Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Good price advantage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

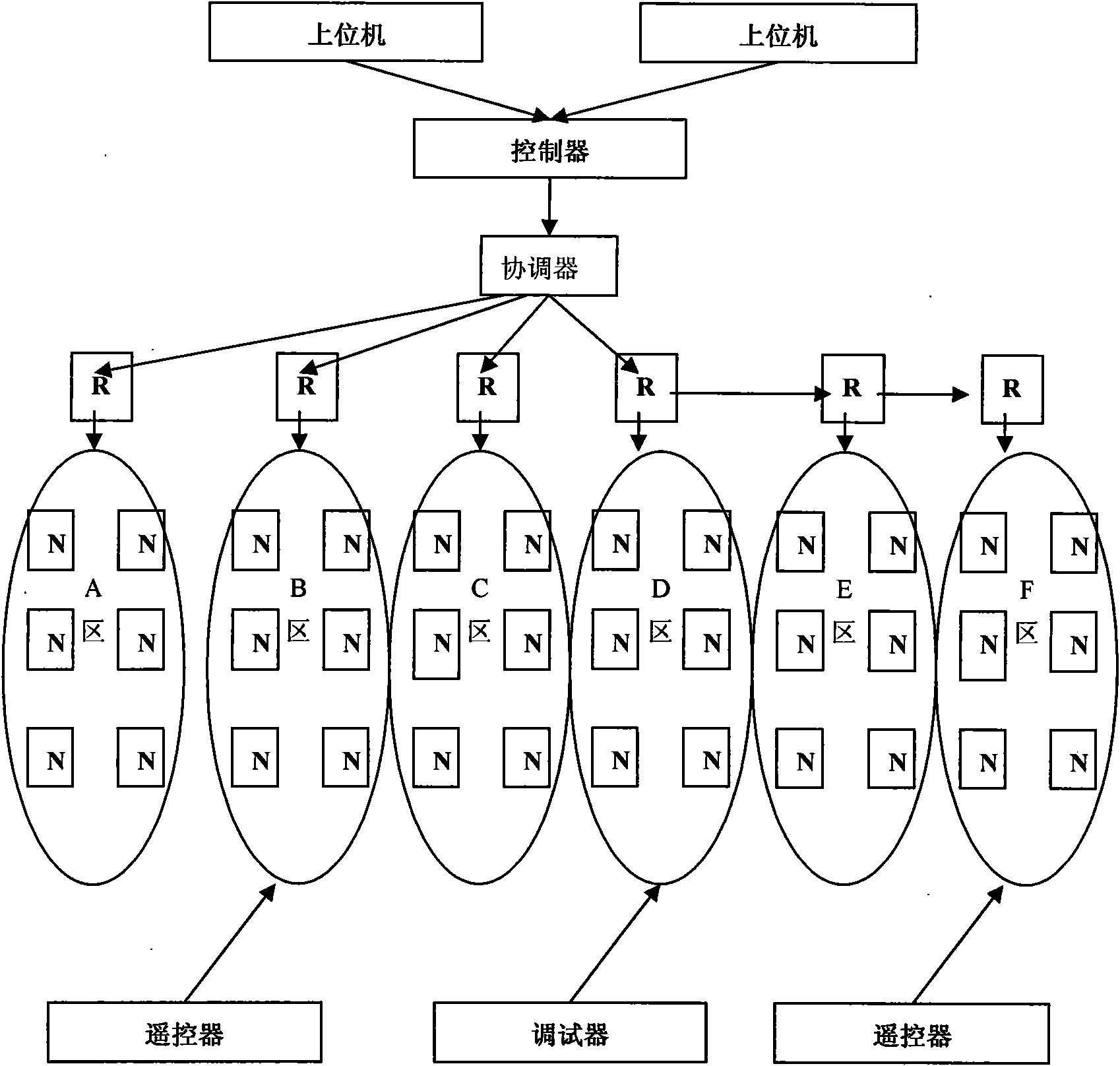

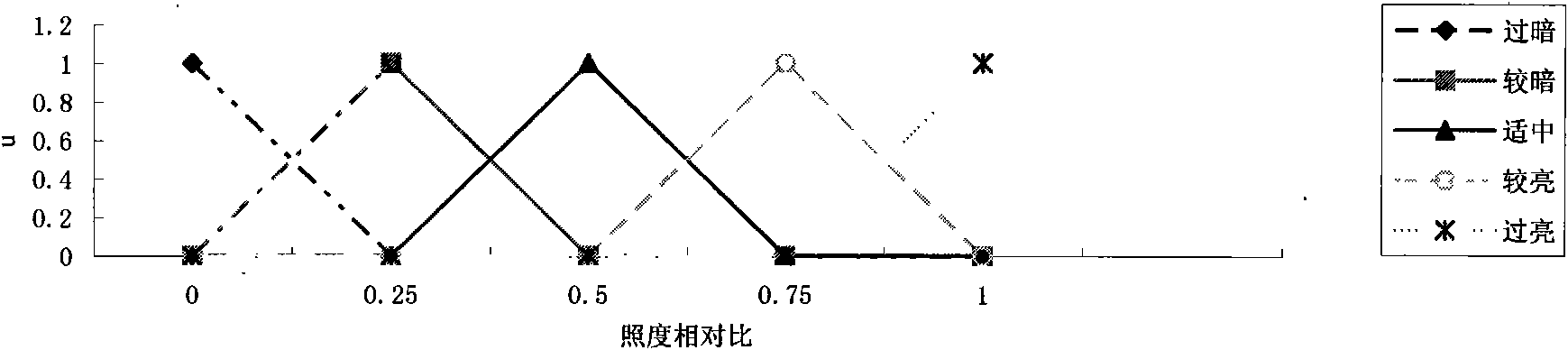

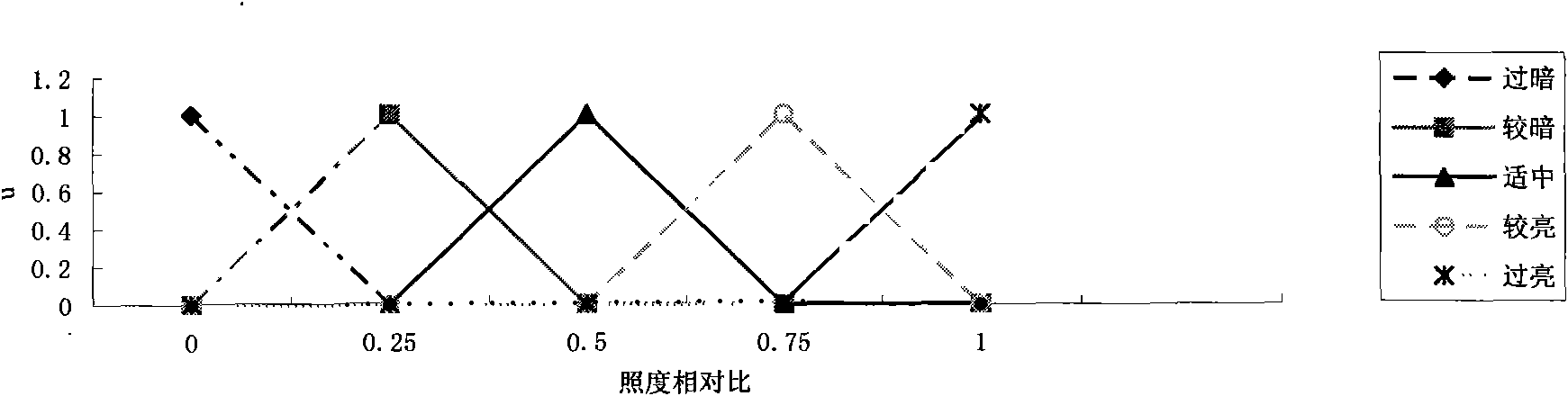

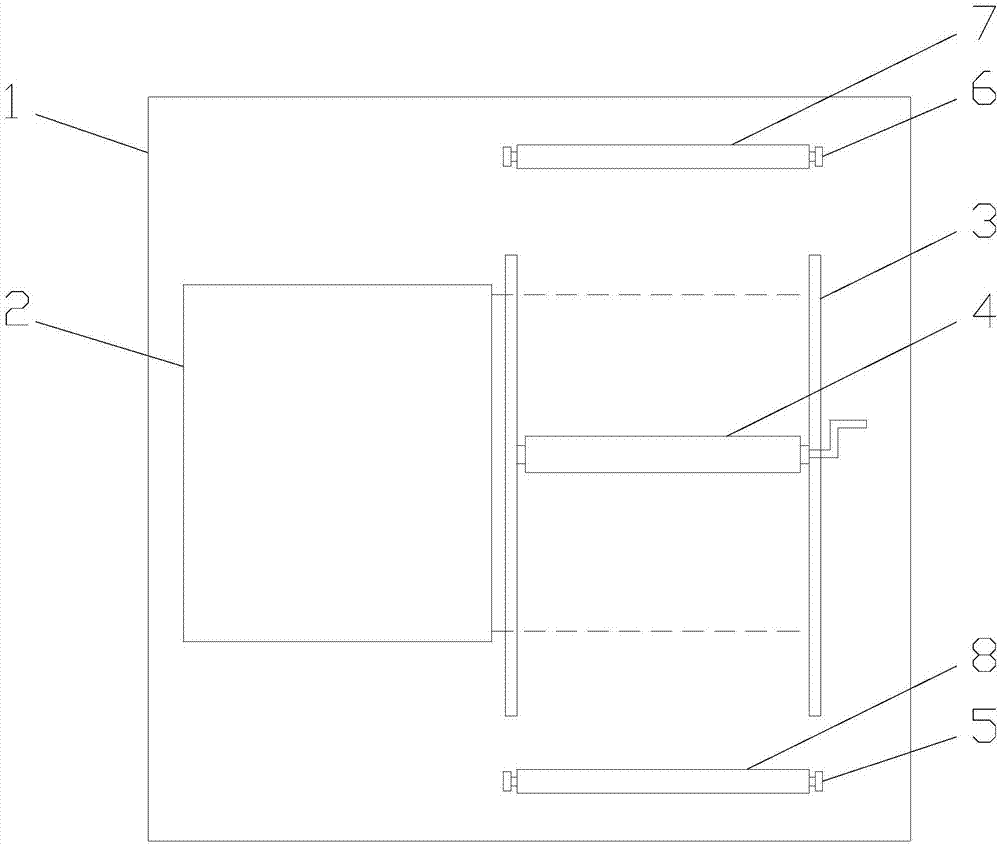

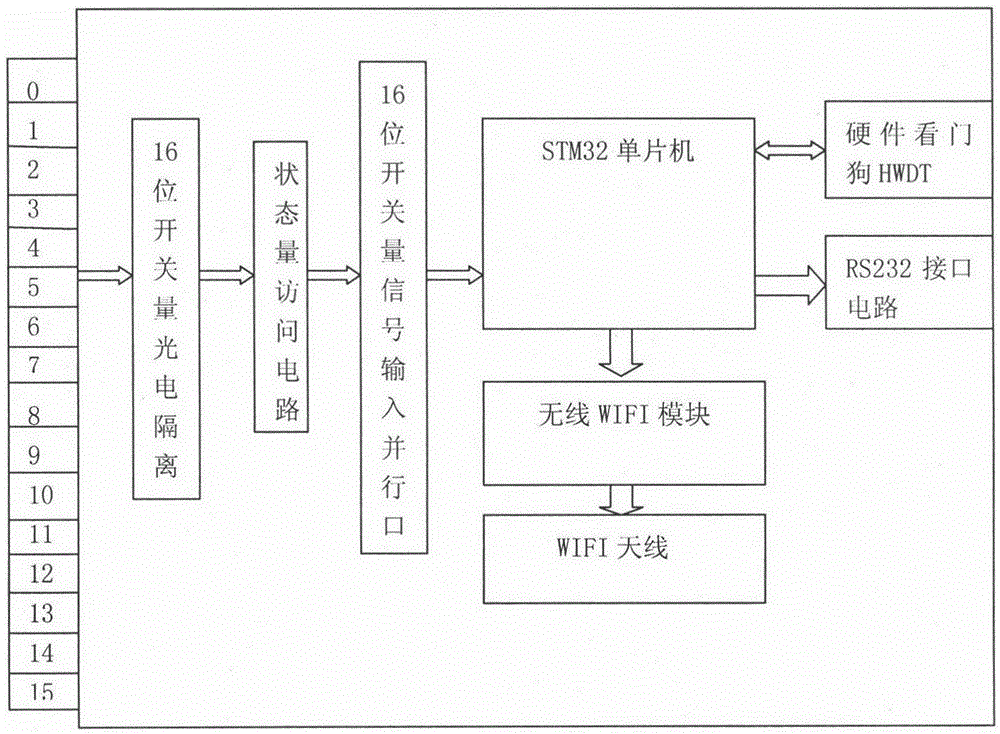

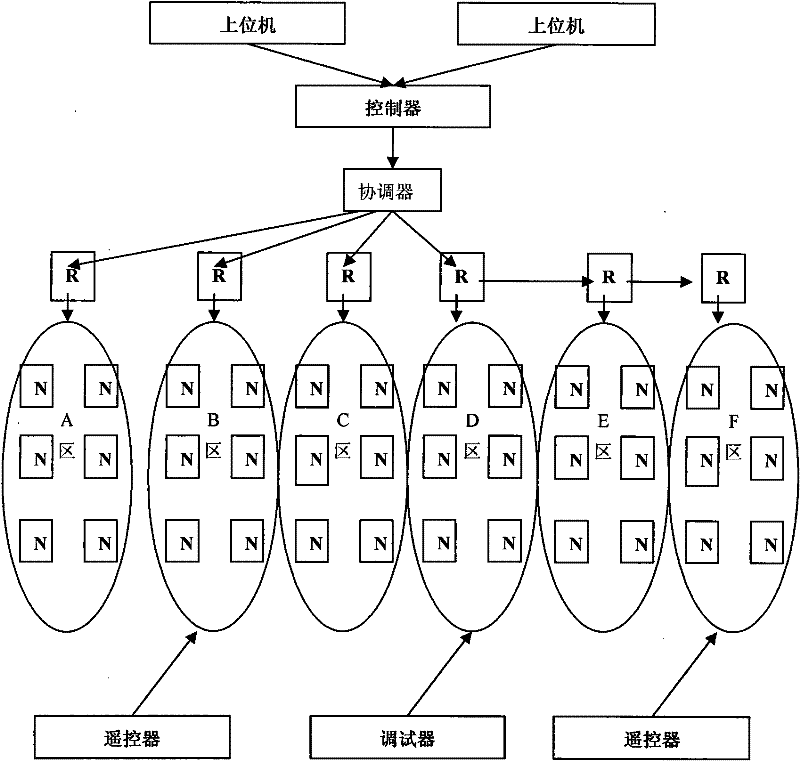

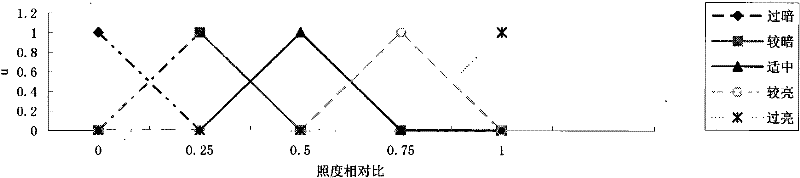

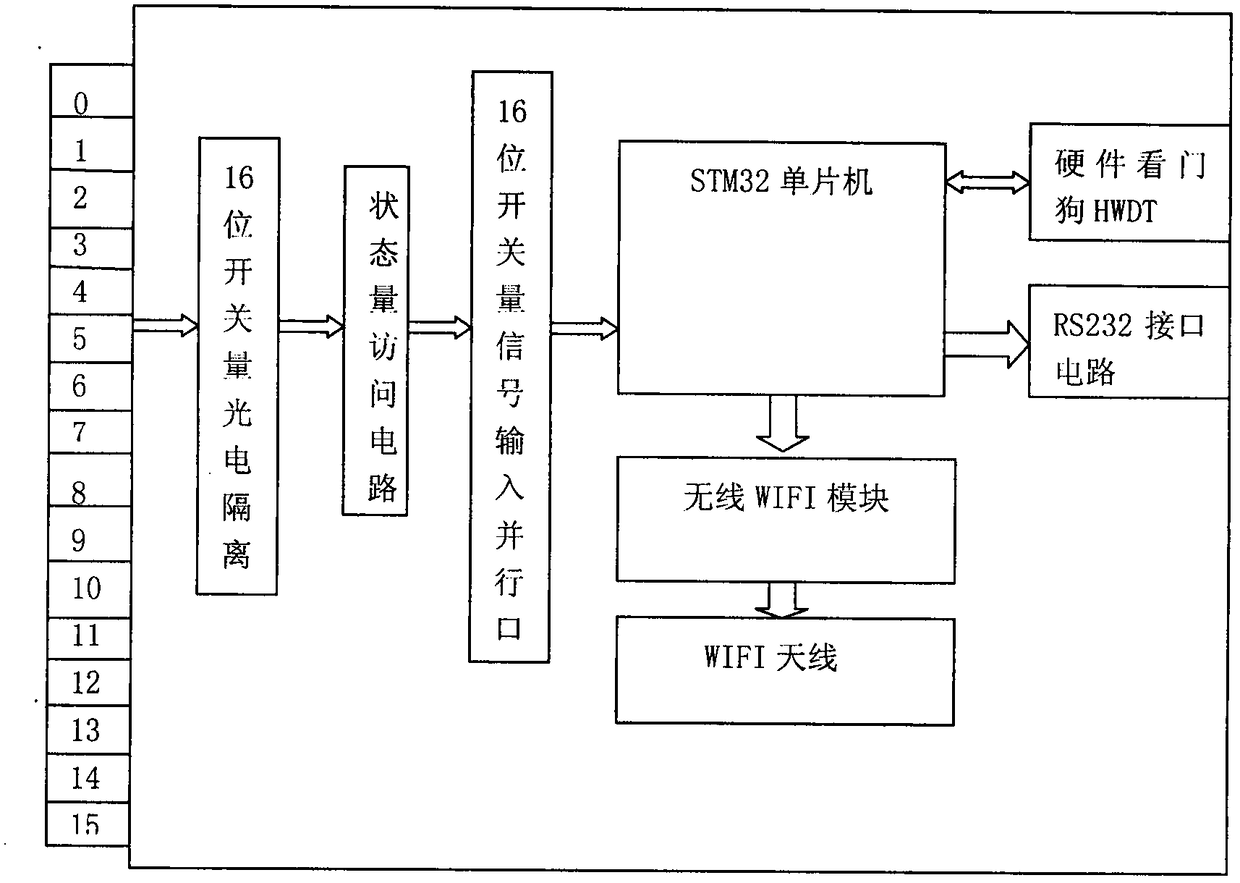

Method and system thereof for monitoring and controlling environments of public place based on Zigbee

ActiveCN101957602AImprove intelligenceImprove security featuresEnergy efficient ICTComputer controlPublic placeWireless sensor networking

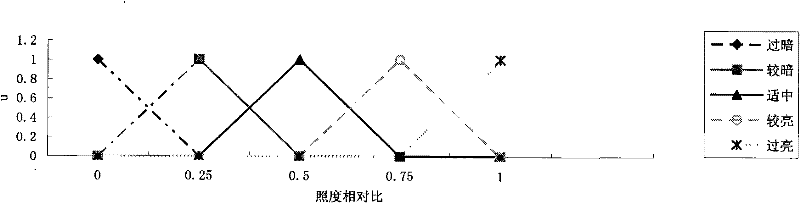

The invention discloses a method for monitoring and controlling environments of a public place based on Zigbee, which comprises the following steps of: collecting environmental parameters in a public place by using a wireless sensor network, sending the acquired environmental parameters to a controller, and carrying out fuzzy modeling and chaotic modeling on the acquired environmental parameters by the controller; establishing a fuzzy neural network according to an established environmental parameter model, and carrying out real-time control on a working apparatus by utilizing the fuzzy neural network; and carrying long-term control on the working apparatus in the public place by utilizing a