribution range is 50 to 150nm), no hard aggregation, high sintering activity and the like. The prepared nano powder material is suitable for the fields of a solid oxide fuel cell, a chemical sensor, a special functional ceramic, a catalyst or a catalyst carrier and the like.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

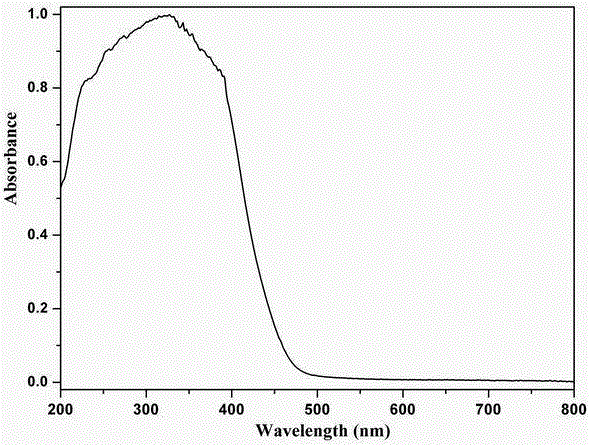

Synthesis method of tungsten trioxide

InactiveCN103011293ADifferent shapesDifferent optoelectronic propertiesTungsten oxides/hydroxidesHydration reactionOrganic dye

The invention provides a synthesis method of tungsten trioxide, belongs to the technical field of inorganic synthesis chemistry, and particularly relates to the synthesis method of the tungsten trioxide. The synthesis method comprises the following steps of: taking sodium tungstate dihydrate and sodium chloride as raw materials; utilizing hydrochloric acid to adjust a pH (Potential of Hydrogen) value of a reaction system to adjust the pH value to 1.5-3.0; carrying out hydrothermal reaction at 170-190 DEG C for 22-28 hours; and washing, centrifuging and drying to obtain tungsten trioxide powder. The obtained tungsten trioxide powder has different shapes and different photoelectric properties. According to the synthesis method disclosed by the invention, a one-step hydrothermal synthesis method is adopted, so that the operation is simple, the repetitiveness is good and the raw material cost is low; and the pH value is simply adjusted to obtain the tungsten trioxide powder with the different shapes and the different photoelectric properties, and the photocatalytic degradation efficiency on an organic dye is higher.

Owner:JILIN UNIV

Method for synthesizing novel thin layer ZSM-5 zeolite with boron-containing framework

InactiveCN102942193AUnique lamellar structureHigh crystallinityPentasil aluminosilicate zeoliteStrong acidsAcid strength

The invention belongs to the crossing field of inorganic synthesis chemistry and material chemistry and relates to a method for synthesizing a thin layer ZSM-5 zeolite with a boron-containing framework. The method includes that a silicon source, a boron source, an aluminum source and a biquaternary ammonium salt template agent are mixed with deionized water to synthesize the thin layer ZSM-5 zeolite with a framework simultaneously containing boron and aluminum in one step through a hydrothermal process. The synthesized zeolite has the advantages that the thin layer sheet shaped appearance is achieved, the degree of crystallinity is high, the synthesized zeolite is in a typical MFI structure, a large outer surface area is achieved, a surface acidity site is fully exposed, and acid strength and strong acid site proportion on the surface of the zeolite can be effectively controlled by adjusting a ratio of boron and aluminum in a fed material. The thin layer ZSM-5 zeolite with the boron-containing framework has an excellent application potential in an acid catalyzed reaction and particularly in a macromolecule splitting and polysaccharide hydrolysis reaction.

Owner:中国寰球工程有限公司辽宁分公司 +1

Low temperature process of preparing RE borate crystal with oxide as precursor

InactiveCN1974885AMeet the requirements of sustainable developmentEasy to operatePolycrystalline material growthFrom normal temperature solutionsRare earthHydrothermal synthesis

The present invention belongs to the field of micron / nanometer material preparing technology and hydrothermal synthesis technology, and is especially low temperature process of preparing RE borate crystal with oxide as precursor. In the hydrothermal system, insoluble RE oxide and hydrated boron trioxide or boron trioxide as the boron source and precursor are reacted at 190-280 deg.c for 12-48 hr, and through further washing, the required RE borate crystal is obtained. The present invention provides one inorganic synthesis way, and the production process has no any pollution. The present invention has simple technological process, easy-to-constitute reaction system, high product purity and other advantages, and is suitable for industrial production.

Owner:TONGJI UNIV

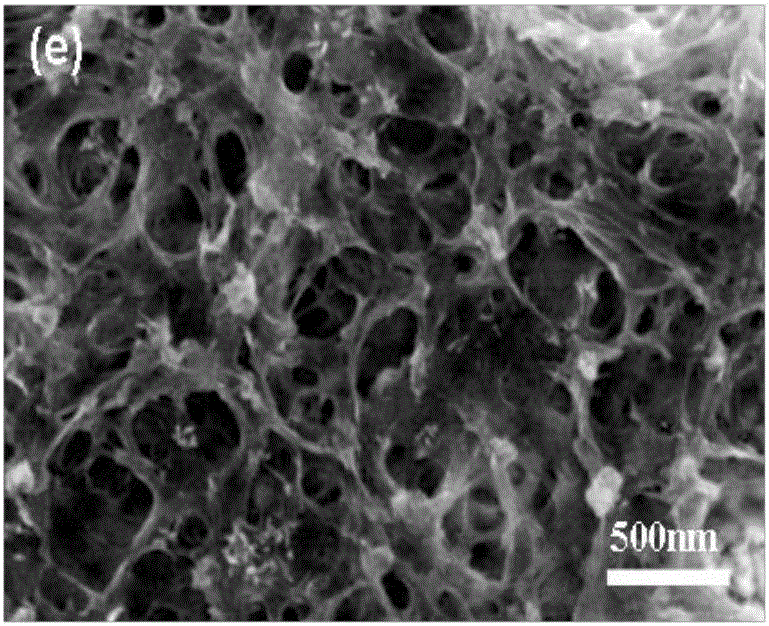

Method for preparing three-dimensional microporous graphene totally without participation of solution

The invention specifically provides a method for preparing three-dimensional microporous graphene totally without participation of a solution, which belongs to the technical field of inorganic synthesis. The method employs chemical vapor deposition and uses elemental transition metal powder or a compound containing a transition metal element as a catalyst so as to prepare a porous metal catalyst skeleton through high temperature reduction; then chemical vapor deposition is used for growing of graphene so as to obtain three-dimensional graphene with the catalyst skeleton; and a template is removed through direct evaporation at a high temperature under vacuum so as to obtain three-dimensional graphene. The method is simple and convenient to operate, and the obtained graphene can completely copy the shape of the template, which enables the designing space of the shape of a material to be great; no solution participates in the whole process of preparation, elimination of waste liquid is not needed, and the method is friendly to environment and can realize rapid and large-scale preparation of high-quality three-dimensional graphene; and the prepared three-dimensional graphene has the advantages of a small gap, great density and the like and has extensive application prospects in fields like spatial heat conduction, electric conduction, medicine, energy and catalyst carriers.

Owner:FUDAN UNIV

Preparation method of thermo-sensitive drug sustained and controlled release mesoporous composite

InactiveCN103495175AStable structureHigh drug loadingOrganic active ingredientsPharmaceutical non-active ingredientsDrug release rateIn situ polymerization

The invention belongs to the technical field of polymer chemistry and inorganic synthesis, and relates to a preparation method of a thermo-sensitive drug sustained and controlled release mesoporous composite. Mesoporous SiO2 microspheres are taken as carriers, and in-situ polymerization is adopted for preparing the mesoporous composite with thermosensitivity. The method includes adding an amides polymerization monomer, a crosslinking agent and an initiating agent into an acetone solvent until being completely dissolved, then adding the mesoporous SiO2 microsphere activated in advance into the mixture, heating in the atmosphere of nitrogen at the temperature of 60 DEG C for 12 hours prior to cooling to the room temperature, and performing suction filtration, washing and vacuum drying to obtain the thermo-sensitive mesoporous composite; adding the thermo-sensitive mesoporous composite into an organic solvent containing a drug, regulating the concentration of the drug, stirring at the temperature of 45 DEG C for 48 hours prior to filtering and washing to obtain a solid, and dying the solid in vacuum at the temperature of 40-60 DEG C. The method has the advantages of simple process, convenience in operation and the like, and the obtained thermo-sensitive drug sustained and controlled release mesoporous composite has the advantages of stable structure, high drug loading capacity, good thermosensitivity, stable drug release rate and the like and can be applied to the field of drug controlled release.

Owner:BEIJING UNIV OF TECH

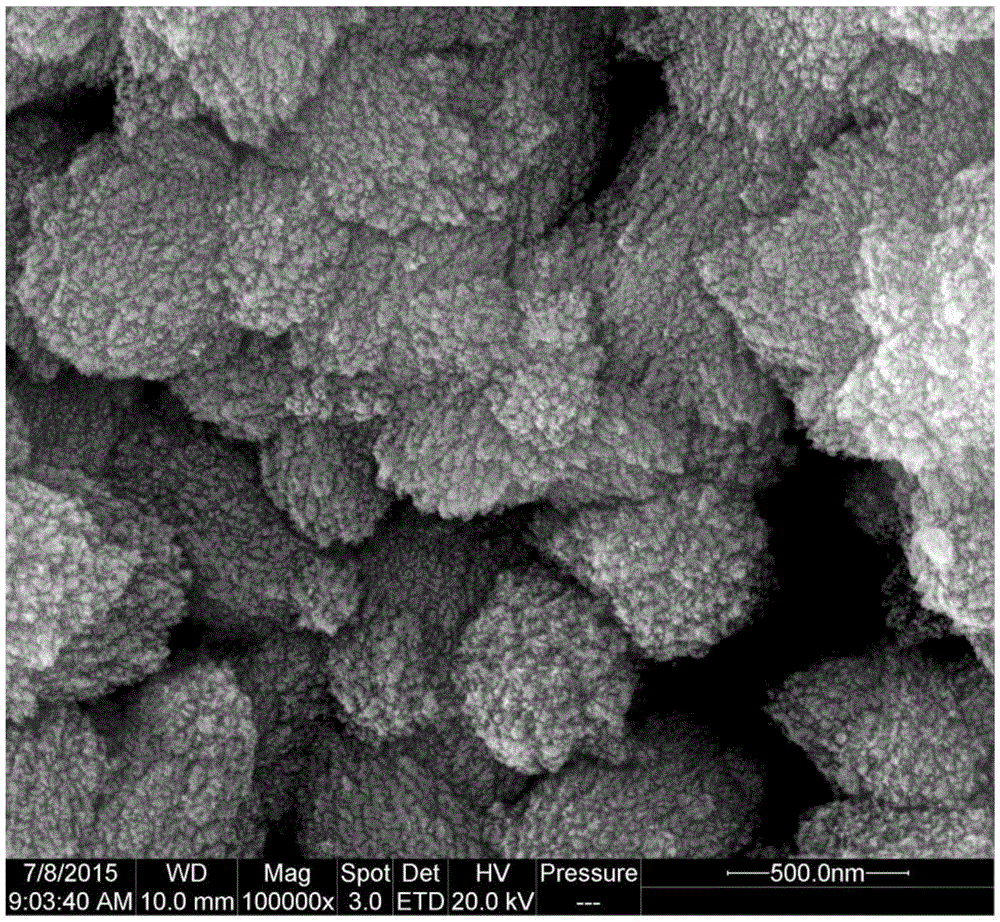

Synthesis method of nanometer ZSM-5 molecular sieve

ActiveCN106809858AMaterial nanotechnologyPentasil aluminosilicate zeoliteSynthesis methodsInorganic Syntheses

The invention provides a synthesis method of a nanometer ZSM-5 molecular sieve, and belongs to the technical field of inorganic synthesis and catalyst preparation. The method uses silica sol and sodium metaaluminate as a silicon source and an aluminum source. In the synthesis process, tetrapropylammonium hydroxide and polyethyleneimine can be added in the synthesis process to be used as an organic template agent, or only the polyethyleneimine is added; after the raw material mixing, gelling is performed for 0.5 to 10 hours after the raw material mixing; then, the materials are transferred into a high-pressure reaction kettle to be crystallized at 120 to 180 DEG C; after the obtained ZSM-5 molecular sieve is roasted, the crystal grain dimension is smaller than 50nm. The molecular sieve prepared by the method has the advantages that the crystal grain size is small; the particle diameter is uniform; the operation is simple; the amplified production is easy, and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Inorganic synthesis method for regulating morphology of ZSM-5 molecular sieve

ActiveCN106348312AGood structuring reaction performanceAvoid it happening againPentasil aluminosilicate zeoliteAromatizationInorganic Syntheses

The invention provides an inorganic synthesis method for regulating the morphology of a ZSM-5 molecular sieve. The method at least comprises the following steps: (1) adding a silicon source, an alkali source and an aluminum source into pure water respectively, and stirring uniformly to obtain silica-alumina gel; (2) adding a molecular sieve morphology regulation inorganic additive and a zeolite seed crystal into the silica-alumina gel, and stirring uniformly to obtain a gel mixture; and (3) transferring the gel mixture into a sealed reaction kettle for crystallization, and then separating and drying the crystallized product to obtain a ZSM-5 molecular sieve, wherein the morphology of the ZSM-5 molecular sieve is suitable to be controlled by regulating the addition amount of the molecular sieve morphology regulation inorganic additive. Through the method provided by the invention, a low-silicon ZSM-5 molecular sieve with a regulatable morphology and a silica-alumina ratio controllable in a certain range can be obtained, and the low-silicon ZSM-5 molecular sieve has relatively high crystallinity and purity and good aromatization reaction performance; and moreover, a roasting step is saved in the production process, and environmental pollution is reduced.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

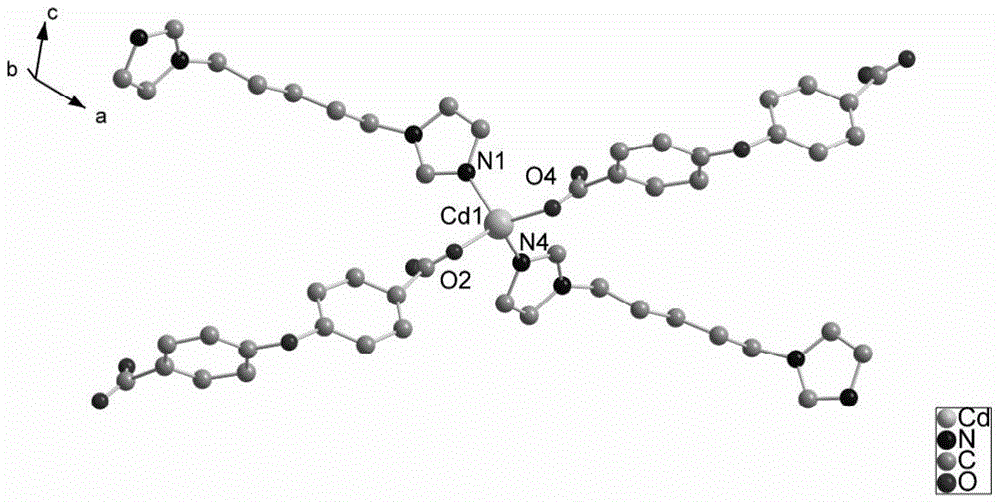

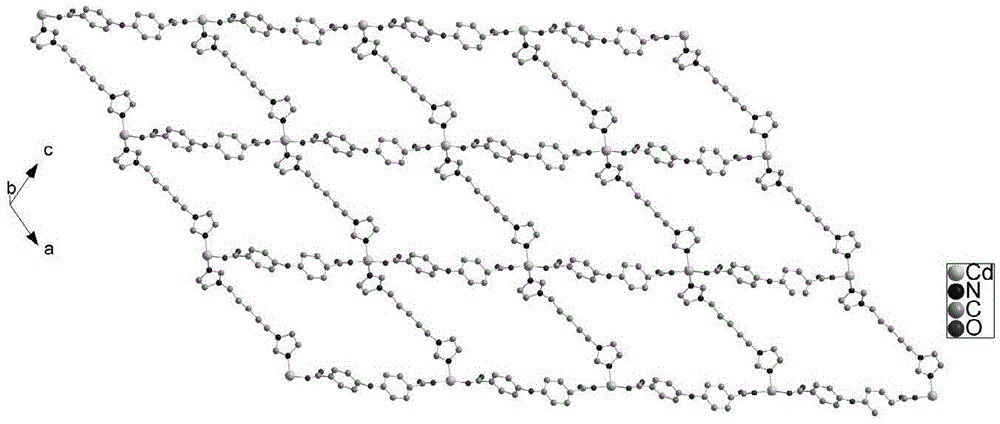

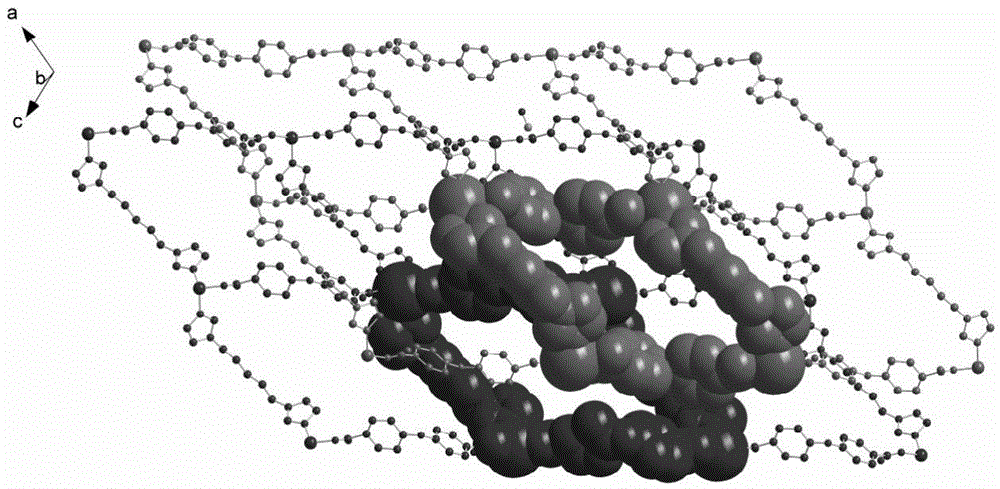

Multifunctional cadmium complex constructed based on mixed organic ligands and application thereof

