Environment-friendly oil-resistant asphalt pavement material and preparation method thereof

A kind of asphalt pavement, environment-friendly technology, applied in the direction of on-site coagulation pavement, building insulation materials, roads, etc. Stone adhesion and other problems, to achieve the effect of unaffected low temperature performance, improved oil resistance, and reduced hot mixing and construction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

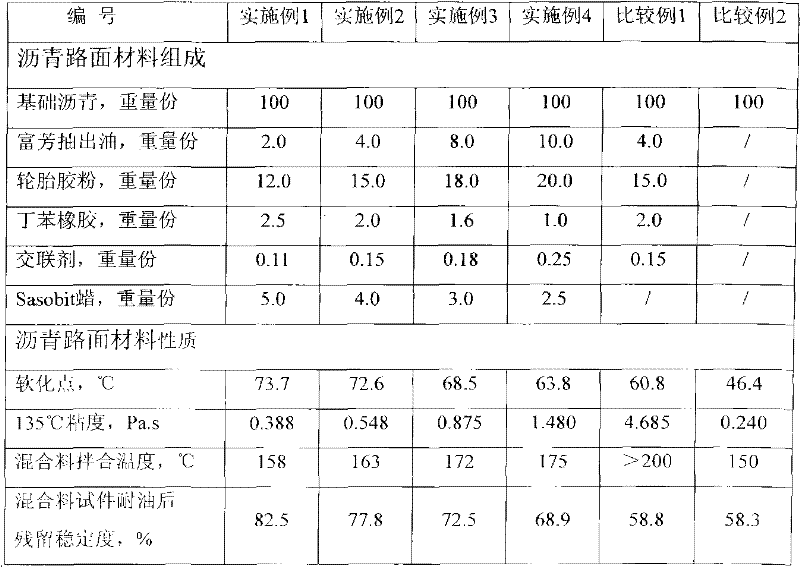

Embodiment 1

[0023] Select asphalt with a needle penetration of 92 1 / 10mm and a softening point of 46.4°C as the base asphalt. Take 100 parts of the base asphalt in a molten state, add 2 parts of aromatic-rich extract oil and 5 parts of Sasobit wax, and heat the mixture at a temperature of 145°C and Under the condition of stirring speed of 350rpm / min, stir and react for 45 minutes, continue to heat up to 165°C, add 12 parts of waste tire rubber powder and 2.5 parts of styrene-butadiene rubber (SBR) to heat-swell for 60 minutes, and then add 0.11 parts of cross-linking agent sulfur, Grind for 45 minutes at 170° C. in a high shear machine or a colloid mill to prepare the environmentally friendly oil-resistant asphalt pavement material of the present invention. The properties are shown in Table 2. According to the standard of the Ministry of Communications "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" JTJ052-2000, the asphalt pavement material is used as a binder, ...

Embodiment 2

[0025] Prepare asphalt pavement material according to the method of Example 1, the difference is that the addition of Sasobit wax is 4 parts, the addition of extracted oil is 4.0 parts, the addition of tire rubber powder and SBR is 15 parts and 2.0 parts respectively, and the addition of crosslinking agent sulfur for 015 copies. Its properties are shown in Table 2, and the mixture specimen is 3 # After soaking in aviation kerosene for 24 hours, the oil resistance results are shown in Table 2.

Embodiment 3

[0027] Prepare asphalt pavement material according to the method of Example 1, the difference is that the addition of Sasobit wax is 3 parts, the addition of extracted oil is 8.0 parts, the addition of tire rubber powder and SBR is 18 parts and 1.5 parts respectively, and the addition of crosslinking agent sulfur is 0.18 parts. Its properties are shown in Table 2. The mixture specimen was heated at 30°C for 3 # After soaking in aviation kerosene for 24 hours, the oil resistance results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com