chaotic perturbation control method. In the invention, the fuzzy neural network and the chaotic perturbation control method are combined together, and the working apparatus is controlled according to season change of natural conditions, such as sunshine, temperature, and the like at the site of the public place so as to achieve the purposes of energy saving and humanization. Furthermore, the wireless sensor network adopts a wireless sensor network based on Zigbee, has the characteristics of an ad hoc network and low power consumption and avoids the arrangement difficulty of a collection point when the traditional cable is wired.

Owner:河南天擎机电技术有限公司

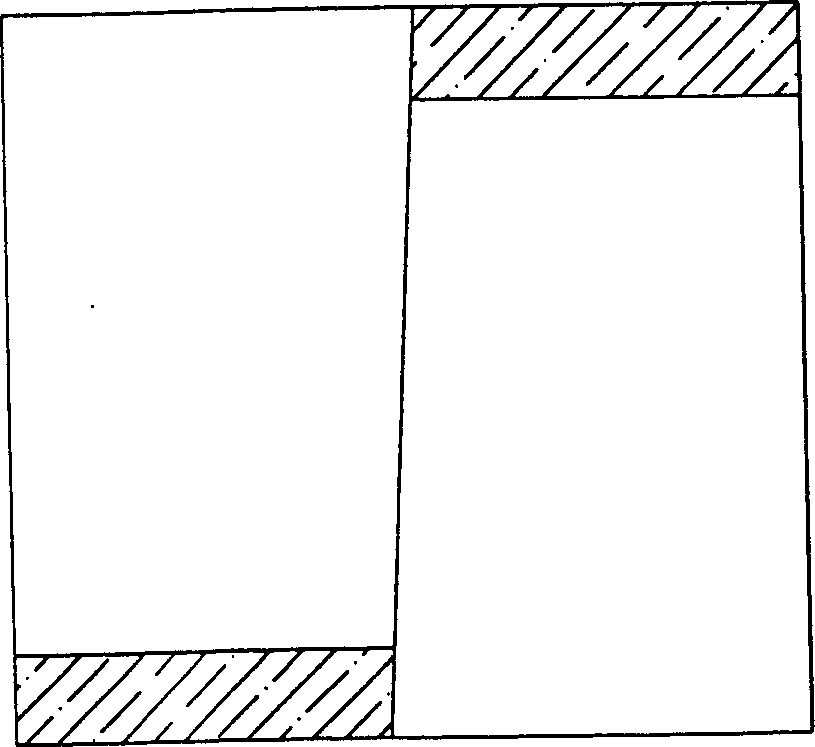

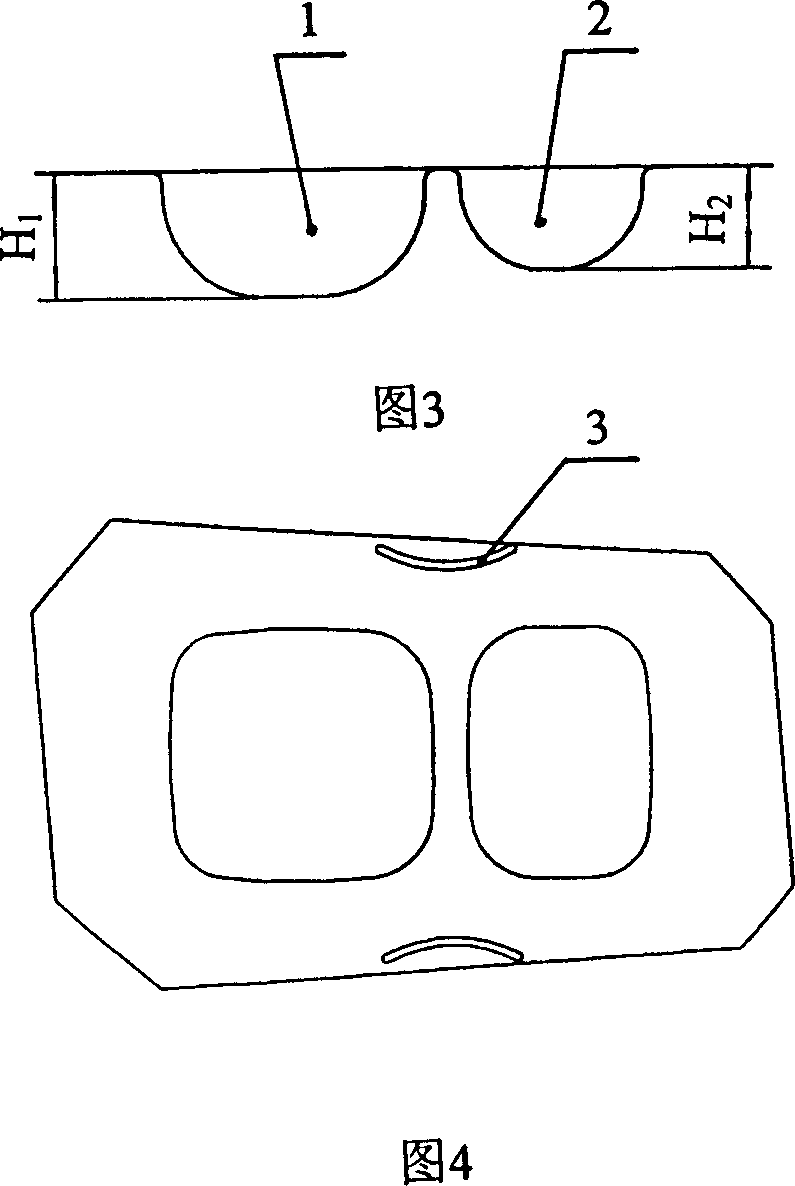

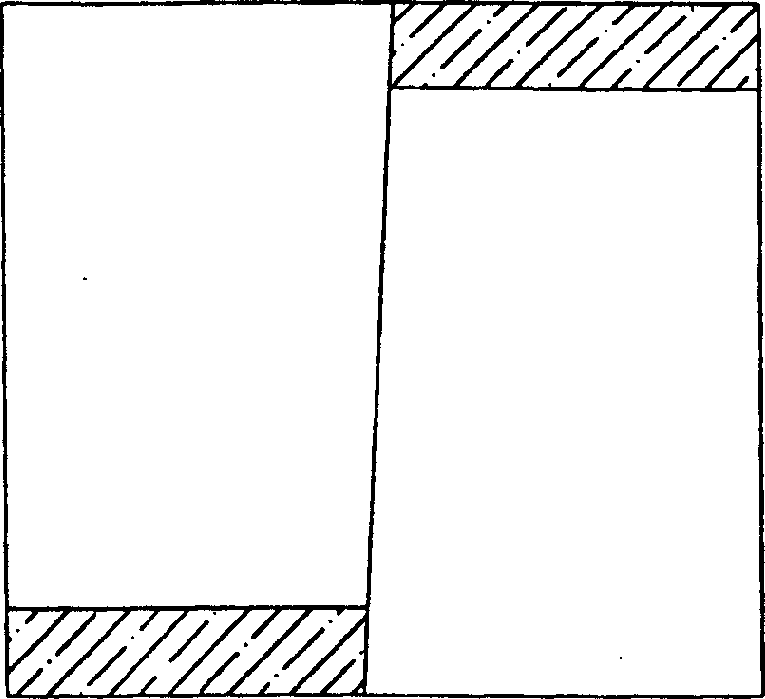

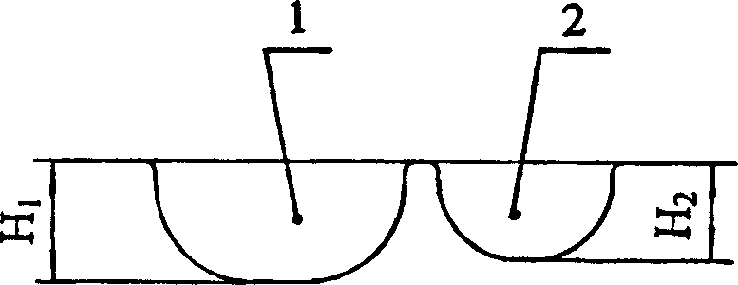

Integral stretching technology of double (three)-tank stainless steel water tanks

The invention is a stainless steel double-tanked (three-tanked) water tank stretching technique, including the working procedures such as batching, shearing angle, first stretching, shearing side, washing, annealing, second stretching, cutting side, punching hole, surface processing, etc. The water tank made by the working procedures forms a through structure without welding, reducing production cost and avoiding the problems of water leakage and of affecting fastness, thus heightening the whole quality and service life of the water tank.

