Refractory material used for ladle and preparation method of refractory material

A technology of refractory materials and ladles, applied in the field of refractory materials, can solve problems such as aggravating safety hazards, reducing service life, and difficult handling, and achieves the effects of ensuring service life and effect, improving thermal stability, and good volume stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

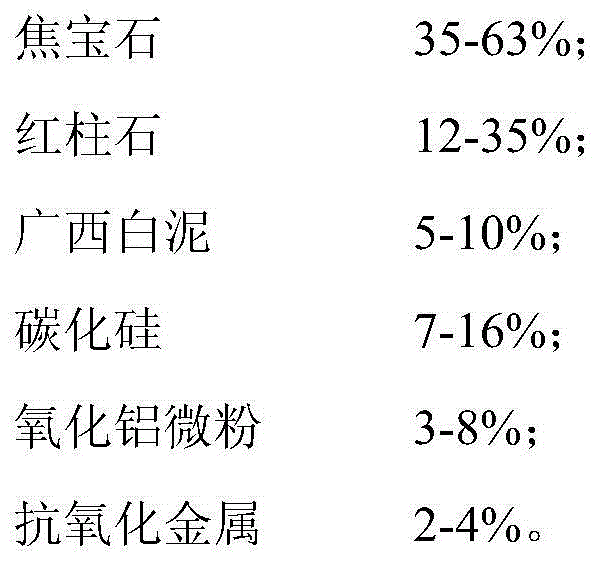

[0030] A refractory material for ladle, made of the following raw materials,

[0031]

[0032] Preparation:

[0033] (1) Mix silicon carbide, alumina micropowder, metal silicon, Guangxi white mud and andalusite fine powder with a particle size of -200 mesh evenly.

[0034] (2) Mix the burnt gem particles with a particle size of 1.0-3.0mm, the burnt gem particles with a particle size of 0.1-1mm, and the andalusite particles with a particle size of 0.1-1mm, add a binder and water, stir evenly, and then Add the compound that step (1) obtains, continue to stir 5min; Wherein, binding agent is sulfurous acid paper pulp waste liquid, and add-on accounts for coke gemstone, andalusite, Guangxi white mud, silicon carbide, aluminum oxide micropowder and metal silicon total mass 2%; water accounts for 3% of the total mass of coke gemstone, andalusite, Guangxi white mud, silicon carbide, alumina micropowder and metal silicon.

[0035] (3) The agitated mixture obtained in step (2) is p...

Embodiment 2

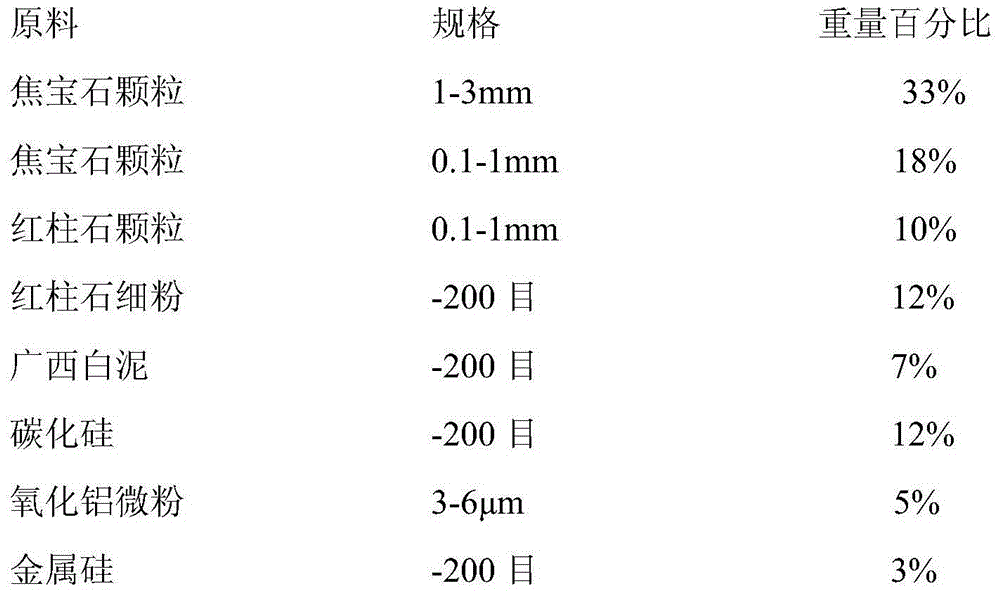

[0037] A refractory material for ladle, made of the following raw materials,

[0038]