InactiveCN105542188AImprove thermal stabilityGood reproducibilityLuminescent compositionsBenzoic acidInorganic Syntheses

The invention belongs to the technical field of organic and inorganic synthesis, and in particular discloses a multifunctional cadmium complex constructed based on mixed organic ligands and application of the multifunctional cadmium complex. The multifunctional cadmium complex is characterized in that the complex is of a single-node two-dimensional (4, 4) mesh topology structure; a chemical expression formula of the complex is represented by [Cd(1,5-bip)(oba)]n, wherein H2oba is a negative bivalent anionic ligand 4,4minute-oxybis(benzoic acid) with a structure represented by a formula 2; 1,5-bip is a nonionic ligand 1,5-diimidazolyl pentane with a structure represented by a formula 3. The invention discloses application of the constructed cadmium complex as a potential fluorescent material. The formula 2 and the formula 3 are shown in the description.

Owner:SHAANXI UNIV OF TECH

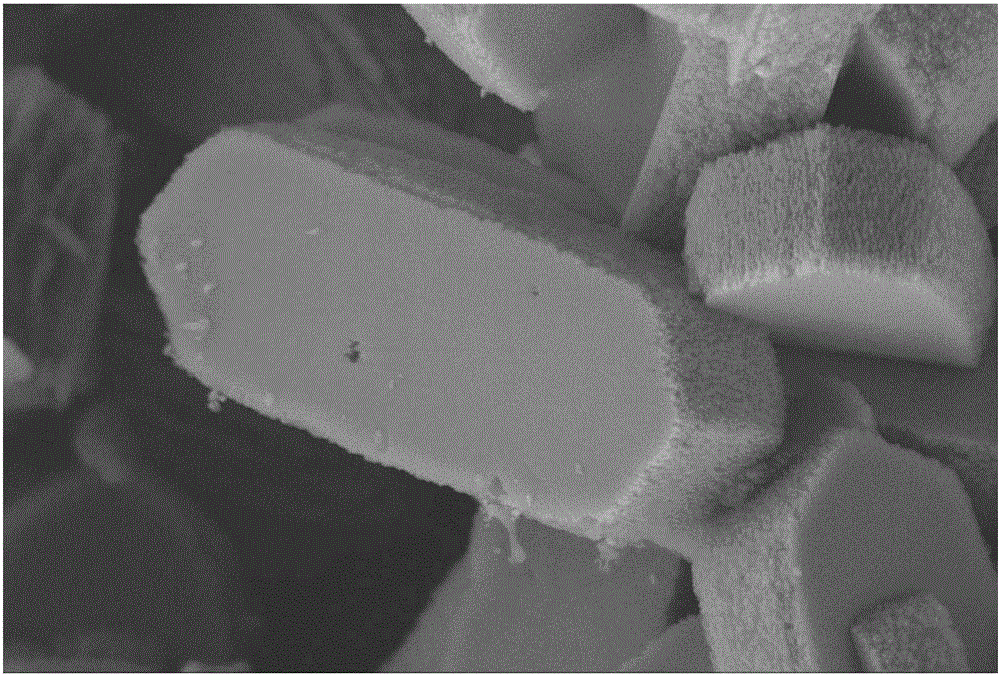

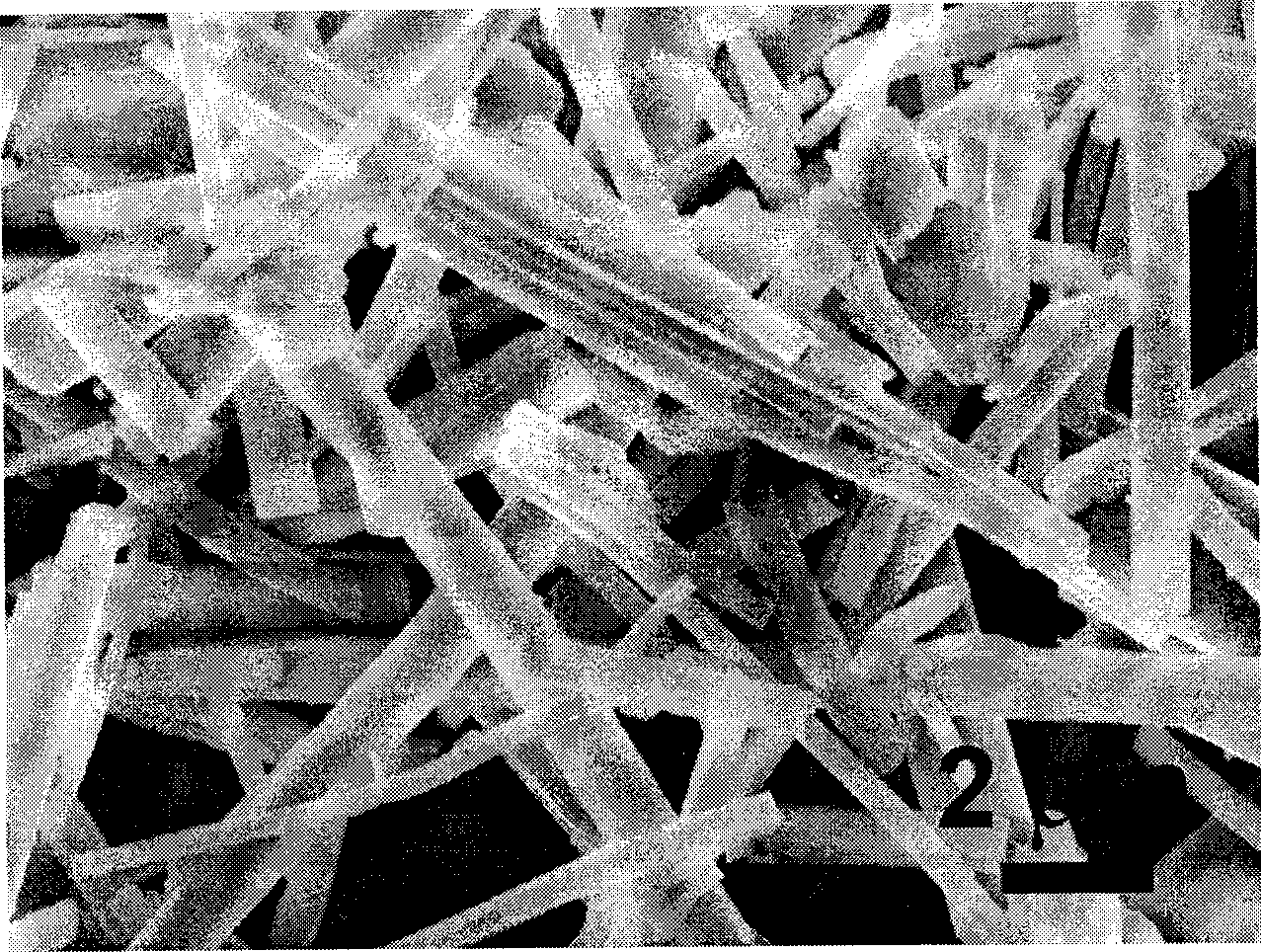

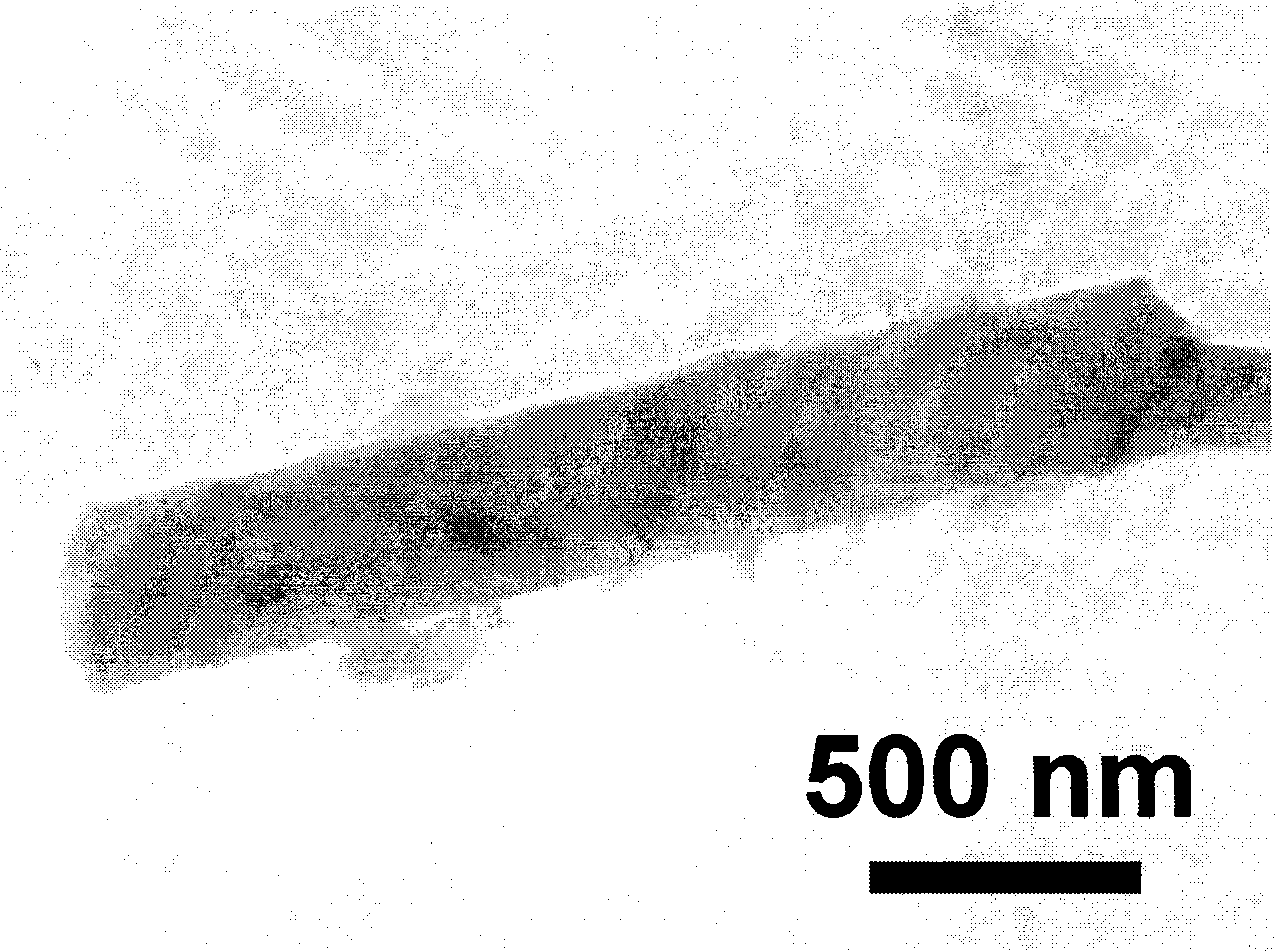

Synthesis method of ZSM-5 molecular sieve and ZSM-5 molecular sieve

The invention relates to a method for synthesizing nanometer ZSM-5 molecular sieves with sheet-like interlaced self-supporting structures, and belongs to the technical field of inorganic synthesis and catalyst preparation. In this method, silica sol and sodium metaaluminate are used as silicon source and aluminum source, and one or two or more organic substances in piperazine, morpholine, triethylenediamine, and piperidine are added in the synthesis, and the raw materials are mixed in 20-50 °C for gelation for 0.5-10 hours, and then transferred to a high-pressure reactor for crystallization at 120-180 °C, and the obtained ZSM-5 molecular sieve has a sheet-like interlaced self-supporting structure after roasting.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

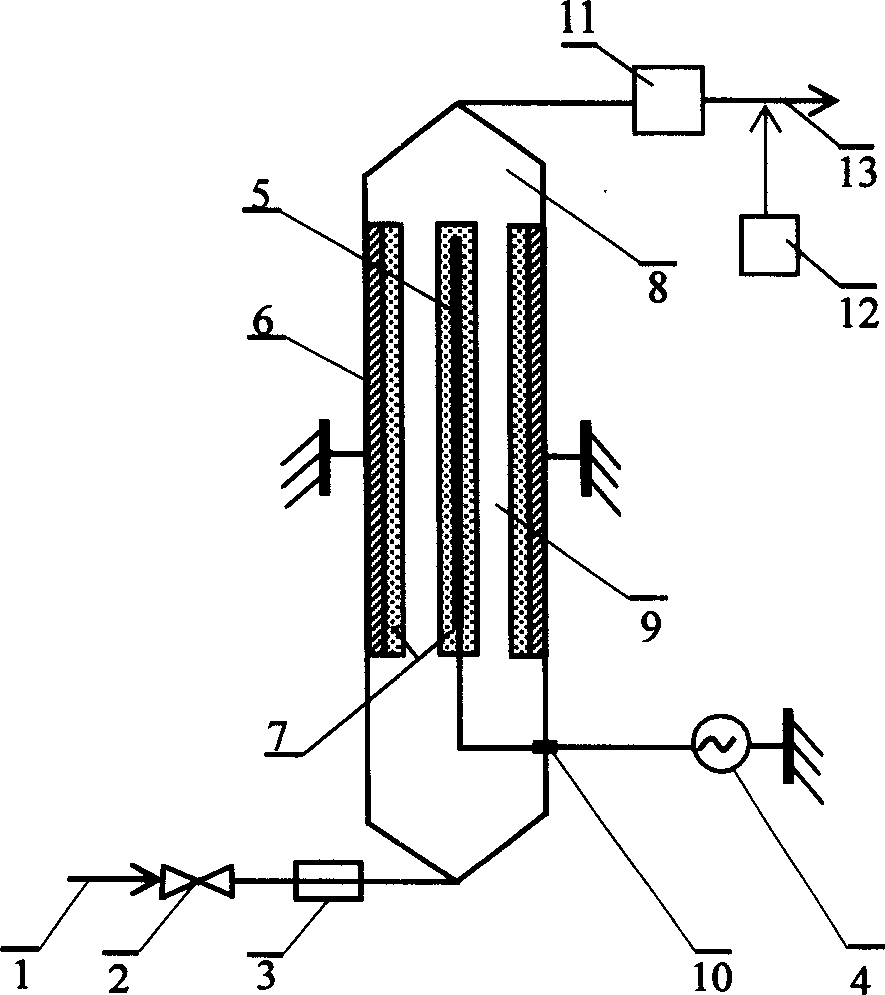

Method for producing acetylene for cracking natural gas by micro discharge

InactiveCN101050158AFix stability issuesImprove conversion rateHydrocarbon by hydrocarbon crackingProduct gasInorganic Syntheses

This invention discloses a method for preparing acetylene by micro-discharge pyrolysis of natural gas. The conversion rate of methane is higher than 70%. The selectivity of acetylene is 80-90%. The selectivity of C2 is 85-95%. The energy consumption of acetylene is lower than 10 kWh / kg. The method can avoid electrode ablation problem faced by acetylene preparation by plasma pyrolysis of natural gas. Besides, the method lowers the energy consumption, and increases the conversion rate of methane as well as the selectivity of acetylene. The method can also be used in synthesis of other novel organic and inorganic matters.