Owner:ZHEJIANG FRANTA

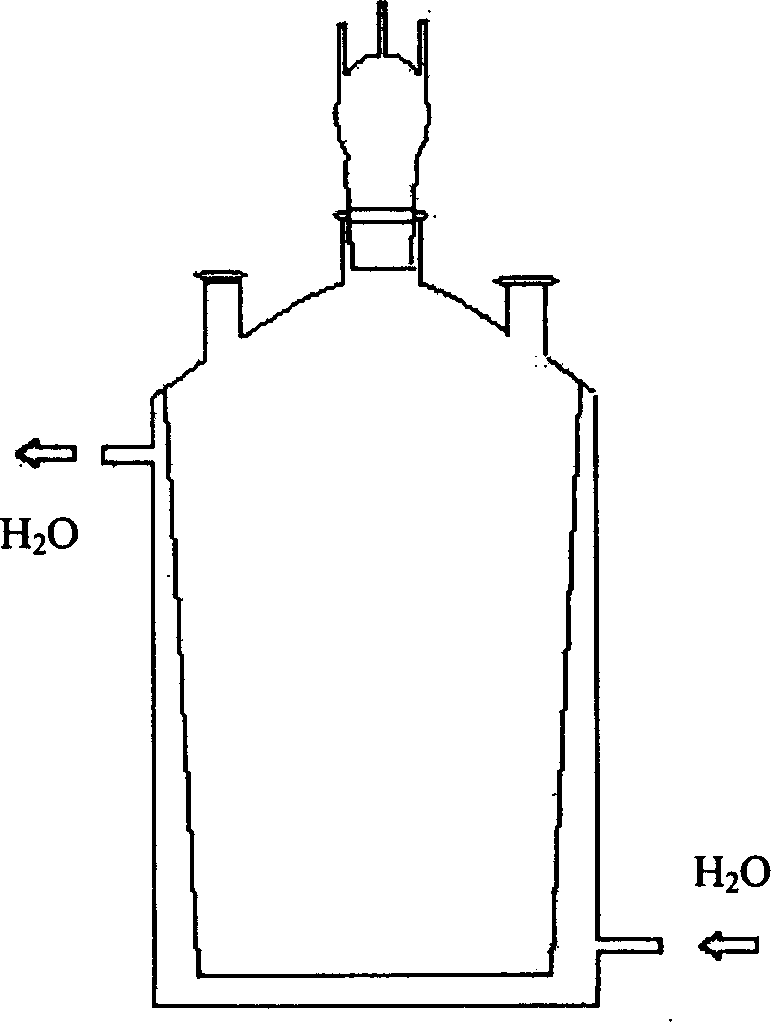

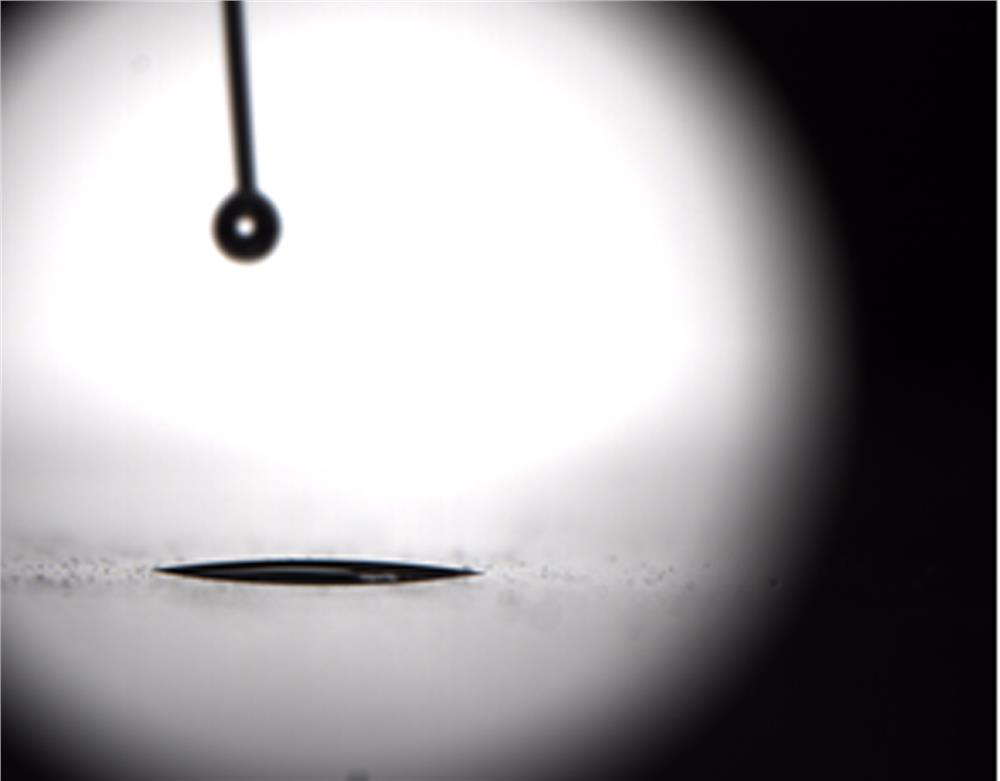

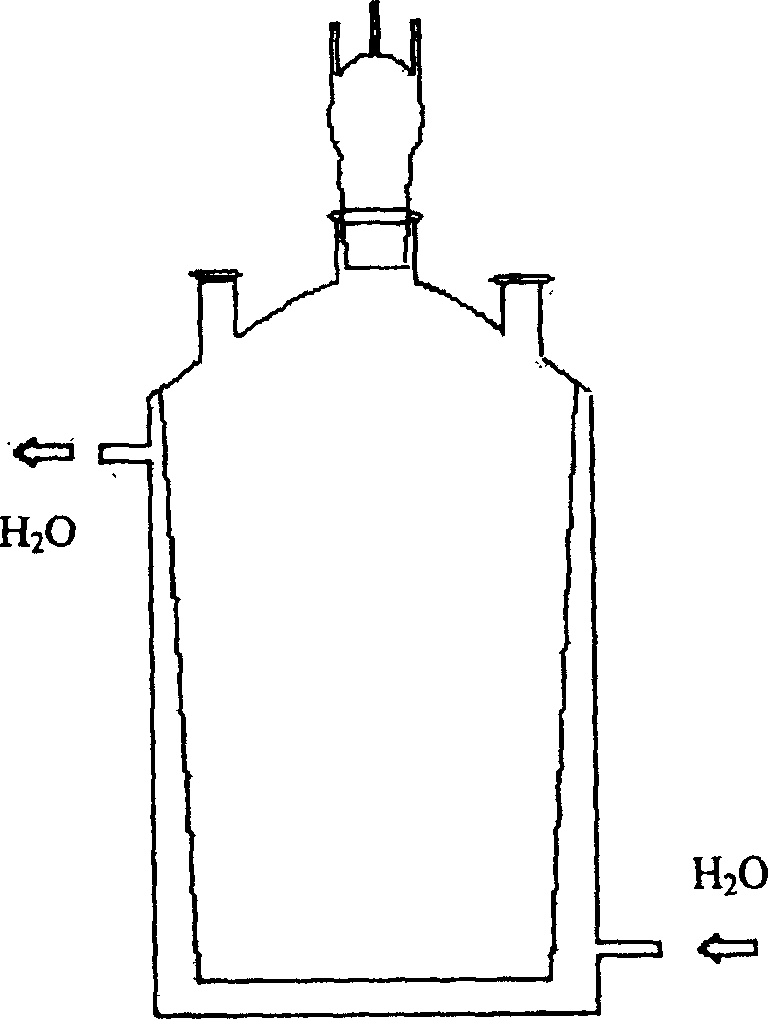

Model of mouth cavity biomembrane and method for forming mouth cavity biomembrane

InactiveCN1480110AVerify Application PerformanceSimple working processBioreactor/fermenter combinationsBiological substance pretreatmentsBottleBiological membrane

An oral biomembrane model equipment is composed of alkali solution container, culture medium container, fermentor, constant-current culture chambers and sample bottle. A process for forming the oral biomembrane includes aseptic connection of said equipment, inoculating experimental bacterial strain into fermentator, continuous culture, regulating pH=7.0, adding artificial saliva as culture medium, culturing, continuing to culture in parallel constant-current culture chambers, and mediating it on hydroxyphosphorite sheet to obtain oral biomembrane.

Owner:SICHUAN UNIV

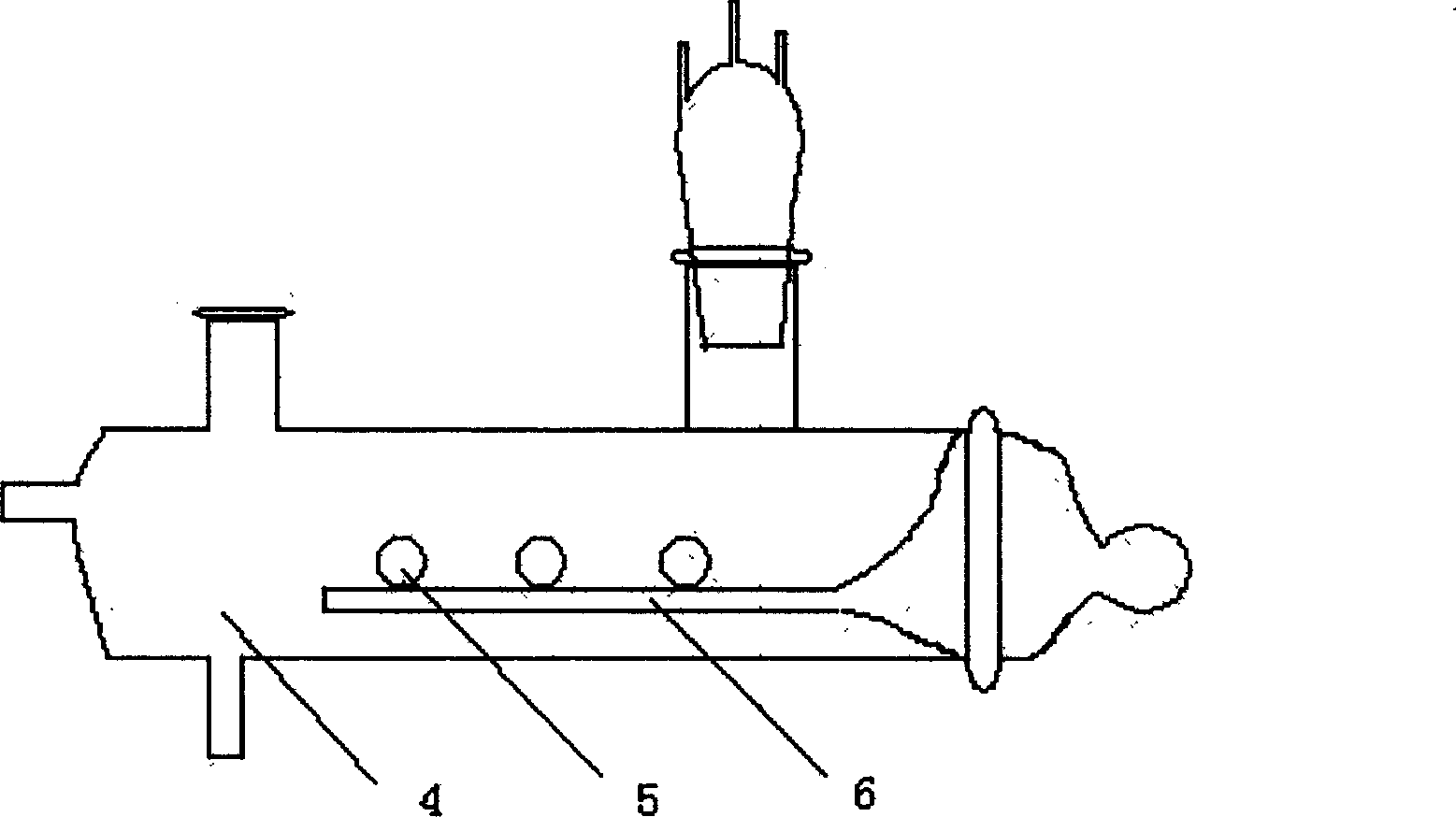

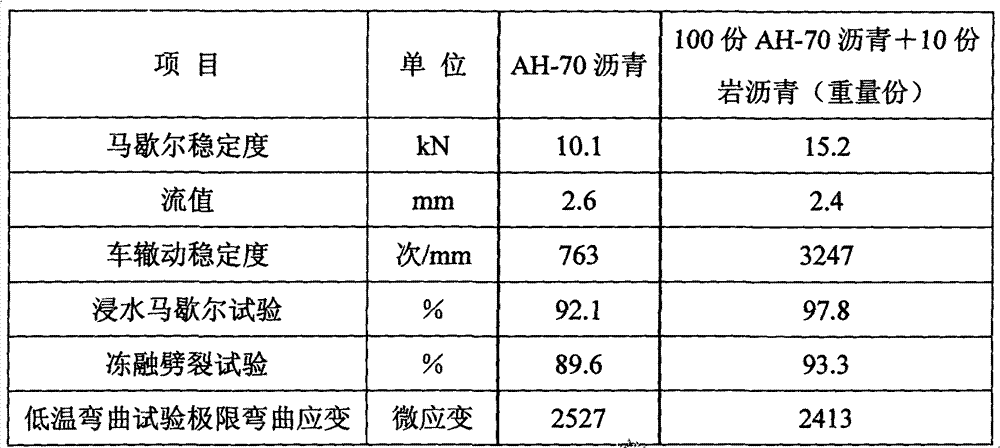

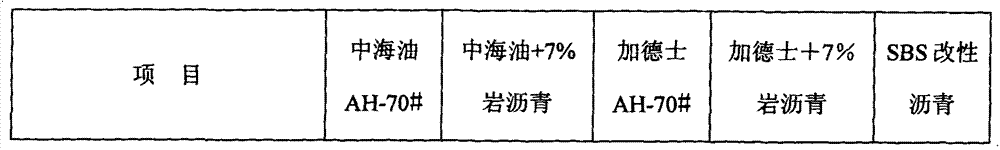

Rock asphalt modified asphalt and preparation method thereof

InactiveCN102952406ASimple production processReduce energy consumptionBuilding insulationsColloidColloid mill

The invention discloses rock asphalt modified asphalt and a preparation method thereof. The rock asphalt modified asphalt comprises 100 parts of matrix asphalt and 5-10 parts of rock asphalt. The preparation method includes: adding rock asphalt into matrix asphalt, and stirring at 150-170 DEG C for 30-60 minutes to obtain rock asphalt modified asphalt, wherein the rock asphalt is imported. Compared with the prior art, the rock asphalt modified asphalt has the advantages of stripping resistance, durability, rutting resistance at high temperature, aging resistance and the like. In addition, the rock asphalt modified asphalt is simple in production process and low in energy consumption and production cost, and needs no special equipment such as colloid mill.

Owner:SHANGHAI SENRUI ROAD ENG TECH

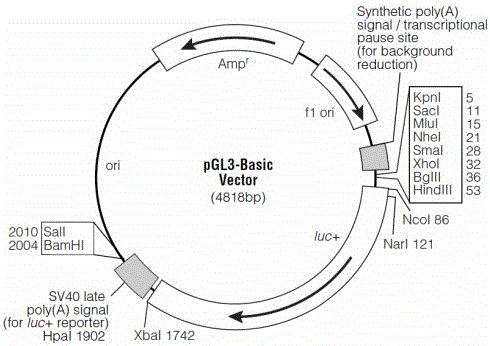

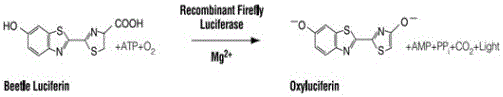

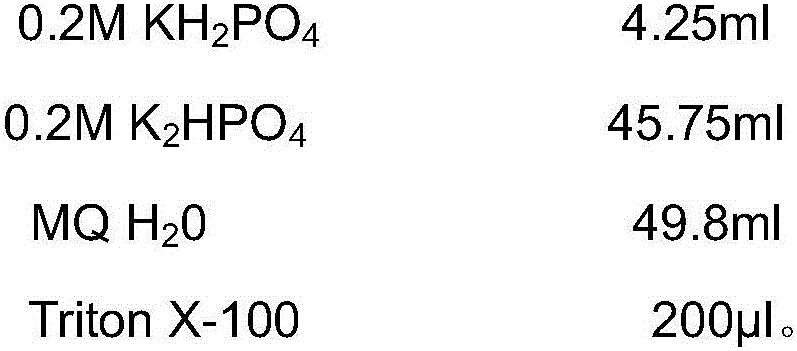

Method of detection of transcription factor expression activity by luciferase reporter gene system

InactiveCN106399461ALow costGood price advantageMicrobiological testing/measurementBiological material analysisMarket potentialTime-Consuming

The invention provides a method of detection of transcription factor expression activity by a luciferase reporter gene system; the method comprises the steps: based on the luciferase characteristics of being lasting, stable and easy to detect, co-transfecting cells with a luciferase reporter gene vector containing a target gene promoter and a transcription factor expression plasmid; after the cells are cultured, carrying out lysis of a certain number of cells with a cell lysis buffer liquid, collecting a lysate containing luciferase, and centrifuging to take a supernatant; and then real-timely detecting luciferase expression intensity data in a luciferase activity detection buffer liquid, at the same time, detecting the luciferase concentration, correcting, and then calculating to obtain the transcription factor expression quantity, namely the transcription factor expression activity needing to detection. The method is simpler and more feasible in whole operation process, shorter in time consuming, higher in flux, relatively high in repeatability and accuracy, and lower in operating costs, thereby having broad application prospects, and having excellent market potential.

