Method for preparing novel magnetic fluorescent nanometer composite material

A magnetic nanometer, a certain amount of technology, applied in the direction of magnetic materials, luminescent materials, magnetic objects, etc., can solve the problems of lengthy multi-step reactions, affecting the practical application of magnetic nanoparticles, complex synthesis steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

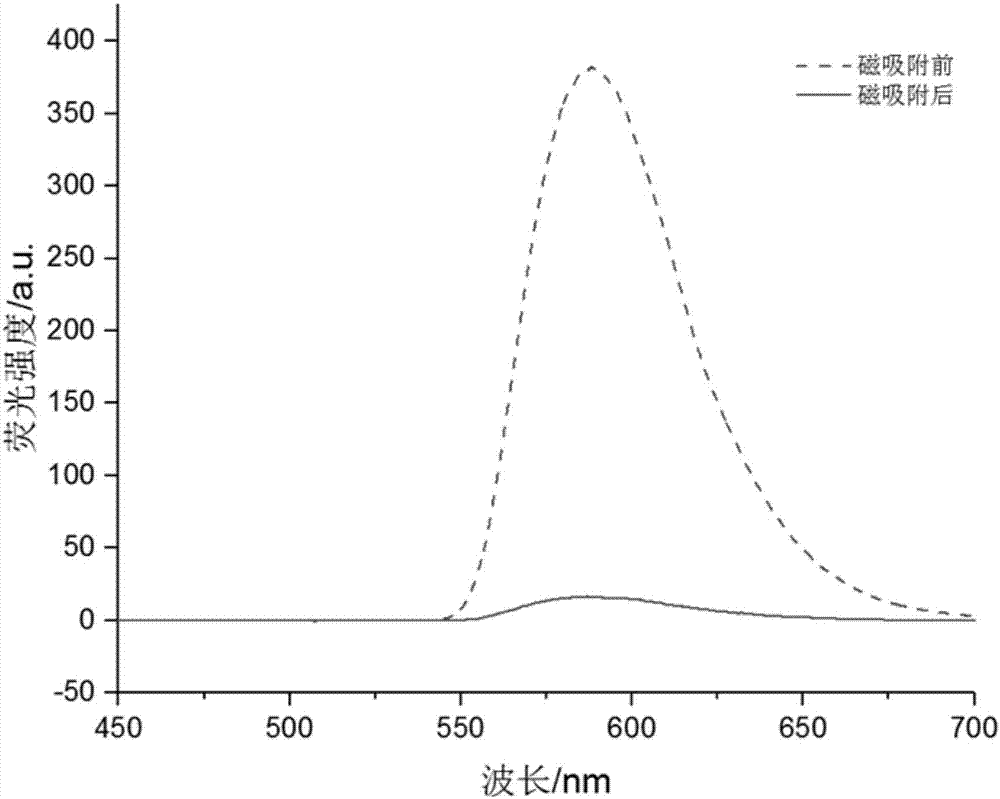

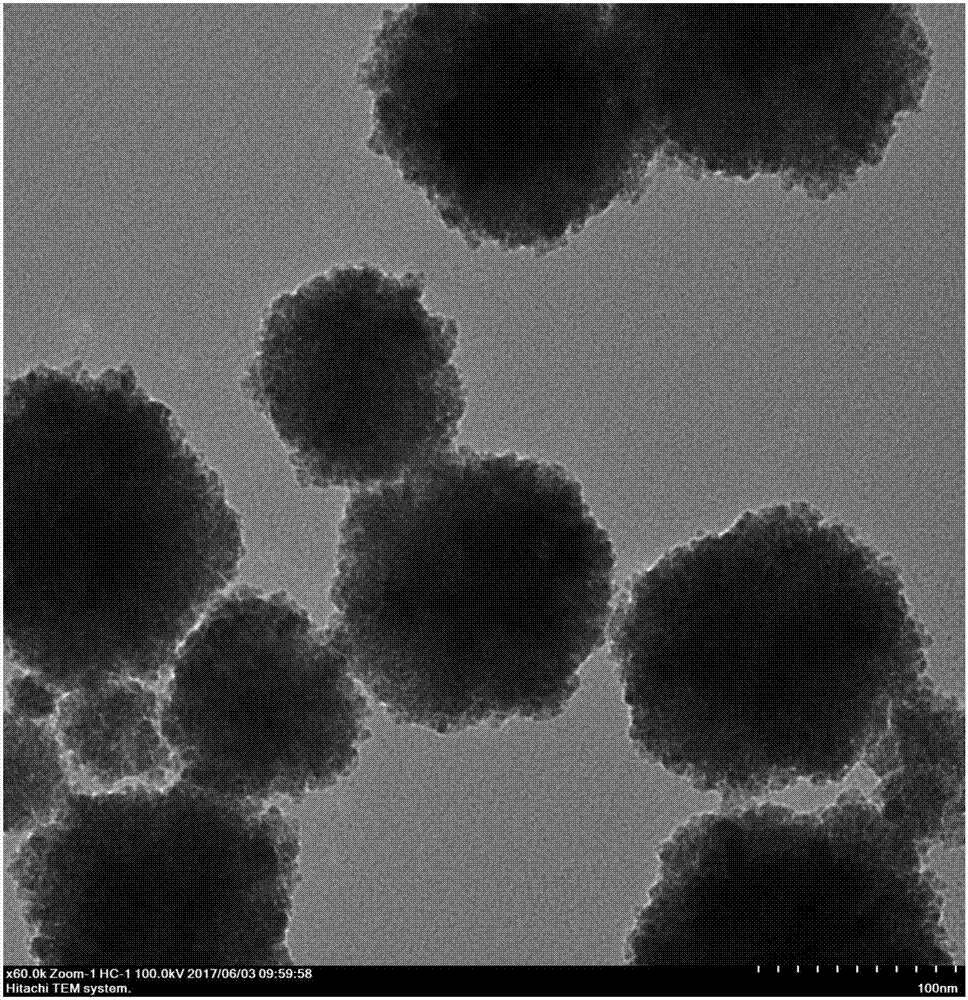

[0032] Synthesis of magnetic fluorescent nanocomposites of carboxyl-modified magnetic nanomaterials and amino-modified ZnS quantum dots:

[0033] 1) Take 1.95g FeCl 3 , 0.6g trisodium citrate, 60mL ethylene glycol, put into the beaker; ultrasonically dissolve, and start stirring, during the stirring process, slowly add 3.6g anhydrous sodium acetate; put the above product into the reaction kettle, at 200 degrees Celsius After heating in the oven for 12 hours, cool to room temperature; put the obtained product in the refrigerator for 20 minutes, put the product in a centrifuge tube for 4 to 5 hours in vacuum freeze-drying, and then store it at 4 degrees Celsius;

[0034] 2) Take 1.797g of ZnSO 4 ·7H 2 O and 98.955 mg of MnCl 2 4H 2O, and 20mL of deionized water were added successively in a 50mL three-necked flask, and the mixture was stirred at room temperature for 30 minutes under nitrogen protection;

[0035] 3) 1.801g of Na 2 S·4H 2 O (dissolved in 5 mL of water) was s...

Embodiment 2

[0040] Synthesis of magnetic fluorescent nanocomposites of carboxyl-modified magnetic nanomaterials and amino-modified ZnS quantum dots:

[0041] 1) Take 1g FeCl 3 , 0.2g trisodium citrate, and 60mL ethylene glycol were added to the beaker; the above-mentioned mixed solution was dissolved by ultrasonic waves, and stirring was started. During the stirring process, 2g of anhydrous sodium acetate was slowly added; the above-mentioned product was put into the reaction kettle, and After heating in an oven at 200 degrees Celsius for 12 hours, cool to room temperature; freeze the product in the refrigerator for 20 minutes, then place the product in a centrifuge tube for 4 to 5 hours in vacuum freeze-drying, and then store it at 4 degrees Celsius;

[0042] 2) Take 1.152g of ZnSO 4 ·7H 2 O and 39.42 mg of MnCl 2 4H 2 O, and 20mL of deionized water were added successively in a 50mL three-necked flask, and the mixture was stirred at room temperature for 30 minutes under nitrogen prot...

Embodiment 3

[0048] Synthesis of magnetic fluorescent nanocomposites of carboxyl-modified magnetic nanomaterials and amino-modified ZnS quantum dots:

[0049] 1) Take 3g FeCl 3 , 1.5g trisodium citrate, and 60mL ethylene glycol were added to the beaker; the above-mentioned mixed solution was dissolved by ultrasonic waves, and stirring was started. During the stirring process, 5g of anhydrous sodium acetate was slowly added; Heating in an oven at 200 degrees Celsius for 12 hours, cooling to room temperature; freezing the product in the refrigerator for 20 minutes, placing the product in a centrifuge tube for 4 to 5 hours in vacuum freeze-drying, and then storing it at 4 degrees Celsius;

[0050] 2) Take 2.304g of ZnSO 4 ·7H 2 O and 197.1 mg of MnCl 2 4H 2 O, and 20mL of deionized water were added successively in a 50mL three-necked flask, and the mixture was stirred at room temperature for 30 minutes under nitrogen protection;

[0051] 3) Add 2.4g of Na 2 S·4H 2 O (dissolved in 5 mL ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com