Waterproofing construction method for basement of building engineering

A construction method and technology of construction engineering, applied in the direction of construction, infrastructure engineering, protection devices, etc., can solve problems such as viscosity drop, basement water leakage, and poor waterproof performance, so as to prevent water channeling, excellent tensile strength, vertical and horizontal The effect of large pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

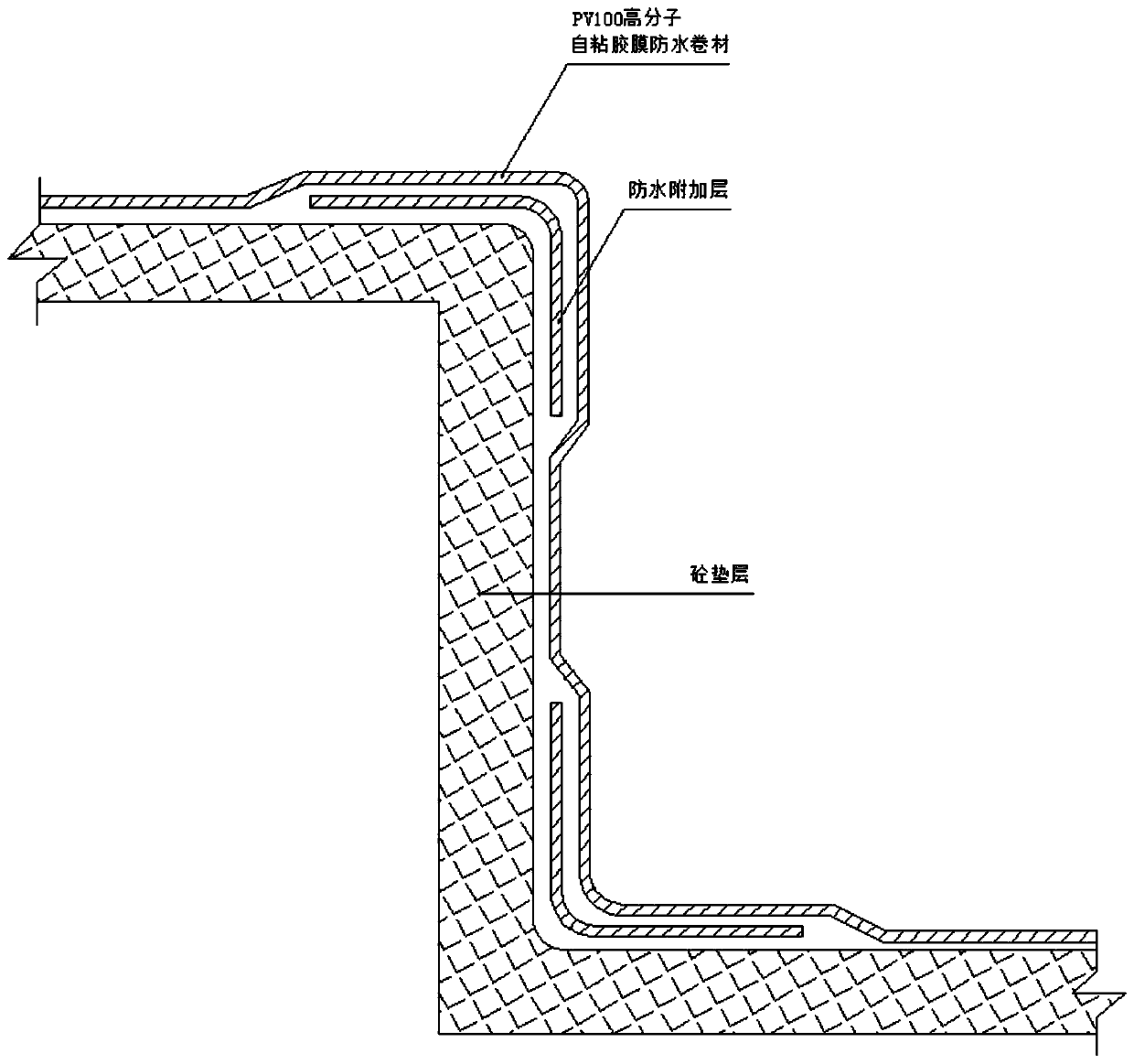

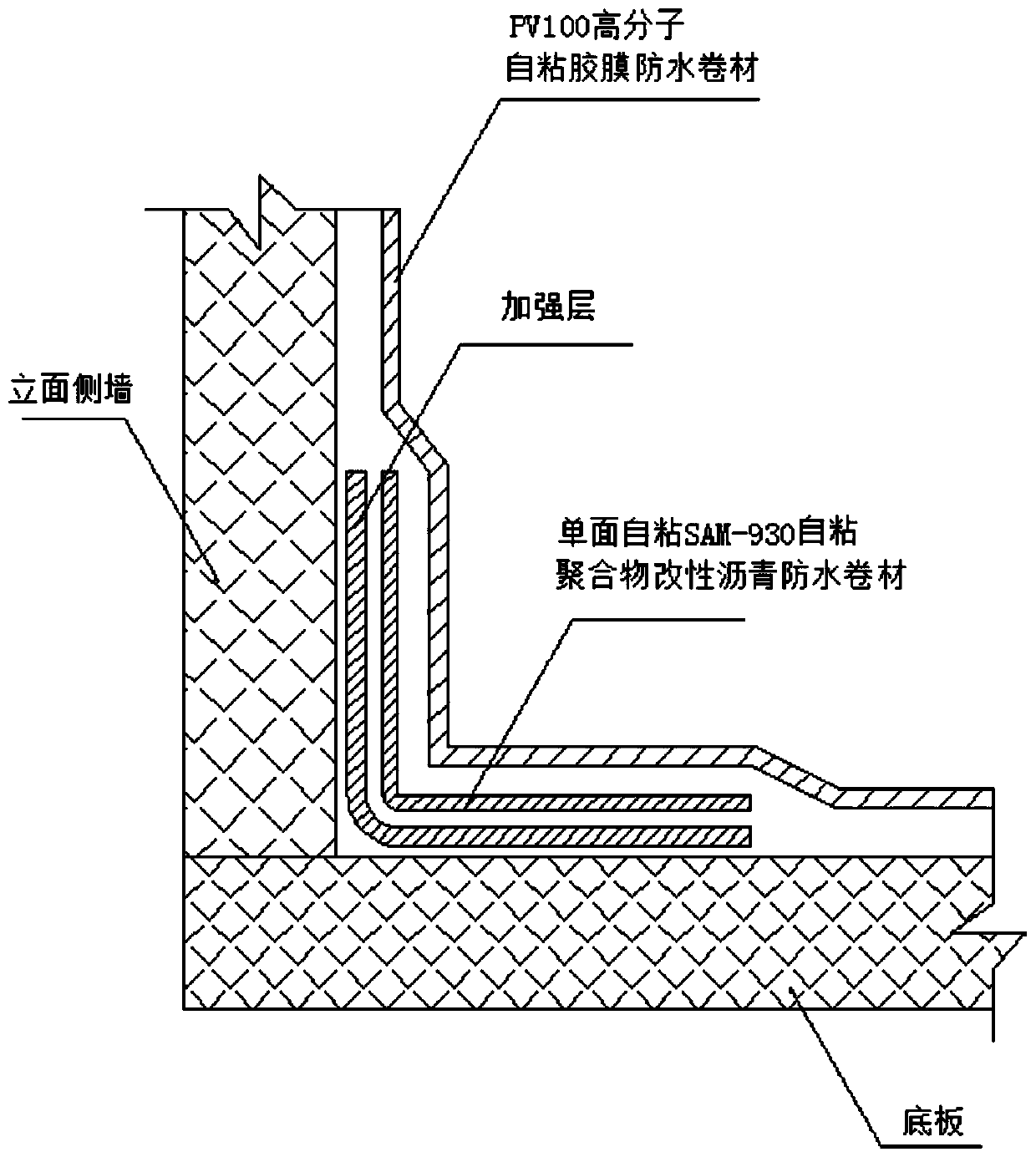

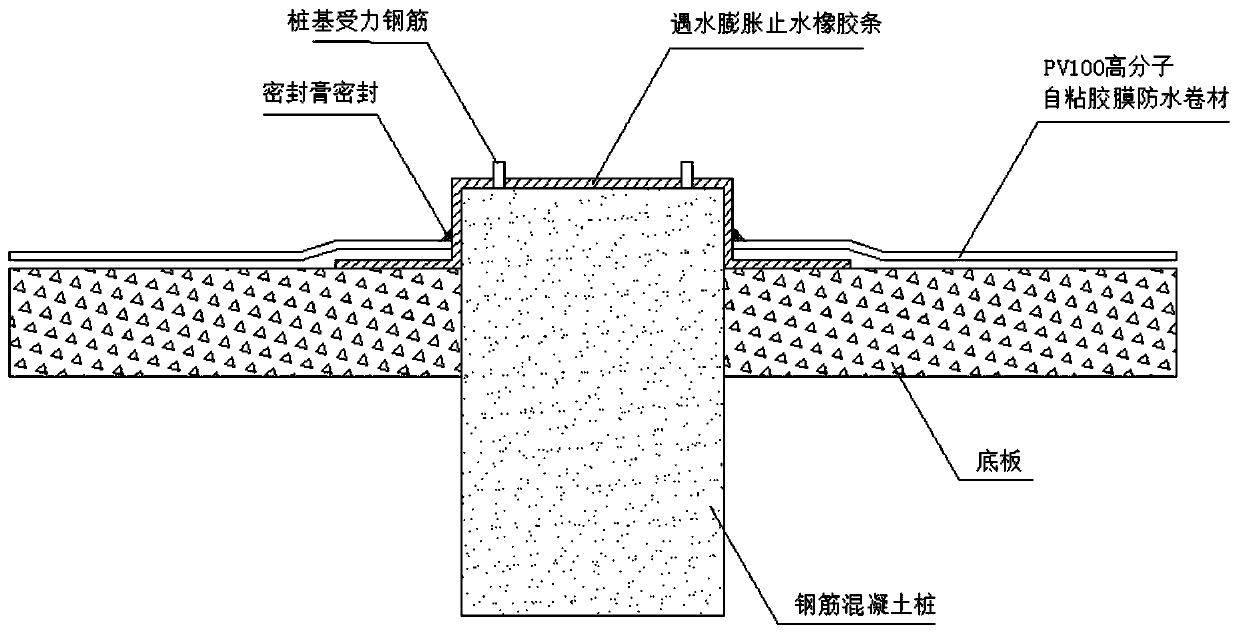

[0035] The present invention provides the following technical solutions: a waterproof construction method for a construction project basement, comprising the following steps:

[0036] S1: Clean up dust, sundries, oil stains and open water on the surface of the base to make the surface smooth and clean. If there is leakage in the base, it should be plugged and drained in advance to avoid affecting the construction of the waterproof layer. If the base is flat If it does not meet the requirements, use 1:2.5 cement mortar to fill and level it. If there are steel heads protruding from the surface of the base layer and sharp objects such as bolt lights, they should be cut off and leveled;

[0037]S2: Release the control line for coil laying on the base layer to accurately control the coil laying position and lap width, and avoid misalignment and skewing during the coil laying process;

[0038] S3: On the basis of the foundation treatment and elastic line positioning, the constructio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com