Baseless double-sided adhesive sheet or tape, and method for manufacturing the same

A double-sided adhesive, no substrate technology, applied in the field of double-sided adhesive sheets, double-sided adhesive sheets or tapes, can solve the problems of reducing initial adhesion, reducing adhesive strength, low viscosity, etc. The effect of reducing burden on raw materials, reducing stress, and relieving stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

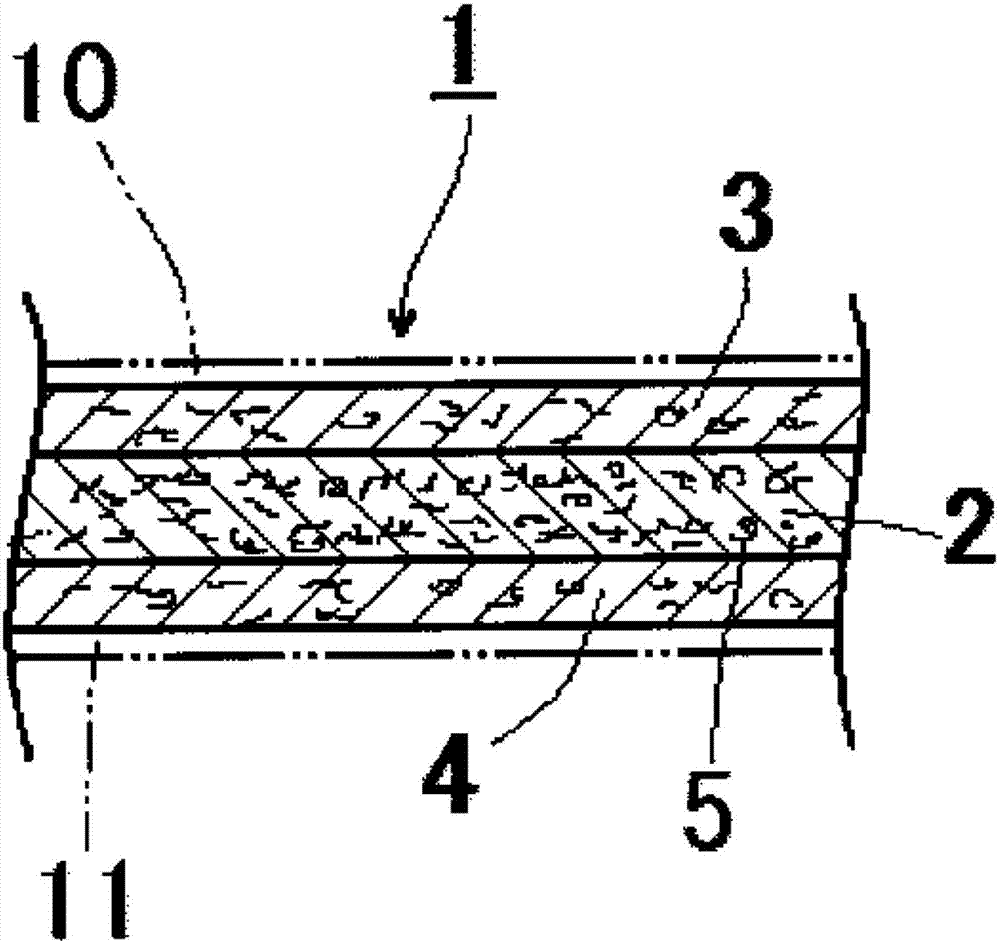

[0118]Example 1: Formation of a three-layer film by UV curing reaction

[0119] By dissolving 10 wt % of added hydrogenated terpene phenol (manufactured by Yasuhara Chemical Co., Ltd., YS Polyster UH) as a tackifier in a polymer such as 2-ethylhexyl acrylate, butyl acrylate, etc. The acrylic syrup composition was prepared in 100% by weight of acrylic syrup (slurry manufactured by Soken Chemical & Engineering Co., Ltd.; trade name WS) as a primary polymerized prepolymer obtained in a monomer such as base or acrylic acid, thereby Adhesive layers 3 and 4 were prepared for use as front and back layers.

[0120] 0.7 wt % of PET short fibers having a fiber diameter of 5 denier and a fiber length of 5 mm were added to 100 wt % of the acrylic size composition and dispersed using a stirrer.

[0121] In addition, 0.5wt% of an acetophenone-based photopolymerization initiator (manufactured by Ciba Specialty Chemicals; trade name IRGACURE 184) was added to 100wt% of the acrylic paste comp...