Owner:DALIAN MARITIME UNIVERSITY

Method for preparing niobium pentoxide nano stick

InactiveCN101391770ASimple methodAchieve mass productionSilicon compoundsState of artInorganic Syntheses

The invention relates to a preparation method for a niobium pentaoxide nano rod which belongs to the field of inorganic synthesis and preparation, and particularly relates to a preparation method for a nano rod. The invention solves the problems that the equipment used for preparing the niobium pentaoxide one-dimensional nano-material is expensive and the reaction process is complex in the prior art. The invention comprises the following steps: 1. the calcium niobate nano rod is mixed with the hydrochloric acid with the concentration of 0.01 to 1mol / L in accordance with the mol ratio of 1:10 to 20 and then stirred for 30 to 120 minutes by magnetic force, later the obtained product undertakes centrifugal separation and is rinsed for 3 to 5 times with deionized water so as to obtain the niobate nano rod; 2. the niobate nano rod is annealed for 1 to 3 hours in the air at the temperature of 600 to 750 DEG C, then a niobium pentaoxide nano rod is obtained. The method is simple and feasible, can obtain one-dimensional niobium pentaoxide nano-material without expensive equipment for production, and can realize large-scale production.

Owner:HARBIN INST OF TECH

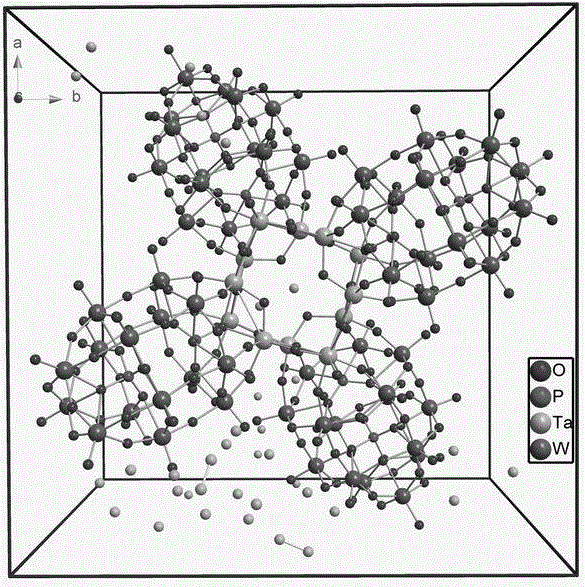

Ta/W mixed heteropoly acid, preparation method and application thereof in acid catalysis and proton conduction

InactiveCN106362796AStrong acidHigh acid catalytic activityOrganic chemistryOrganic compound preparationHeteropoly acidStrong acids

The invention discloses a Ta / W mixed heteropoly acid, a preparation method and application thereof in acid catalysis and proton conduction, belonging to the technical field of inorganic synthesis and acid catalysis. The invention has the essential technical scheme that the molecular formula of the Ta / W mixed heteropoly acid is H2O[P8W60Ta12(H2O)4(OH)8O236].125H2O, the Ta / W mixed heteropoly acid is composed of 1 tetramer Ta / W mixed heteropoly anion, 20 protons and 125 crystalline water molecules, and measured with dicinnamalacetone as an indicator in acetonitrile, the Hammett acid strength of the Ta / W mixed heteropoly acid is -2.91. The invention also discloses a preparation method of the Ta / W mixed heteropoly acid and application thereof in acid catalysis and proton conduction. The prepared Ta / W mixed heteropoly acid has the strongest acidity among the currently known heteropoly acids, and the strong acid property causes the Ta / W mixed heteropoly acid to have higher acid catalysis activity; and a large number of hydrogen bonds exist in the solid state structure of the prepared Ta / W mixed heteropoly acid and further form a hydrogen bond network, therefore the mixed heteropoly acid has stronger proton conducting power.

Owner:HENAN NORMAL UNIV

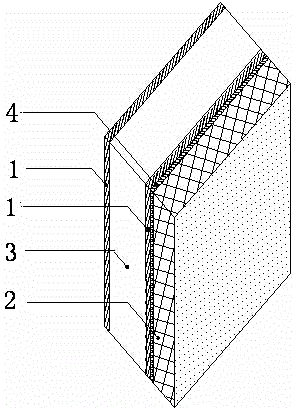

Energy-saving integrated board with inorganic synthesis finish and processing technology thereof

InactiveCN104831890AImprove securityImprove adhesionCovering/liningsSynthetic resin layered productsPolyurethane adhesiveThermal insulation

The invention relates to an energy-saving integrated board with an inorganic synthesis finish and a processing technology thereof, and belongs to the technical field of building board structures. The processing technology includes the steps that step1, a polyurethane board is cut according to the size of a finish coat; step2, polyurethane adhesive and polyaryl polymethylene isocyanate are mixed according to the mass ratio of 1:1-2, the temperature of a mixed material is controlled within 15 DEG C-50 DEG C, and then the mixed material is evenly poured between the polyurethane board and the finish coat; step3, a board obtained through the step2 is placed into a press machine, and pressure of 0.02 MPa-0.1 MPa is exerted on the board through the press machine so that the polyurethane board and the finish coat can be combined integrally; step4, after compositing is performed in the press machine for 1-1.5 hours, the obtained composite integrated board with the inorganic synthesis finish can be taken out. The energy-saving integrated board is excellent in thermal insulation and waterproof performance and convenient and rapid to construct, and the finish coat is not prone to cracking and falling.

Owner:WANHUA ENERGY-SAVING TECH GRP CO LTD

Method for preparing differently morphological hydroxyapatite by using waste shell

InactiveCN105800577AHigh purityUnique BiocompatibilityPhosphorus compoundsWater bathsInorganic Syntheses

The invention discloses a method for preparing differently morphological hydroxyapatite by using waste shells and belongs to the field of inorganic synthesis. The differently morphological hydroxyapatite is prepared under a constant-temperature water bath condition by using waste shells as a calcium source, using ammonium phosphate as a phosphorus source and regulating a pH value through ammonia water; in a process, the waste shells are used as raw materials, no morphology regulating agent or other surfactant is added, and the pH value is regulated in a constant-temperature water bath reaction process to achieve the purpose of preparing the differently morphological hydroxyapatite. The method for preparing the differently morphological hydroxyapatite by using the waste shells has the features of mild reaction conditions, high product purity, no impurities and stable quality, the production cost is low, no waste is discharged, the process flow is short, the synthesis time is short, the differently morphological hydroxyapatite with a higher utilization value is produced, and a new direction is opened for industrial production of morphologically controllable hydroxyapatite.

Owner:浙江海富海洋生物科技有限公司

In-situ Raman sample pool

InactiveCN101464253AEnhanced Raman signalAvoid distractionsRaman scatteringChemical reactionInorganic Syntheses

The invention relates to an in-situ Raman cell. A cell body is made of stainless steel and lined with polyfluortetraethylene inside; a thermocouple is arranged in a stainless steel kettle body; a heating pipe is helically coiled outside the kettle body; top threads and a quartz lens fixed by an O-shaped ring are arranged at the top part of a sample cell; a flange disk type design is adopted between a top cover of an in-situ cell and the cell body; and because the quartz lens is adopted as a window to increase a collection solid angle, the invention improves the collection efficiency of Raman diffused light, and can be applied to inorganic synthesis and chemical reaction in a monitoring high-temperature and high-pressure hydrothermal system.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

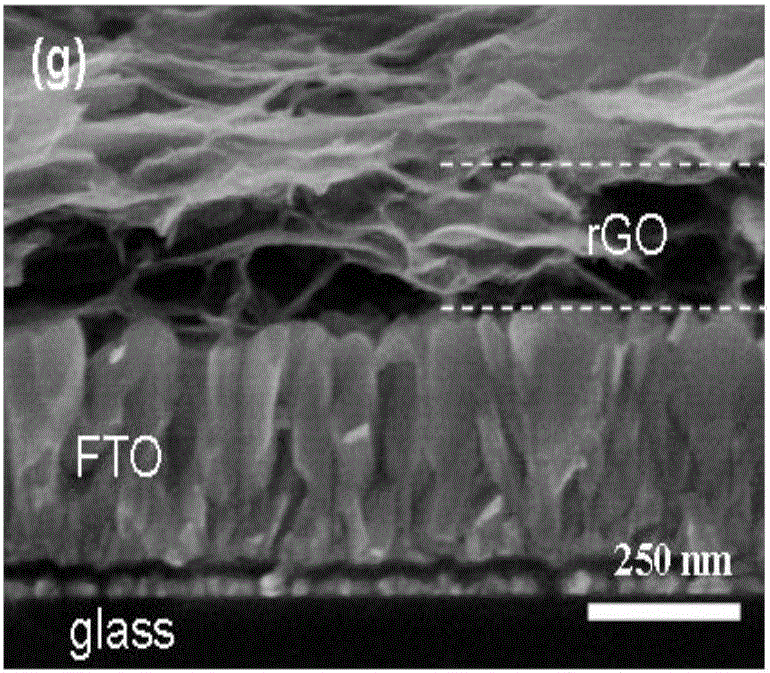

Preparation method and application for composite film of copper, zinc, tin, sulphur and three-dimensional graphene

The invention relates to a preparation method and application for a composite film of copper, zinc, tin, sulphur and three-dimensional graphene. The preparation method is characterized by adapting the hydrothermal technology in inorganic synthesis to grow copper, zinc, tin and sulphur nanometer materials on the surface of a three-dimensional porous graphene film and in the porous space thereof and then preparing the composite film of copper, zinc, tin and sulphur nano-particles and three-dimensional graphene. According to the measurement experiment of morphology and electrochemistry, the composite film of copper, zinc, tin, sulphur and three-dimensional graphene has high specific surface area, high conductivity and high catalytic characteristic, and can be used as the photo anode materials of dye-sensitized solar cells.