Owner:MIAOSHUN SHANGHAI BIOTECH CO LTD

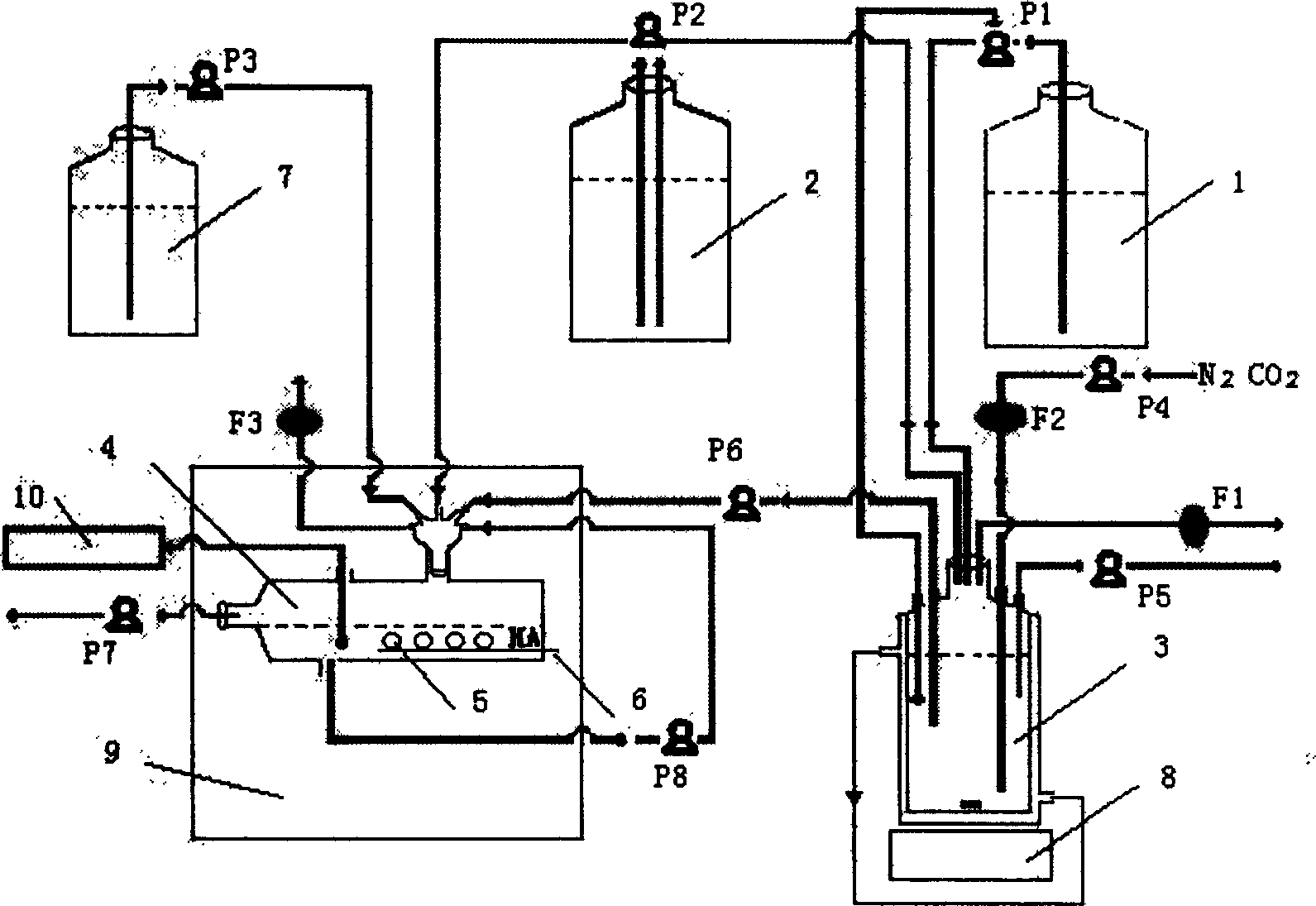

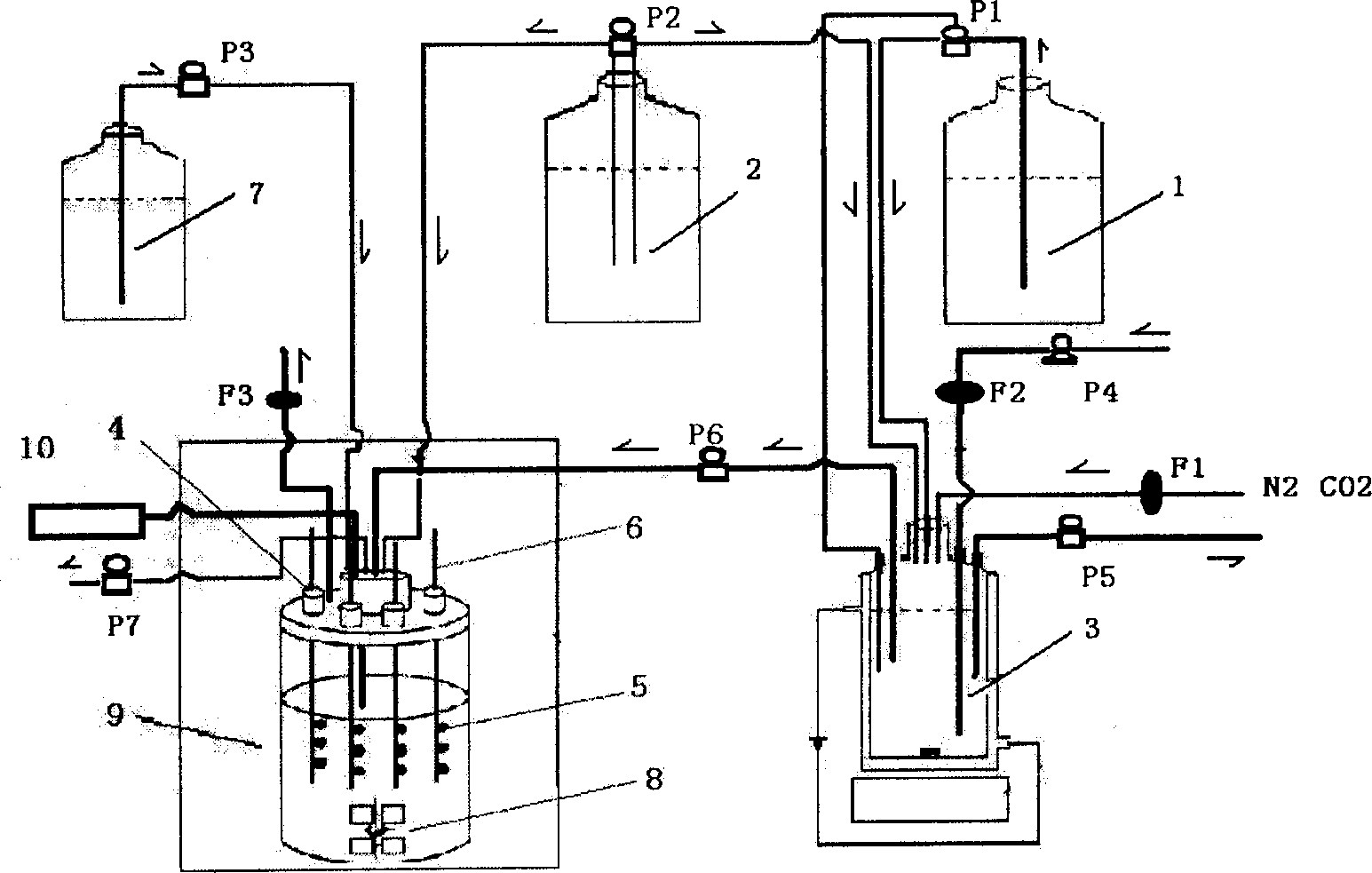

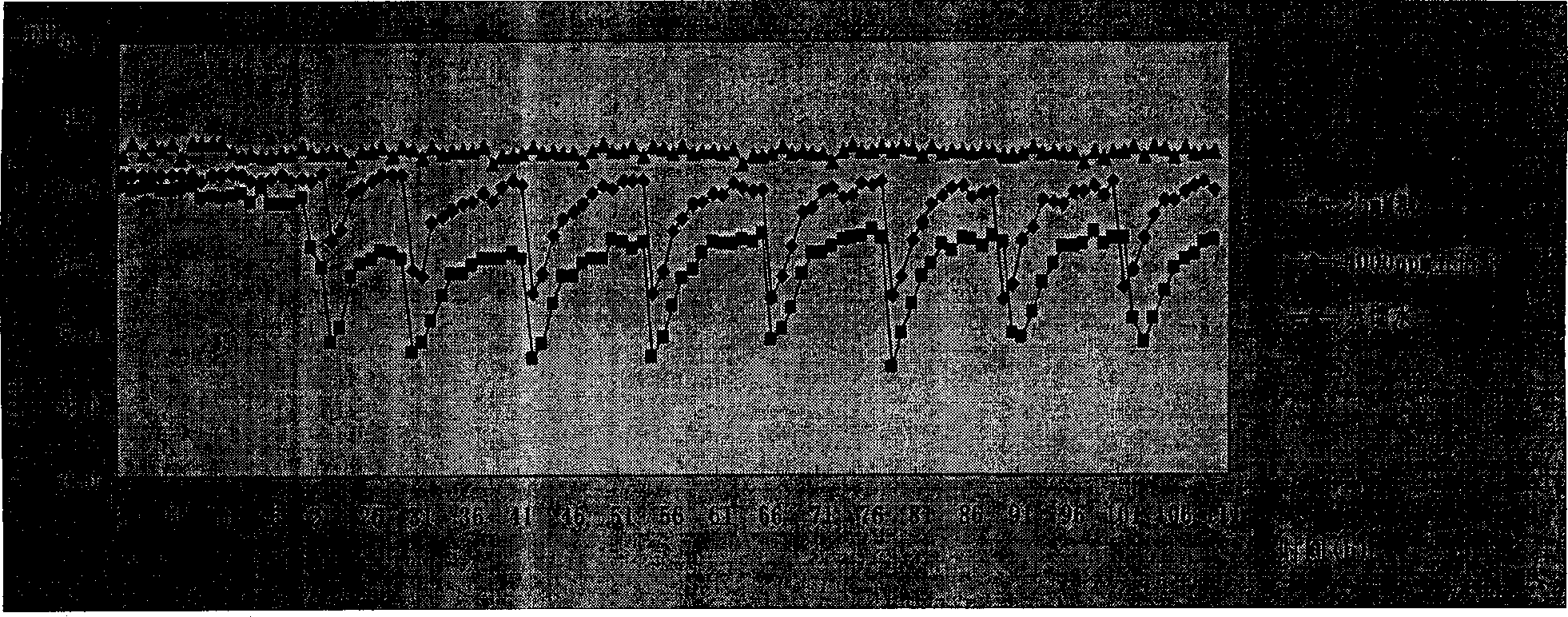

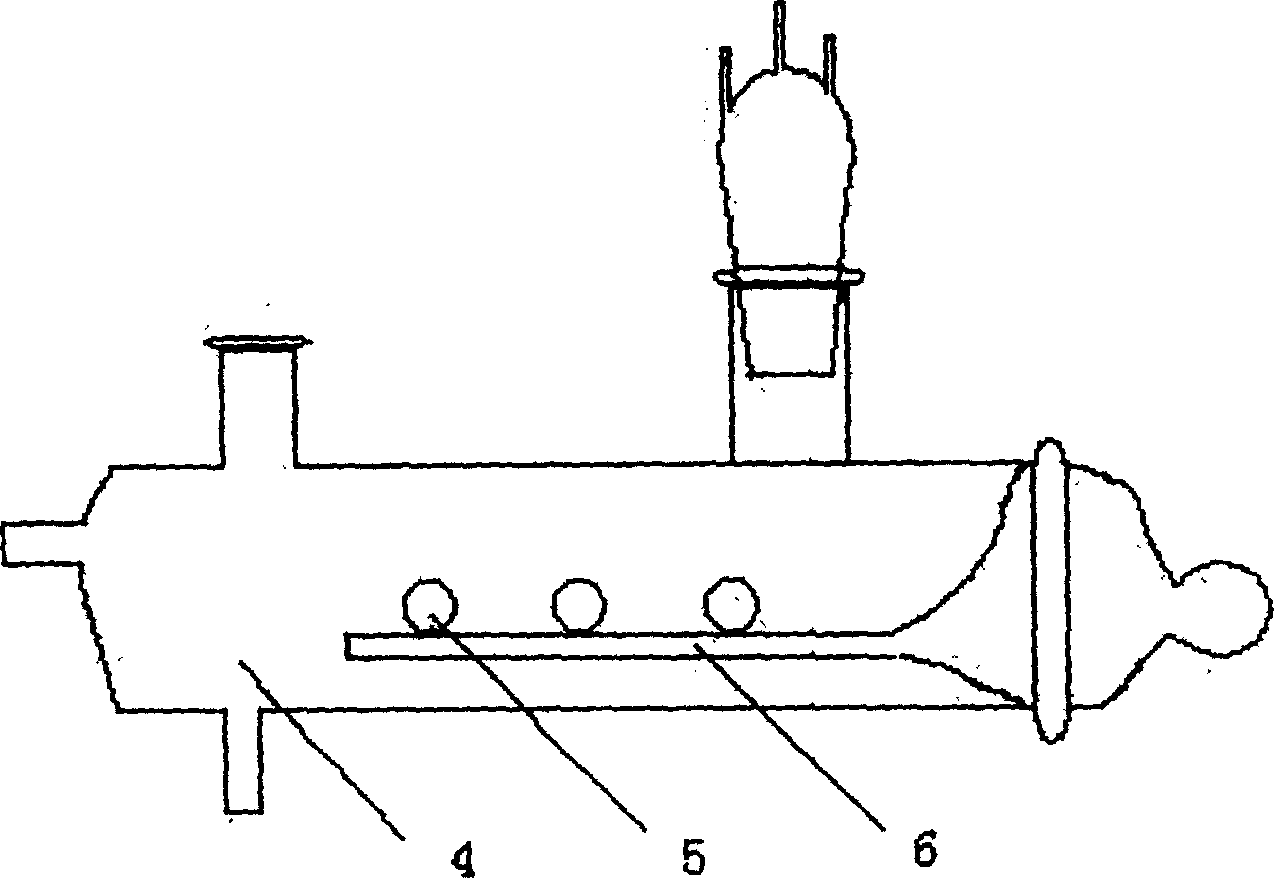

Oral biological film dynamic model device and its oral biological film forming method

InactiveCN1858200ARealize longitudinal continuous real-time monitoringEfficient formationBioreactor/fermenter combinationsBiological substance pretreatmentsPeristaltic pumpDynamic models

The dynamic oral cavity biomembrane model device includes an alkali liquor tank, a culture medium tank, a fermenting tank, a constant flow culture chamber and a sample applying bottle. It features the constant flow culture chamber comprising several serially connected vertical standard cylindrical constant flow culture chambers, the alkali liquor tank connected through peristaltic pump P1 to the fermenting tank, the culture medium tank connected peristaltic pump P2 to the fermenting tank, the fermenting tank with N2 and CO2 introduction through filter F2 and peristaltic pump P4 and waste liquid and waste gas exhaust through peristaltic pump P5 and filter F1, the constant flow culture chamber connected through peristaltic pump P6 to the fermenting tank and with waste liquid and waste gas exhaust through peristaltic pump P7 and filter F3, and the culture medium tank and the sample applying bottle connected through peristaltic pumps P2 and P3 to the constant flow culture chamber.

Owner:SICHUAN UNIV

Method for preparing modified starch by oxidation and succinic anhydride esterification

The invention provides a method for preparing modified starch by oxidation and succinic anhydride esterification. The method comprises the following steps of: dissolving starch into water to form starch milk, performing oxidation reaction on sodium hypochlorite oxidant and starch to obtain oxidized starch, then removing chlorine, performing esterification reaction by adopting succinic anhydride, and finally dehydrating and drying the reaction product to obtain the modified starch. When the modified starch prepared by the method is used as starch size, the modified starch has the properties of good fluidity, low viscosity and high-concentration use of the oxidized starch; and because the succinic anhydride esterification solves the problem of poor thermal stability of the oxidized starch, the modified starch has the advantages that: adhesion of warps is remarkably improved; a size film has strong forming capability, good mechanical strength and extensibility; the paste has stable viscosity and good fluidity; the size has certain moisture absorption property; the modified starch has good co-solvency with a synthetic size; the film is easy to dissolve in water, and de-sizing is easy; and the paste has high thermal stability, is not affected by high-temperature melting and the like.

