Green and environment-friendly permeable asphalt mixture for cold regions and method for preparing green and environment-friendly permeable asphalt mixture

A green, environmentally friendly, permeable asphalt technology, applied in the direction of climate change adaptation, can solve the problems of permeable asphalt pavement not suitable for use in cold areas, poor water permeability, unsatisfactory asphalt pavement strength, etc., to achieve major engineering application value, increase viscosity, The effect of improving high temperature stability and low temperature crack resistance and frost resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A green environment-friendly permeable asphalt mixture in cold regions, the preparation raw materials are composed of the following components in parts by weight: 220 parts of steel slag, 9.00 parts of SBS modified asphalt, 6.26 parts of limestone mineral powder, 1.27 parts of diatomite, and a particle size of 0.82 parts of 40-60 mesh rubber powder, 0.64 parts of TPS asphalt high viscosity agent, 0.27 parts of ethylene bis stearic acid amide, 0.71 parts of basalt fiber;

[0027] The specific preparation method is as follows:

[0028] Step 1, weigh 220 parts of steel slag, 9 parts of SBS modified asphalt, 6.26 parts of limestone mineral powder, 1.27 parts of diatomaceous earth, 0.82 part of rubber powder, 0.64 part of TPS asphalt high-viscosity agent, ethylene bis-stearin 0.27 part of acid amide, 0.71 part of basalt fiber, set aside;

[0029] Step 2, heating SBS modified asphalt to 165-170°C, then adding rubber powder, TPS asphalt high viscosity agent and ethylene bis s...

Embodiment 2

[0034] A green environment-friendly permeable asphalt mixture in cold regions, the preparation raw materials are composed of the following components in parts by weight: 210 parts of steel slag, 8.80 parts of SBS modified asphalt, 6.36 parts of limestone mineral powder, 1.14 parts of diatomite, and a particle size of 0.70 parts of 40-60 mesh rubber powder, 0.53 parts of TPS asphalt high viscosity agent, 0.25 parts of stearic acid amide, 0.47 parts of basalt fiber;

[0035] The preparation method is the same as that of Example 1, except that the formula of Example 1 is changed into that of Example 2.

Embodiment 3

[0037] A green environment-friendly permeable asphalt mixture in cold regions, the preparation raw materials are composed of the following components in parts by weight: 230 parts of steel slag, 9.53 parts of SBS modified asphalt, 6.14 parts of limestone mineral powder, 1.23 parts of diatomite, and a particle size of 0.95 parts of 40-60 mesh rubber powder, 0.76 parts of TPS asphalt high viscosity agent, 0.30 parts of stearic acid amide, 0.94 parts of basalt fiber;

[0038] The preparation method is the same as that of Example 1, except that the formula of Example 1 is changed into that of Example 3.

[0039] It should be noted that the steel slag in Examples 1-3 comprises the following components in weight percent: Fe 2 o 3 : 6%, FeO: 25%, SiO 2 : 15%, CaO: 35%, MgO: 15%, Al 2 o 3 : 3.9%, P: 0.1%;

[0040] The basalt fiber has a length of 6.0 mm and a diameter of 10-13 μm.

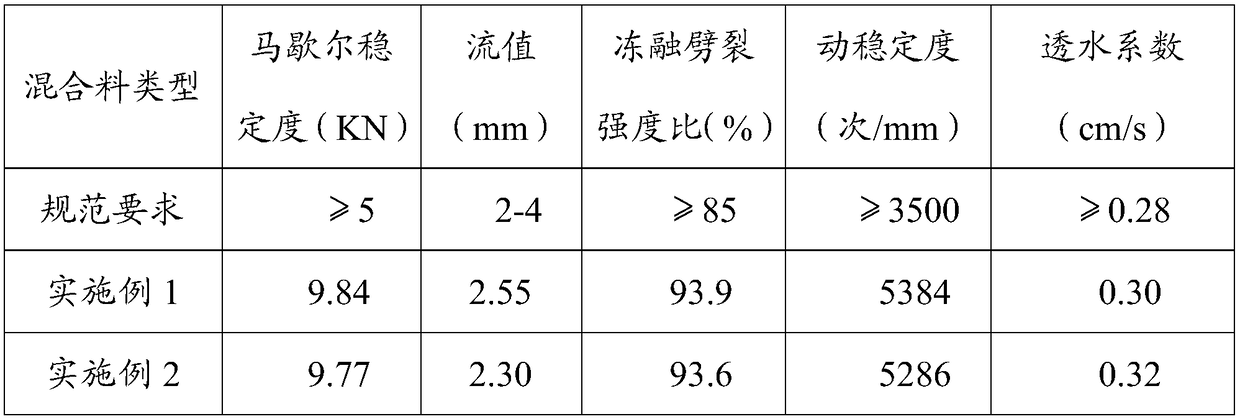

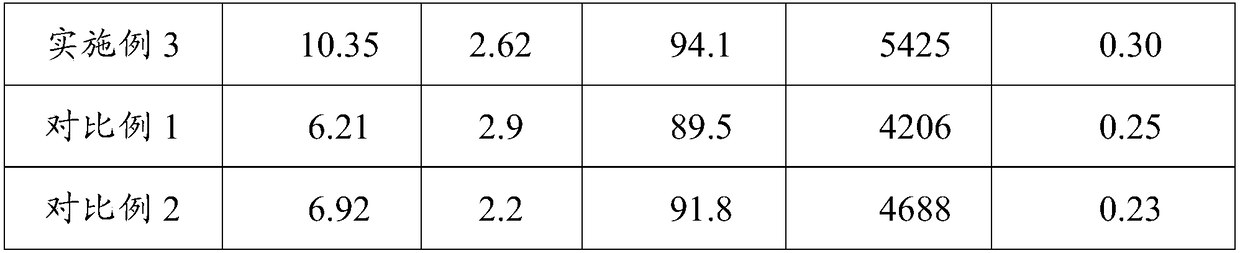

[0041]In order to further illustrate the effect of the present invention, the present invention a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com