Owner:GUANGDONG UNIV OF TECH

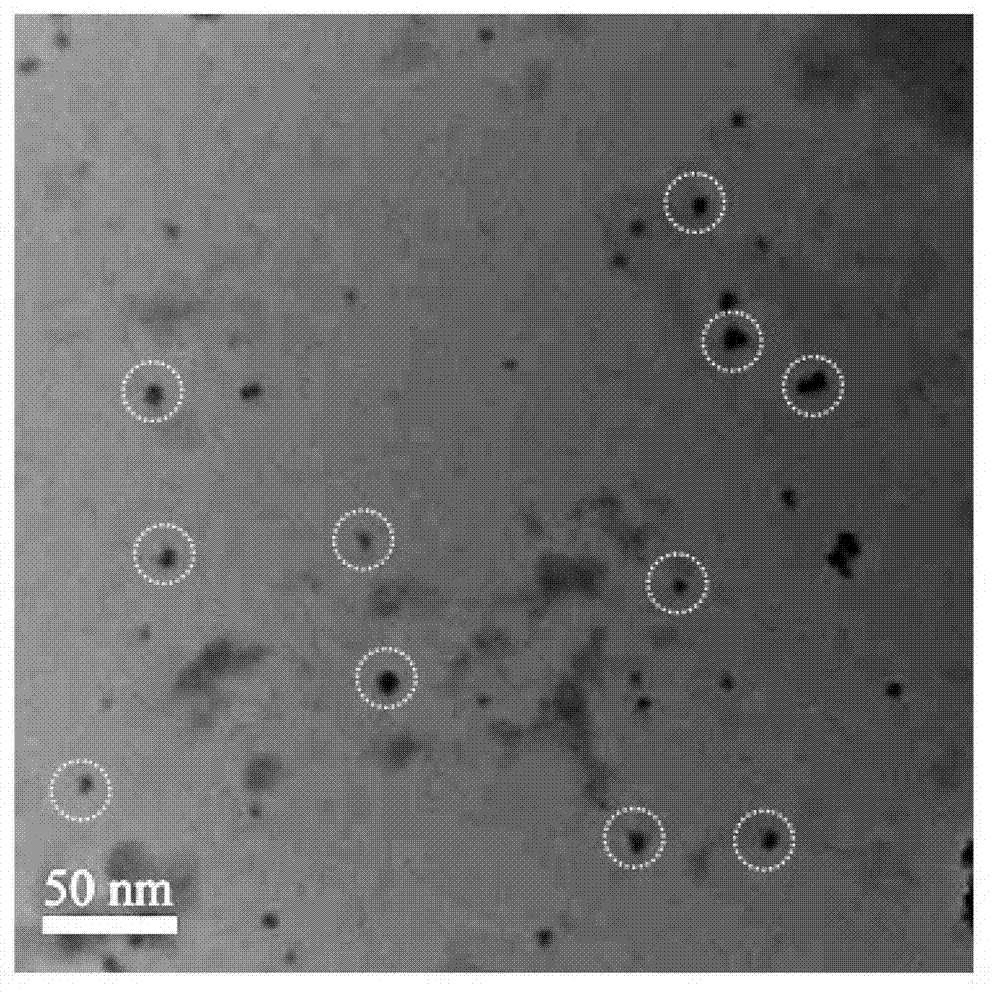

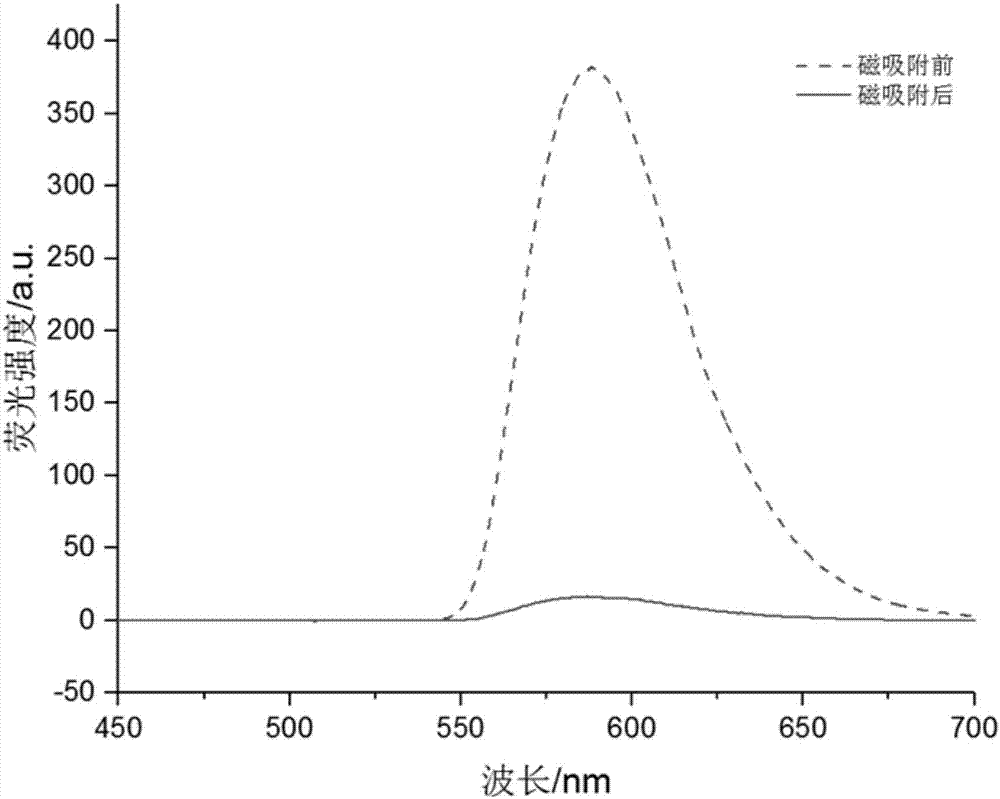

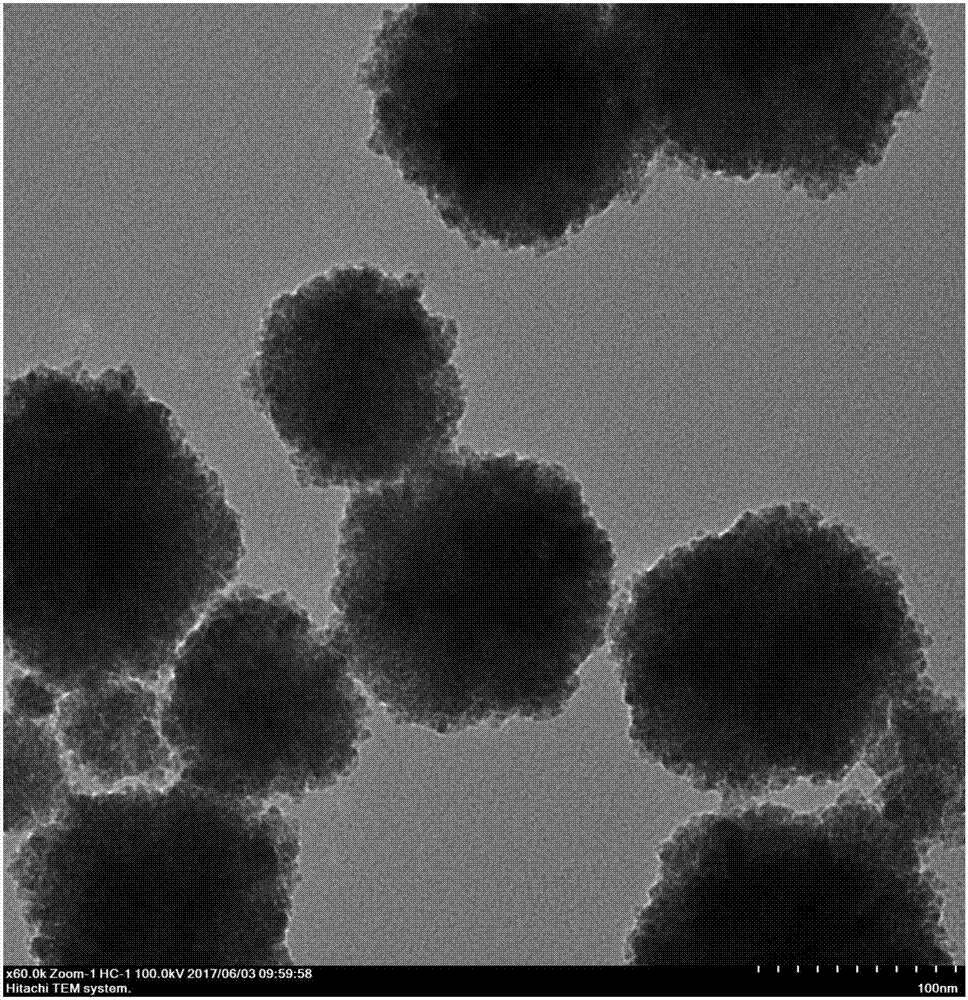

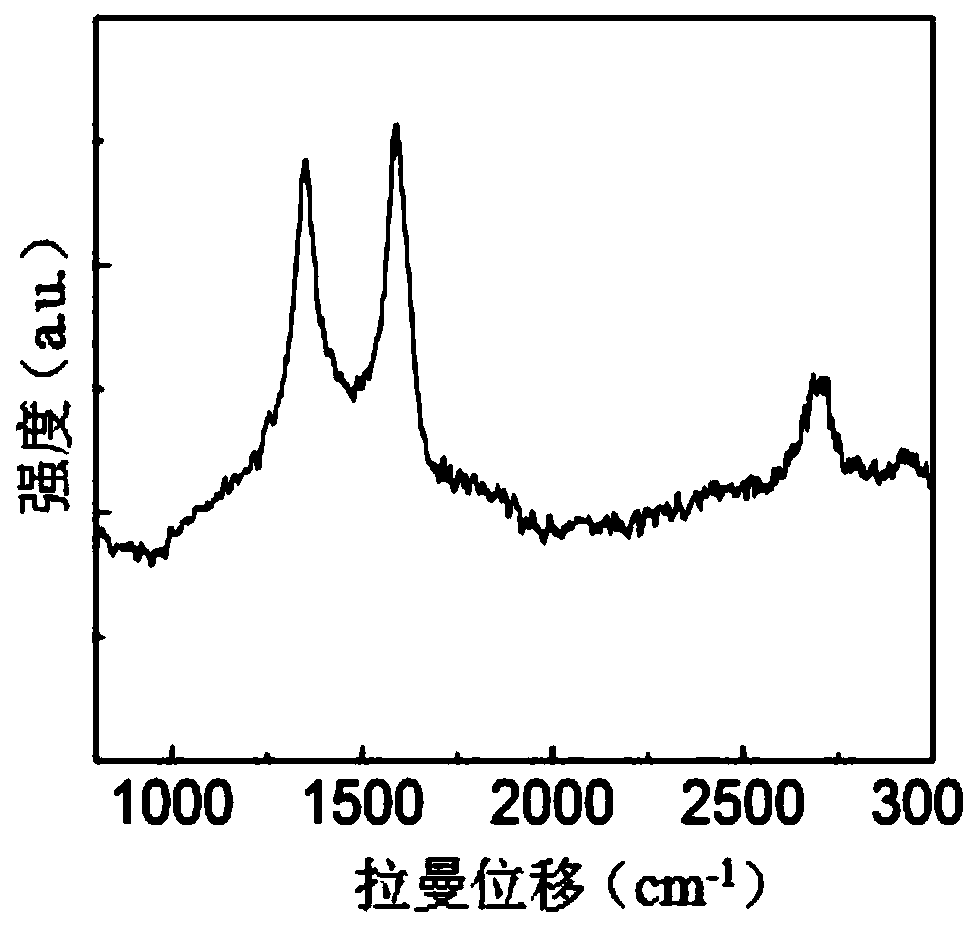

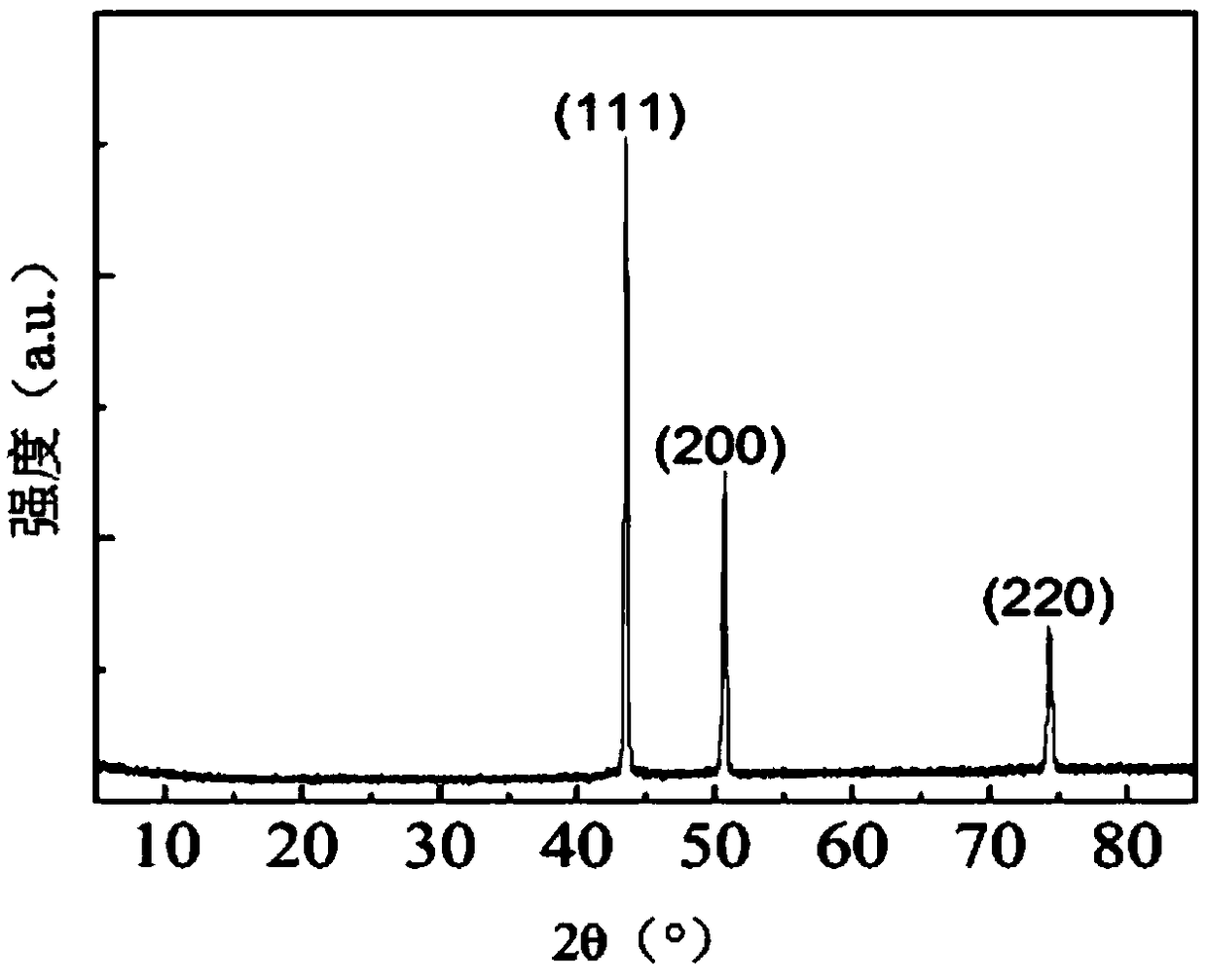

Method for preparing novel magnetic fluorescent nanometer composite material

ActiveCN107964400ASuperparamagneticStrong fluorescenceMaterial nanotechnologyNanoopticsFluorescenceInorganic Syntheses

The invention relates to a method for preparing a novel magnetic fluorescent nanometer composite material and belongs to the field of material chemistry and inorganic synthesis. The method combines magnetic particles and quantum dots and prepares the nanometer composite material with strong magnetic induction effects and high fluorescence performances. The magnetic fluorescent nanometer compositematerial can realize fast separation in a magnetic field and high-intensity fluorescence emission under light excitation. In the magnetic field, the nanometer composite material can be fast adsorbed by magnetic. The nanometer composite material can be fast redispersed after the magnetic field is eliminated. The method has the advantages of simple synthesis processes, high yield, uniform nanoparticle, small particle size and wide application, and has a great potential application value in medical detection, biological sensing, food analysis and environmental protection.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for preparing graphene/copper compound powder

The invention provides a method for preparing graphene / copper compound powder, belongs to the technical field of inorganic synthesis and powder metallurgy and solves the technical problems of poor coating uniformity of graphene on the surface of copper, high cost, complexity in process and the like existing in conventional preparation of the graphene / copper compound powder. The method comprises the following steps of: at an oxygen-free atmosphere, under the condition that the air pressure is 0.001-101325Pa, increasing the temperature of organic copper salt powder to 600-1050 DEG C at the velocity of 1-500 DEG C / minute, performing heating for 0.1-600 minutes, and then performing cooling at the oxygen-free atmosphere to obtain the graphene / copper compound powder. According to the method provided by the invention, copper salt is adopted as a raw material, the price is low, equipment and operation are very simple, and batched production is easy to perform; and the preparation of copper nanometer particles and the coating of the graphene on the surfaces of nanometer particles are realized at the same time in the process of one-step heating.

