Coating with hydrophilic self-cleaning capability and preparation method thereof

A self-cleaning and capable technology, applied in conductive coatings, coatings, etc., can solve the problems of low photoelectric conversion efficiency and visible light utilization, limited application effect, deposition and curing, etc., to achieve small appearance and light transmittance, and improve degradation efficiency. , the effect of reducing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

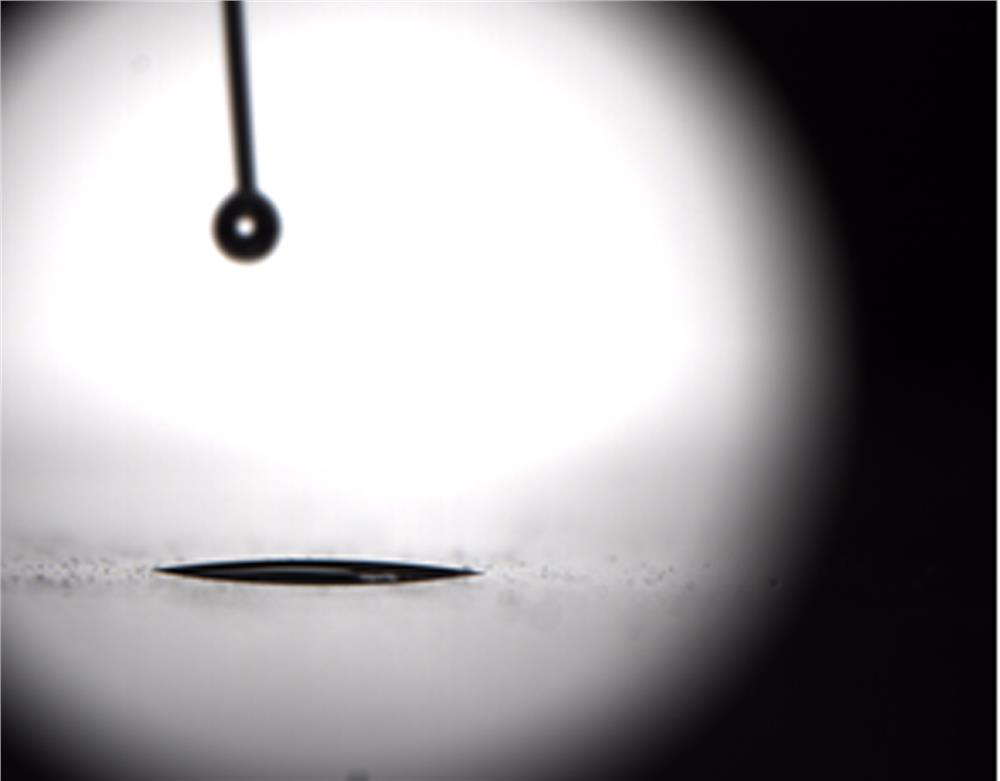

Image

Examples

Embodiment 1

[0038] This example is to use the polymer monomer acrylamide to prepare polymer materials, and modify them to make them hydrophilic. Acrylamide is a derivative of propylene; the specific preparation process is as follows:

[0039] Dissolve 14.216 g of acrylamide solid in 100 mL of ultrapure water, stir the solution at 200 rpm in a water bath at 30 °C for 3 min to fully dissolve, then add 0.1 mL of (3-mercaptopropyl) Trimethoxysilane solution is added thereto, the volume fraction of the (3-mercaptopropyl)trimethoxysilane solution is 10%, and the diluent of (3-mercaptopropyl)trimethoxysilane is tetrahydrofuran, and then added 1 mL of 0.1 mol / L acetic acid solution, followed by 0.57 mL of silane coupling agent TMSPMA, stirred at 30°C for 5 min, and finally added 0.2 mL of 0.1 mol / L photoinitiator I-2959, stirred After 10 minutes, let it stand for later use;

[0040] The prepared coating was sprayed on the tempered glass with a high-pressure spray gun, and cured after 24 hours of...

Embodiment 2

[0043] Change the amount of acrylamide added in step (1) to 7.1797 g. The amount of other experimental materials and preparation steps are the same as in Example 1 to obtain the coating prepared in Example 2, and then carry out the same coating method as in Example 1 And measuring method, measure the performance of the prepared coating of embodiment 2;

Embodiment 3

[0045] Change the amount of acrylamide added in step (1) to 3.5899 g, and the amount of other experimental materials and preparation steps are the same as in Example 1 to obtain the coating prepared in Example 3, and then carry out the same coating method as in Example 1 and measurement methods to measure the performance of the prepared coatings in implementation 3;

[0046] From the effects of Example 2 and Example 3 shown in Table 1, we can see that reducing the concentration of polymer monomers will indeed improve the transparency of the coating, but as the concentration of polymer monomers decreases, the coating The aging resistance and hardness of the layer will gradually decrease, which will cause the coating to quickly lose its hydrophilicity and antifouling properties, so we need to find a better polymer monomer concentration, so that the prepared coating has both Good transparency, but also has good anti-aging performance and hardness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com