Owner:内蒙古奈伦农业科技股份有限公司

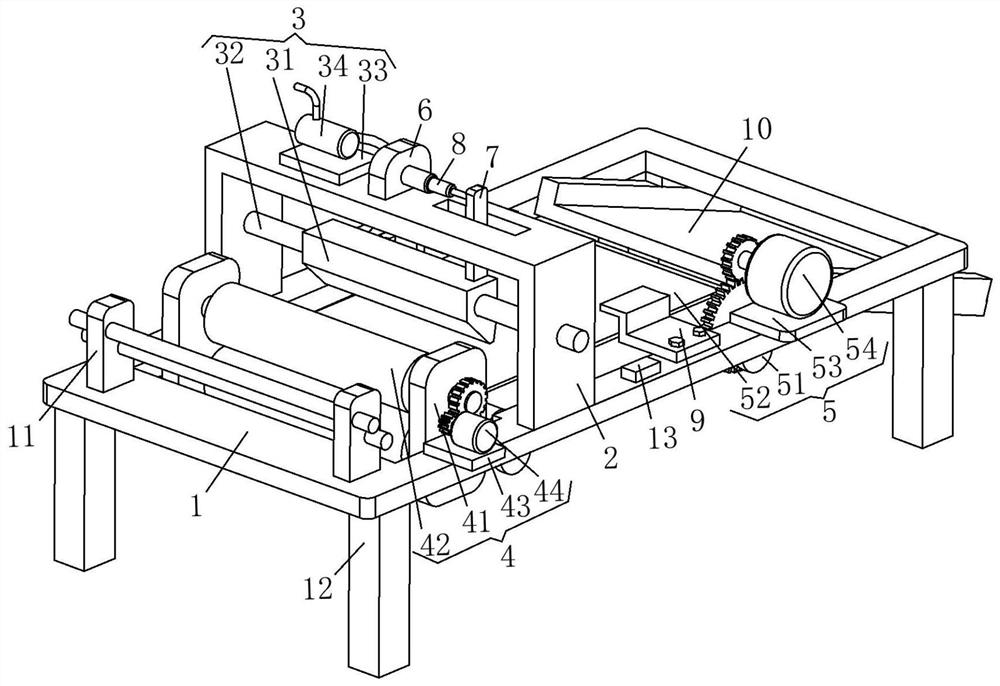

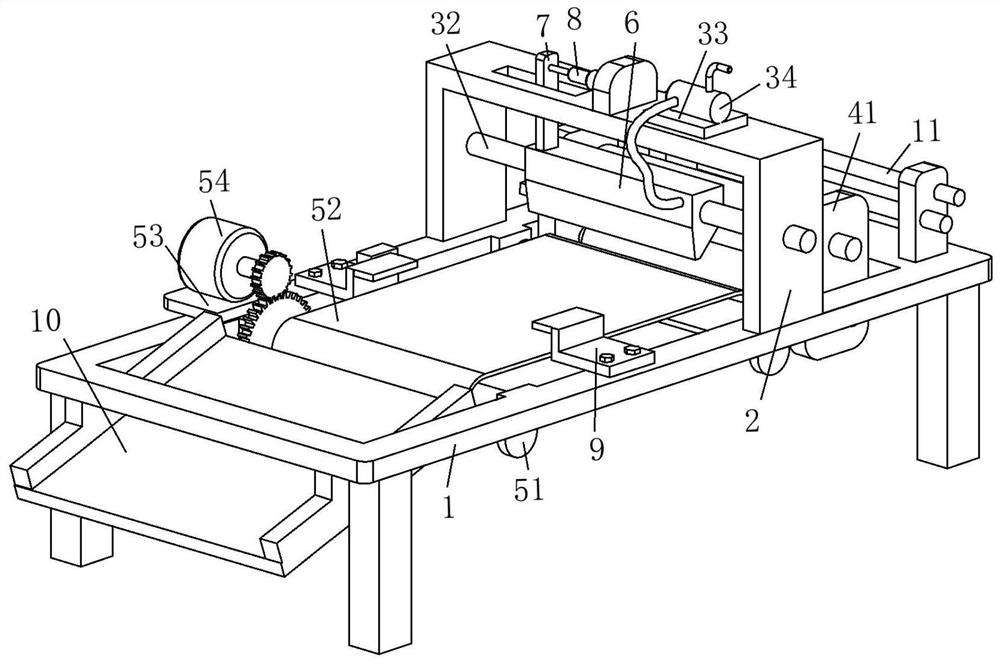

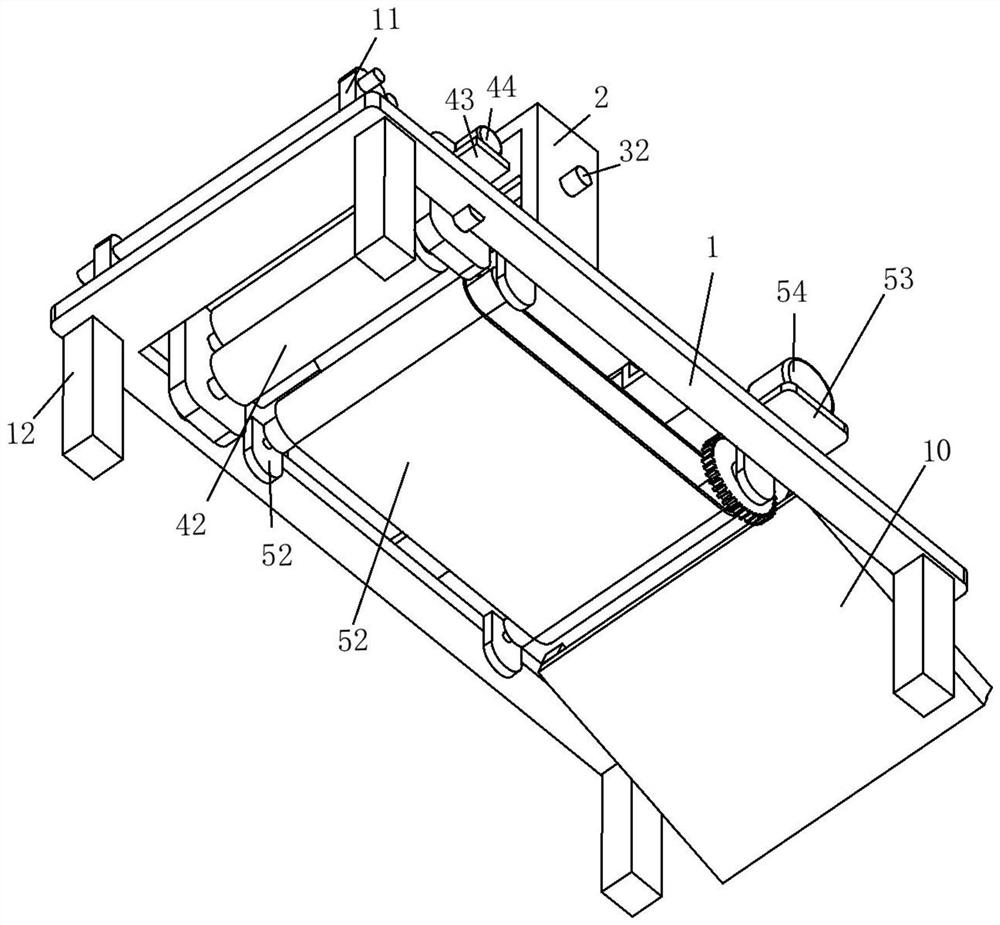

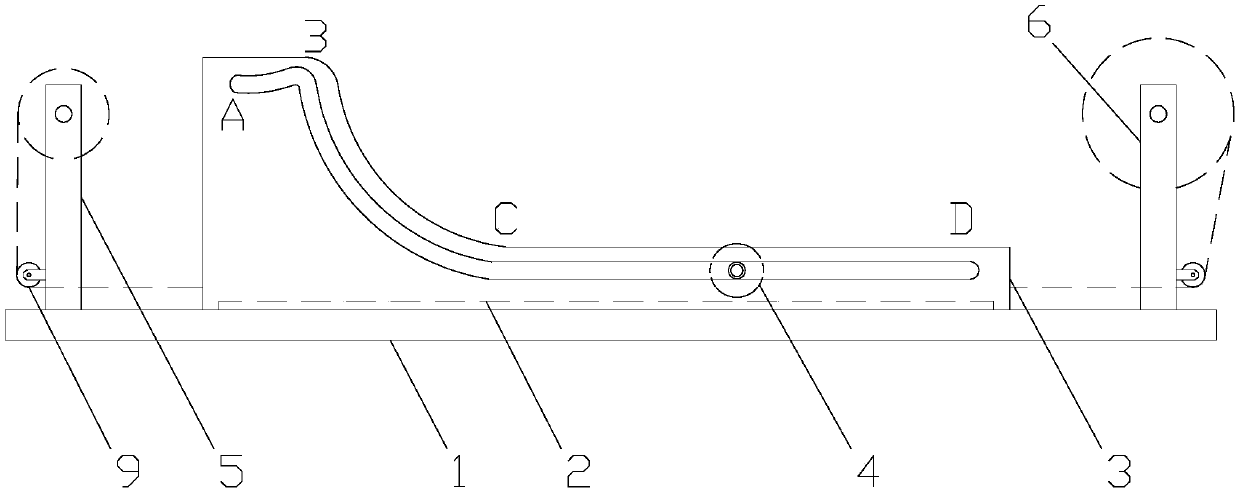

Semi-automatic textile printing equipment

ActiveCN107471816ASimple printing processEfficient printing processTransfer printingTextile printerSemi automatic

The invention discloses semi-automatic textile printing equipment. The semi-automatic textile printing equipment comprises a bottom plate, a printing table is movably mounted on the bottom plate, and can be fixed to a waiting position and a working position, two first supports arranged symmetrically are mounted on the two sides of the working position, a guide rail is arranged on each first support, a slide block is mounted in each guide rail, the two ends of a hot pressing roller are mounted in the slide blocks arranged on the two sides of the hot pressing roller, a second support and a third support are arranged on the bottom plate, and a discharging roller and a feeding roller are rotatably mounted on the second support and the third support correspondingly. The semi-automatic textile printing equipment utilizes a simple mechanical transmission structure to make the printing technology of textile fabrics to be simpler and more efficient, has good operability, and has a good price advantage at the same time.

Owner:安徽双盈纺织有限公司

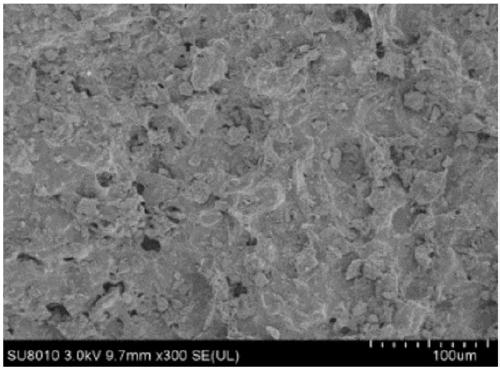

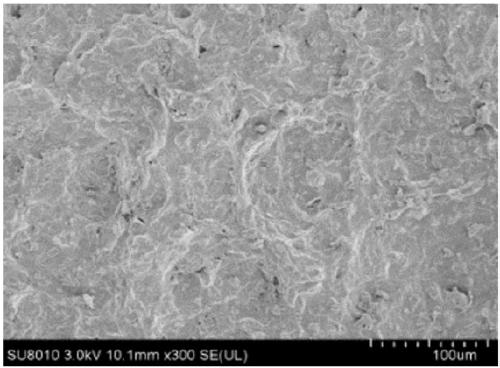

Support-free pure activated carbon membrane, preparation method and application thereof

ActiveCN106345319AImprove thermal stabilityReduce manufacturing costMembranesSemi-permeable membranesMicron scaleParticulates

The invention discloses a support-free pure activated carbon membrane, a preparation method and application thereof. The support-free pure activated carbon membrane is formed by taking graphene as a cross-linking agent for connection, can be independent of a base to exist stably and is high in chemical corrosion resistance and thermostability. The support-free pure activated carbon membrane is provided with controllable pore structures and is high in contaminant adsorbing property, and pore size can be adjusted from micron scale to nano scale by regulation of cross-linking agent additive amount, so that the multifunctional independent pure carbon membrane further has an effect of removing particulate pollutants and micromolecular pollutants and can be applied to environmental contaminated water treatment and the fields of drinking water purification, air purification and the like.

Owner:ZHEJIANG UNIV

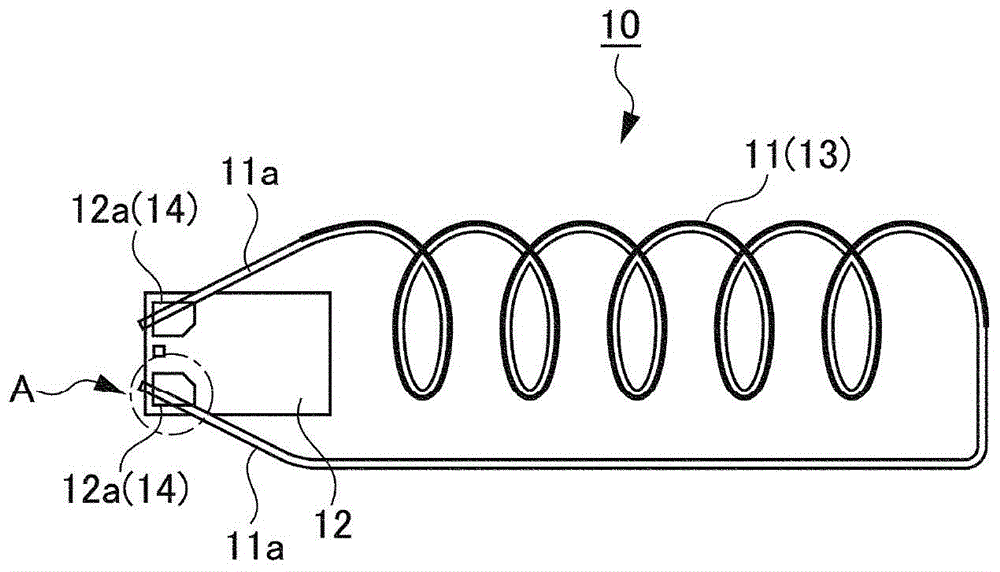

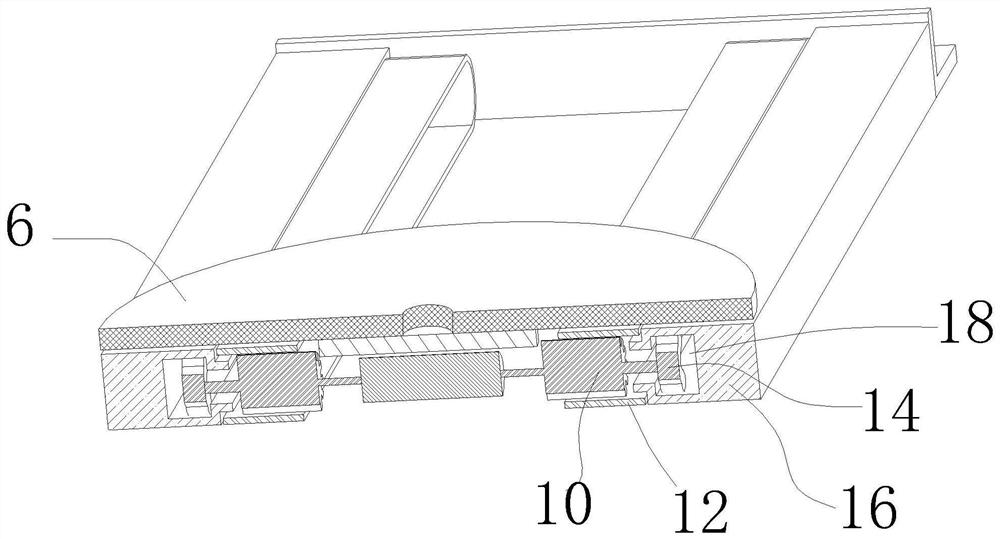

Method for manufacturing antenna part

InactiveCN104347924ASave energyIncrease production capacityAntenna supports/mountingsSolid-state devicesEngineeringSemiconductor

Provided is a method of manufacturing an antenna part that can be produced easily and inexpensively, the method comprising the steps of: forming a coil part 11 by a wire material 13 having an insulation coating 16, and removing the insulation coating 16 from both end portions 11a of the coil part 11; forming a connection region 12a of an electrically-conductive metal on the semiconductor substrate 12, and further forming a solder layer 14 on the connection region 12a; wiring the coil part 11 on the connection region 12a so that each end portion 11a of the coil part 11 to be in contact with the solder layer 14; and melting the solder layer 14 by heat to allow each end portions 11a to enter into the solder layer 14, and thus to electrically connect the connection region 12a and the coil part 11 through the solder layer 14.