Embodiment 2

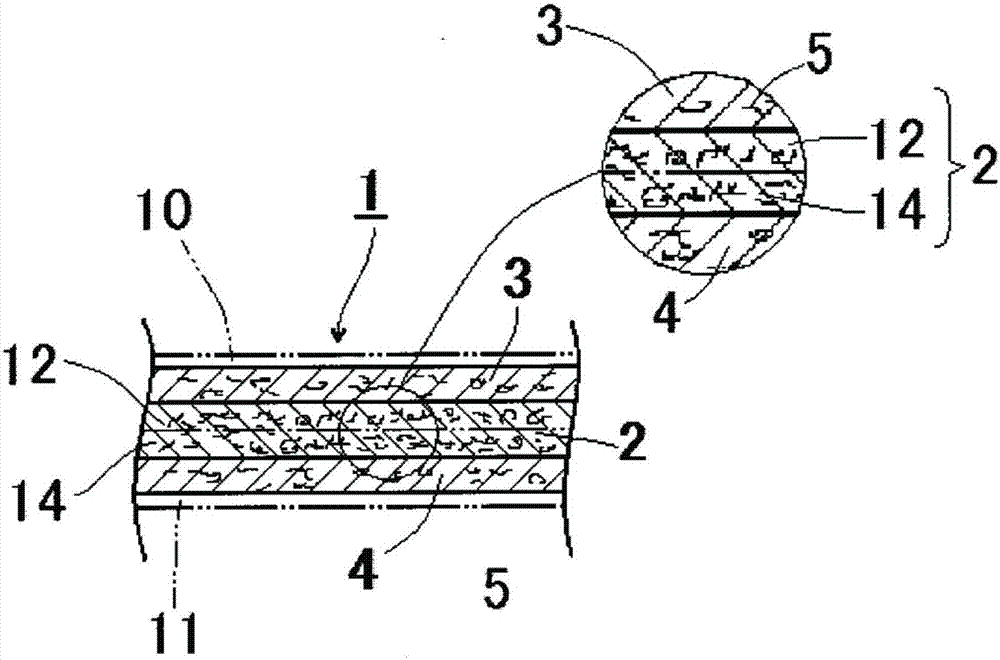

[0130] Example 2: Solvated Layer 2 Formation, Fiber Insertion in Layer 2

[0131] like figure 2 As shown, Example 2 is a manufacturing method in which a structure is provided by preparing an adhesive layer 3 provided on a release paper 10 in which fibers 5 are dispersed and an adhesive layer 3 provided on a release paper 10 in which fibers 5 are dispersed. Structure of adhesive layer 12 of fiber 5; preparation having adhesive layer 4 with fiber 5 dispersed therein provided on release paper 11 and adhesive with fiber 5 dispersed therein provided on adhesive layer 4 The structure of the layer 14; and the compatibility layer (adhesive layer) 2 is provided by polymerizing the adhesive layer 14 with the adhesive layer 12.

[0132] Adhesive layers 3, 4, 12, and 14 used a solvated acrylic composition (manufactured by Ipposha Oil Industries Co., Ltd., trade name 520) as an adhesive by applying a solution polymerization method such as 2-ethylhexyl acrylate. , butyl acrylate or acryl...

Embodiment 3

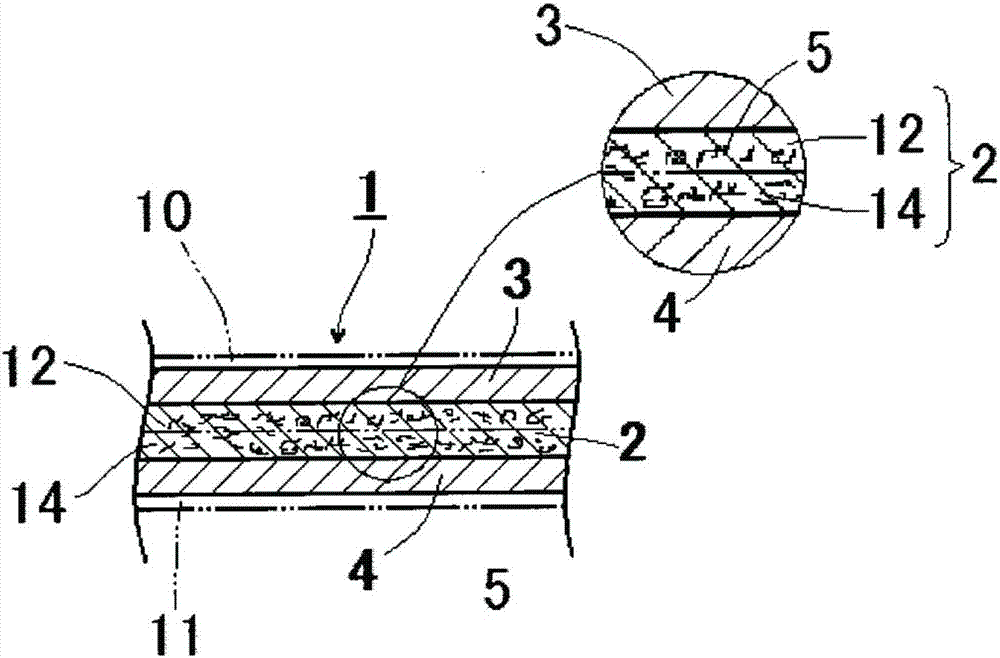

[0137] Example 3: Solvated layer 2 formation with fibers inserted into layer 1

[0138] like image 3 As shown, Example 3 is a manufacturing method in which a structure is provided by preparing an adhesive having an adhesive layer 3 disposed on a release paper 10 and an adhesive having fibers 5 dispersed therein disposed on the adhesive layer 3 The structure of the layer 12; prepare the structure with the adhesive layer 4 disposed on the release paper 11 and the adhesive layer 14 disposed on the adhesive layer 4 in which the fibers 5 are dispersed; and by making the adhesive layer 14 is polymerized with adhesive layer 12 to provide a compatible layer (adhesive layer) 2 .

[0139] Adhesive layers 3, 4, 12, and 14 used a solvated acrylic composition (manufactured by Ipposha Oil Industries Co., Ltd., trade name 520) as an adhesive by applying a solution polymerization method such as 2-ethylhexyl acrylate. , butyl acrylate or acrylic acid and other monomers obtained from the pri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com