[0039] Preparation:

[0040] (1) Mix silicon carbide, alumina micropowder, metal silicon, Guangxi white mud and andalusite fine powder with a particle size of -200 mesh evenly.

[0041] (2) Mix the burnt gem particles with a particle size of 1.0-3.0mm, the burnt gem particles with a particle size of 0.1-1mm, and the andalusite particles with a particle size of 0.1-1mm, add a binder and water, stir evenly, and then Add the compound that step (1) obtains, continue to stir 3min; Wherein, binding agent is sulfurous acid paper pulp waste liquid, and the addition accounts for coke gemstone, andalusite, Guangxi white mud, silicon carbide, aluminum oxide micropowder and metal silicon total mass 2%; water accounts for 3% of the total mass of coke gemstone, andalusite, Guangxi white mud, silicon carbide, alumina micropowder and metal silicon.

[0042] (3) The agitated mixture obtained in step (2...

Embodiment 3

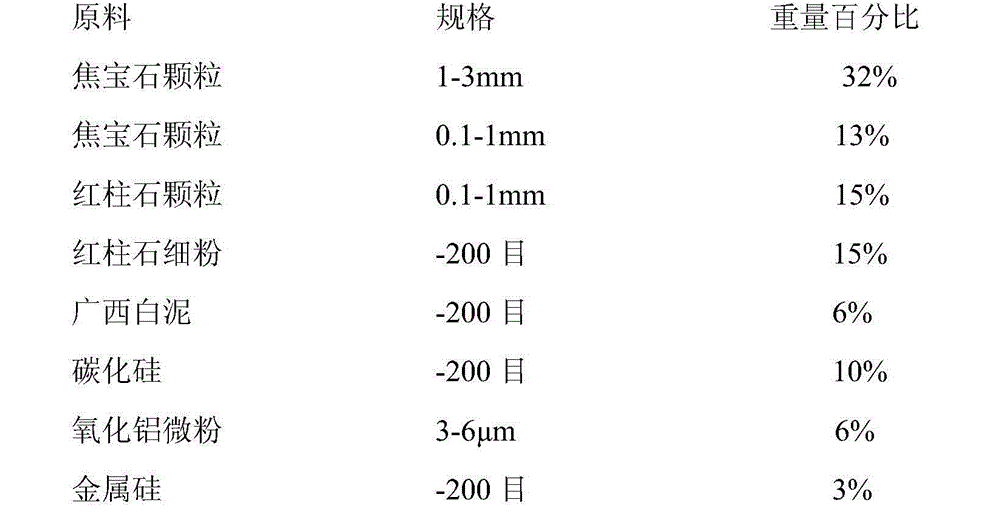

[0044] A refractory material for ladle, made of the following raw materials,

[0045]

[0046] Preparation:

[0047] (1) Mix silicon carbide, alumina micropowder, metal silicon, Guangxi white mud and andalusite fine powder with a particle size of -200 mesh evenly.

[0048] (2) Mix the burnt gem particles with a particle size of 1.0-3.0mm, the burnt gem particles with a particle size of 0.1-1mm, and the andalusite particles with a particle size of 0.1-1mm, add a binder and water, stir evenly, and then Add the compound that step (1) obtains, continue to stir 3min; Wherein, binding agent is sulfurous acid paper pulp waste liquid, and the addition accounts for coke gemstone, andalusite, Guangxi white mud, silicon carbide, aluminum oxide micropowder and metal silicon total mass 2%; water accounts for 3% of the total mass of coke gemstone, andalusite, Guangxi white mud, silicon carbide, alumina micropowder and metal silicon.

[0049] (3) The agitated mixture obtained in step (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com