Interlayer type composite material wallboard

A composite material and interlayer technology, applied in the direction of building materials, layered products, synthetic resin layered products, etc., to achieve enhanced seismic performance, light weight, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

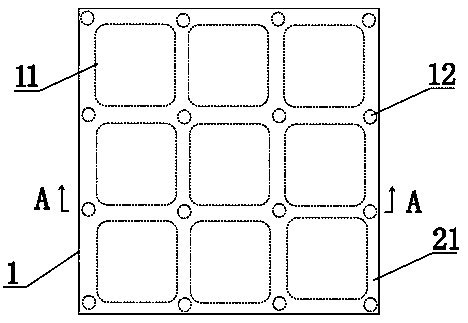

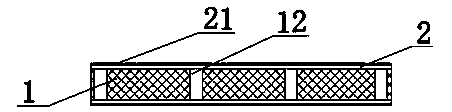

[0012] The present invention will be further described below in conjunction with the drawings.

[0013] See figure 1 with figure 2 , The sandwich composite wallboard of the present invention includes a sandwich layer 1 and a panel 2. The upper and lower surfaces of the sandwich layer 1 are provided with grid-shaped grooves 11, and the sandwich layer is along the intersection of the grooves 11 1 is provided with perforations 12 in the thickness direction, the perforations 12 are filled with resin and form resin columns. On the upper and lower surfaces of the sandwich layer 1, a panel 2 formed by curing fiber cloth layers and resin is provided, and the outer surface of the panel 2 is provided There is a functional coating 21. The sandwich layer 1 is polyurethane foam. The perforation 12 is circular. The functional coating 21 is a gypsum coating.

[0014] In use, the type and thickness of the sandwich layer 1, the type and number of layers of the panel 2, the type of resin, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com