Energy-saving integrated board with inorganic synthesis finish and processing technology thereof

A technology of inorganic synthesis and processing technology, which is applied in the field of building board structure, can solve the problems of substandard waterproof performance of the system, easy cracking and falling off of the veneer layer, complicated construction technology, etc., to overcome poor quality control, ingenious structural design, and production The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

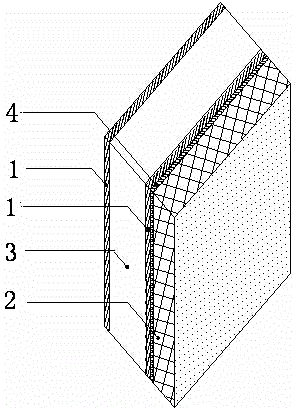

[0018] The energy-saving inorganic synthetic decorative integrated board of this embodiment includes a polyurethane board for interface enhancement, fire protection, and heat preservation, a decorative layer 2 for decoration and fire protection, and an adhesive layer 4. The polyurethane board passes through the adhesive. Layer 4 and facing layer 2 are integrated, and the polyurethane sheet includes coiled material layer 1, insulation layer 3, and coiled material layer 1; Any one of surface brick, ceramic fiber board, soft porcelain, ceramic sheet, marble tile, and ceramic plate; coil layer 1 is an interface sheet made of flame-retardant polymer glue, and the base material of coil layer 1 It is any one of glass fiber, mesh cloth, and non-woven fabric, wherein the coil layer 1 made of glass fiber as the base material is a glass fiber coil, and the glass fiber coil is made of flame-retardant polymer glue The slurry is used as the base fabric, and a number of glass fibers are adde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com