Owner:HARBIN INST OF TECH

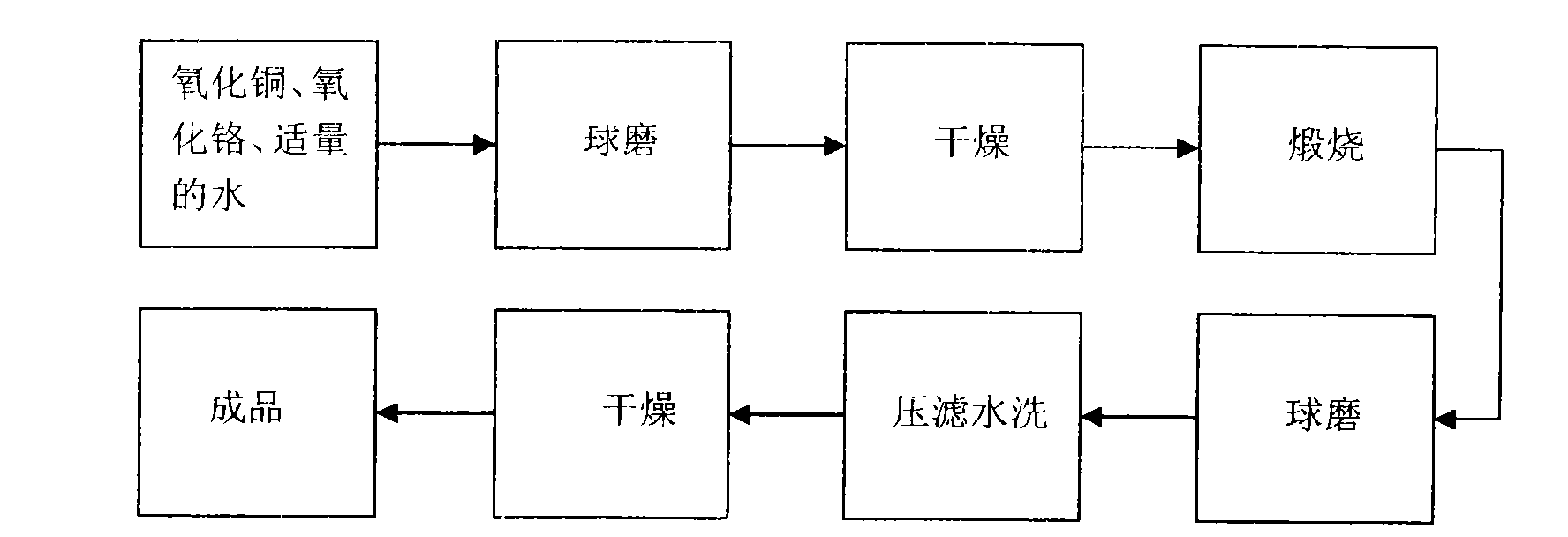

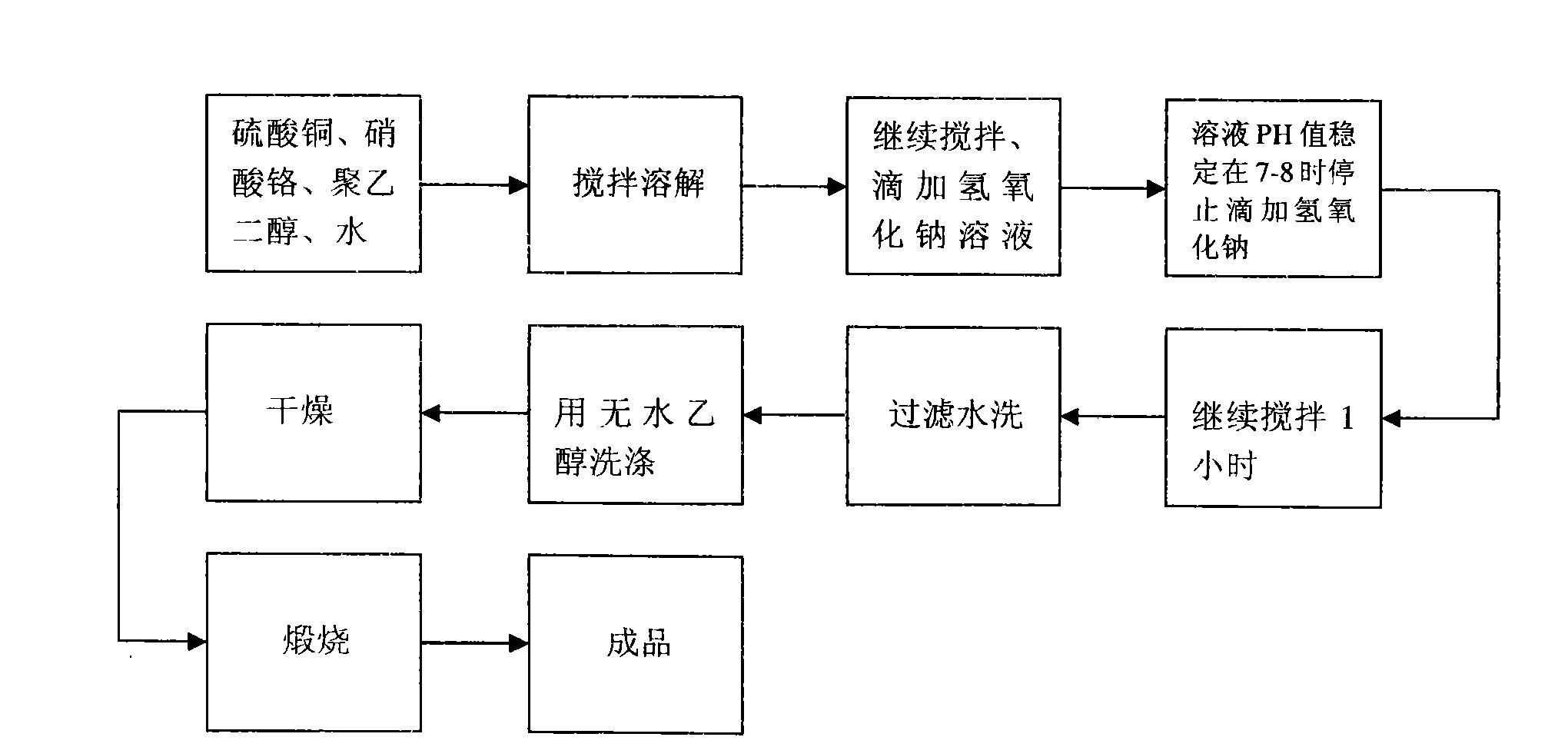

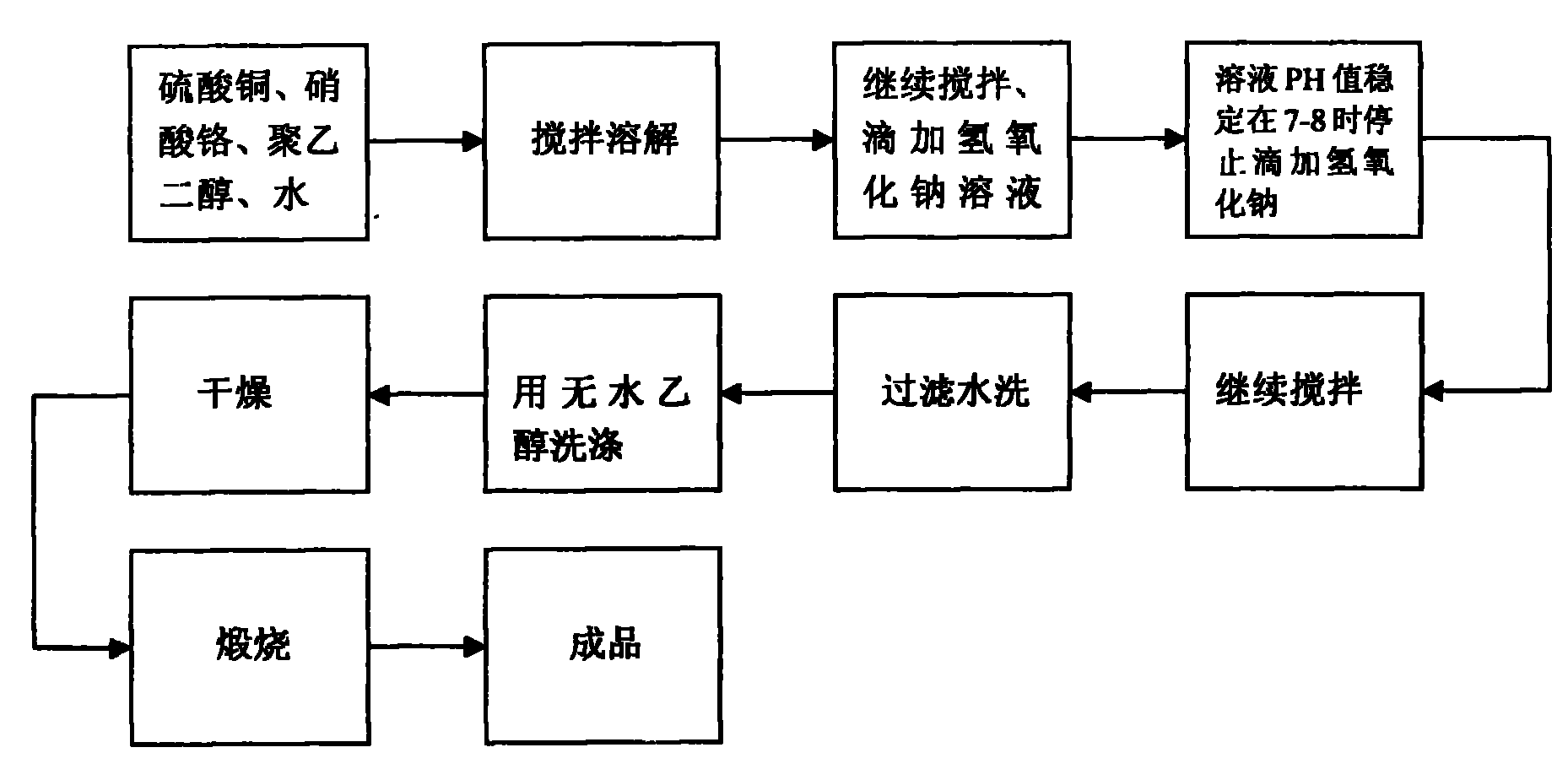

Method for preparing copper and chromium black pigment

InactiveCN102153891AImprove high temperature resistanceNo light fastnessCoatingsPigment treatment with macromolecular organic compoundsAlcoholGram

The invention relates to an inorganic synthesis method for preparing a copper and chromium black pigment. The copper and chromium black pigment has the following raw material formula: 250 grams of bluevitriod, 340 to 460 grams of chromium nitrate nonahydrate, 27 to 37 grams of polyethylene glycol and 170 to 230 ml of absolute alcohol. Due to the adoption of the method, the problems of large particles and uncentralized particle diameter distribution of the copper and chromium black pigment produced by a conventional method are solved; the production steps are simplified; the calcining temperature is reduced; and compared with an organic pigment, the copper and chromium black pigment has good high temperature stability and wide application range.

Owner:邵阳县彩鑫制釉有限公司

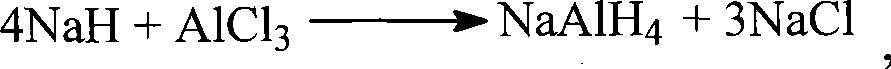

Method for preparing sodium aluminum hydride

The invention discloses a method for preparing sodium aluminum hydride, wherein liquid sodium, solid aluminum and hydrogen gas are reacted at heating condition to prepare the sodium aluminum hydride. The invention provides sodium aluminum hydride prepared by the method. The invention belongs to inorganic synthesis field. Compared with prior art, the method for preparing sodium aluminum hydride can finish preparation of the sodium aluminum hydride by one step. The technical scheme provided by the present invention is especially suitable for sodium aluminum hydride industrialization production.