Owner:SUMIDA CORP

Oral biological film dynamic model device and its oral biological film forming method

InactiveCN100408669CEfficient formationStable formationBioreactor/fermenter combinationsBiological substance pretreatmentsPeristaltic pumpDynamic models

The dynamic oral cavity biomembrane model device includes an alkali liquor tank, a culture medium tank, a fermenting tank, a constant flow culture chamber and a sample applying bottle. It features the constant flow culture chamber comprising several serially connected vertical standard cylindrical constant flow culture chambers, the alkali liquor tank connected through peristaltic pump P1 to the fermenting tank, the culture medium tank connected peristaltic pump P2 to the fermenting tank, the fermenting tank with N2 and CO2 introduction through filter F2 and peristaltic pump P4 and waste liquid and waste gas exhaust through peristaltic pump P5 and filter F1, the constant flow culture chamber connected through peristaltic pump P6 to the fermenting tank and with waste liquid and waste gas exhaust through peristaltic pump P7 and filter F3, and the culture medium tank and the sample applying bottle connected through peristaltic pumps P2 and P3 to the constant flow culture chamber.

Owner:SICHUAN UNIV

Gluing device for corrugated carton production

InactiveCN111703120AImprove uniformitySimple manufacturing processBox making operationsPaper-makingCartonStructural engineering

The invention discloses a gluing device for corrugated carton production. The gluing device comprises a mounting frame, a connecting frame, a gluing mechanism, a leveling mechanism and a conveying mechanism, wherein the mounting frame is rectangular; the connecting frame is fixedly connected to the surface of the middle position of the mounting frame; the connecting frame is reversely U-shaped; the left end of the mounting frame is connected with the leveling mechanism; the right side of the mounting frame is connected with the conveying mechanism; the gluing mechanism comprises a glue box, slide rods, a connecting plate and a glue pump; two sides of the glue box are slidingly connected into slide holes formed in the middle position of the connecting frame through the slide rods; a glue outlet hole is formed in the lower end of the glue box; the glue pump is fixedly connected to the upper surface of the connecting frame through the connecting plate; and an output end of the glue pump communicates with a liquid inlet of the glue box through a hose. The gluing device for corrugated carton production is low in failure rate, low in manufacturing cost, excellent in stability, high in production efficiency, low in maintenance cost and excellent in use effect.

Owner:李泽锋

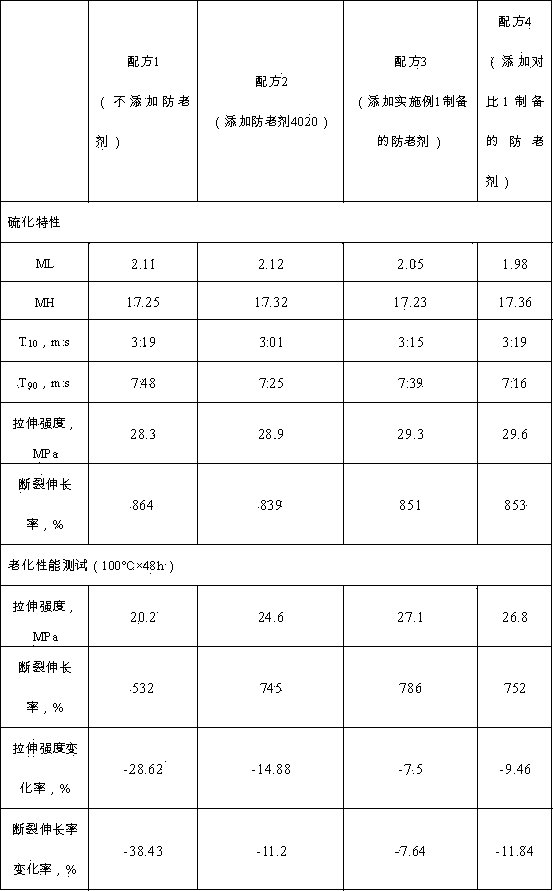

Method for preparing protective material for rubber by recycling textile white mud

The invention relates to a method for preparing a protective material for rubber by recycling textile white mud. The preparation method is characterized by comprising the steps: 1) dissolving the textile white mud in sodium hydroxide, filtering with activated carbon after complete dissolution to obtain a sodium terephthalate clarified solution, adding a pre-prepared calcium chloride solution intothe clarified solution, filtering, washing and drying to obtain a calcium terephthalate organic framework material; 2) respectively dissolving the organic framework material obtained in the 1) and ananti-aging agent 4020 in dimethylformamide to obtain respective solutions; 3) mixing the solutions obtained in the 2), and carrying out a reaction under certain conditions under the action of a catalyst and an oxidant to obtain a coordination chelate; and 4) finally cooling to a proper temperature, and crushing to obtain the target product. The obtained product has the advantages of obvious priceadvantage, low possibility of caking, and capability of providing full-life-cycle protection for rubber products and preventing the products from becoming red.

Owner:常州市五洲环保科技有限公司 +2

Coating with hydrophilic self-cleaning capability and preparation method thereof

ActiveCN114350192AHigh hardnessGood adhesionElectrically-conductive paintsPolymer sciencePhosphonium salt

Owner:湖南中大智洁科技有限公司

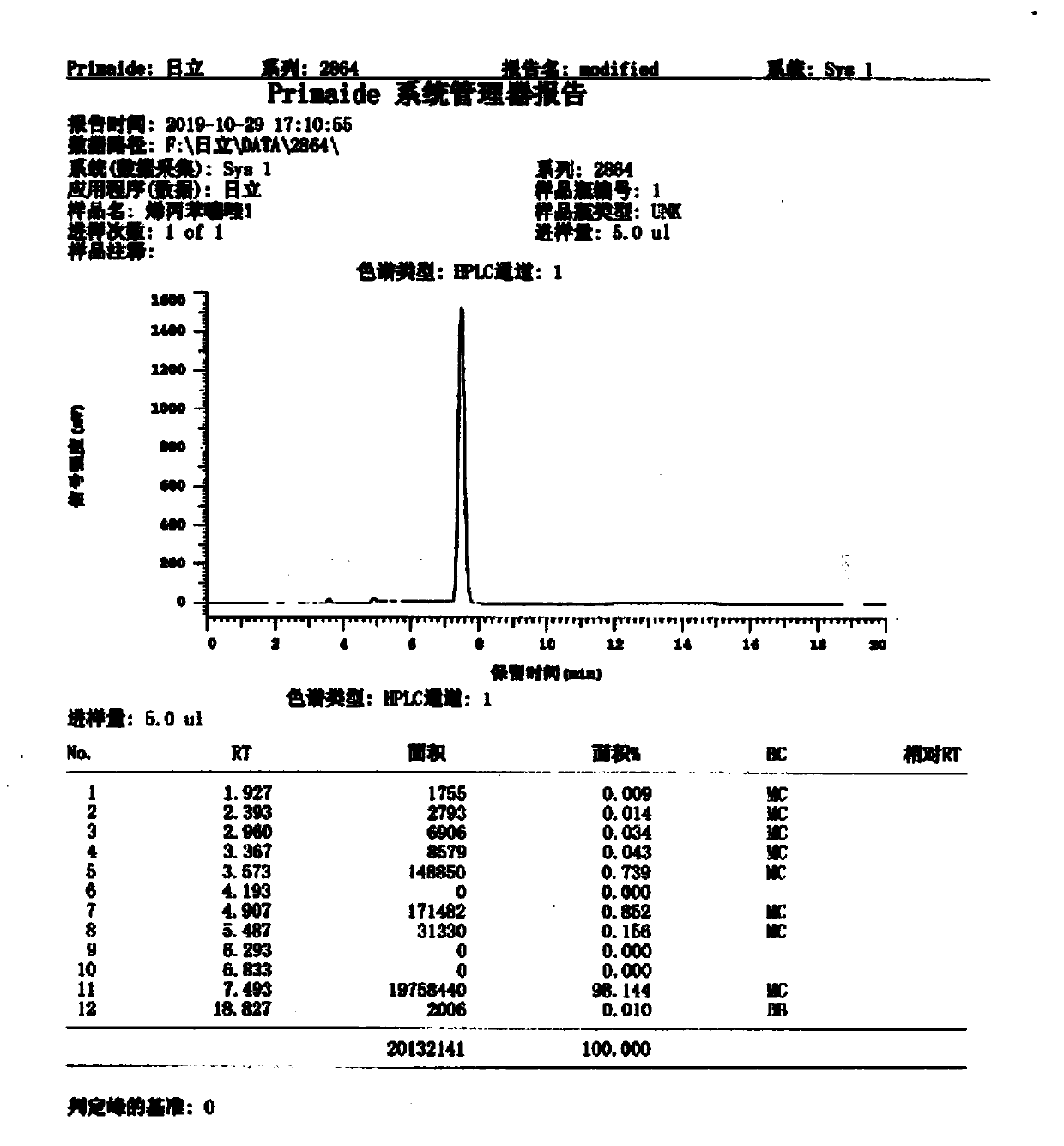

Preparation method of probenazole

The invention provides a preparation method of probenazole. The method comprises the following steps: by taking saccharin as an initial raw material, chlorinating with thionyl chloride in 1, 4-dioxaneto obtain a chloride, adding a high-boiling-point solvent to remove the solvent dioxane and excessive thionyl chloride, directly carrying out substitution reaction with a sodium salt or a potassium salt of allyl alcohol, and carrying out centrifugal desalination and cooling recrystallization to directly obtain high-purity probenazole. The preparation method is capable of solveing the problem of difficult kettle rotation caused by chloride solidification in the prior art, avoiding the generation of allyl chloride during etherification by allyl alcohol, and reducing the water washing procedurein the traditional method. Compared with the traditional method, the advantages are that the preparation method is simple and convenient to operate, high in yield, less in three wastes and high in purity of the obtained product, greatly saves the production cost and the environmental protection cost, and is easy to realize industrialization.

Owner:天津北方食品有限公司

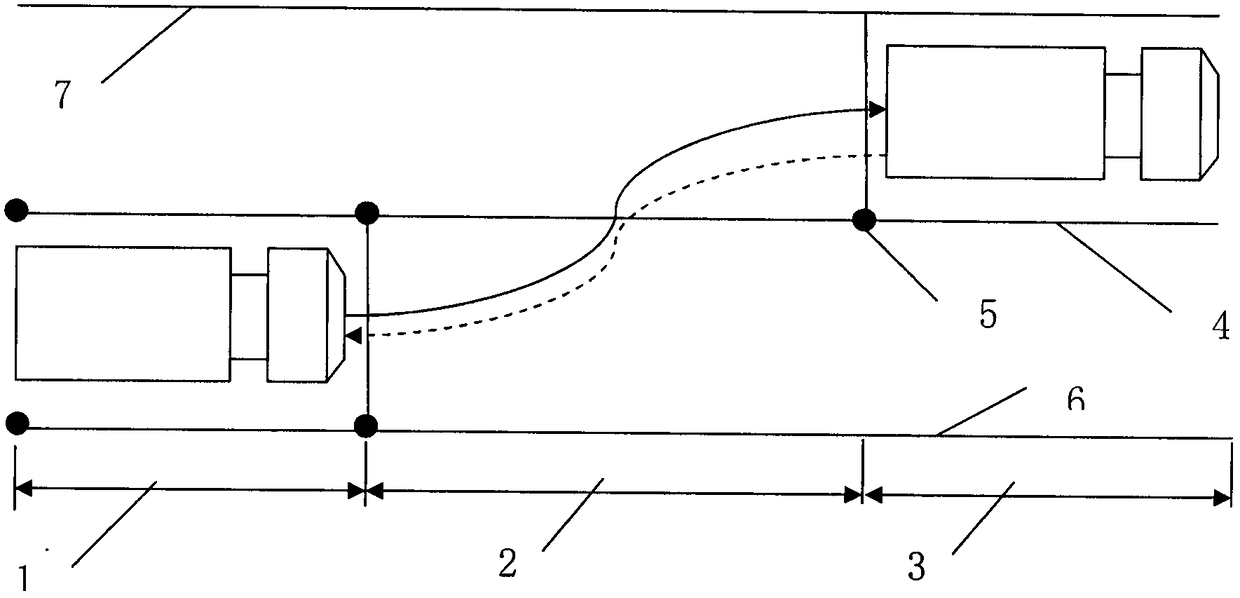

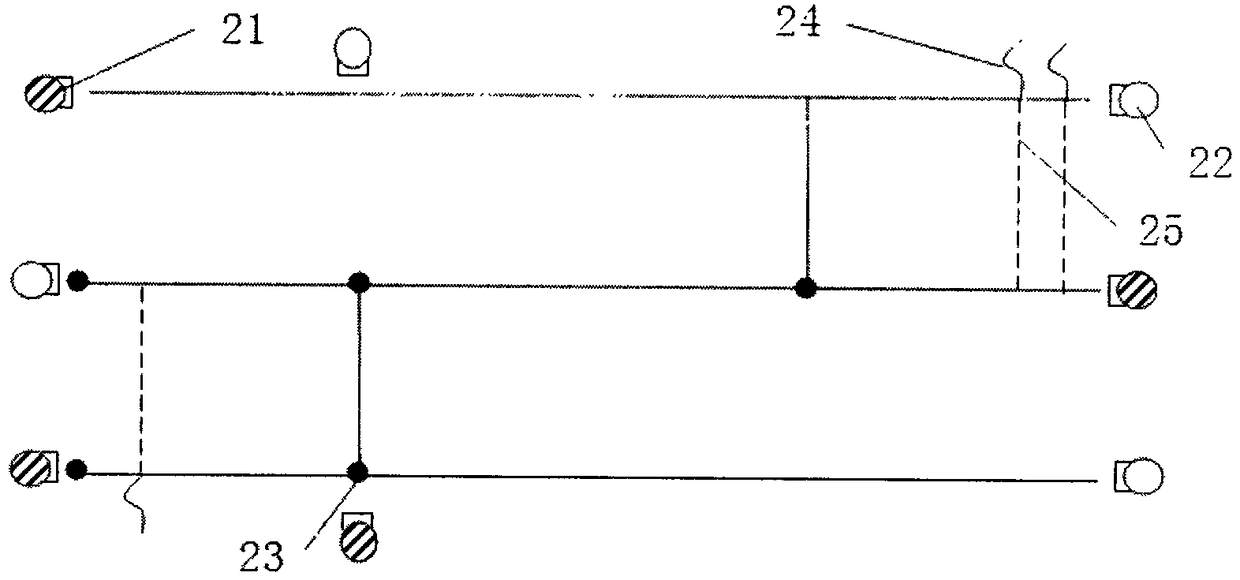

System and method of detecting reverse shift of tractor

The invention provides a system and a method of detecting reverse shift of a tractor, which belongs to the field of traffic control. The system comprises photoelectric sensors, pressure-sensitive cables, hanging rods and a signal acquisition board, wherein each hanging rod is provided with a Hall sensor; each photoelectric sensor comprises a photoelectric sensor transmitting end and a photoelectric sensor receiving end; signals generated by the photoelectric sensors, the pressure-sensitive cables and the Hall sensors enter the signal acquisition board, and the signal acquisition board carries out data acquisition and forwarding; a first photoelectric sensor transmitting end is arranged at the left end of the left line of a road, and the right end is provided with a first photoelectric sensor receiving end; a second photoelectric sensor receiving end is arranged at the left end of the middle line of the road, and the right end is provided with a second photoelectric sensor transmitting end; and a third photoelectric sensor transmitting end is arranged at the left end of the right line of the road, and the right end is provided with a third photoelectric sensor receiving end.

