Preparation method of lateral insulating layer of high-gradient zinc oxide voltage-sensitive valve plate

A pressure-sensitive valve, zinc oxide technology, applied in resistance manufacturing, electrical components, resistors and other directions, can solve the problem of inability to meet the requirements of large inrush current, to ensure work controllability, reduce edge current density, avoid The effect of perforation breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

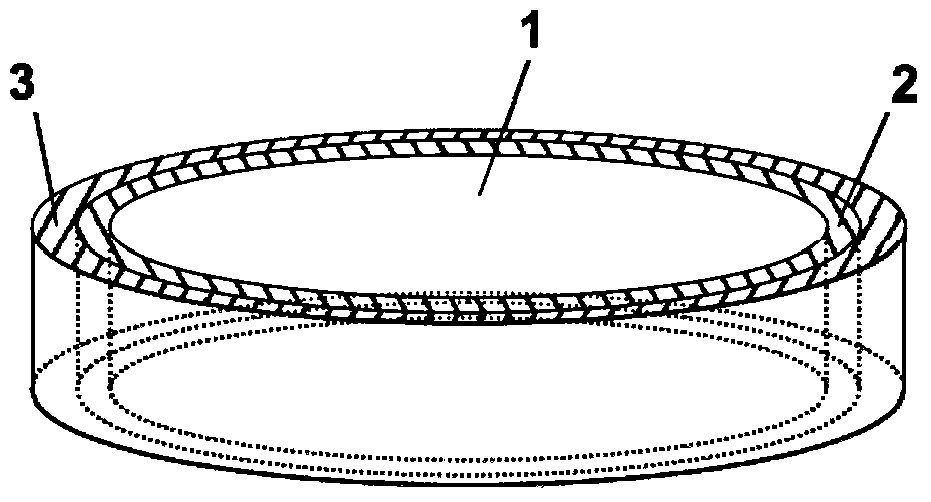

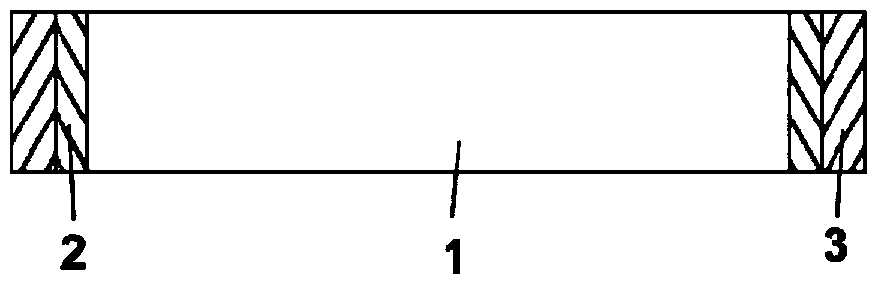

[0026] The preparation method of the side insulating layer of the high-gradient zinc oxide varistor disc proposed by the present invention comprises the following steps:

[0027] (1) Prepare a polyvinyl alcohol aqueous solution with a mass percentage concentration of 15-25%, and uniformly mix the polyvinyl alcohol aqueous solution and pure ethanol at a volume ratio of 3:1 to obtain a mixed solution; 2 o 3 , Sb with a mass percentage of 10-30% 2 o 3 , SiO with a mass percentage of 30-50% 2 and Fe with a mass percentage of 10-30% 2 o 3 Mix evenly to obtain a mixed powder, mix the above mixed powder with the mixed solution and ball mill for 12-24 hours to obtain a high-resistance layer slurry with a solid content of 10-60%;

[0028] (2) Evenly coat the above-mentioned high-resistance layer slurry on the side of the molded zinc oxide varistor valve blank that has not been degummed, with an average thickness of less than 3 mm. After the ethanol in the high-resistance layer slu...

Embodiment 1

[0038] According to the preparation method of the side insulation layer introduced in the patent specification of the present invention, the side insulation of a high voltage gradient varistor valve plate of a certain type D35 is carried out.

[0039] (1) Prepare a polyvinyl alcohol aqueous solution with a mass percentage concentration of 18%, and uniformly mix the polyvinyl alcohol aqueous solution and pure ethanol at a volume ratio of 3:1 to obtain a mixed solution; 2 o 3 , Sb with a mass percentage of 25% 2 o 3 , SiO with a mass percentage of 35% 2 and 25% Fe by mass 2 o 3 Mix evenly to obtain a mixed powder, mix the above mixed powder with the mixed solution and ball mill for 15 hours to obtain a high-resistance layer slurry with a solid content of 25%;

[0040] (2) Evenly coat the above-mentioned high-resistance layer slurry on the side of the molded zinc oxide varistor valve blank that has not been degummed, with an average thickness of less than 3 mm. After the eth...

Embodiment 2

[0050] According to the preparation method described in Example 1, a side insulating layer was prepared for a high-voltage gradient varistor valve plate of a certain type D70.

[0051] (1) Prepare a polyvinyl alcohol aqueous solution with a mass percentage concentration of 23%, and uniformly mix the polyvinyl alcohol aqueous solution and pure ethanol at a volume ratio of 3:1 to obtain a mixed solution; 2 o 3 , Sb with a mass percentage of 15% 2 o 3 , SiO with a mass percentage of 45% 2 and 15% by mass of Fe 2 o 3 Mix evenly to obtain a mixed powder, mix the above mixed powder with the mixed solution and ball mill for 22 hours to obtain a high-resistance layer slurry with a solid content of 50%;

[0052] (2) Evenly coat the above-mentioned high-resistance layer slurry on the side of the molded zinc oxide varistor valve blank without debinding, with an average thickness of less than 3 mm. After the ethanol in the high-resistance layer slurry volatilizes, After the layer sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com