Method for preparing protective material for rubber by recycling textile white mud

A protective material and resource-based technology, applied in the field of rubber formulations, can solve problems such as insufficient long-term protective effect, influence on mixing effect, redness of products, etc., achieve excellent short-term protective performance, good long-term protective performance, and solve easy caking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

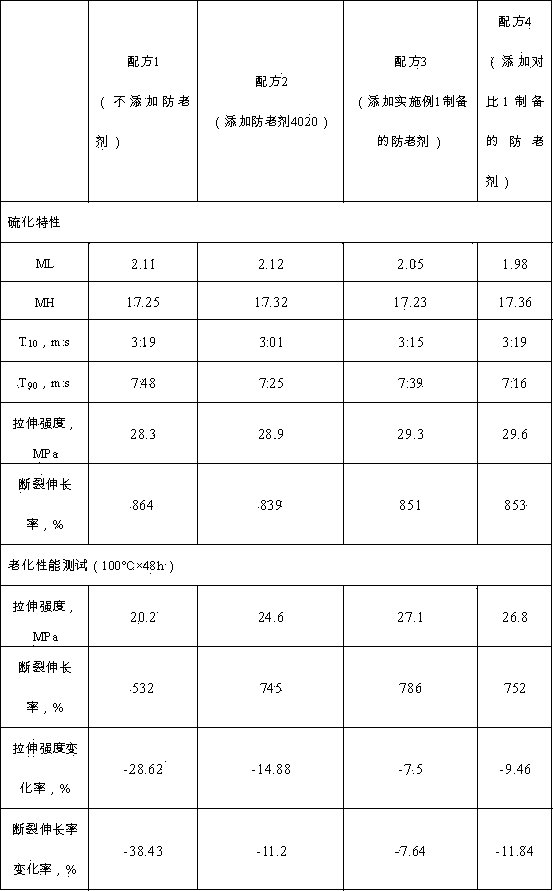

Examples

Embodiment 1

[0026] A kind of textile white clay resources of the present invention prepares the method for protective material for rubber, comprises the following steps:

[0027] (1) Preparation of metal-organic framework material precursor: under constant stirring, add textile clay into 1% sodium hydroxide solution according to the stoichiometric relationship, and after it is completely dissolved, add 0.5% activated carbon in the mass percentage of the solution , stirred for 10 min to make it evenly dispersed in the solution, and then filtered to obtain the decolorized sodium terephthalate clarified solution 1;

[0028] (2) Under continuous stirring, add the pre-configured calcium chloride solution with a mass percentage of 25% to the clarified liquid 1 obtained in step (1), continue to stir and react at a speed of 50r / min for 20min, then filter and wash 1. Obtain calcium terephthalate organic framework material after drying;

[0029] (3) Under continuous stirring, add the calcium terep...

Embodiment 2

[0038] The difference between embodiment 2 and embodiment 1 is:

[0039] A kind of textile white clay resources of the present invention prepares the method for protective material for rubber, comprises the following steps:

[0040] In step (1), the metal-organic framework material precursor is prepared: under constant stirring, add textile white mud to 35% sodium hydroxide solution according to the stoichiometric relationship, and after it is completely dissolved, add 0.5% activated carbon, stirred for 20min to make it evenly dispersed in the solution, and then filtered to obtain the decolorized sodium terephthalate clarified solution 1;

[0041] In step (2), under continuous stirring, add the pre-configured saturated calcium chloride solution into the clarified liquid 1 obtained in step (1), continue to stir and react at a speed of 700r / min for 150min, then filter, wash, Obtain calcium terephthalate organic framework material after drying;

[0042] In step (5), after mixin...

Embodiment 3

[0046] The difference between embodiment 3 and embodiment 1 is:

[0047] A kind of textile white clay resources of the present invention prepares the method for protective material for rubber, comprises the following steps:

[0048] In step (1), the metal-organic framework material precursor is prepared: under constant stirring, add textile white mud to 20% sodium hydroxide solution according to the stoichiometric relationship, and after it is completely dissolved, add 0.5% activated carbon, stirred for 15 minutes to make it uniformly dispersed in the solution, and then filtered to obtain the decolorized sodium terephthalate clarified solution 1;

[0049] In step (2), under continuous stirring, the pre-configured calcium chloride solution with a mass percentage of 32% is added to the clarified liquid 1 obtained in step (1), and the stirring reaction is continued at a speed of 500r / min for 60min. Then filter, wash and dry to obtain calcium terephthalate organic framework mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com