Rare-earth modified asphalt and preparation method thereof

A technology of modified asphalt and asphalt, which is applied to building components, building insulation materials, buildings, etc. It can solve the problems of complex production process, high temperature resistance to rutting, poor durability road surface, etc., and achieve simple production process, low cost and long service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

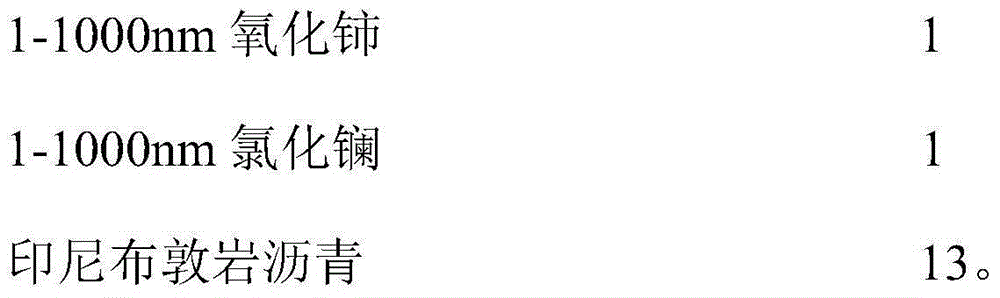

[0037] A kind of rare earth compound modified pitch is composed as follows in parts by weight:

[0038]

[0039]

[0040] The preparation method of the modified asphalt is as follows: first, the base asphalt is metered into the asphalt tank with a stirring device through a flow meter and heated to 120-140 ° C, and the rare earth compound is added into the tank according to the specified ratio and stirred for 30 minutes, and then the temperature is raised To 185-190 ℃, add rock asphalt into the tank according to the specified proportion, and stir and mix thoroughly for 20-30 minutes. After processing, pump it into a storage tank and incubate for 1-2 hours before use.

Embodiment 2

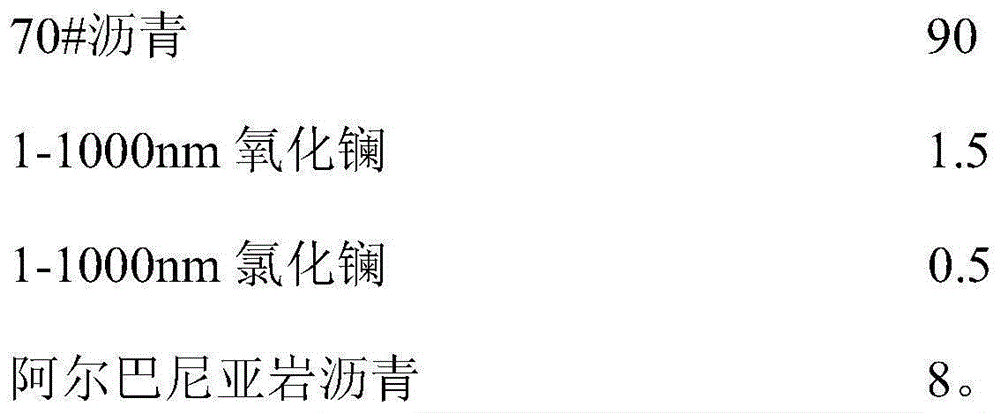

[0042] A kind of rare earth compound modified pitch is composed as follows in parts by weight:

[0043]

[0044] The preparation method of this modified pitch is the same as in Example 1.

Embodiment 3

[0046] A kind of rare earth compound modified pitch is composed as follows in parts by weight:

[0047] Binhua 90# asphalt 85

[0048] 1-1000nm cerium oxide 0.5

[0049] Qingchuan rock asphalt 12.

[0050] The preparation method of this modified pitch is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com