Owner:YINGLI ENERGY CHINA

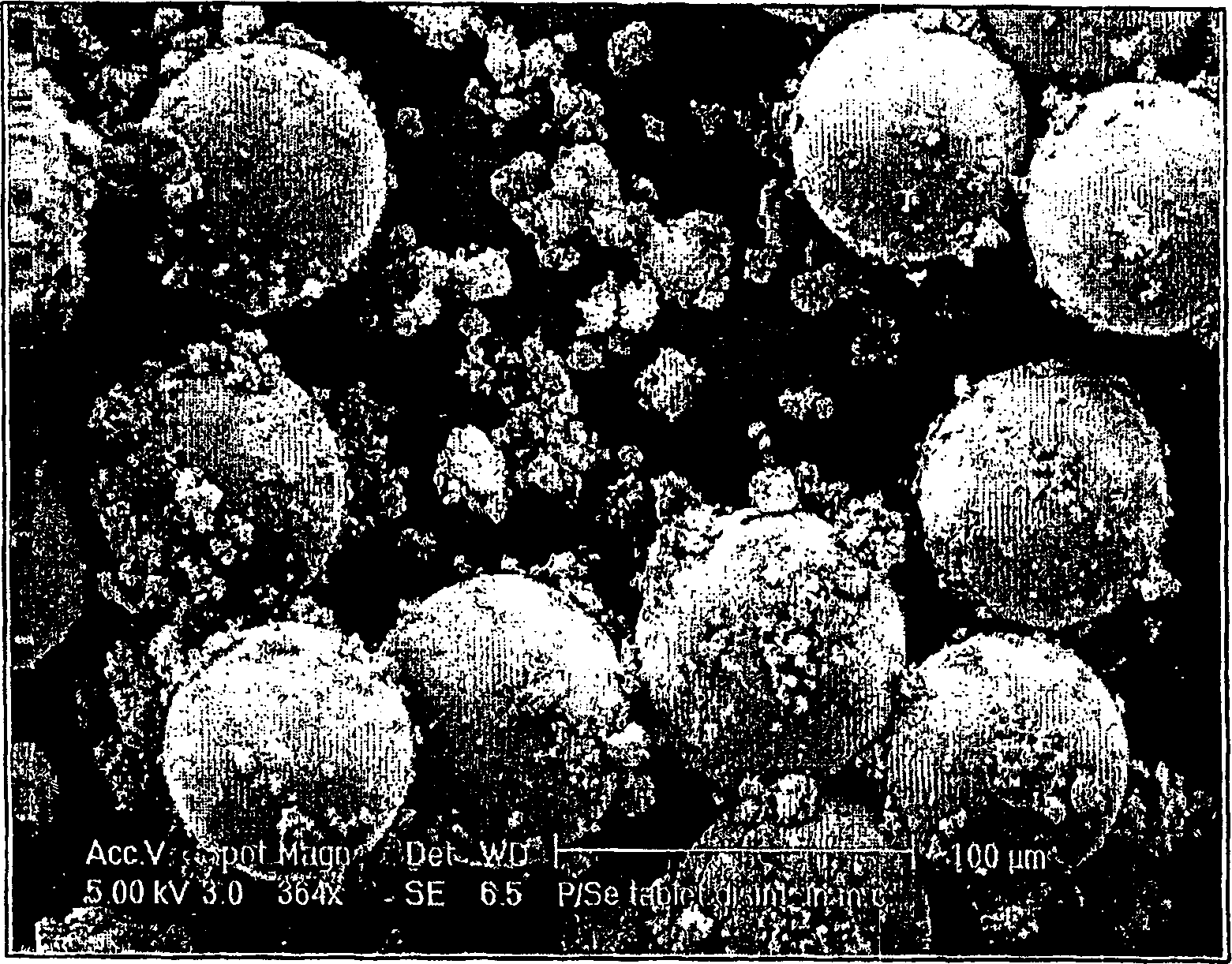

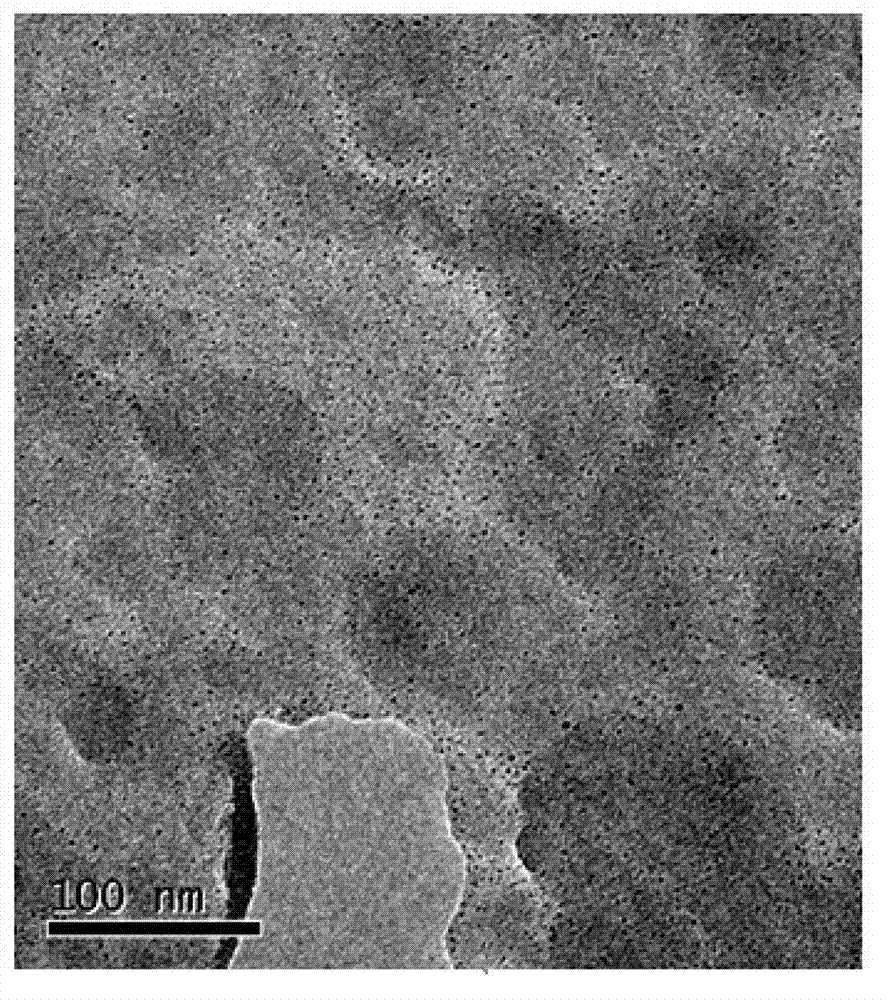

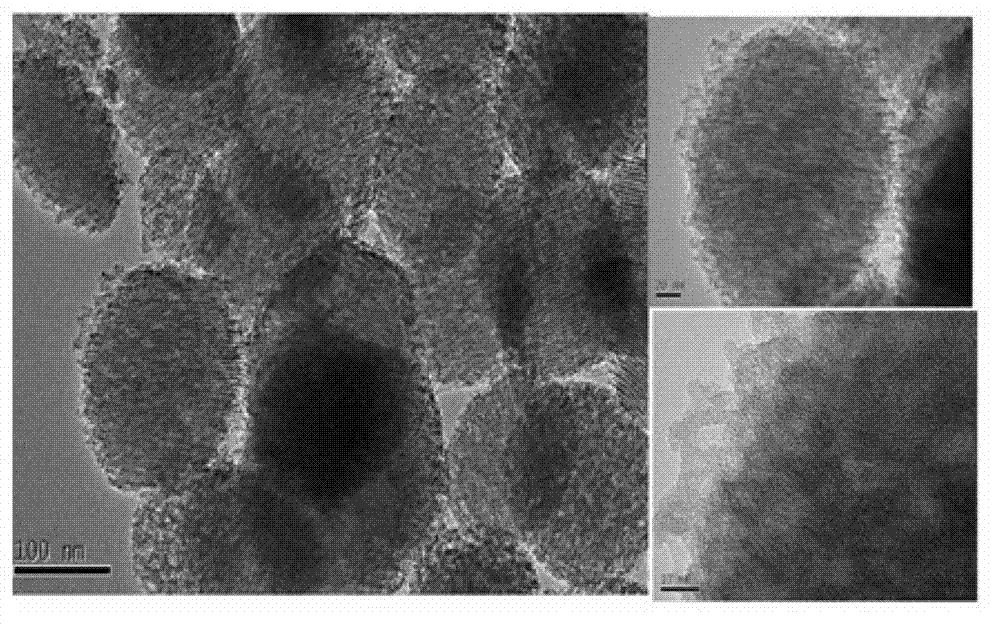

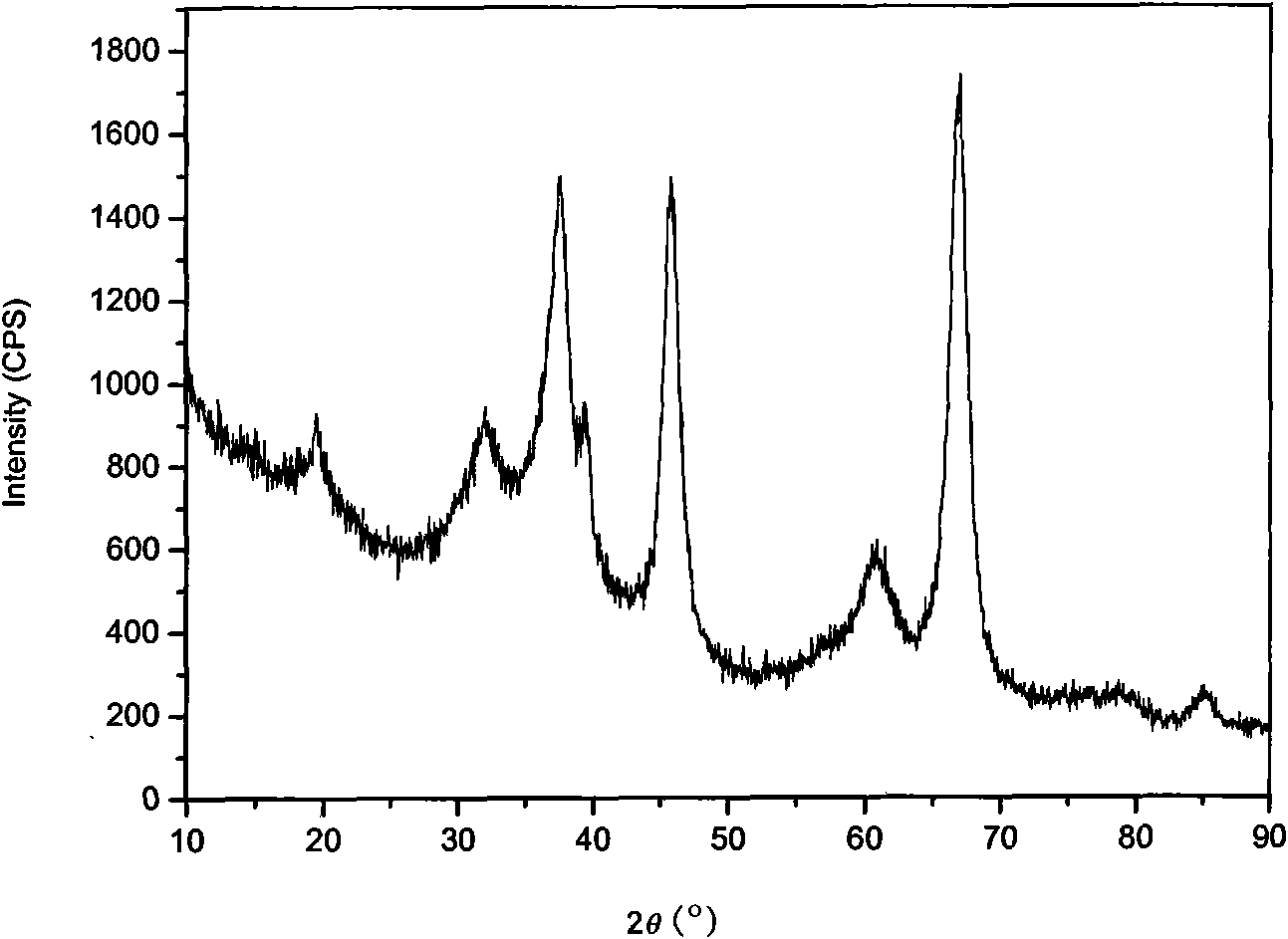

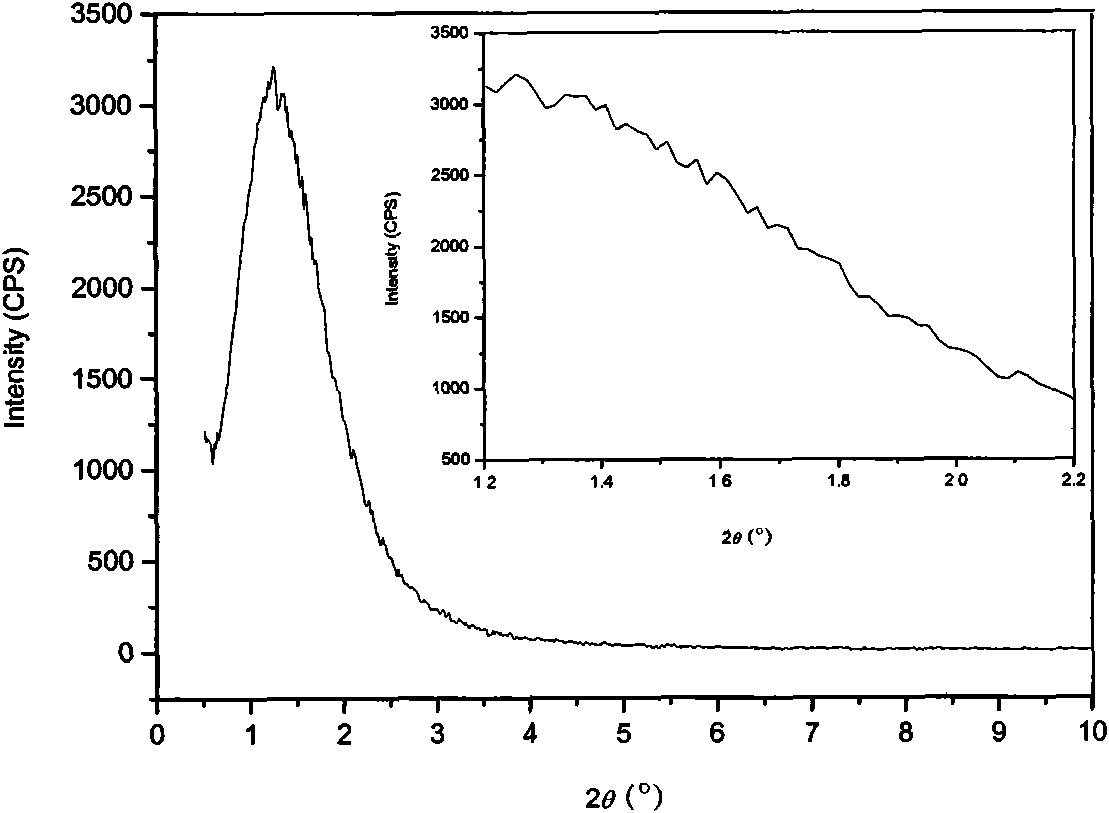

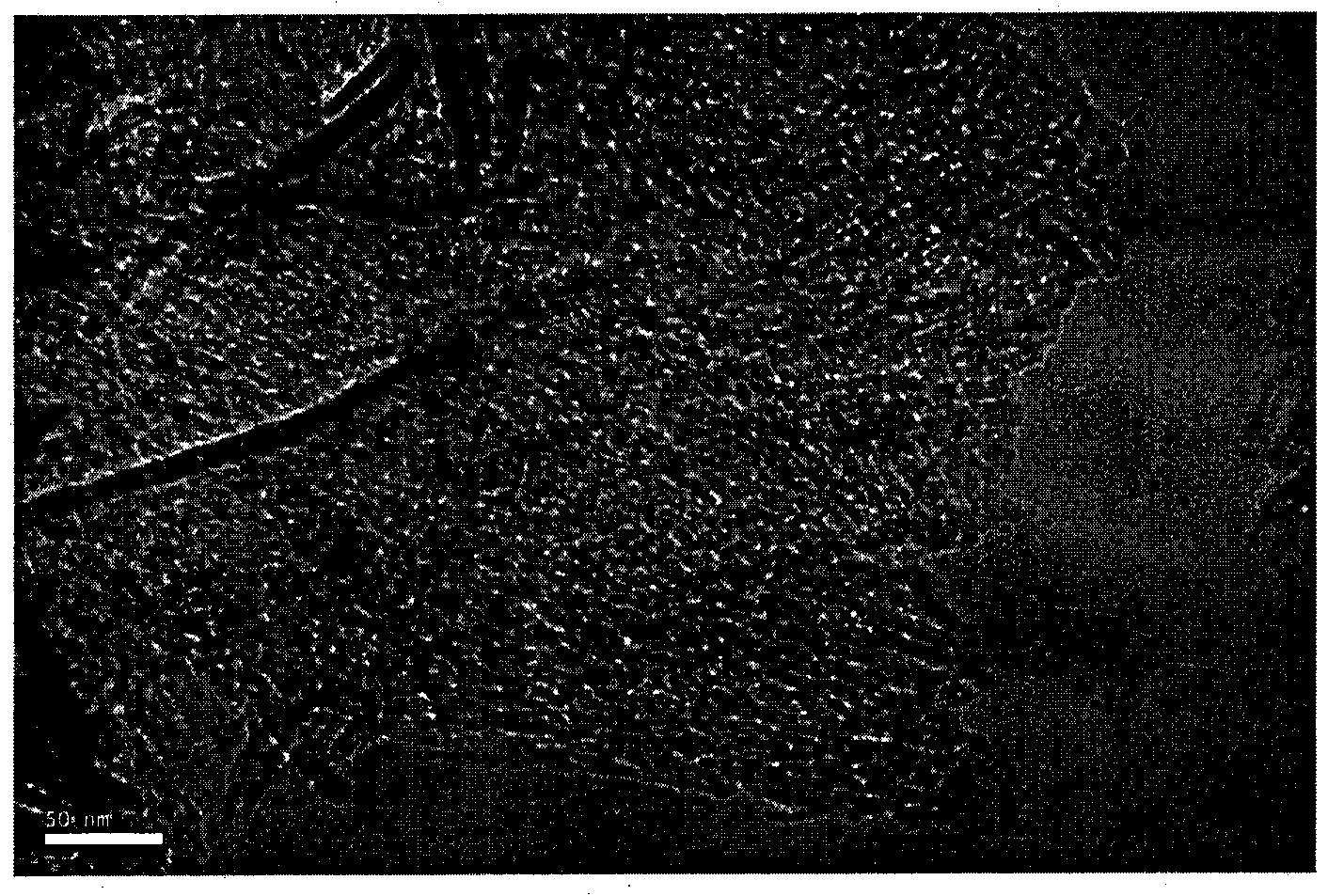

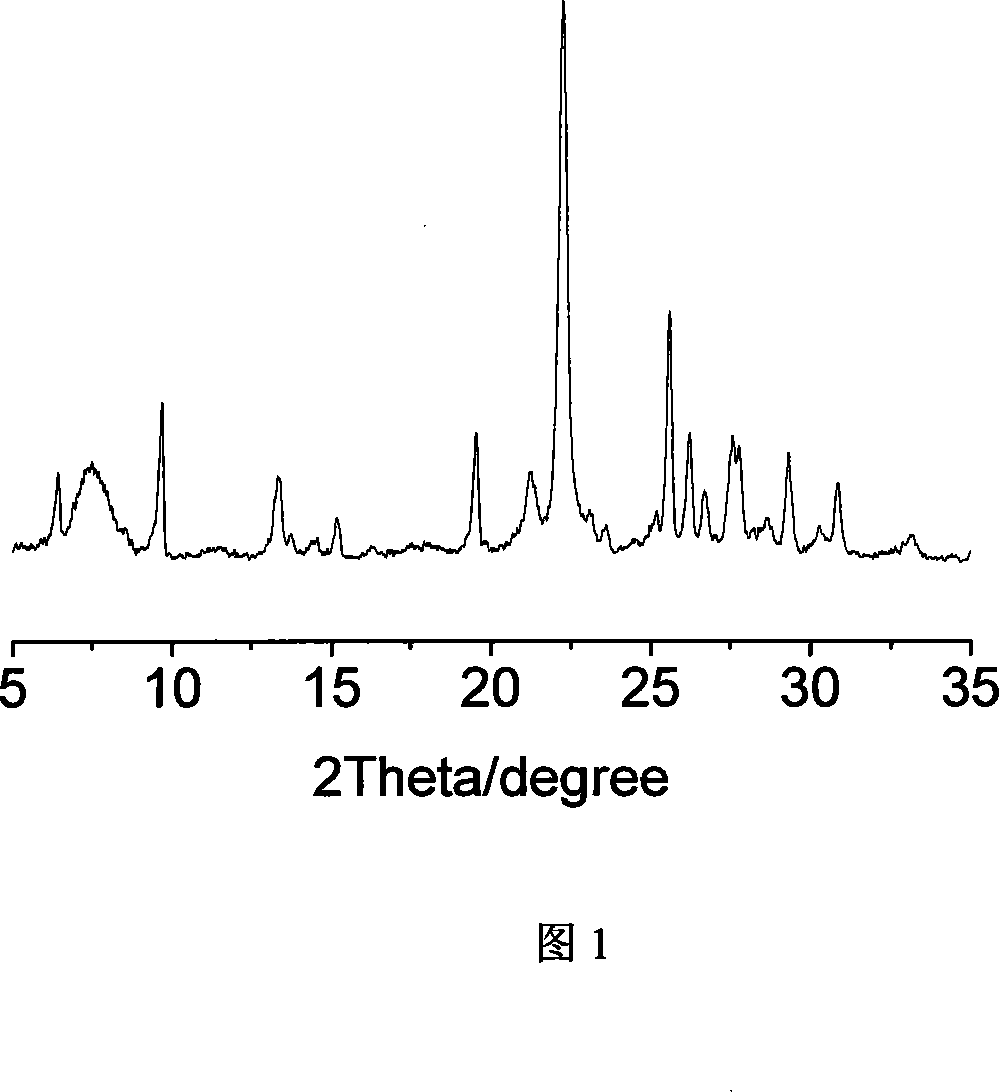

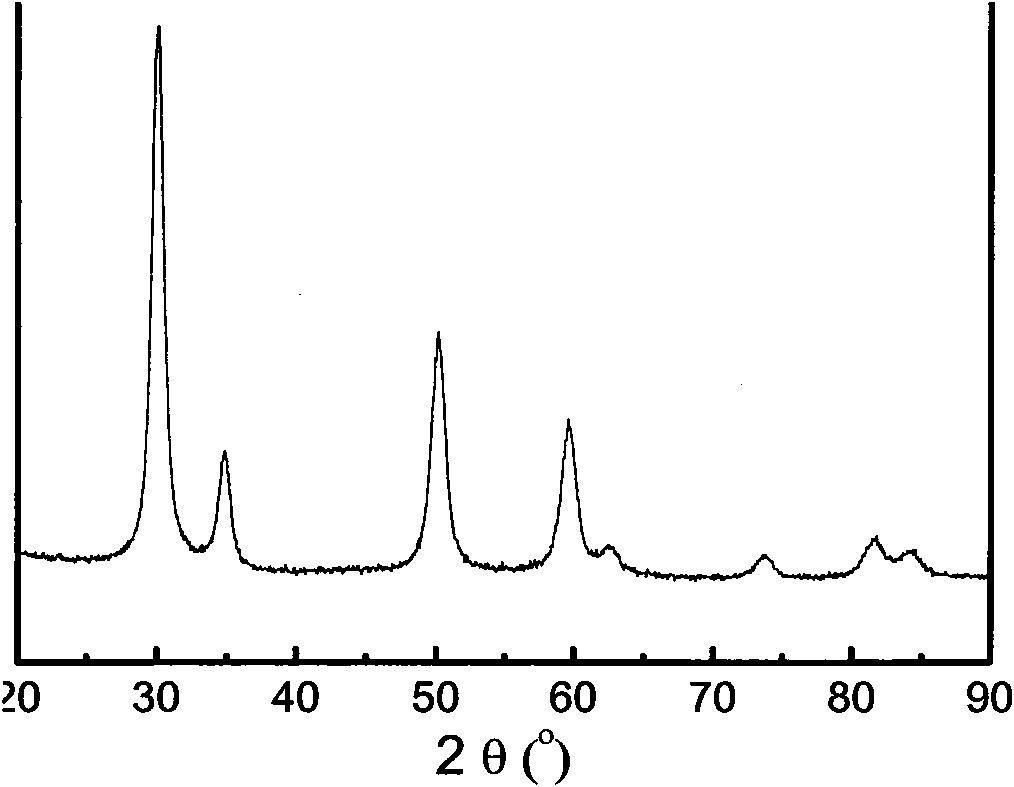

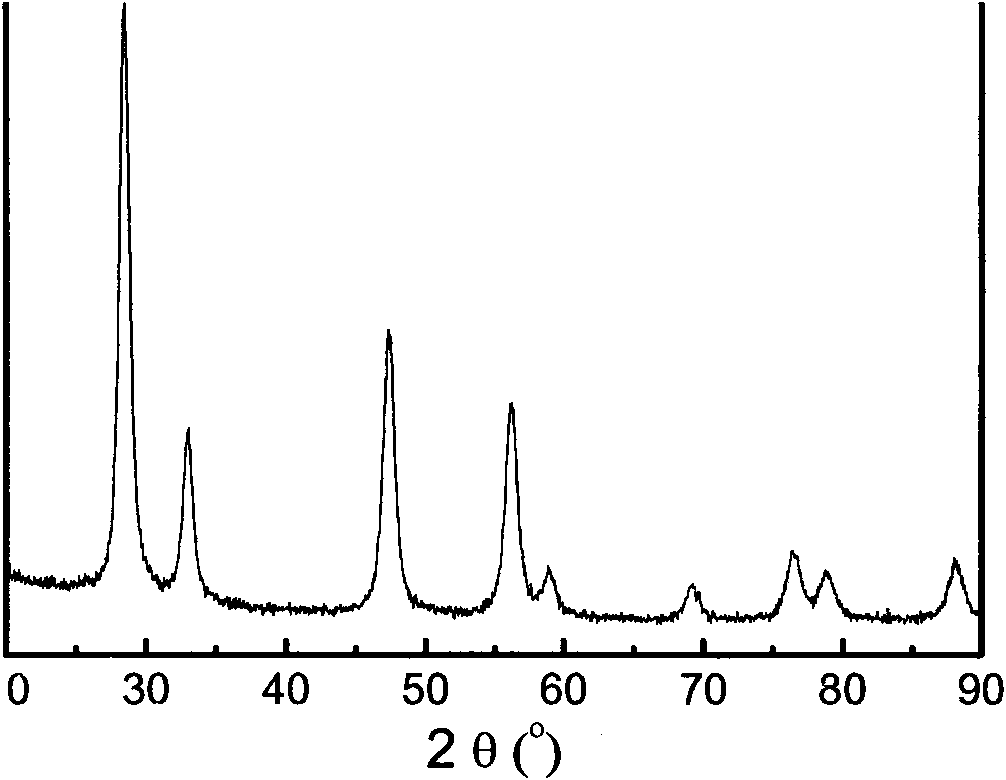

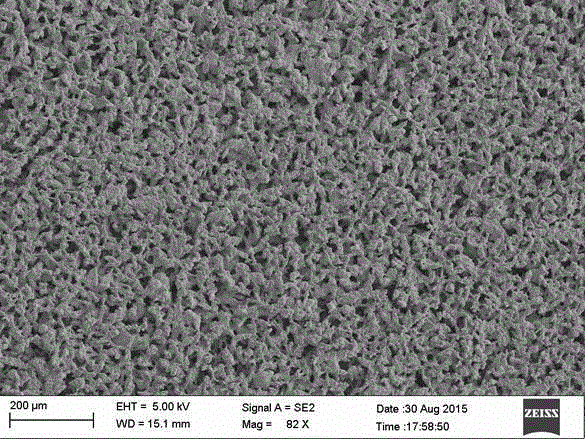

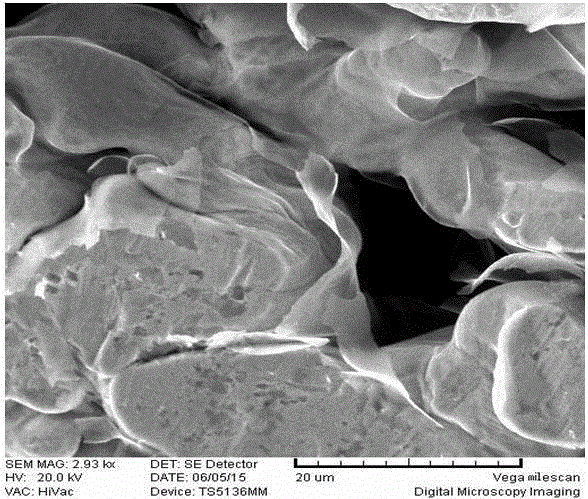

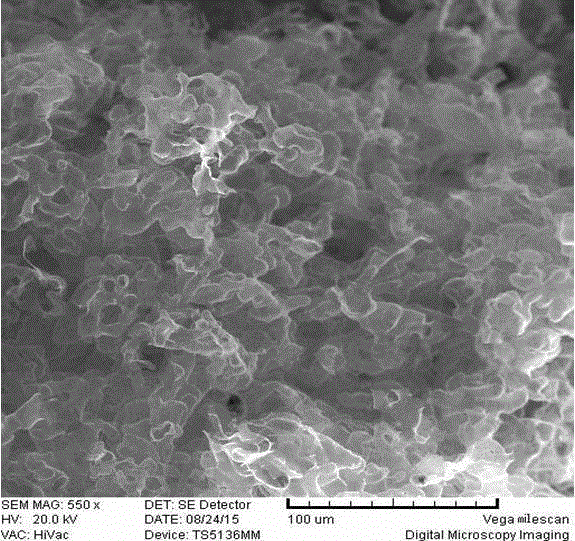

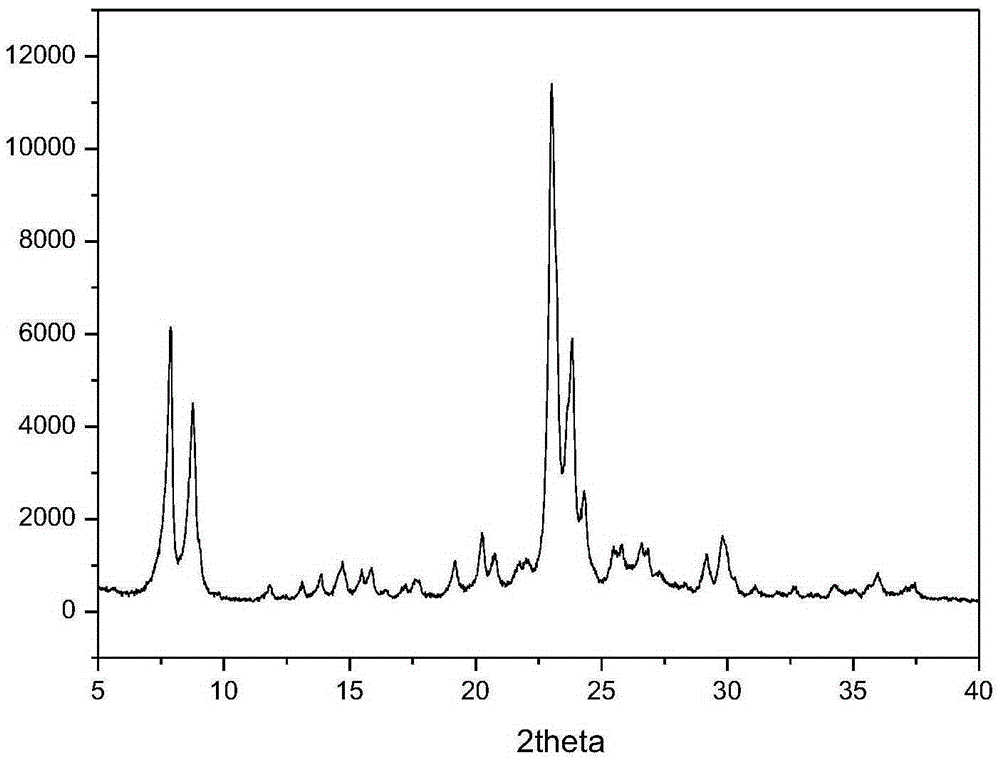

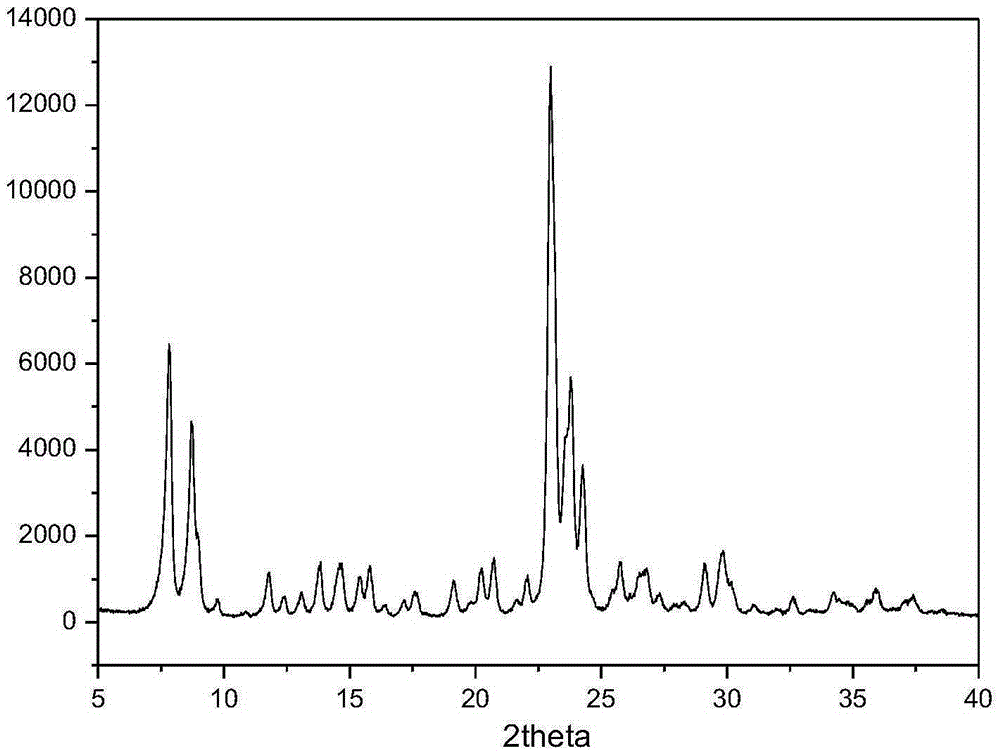

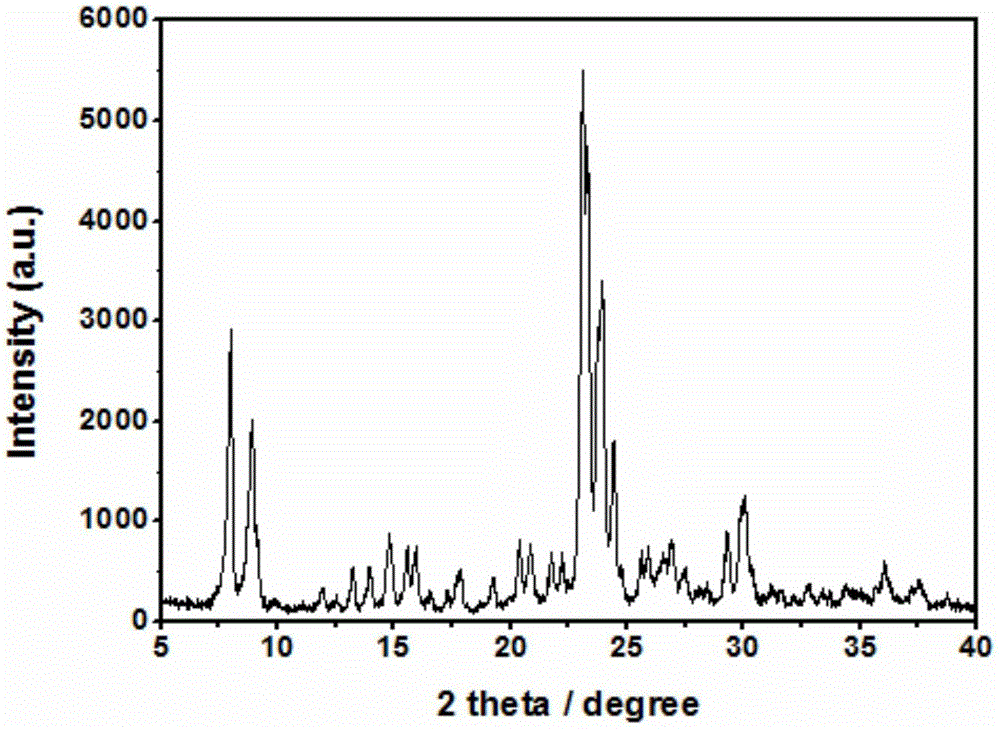

Method for preparing laminar Li [Ni1/2Mn1/2]O2 material in use for lithium ion battery

InactiveCN1960035AReduce shufflingElectrode manufacturing processesLithium compoundsPhysical chemistrySodium-ion battery

Belonging to technical area of inorganic synthesis, and preparing anode material of lithium ion battery, the method modifies laminated structured material Li [Ni1 / 2Mn1 / 2] O2 in use for lithium ion battery. Characters are that coprecipitation is prepared from carbonate as precipitating agent; carrying out pretreatment at 400-850 deg.C for precursor i.e. coprecipitation under inert or reductive atmosphere. Advantages are: simple technique, good repeatability of operation, short cycle, low production costs, obvious effect of modification, lowered mixed arrangement of anode material Li / Ni to 6.0-6.5 %, stable laminated structure, and reversible capacity being as 85-200mAh / g.

Owner:UNIV OF SCI & TECH BEIJING