Owner:TIANJIN POLYTECHNIC UNIV

Method and system thereof for monitoring and controlling environments of public place based on Zigbee

ActiveCN101957602BImprove intelligenceImprove security featuresEnergy efficient ICTComputer controlPublic placeWireless sensor networking

Owner:河南天擎机电技术有限公司

Composite material for repairing deletion of tooth and human hard tissues and its preparation

InactiveCN1267080CImprove mechanical propertiesTranslucentImpression capsDentistry preparationsArtificial hip jointsHard tissue

A composite material for reparing tooth and human hard tissue is prepared through preparing the partly sintered ceramics, surficial coupling, and vacuum dipping in resin while in-situ polymerizing.

Owner:李石保

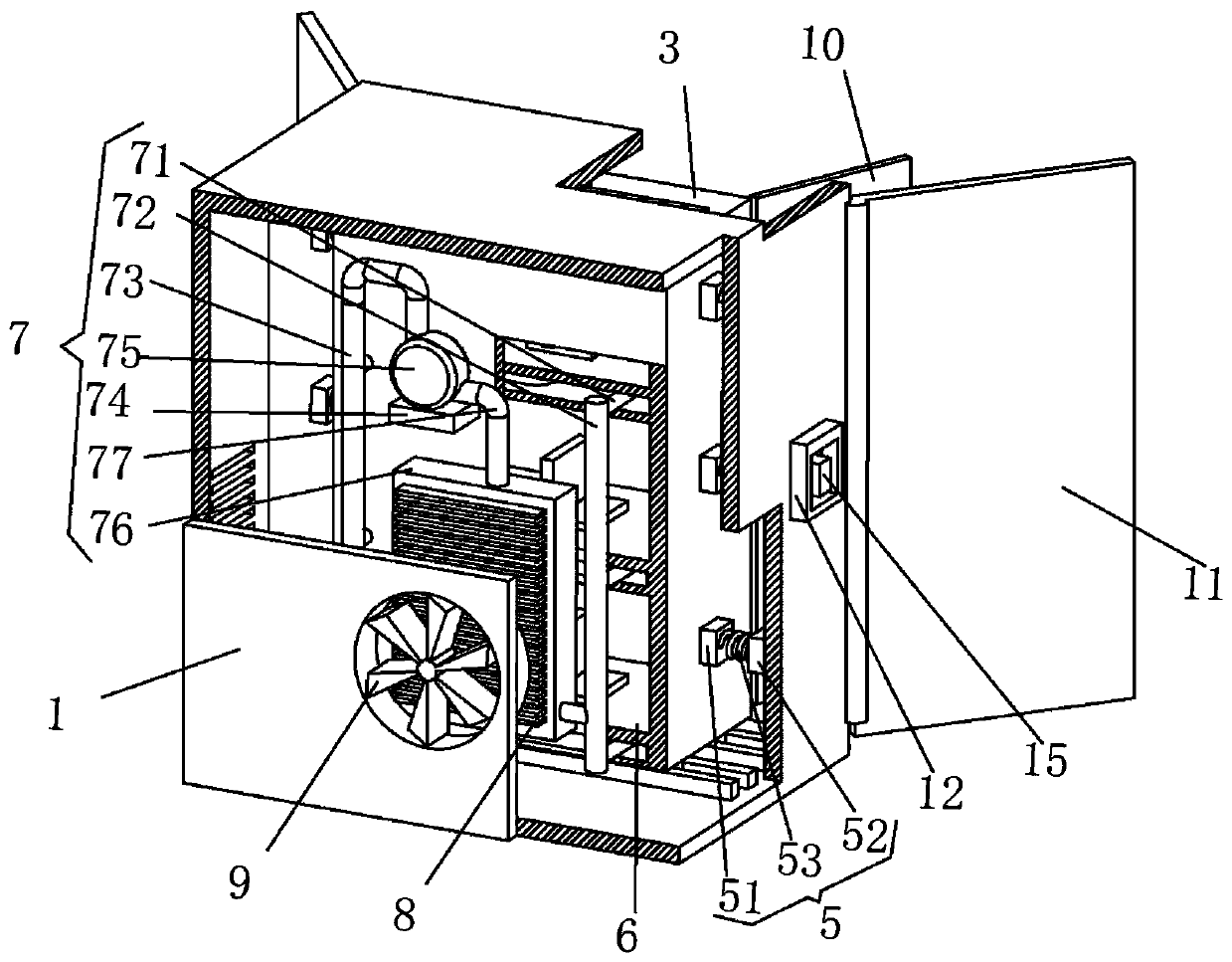

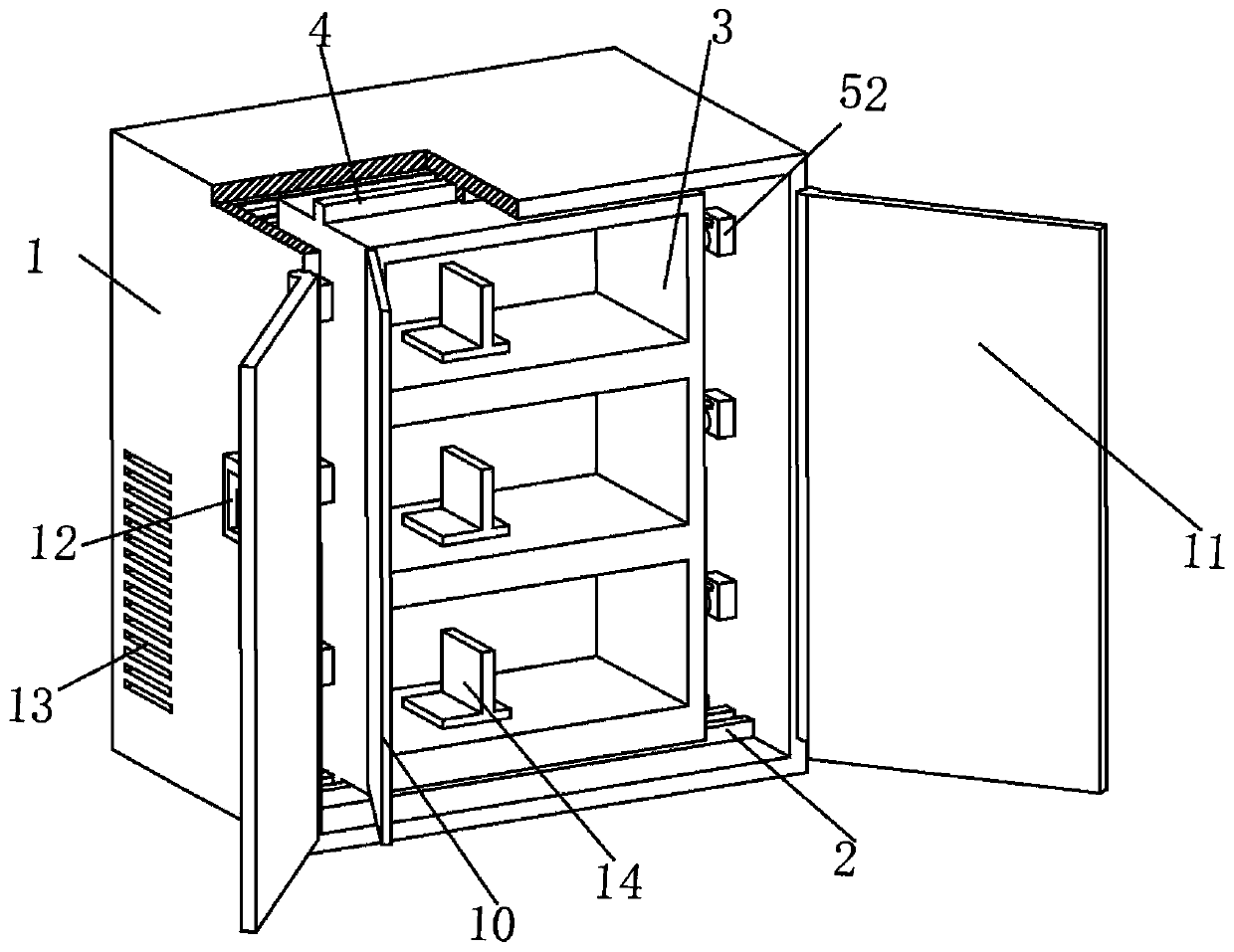

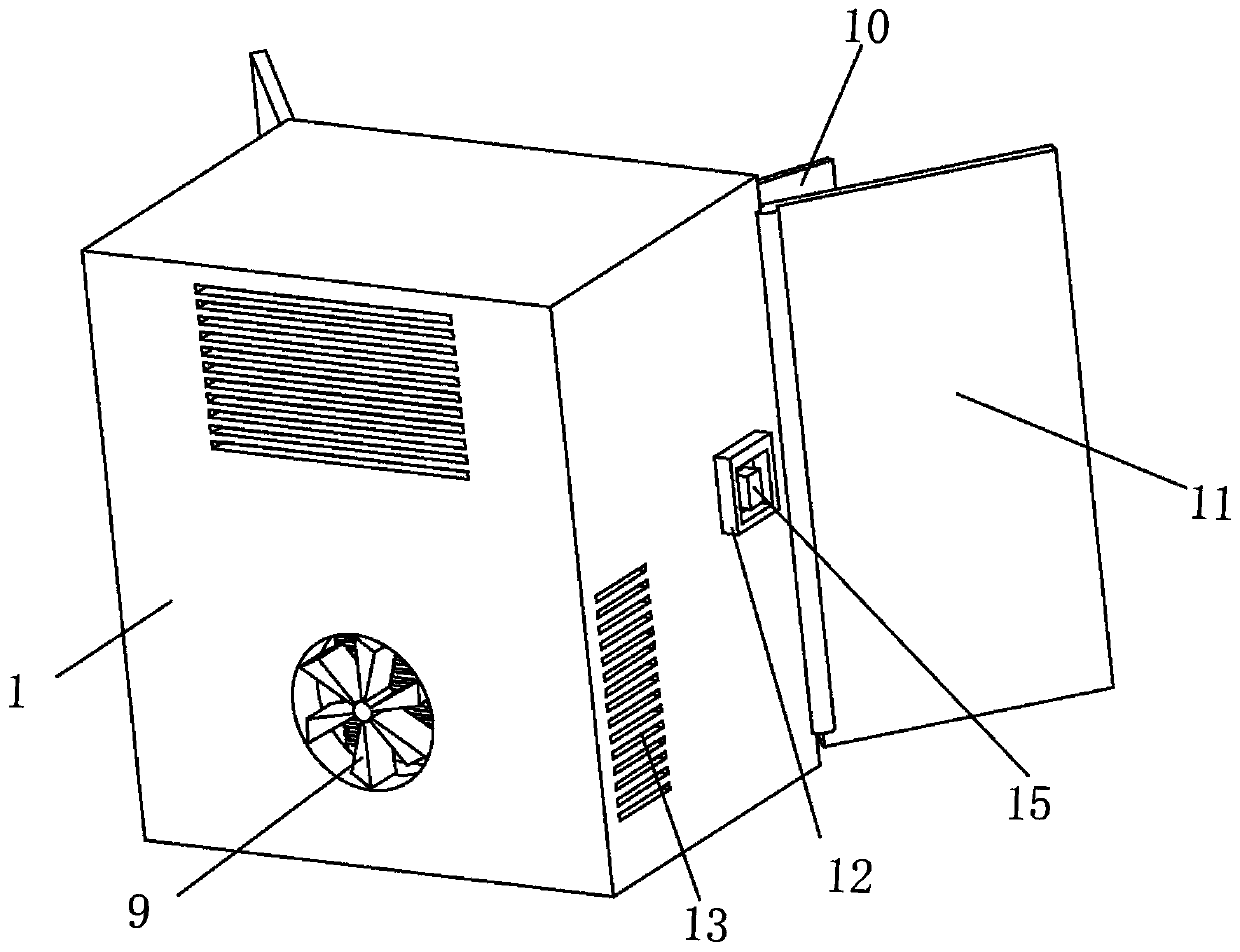

Marine frequency conversion cabinet with high stability

InactiveCN111224532AImprove stabilityTake away quicklyModifications for power electronicsPower conversion systemsConvertersFrequency changer

The invention discloses a marine frequency conversion cabinet with high stability. The marine frequency conversion cabinet comprises an outer box body, a sliding rail, an inner box body, a sliding strip, a buffer unit, a hollow heat conduction partition plate and a circulation unit; the appearance of the outer box body is in a cuboid shape. The front side of the outer box body is arranged to be inan opening shape, and two sides of the middle position of the upper surface of the lower plate of the outer box body and the middle position of the upper plate are each fixedly connected with a sliding rail. The inner box body is in a box shape with an opening in the front side. A sliding strip is fixedly connected to each of the upper surface, corresponding to the sliding rail, of the inner boxbody and the lower surface of the lower plate; the sliding strips are connected with the corresponding sliding rails in a sliding manner; the inner wall of the inner box body is fixedly connected withthe hollow heat conduction partition plate at equal intervals. According to the invention, the frequency conversion cabinet has the advantages that the cabinet is good in damping effect, high in heatdissipation efficiency and good in moisture resistance, can be applicable to high-shaking places such as ships, meets heat dissipation requirements of high-power frequency converters and is not easyto damage, and heat dissipation requirements of the high-power frequency converters can be met.

