Safe and environment-friendly asphalt for road and preparation method thereof

A safe and environmentally friendly, road petroleum asphalt technology, applied in building insulation materials, building components, climate change adaptation, etc., can solve problems such as poor flame retardancy, reduce secondary pollution, less black smoke, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

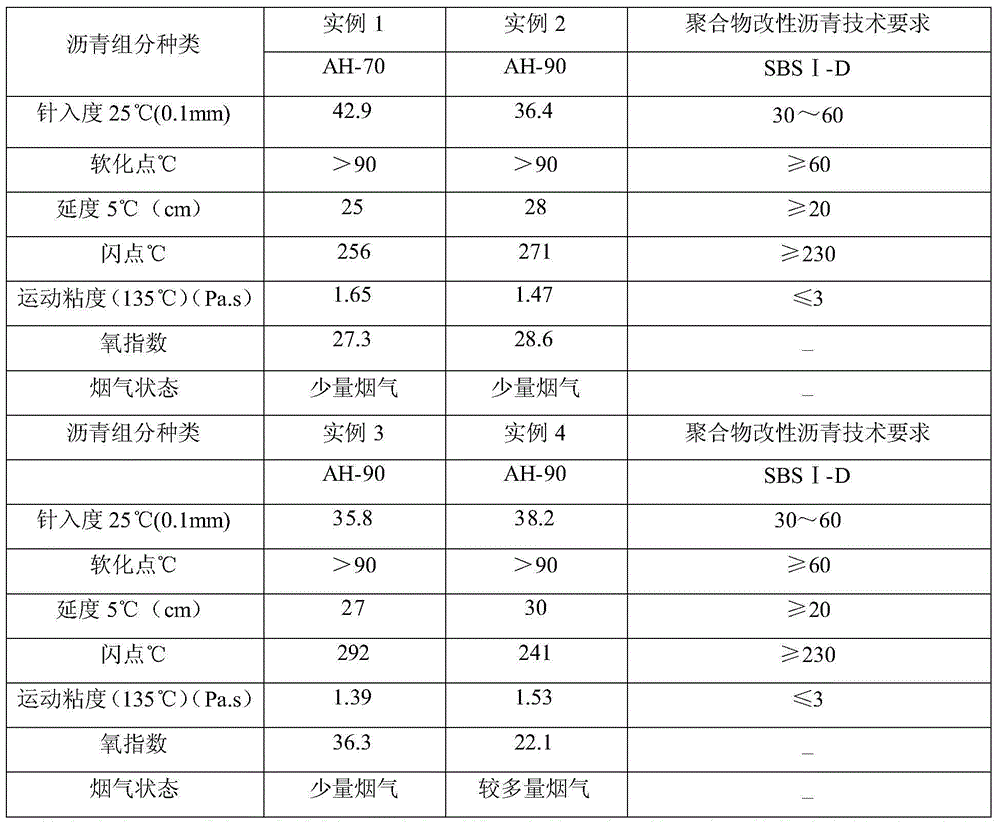

Examples

example 1

[0014] Composition: 80 parts of heavy traffic road petroleum asphalt AH-70, 9 parts of high viscosity modifier TPS, 3 parts of Sasobit warm mix asphalt modifier, 4 parts of polyphosphate amine with a polymerization degree of 1200, and 1 part of pentaerythritol.

[0015] Preparation: 1) Molten heavy-traffic road petroleum asphalt: keep the heavy-traffic road petroleum asphalt at 130°C to reach a molten state; 2) Add high-viscosity modifier: add high-viscosity modifier to the molten heavy-traffic road petroleum asphalt, Stir while adding until all the additives are immersed in the asphalt, then put the asphalt in an oven at 105°C for about two hours, then use a high-speed shearer to cut at 4000r / min for 30min, and finally the high-viscosity modifier is The tiny particles are evenly distributed in the asphalt; 3) Add warm-mix asphalt modifier and flame retardant: Then add warm-mix modifier to the asphalt, stir while adding, and continue to shear at 4000r / min for 30min at high spee...

example 2

[0017] Composition: 80 parts of heavy traffic road petroleum asphalt AH-90, 10 parts of high viscosity modifier TPS, 2 parts of Sasobit warm mix asphalt modifier, 4 parts of polyphosphate amine with a polymerization degree of 5000, and 1 part of pentaerythritol.

[0018] Preparation: 1) Molten heavy-traffic road petroleum asphalt: keep the heavy-traffic road petroleum asphalt at 140°C to reach a molten state; 2) Add high-viscosity modifier: add high-viscosity modifier to the molten heavy-traffic road petroleum asphalt, Stir while adding until all the additives are immersed in the asphalt, then put the asphalt in an oven at 105°C for about two hours, and then cut it with a high-speed shearer at 5000r / min for 30min, and finally the high-viscosity modifier will be in the form of tiny particles Evenly distributed in the asphalt; 3) Add warm mix asphalt modifier and flame retardant: Then add warm mix modifier to the asphalt, stir while adding, and continue to shear at 5000r / min for ...

example 3

[0020] Composition: heavy traffic road petroleum asphalt AH-9080 parts, high viscosity modifier TPS10 parts, Sasobit warm mix asphalt modifier 2 parts, methylcyclopentadiene manganese tricarbonyl 2 parts, polyphosphate amine with a polymerization degree of 3000 2 parts, 0.5 parts of pentaerythritol.

[0021] Preparation: 1) Molten heavy-traffic road petroleum asphalt: keep the heavy-traffic road petroleum asphalt at 150°C to reach a molten state; 2) Add high-viscosity modifier: add high-viscosity modifier to the molten heavy-traffic road petroleum asphalt, Stir while adding until all the additives are immersed in the asphalt, then put the asphalt in an oven at 105°C for about two hours, then cut it with a high-speed shear for 30 minutes, and finally the high-viscosity modifier is uniformly distributed in the form of tiny particles 3) Add warm-mix asphalt modifier and flame retardant: then add warm-mix modifier to asphalt, stir while adding, and continue to shear at 4000-5000r / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com