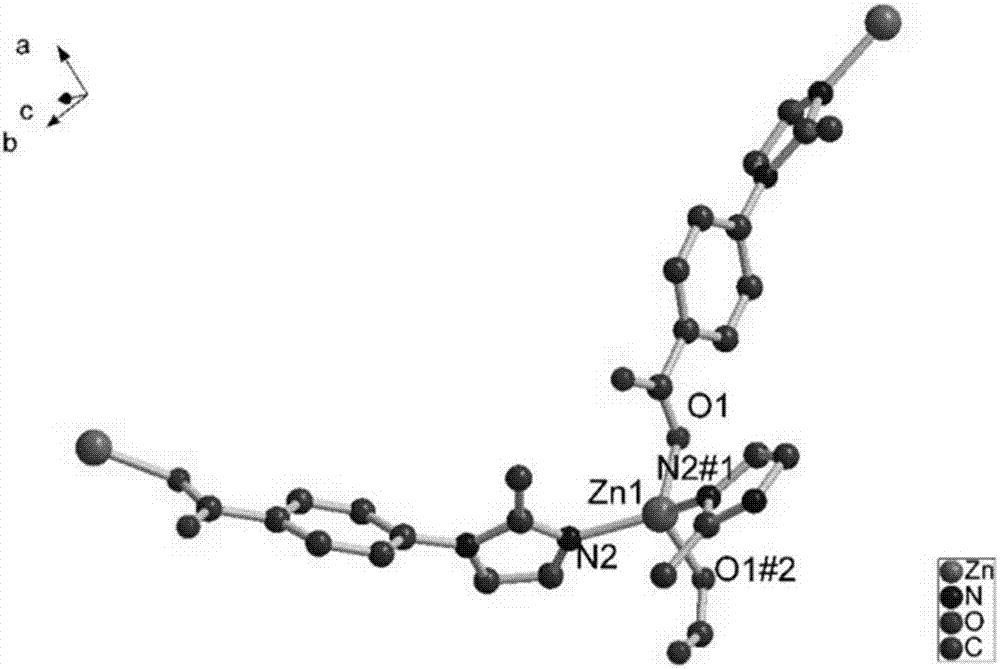

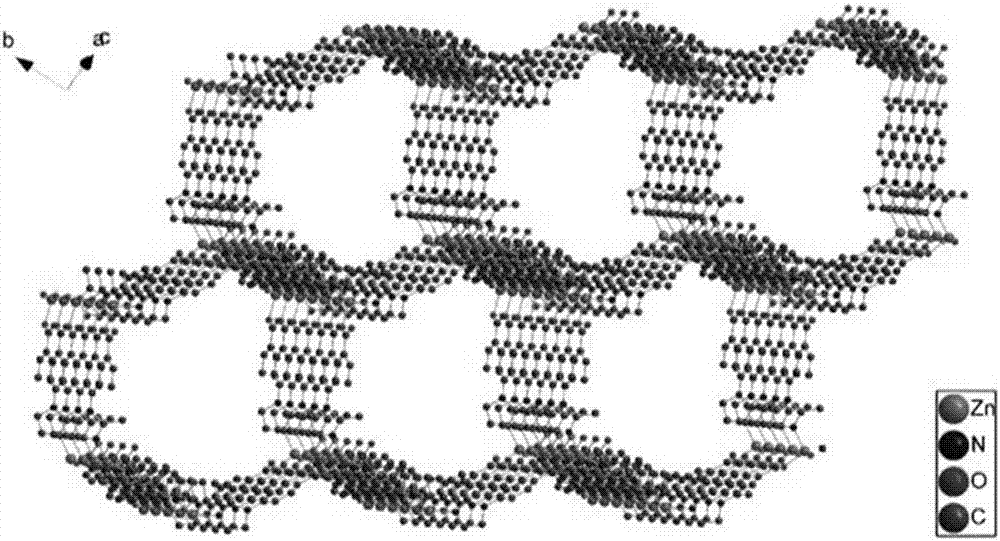

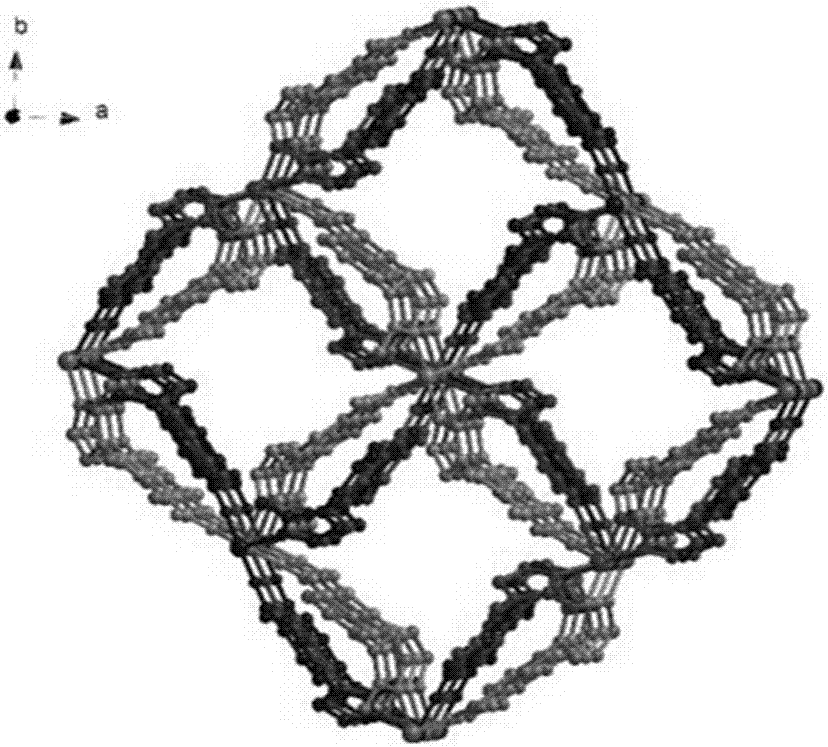

Zinc complex constructed based on of 4-(2-methylimidazole) benzoic acid and application thereof

ActiveCN107286099AImprove thermal stabilityGood reproducibilityGas treatmentOther chemical processesBenzoic acidSpace group

The invention belongs to the technical field of organic and inorganic synthesis, particularly discloses a zinc complex constructed based on of 4-(2-methylimidazole) benzoic acid and application thereof. The molecular formula of a crystal is [Zn(MIBA)2]n, wherein HMIBA is negative one valent ligand 4-(2-methylimidazole) benzoic acid shown as a formula 1, and belongs to an orthorhombic crystal system; a P4nc space group, cell parameters a is equal to 14.1883(6) A-ring, b is equal to 14.1868(6) A-ring, c is equal to 13.5156(8) A-ring, and beta is equal to 90 degrees. A crystal material of the complex is synthesized by adopting a solvent thermal reaction, a zinc ion is taken as a node of four connections, and a three-dimensional fourfold interlaced microporous structure is formed by bridging ligand 4-(2-methylimidazole) benzoic acid. The crystal material of the complex has the advantages of adsorption performance and fluorescence performance. The microporous crystal material provided by the invention has high fluorescence performance and adsorption performance, and is important to the fields of petrochemical engineering, fine chemical engineering and the like. The formula 1 is shown in the description.