Owner:镇江恒昇船舶设备有限公司

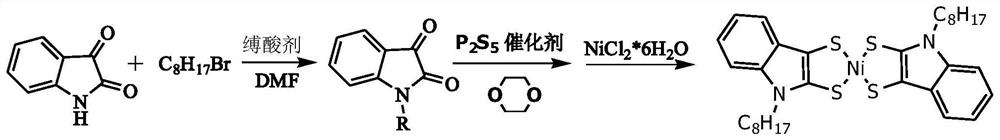

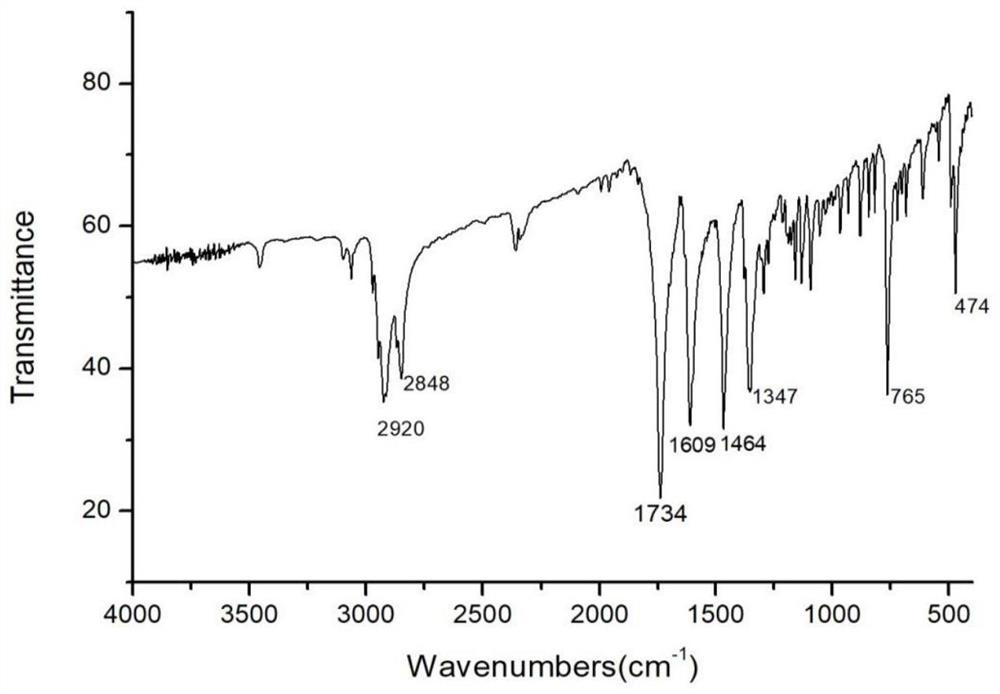

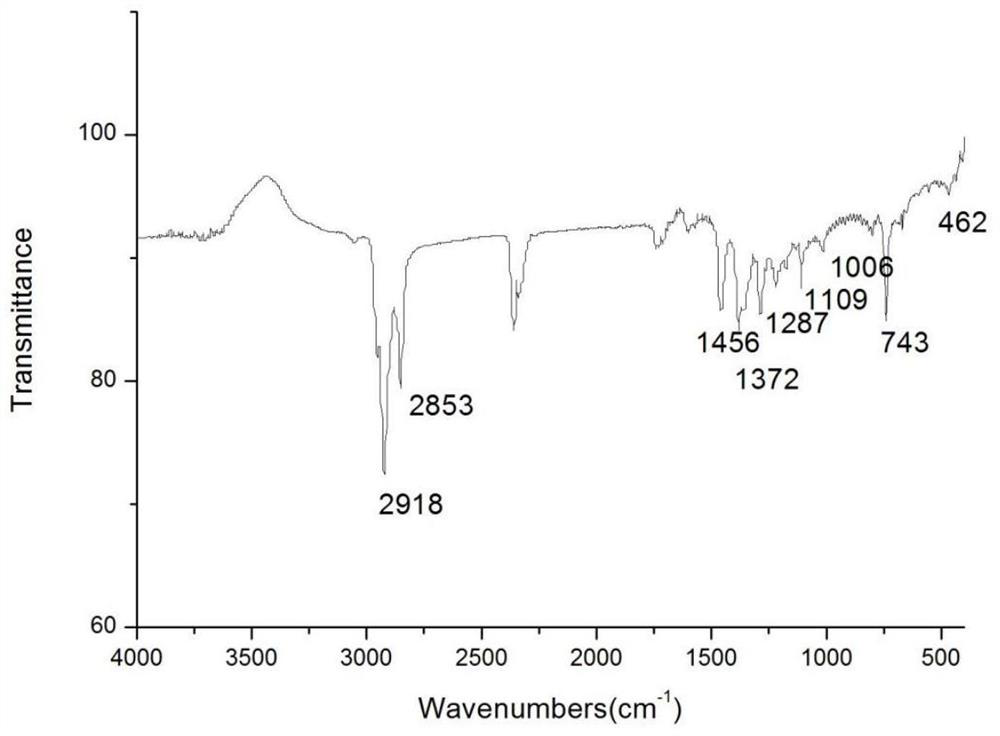

Indole thiodiene metal complex and preparation method thereof

ActiveCN109970619BEmission reductionEasy to operateOrganic chemistryAzo dyesDiketonePhosphorus pentasulfide

The invention relates to the technical field of dye-sensitized solar cell materials, in particular to an indolethiodiene-type metal complex and a preparation method thereof; the invention uses isatin as a starting raw material, through chemical modification, in the nitrogen atom Various substituents R are introduced to obtain chemically modified isatin intermediates, and then further react with phosphorus pentasulfide and divalent metal chlorides to obtain indolethiodiene metal complexes. The invention breaks through the bondage of the benzene ring or naphthalene ring group used in the existing structure to form an intermediate thiodiene metal skeleton, and obtains a series of near-infrared dyes with a substituted indole thiodiene metal complex structure. Utilizing the characteristic of diketone structure in the molecular structure of isatin, a dye intermediate, after adding various modifications to the nitrogen atom, it can be directly complexed with the metal to obtain the target compound, which not only avoids the process steps of "three wastes" , and at the same time developed a new application for isatin dye intermediate.

Owner:SHENYANG NORMAL UNIV

Integral stretching technology of double (three)-tank stainless steel water tanks

A multi-groove overall stretching process for a stainless steel sink, the process includes blanking, corner cutting, first stretching, edge trimming, cleaning, annealing, second stretching, edge trimming, punching, cleaning, surface treatment, etc. Processing procedure. The tank body of the stainless steel sink manufactured through this process is a one-piece structure without welding, and the groove depth can reach 180-250mm, which not only overcomes the defects of many processes and material costs caused by welding, but also reduces the production cost for the enterprise. At the same time, it also avoids the water leakage and fastness problems caused by missing welding and desoldering that are easy to occur during the welding process, thereby improving the overall quality and service life of the sink, and making the appearance and depth of the one-piece stainless steel sink more catering to modern times. It has better price advantage in market competition and creates better economic benefits for enterprises.

Owner:ZHEJIANG FRANTA

Liquid crystal screen with good weather resistance

The invention discloses a liquid crystal screen with good weather resistance. The liquid crystal screen comprises a mounting frame, connecting blocks, connecting holes and a heat dissipation unit. The mounting frame is arranged in a square frame shape, the rear ends of a left side plate and a right side plate of the mounting frame are arranged in a through shape, the edge positions of the upper surface and the lower surface of the mounting frame are each fixedly connected with a connecting block, the connecting blocks are arranged in a long-strip shape, and connecting holes are formed in the middle positions of the two connecting blocks at equal intervals in a through mode; and the heat dissipation unit comprises a vertical heat conduction plate, a heat dissipation wind blocking piece, a rear connecting plate, a heat dissipation fan and a display screen, the vertical heat conduction plate is fixedly connected to the inner wall of the middle position of the mounting frame, and the vertical heat conduction plate divides the mounting frame into a left space and a right space. The liquid crystal screen with the good weather resistance is simple in structure, the good heat dissipation effect on the LED liquid crystal screen can be achieved, a firm installation position can be provided for the liquid crystal screen, and the sealing effect and the protection effect are good.

Owner:常州红光仪表配件有限公司

A system and method for detecting the reversing displacement of a tractor

The invention provides a system and a method of detecting reverse shift of a tractor, which belongs to the field of traffic control. The system comprises photoelectric sensors, pressure-sensitive cables, hanging rods and a signal acquisition board, wherein each hanging rod is provided with a Hall sensor; each photoelectric sensor comprises a photoelectric sensor transmitting end and a photoelectric sensor receiving end; signals generated by the photoelectric sensors, the pressure-sensitive cables and the Hall sensors enter the signal acquisition board, and the signal acquisition board carries out data acquisition and forwarding; a first photoelectric sensor transmitting end is arranged at the left end of the left line of a road, and the right end is provided with a first photoelectric sensor receiving end; a second photoelectric sensor receiving end is arranged at the left end of the middle line of the road, and the right end is provided with a second photoelectric sensor transmitting end; and a third photoelectric sensor transmitting end is arranged at the left end of the right line of the road, and the right end is provided with a third photoelectric sensor receiving end.

Owner:TIANJIN POLYTECHNIC UNIV

Aromatic polyoxadiazole film and preparation method thereof

The invention relates to an aromatic polyoxadiazole film and a preparation method thereof. The preparation method comprises the following steps: taking an aromatic dicarboxylic acid compound and a hydrazine salt as monomers, and carrying out condensation polymerization in fuming sulfuric acid to obtain an aromatic polyoxadiazole solution; extruding the aromatic polyoxadiazole solution through a clothes rack type casting mold, and then conveying the extruded aromatic polyoxadiazole solution into a dilute sulfuric acid coagulating bath for solidification molding to obtain a solidified acid-containing wet-state primary casting film; washing the acid-containing wet-state primary casting film to obtain a primary casting film free of sulfuric acid; and tensioning and drying the primary casting film free of sulfuric acid, carrying out heat setting treatment at 200-350 DEG C, and carrying out trimming and winding to obtain the aromatic polyoxadiazole film. The aromatic polyoxadiazole film canbe widely used as a high-temperature-resistant electric insulation film, a high-temperature-resistant insulation paper / film composite material, a copper-clad film, a high-temperature-resistant permeable film, a carbon film substrate, an aerospace material and the like.

Owner:HUAIHUA UNIV

Security radar system

The invention discloses a security radar system, which comprises a single-line laser radar and a translation module; wherein the single-line laser radar comprises a controller which is controlled by the controller to realize single-beam light two-dimensional scanning, and the translation module is controlled by the controller of the single-line laser radar to realize linear translation of a platform end; the single-line laser radar is fixed at the platform end; the controller cooperatively controls the single-line laser radar and the translation module, so that a scanning signal of the single-line laser radar in a third dimension is synchronous with a two-dimensional scanning signal of the single-line laser radar. According to the security and protection radar system, the three-dimensionalscanning effect can be achieved through the single-line laser radar; compared with a multi-line laser radar, the security and protection radar system has the advantages of being good in price advantage, low in cost and capable of guaranteeing high precision, and the technical problem that high-precision three-dimensional environment perception and organism recognition cannot be achieved in the security and protection field is solved.

Owner:SUZHOU UNION INTELLIGENT TECH CO LTD

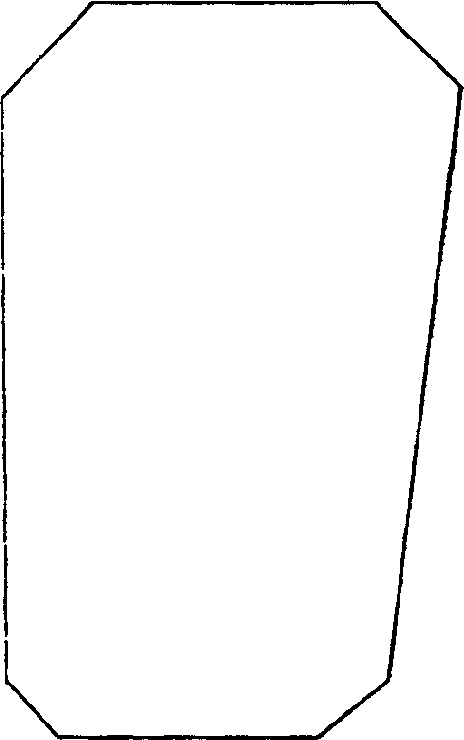

Integral drawn technique for faceplate of buffet dinner stove

An overall drawing process for a buffet stove panel, comprising the following steps: cutting the stainless steel coil material with a shearing machine into a sheet of the required size for the panel; applying pressure to the sheet and drawing it to the required height; applying compression to the workpiece to the required caliber ; Punch out a large-diameter square hole or round hole in the middle of the workpiece that has been punched through the neck; punch out a horizontal groove on the top of the workpiece that has been punched through the large hole; stretch and flang the edge of the middle hole of the workpiece; Polishing, cleaning, inspection and storage. There is no welding between the dining stove panels manufactured by the above-mentioned overall deep drawing process, which overcomes many defects caused by the welding process, such as many procedures, complicated processes, and many manufacturing hours, and reduces production costs; The quality problems caused by missing soldering and desoldering improve the appearance quality and service life of the panel, and also make the buffet stove have a better price advantage and better economic benefits in the market competition.

Owner:宁波格兰特制冷设备制造有限公司

A semi-automatic textile printing equipment

ActiveCN107471816BSimple printing processEfficient printing processTransfer printingTextile printerSemi automatic

The invention discloses semi-automatic textile printing equipment. The semi-automatic textile printing equipment comprises a bottom plate, a printing table is movably mounted on the bottom plate, and can be fixed to a waiting position and a working position, two first supports arranged symmetrically are mounted on the two sides of the working position, a guide rail is arranged on each first support, a slide block is mounted in each guide rail, the two ends of a hot pressing roller are mounted in the slide blocks arranged on the two sides of the hot pressing roller, a second support and a third support are arranged on the bottom plate, and a discharging roller and a feeding roller are rotatably mounted on the second support and the third support correspondingly. The semi-automatic textile printing equipment utilizes a simple mechanical transmission structure to make the printing technology of textile fabrics to be simpler and more efficient, has good operability, and has a good price advantage at the same time.

Owner:安徽双盈纺织有限公司

Method for preparing modified starch by oxidation and succinic anhydride esterification

InactiveCN101880335BImprove liquidityHigh viscosityFibre treatmentHigh concentrationMoisture absorption

The invention provides a method for preparing modified starch by oxidation and succinic anhydride esterification. The method comprises the following steps of: dissolving starch into water to form starch milk, performing oxidation reaction on sodium hypochlorite oxidant and starch to obtain oxidized starch, then removing chlorine, performing esterification reaction by adopting succinic anhydride, and finally dehydrating and drying the reaction product to obtain the modified starch. When the modified starch prepared by the method is used as starch size, the modified starch has the properties ofgood fluidity, low viscosity and high-concentration use of the oxidized starch; and because the succinic anhydride esterification solves the problem of poor thermal stability of the oxidized starch, the modified starch has the advantages that: adhesion of warps is remarkably improved; a size film has strong forming capability, good mechanical strength and extensibility; the paste has stable viscosity and good fluidity; the size has certain moisture absorption property; the modified starch has good co-solvency with a synthetic size; the film is easy to dissolve in water, and de-sizing is easy;and the paste has high thermal stability, is not affected by high-temperature melting and the like.

Owner:内蒙古奈伦农业科技股份有限公司

Model of mouth cavity biomembrane and method for forming mouth cavity biomembrane

InactiveCN1274803CSimple working processEasy to useBioreactor/fermenter combinationsBiological substance pretreatmentsBottleBiological membrane

An oral biomembrane model equipment is composed of alkali solution container, culture medium container, fermentor, constant-current culture chambers and sample bottle. A process for forming the oral biomembrane includes aseptic connection of said equipment, inoculating experimental bacterial strain into fermentator, continuous culture, regulating pH=7.0, adding artificial saliva as culture medium, culturing, continuing to culture in parallel constant-current culture chambers, and mediating it on hydroxyphosphorite sheet to obtain oral biomembrane.

Owner:SICHUAN UNIV

A kind of unsupported activated carbon full carbon film and its preparation method and application

ActiveCN106345319BImprove thermal stabilityReduce manufacturing costMembranesSemi-permeable membranesCarbon filmMicron scale

The invention discloses an unsupported activated carbon full-carbon membrane, a preparation method and application thereof. The activated carbon full-carbon film formed by connecting graphene as a cross-linking agent can exist independently of the substrate, and has high chemical resistance and thermal stability. This multifunctional all-carbon membrane has a controllable pore structure and has super adsorption performance for pollutants. The pore size can be adjusted from micron to nanometer under the control of the amount of crosslinking agent added. According to the above properties, the multifunctional independent all-carbon membrane can achieve the effect of one-step removal of particle pollutants and small molecule pollutants, and can be used in the fields of environmental pollution water treatment, drinking water purification and air purification.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com