Owner:SHAANXI UNIV OF TECH

Dosing form for reagents, use of said dosing form in organic chemical synthesis and production of said dosing form

InactiveCN1429133ASmall article dispensingSequential/parallel process reactionsChemical synthesisOrganic solvent

A dosing form for at least one solid reagent for use in conventional organic and inorganic synthesis, in parallel synthesis, and in split and mix synthesis in combinatorial chemistry is provided as compressed tablets each containing the same predetermined amount of said at least one reagent embedded in a polymer matrix comprising beads of a polymer insoluble in the solvents for the intended synthesis, which tablets are capable of disintegrating in said solvent for release of the at least one reagent and disperse the matrix as polymer beads into the solvent. The polymer beads forming the matrix and the reagents of the dosing form can easily be removed by filtration in order to separate these from a formed soluble product. In a method for producing the dosing form, beads of one or more polymers are mixed with the reagents and compressed into tablets after pre-treatment with an aprotic organic solvent.

Owner:H LUNDBECK AS

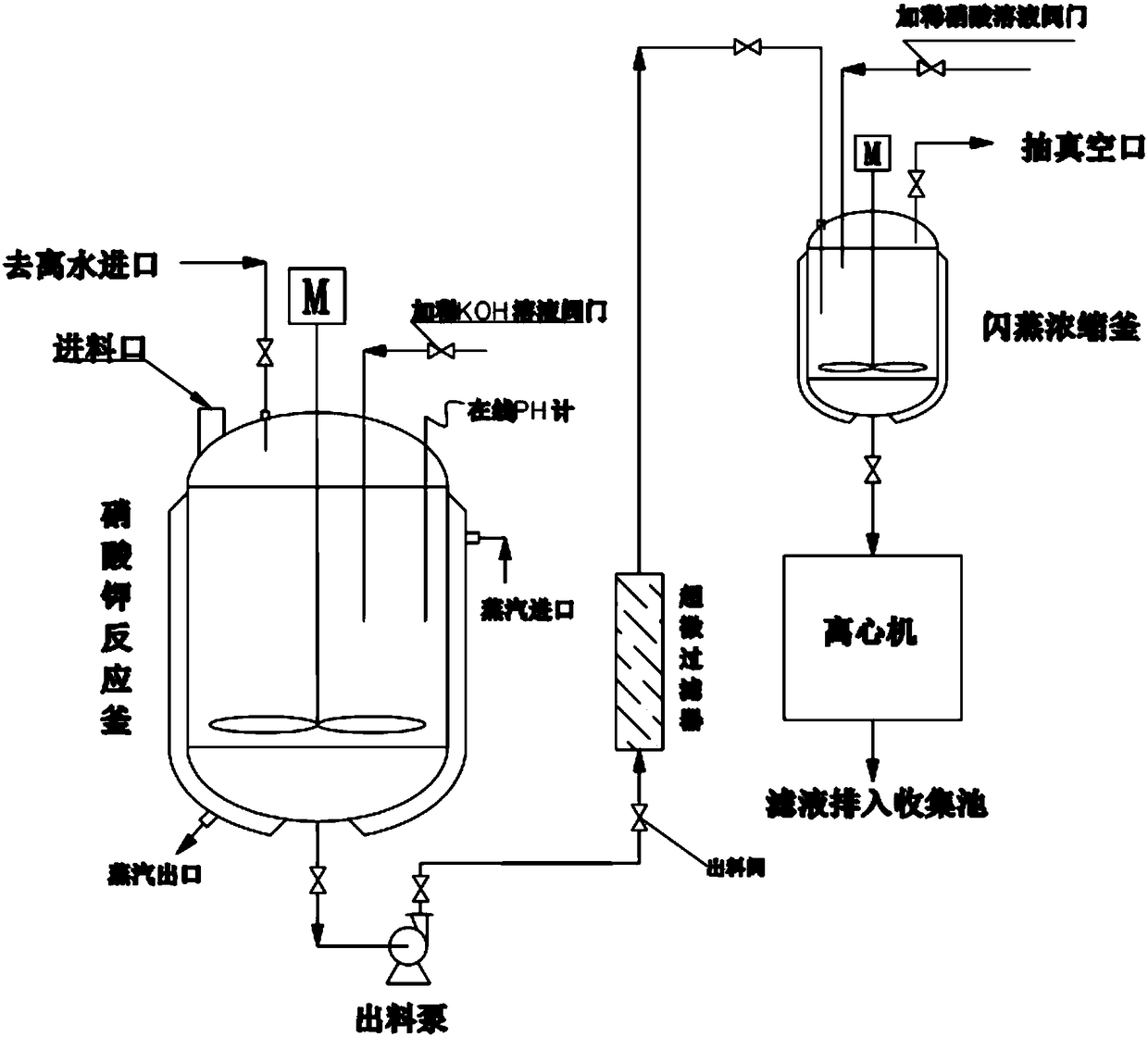

Preparation method of industrial high-grade pure potassium nitrate

InactiveCN108083300ASuitable for industrial productionSimple stepsAlkali metal nitrate purificationAlkali metal nitrate preparationPotassium nitrateDistillation

The invention discloses a preparation method of industrial high-grade pure potassium nitrate and belongs to the field of inorganic synthesis. The preparation method comprises (1) purified potassium nitrate aqueous solution preparation: adding deionized water and industrial potassium nitrate into a potassium nitrate reactor, heating the mixture to 60-80 DEG C, adjusting solution pH to 8.0-8.5 through a potassium hydroxide solution, filtering the solution through an ultra-micro filter with pore diameters of 0.2-1 micrometer, feeding the filtrate into a flash distillation concentration reactor, and adjusting solution pH of the filtrate to 6.5-7 through dilute nitric acid so that a purified potassium nitrate aqueous solution is obtained, and 2) high-grade pure potassium nitrate preparation: concentrating the purified potassium nitrate aqueous solution, putting the concentrate into a centrifugal machine, carrying out solid-liquid separation to obtain potassium nitrate crystals, putting thepotassium nitrate crystals into a vacuum drier and carrying out drying for 1-2h to obtain the superior grade pure potassium nitrate finished product. The preparation method of the industrial high-grade pure potassium nitrate has simple processes, high production efficiency, low impurity content and high purity.

Owner:山西同杰化学试剂有限公司

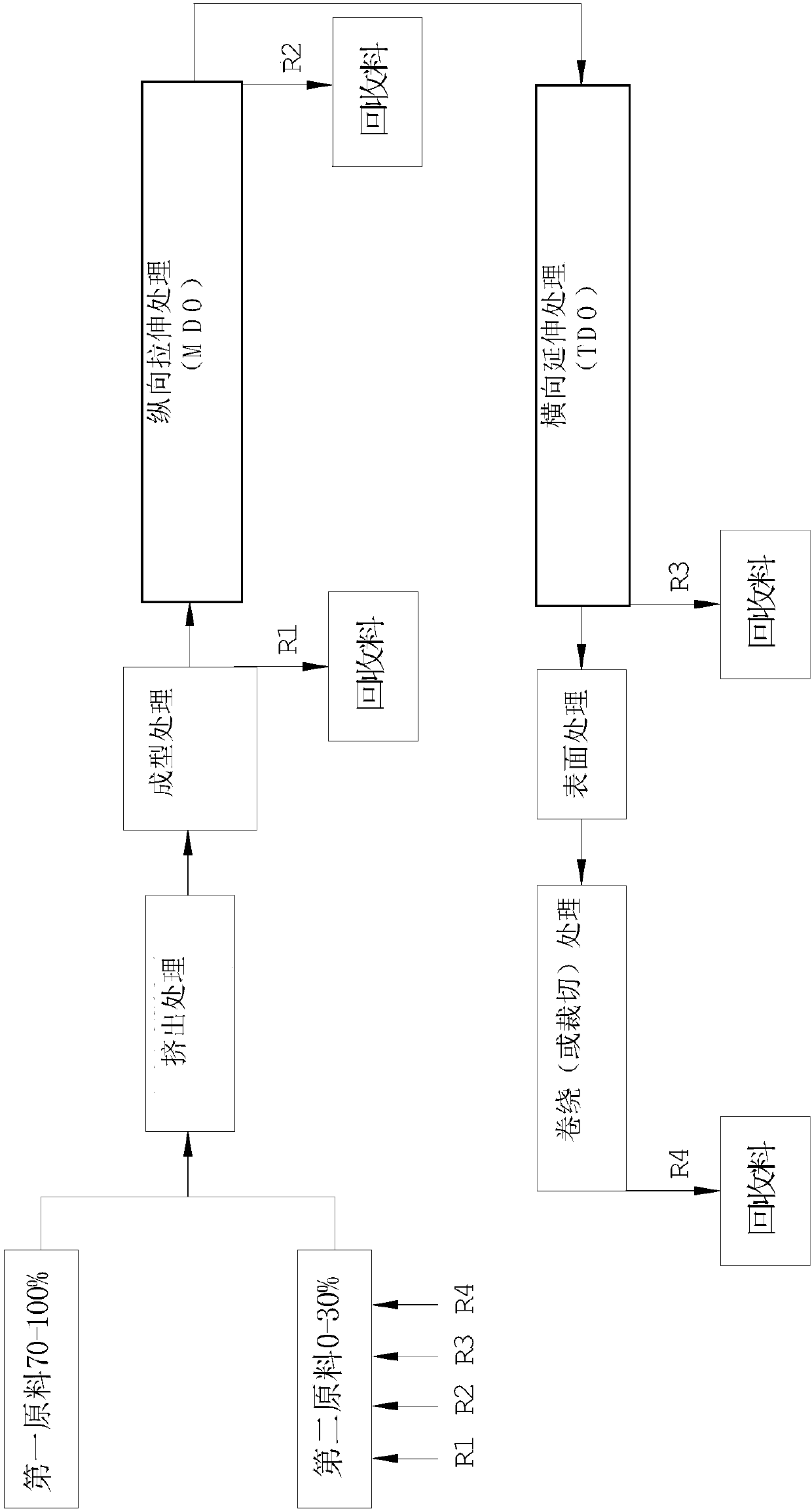

Method for making inorganic synthetic paper

InactiveCN107791533AUniform thicknessUniform densityFlat articlesPolymer scienceVolumetric Mass Density

The invention discloses a method for making inorganic synthetic paper. After first raw materials mainly composed of inorganic mineral powder, polypropylene (PP) and a modifier and second raw materialscomposed of reclaimed materials for preparing the inorganic synthesis paper are heated and fused through an extruder, a molten sheet of a single-layer structure or a three-layer structure is formed through a thin seam former (T-type mold), a sheet even in thickness and appropriate in crystallinity degree is formed through fast cooling molding, and then the inorganic synthetic paper is made through longitudinal drawing treatment, transverse drawing treatment, surface treatment and winding or cutting treatment. The production process is free of rejection ratio, good thickness uniformity, finished product density, finished product opaqueness and physical strength are achieved, the inorganic synthetic paper can be applied to various document, printing and packaging paper, cultural paper, synthetic paper, plastic films and thick materials, and the aim of widening the application range of the inorganic synthetic paper is achieved.

Owner:QUANTA ENG & CONSULTING CO LTD

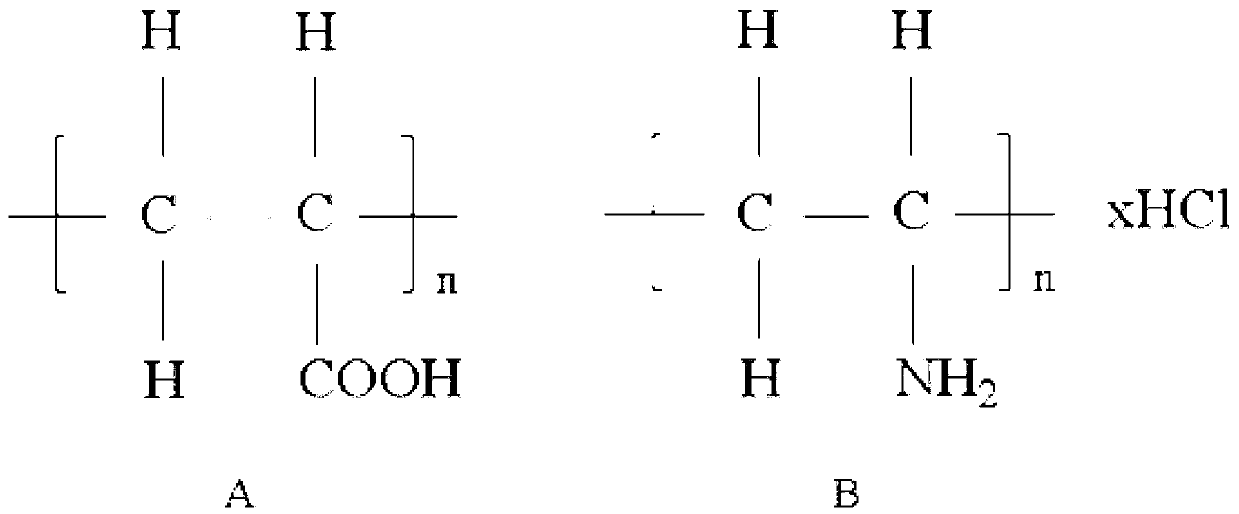

Method for preparing nanoscale zero-valent iron loaded on surfaces of glass beads by virtue of layer-by-layer assembly

The invention belongs to the field of inorganic synthesis, and discloses a method for preparing nanoscale zero-valent iron loaded on the surfaces of glass beads by virtue of layer-by-layer assembly. The method disclosed by the invention comprises the following steps of: using the glass beads as carriers and pre-treating the glass beads, so as to carry negative charges on the surfaces of the carriers, thus facilitating loading a polyelectrolyte and iron; and quantitatively loading ferrous ions on the surfaces of the carriers by virtue of the layer-by-layer self-assembly technology at first, and then reducing the ferrous ions into zero-valent iron by virtue of NaBH4. According to the method disclosed by the invention, the loading capacity and the size of the nanoscale zero-valent iron can be accurately controlled, and the reaction activity of the zero-valent iron can be effectively enhanced.

Owner:WUXI HUANCHUANG ENVIRONMENT TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparing laminar Li [Ni1/2Mn1/2]O2 material in use for lithium ion battery Method for preparing laminar Li [Ni1/2Mn1/2]O2 material in use for lithium ion battery](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/cb540874-fdfe-48b8-83ac-0a51108a6c85/A20061011432100061.PNG)

![Method for preparing laminar Li [Ni1/2Mn1/2]O2 material in use for lithium ion battery Method for preparing laminar Li [Ni1/2Mn1/2]O2 material in use for lithium ion battery](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/cb540874-fdfe-48b8-83ac-0a51108a6c85/A20061011432100062.PNG)

![Method for preparing laminar Li [Ni1/2Mn1/2]O2 material in use for lithium ion battery Method for preparing laminar Li [Ni1/2Mn1/2]O2 material in use for lithium ion battery](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/cb540874-fdfe-48b8-83ac-0a51108a6c85/A20061011432100063.PNG)