Warm mixing shape memory alloy (SMA) asphalt mixture and preparation method thereof

A technology of asphalt mixture and mixture, which is applied in the direction of climate change adaptation, etc., can solve the problem that SMA asphalt mixture is not easy to be compacted, and achieve the effects of easy storage production, extended transportation distance, and convenient addition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

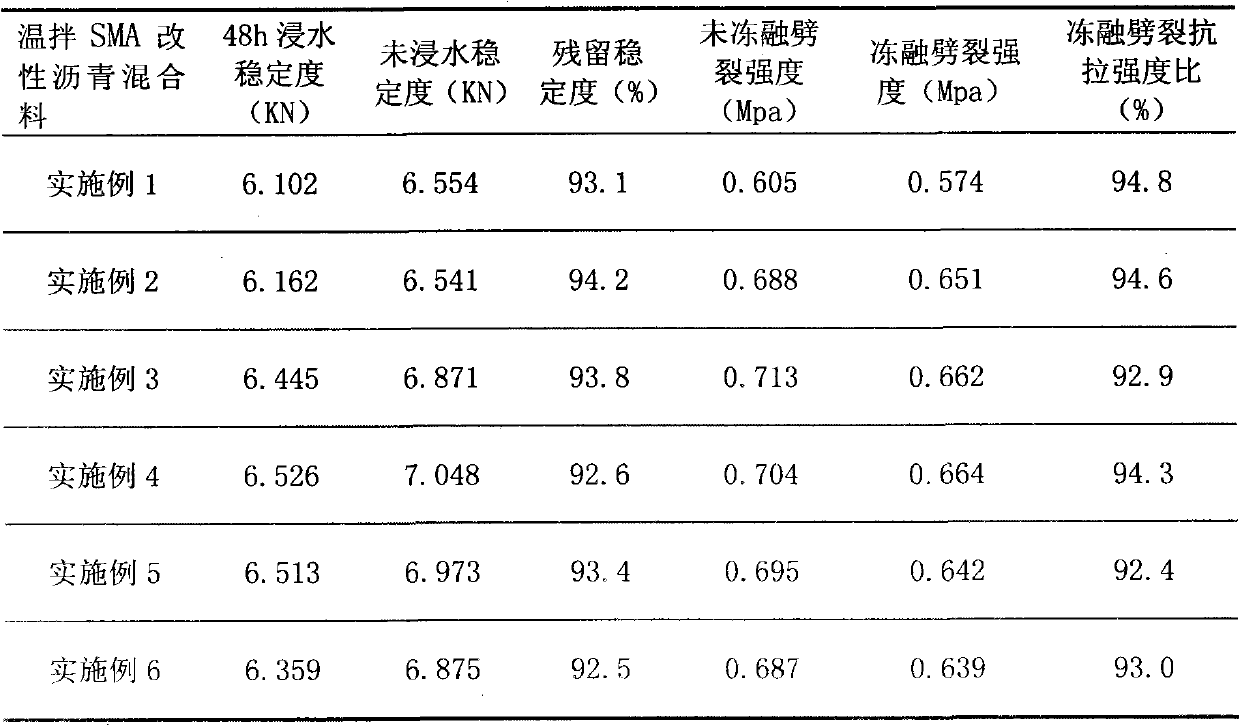

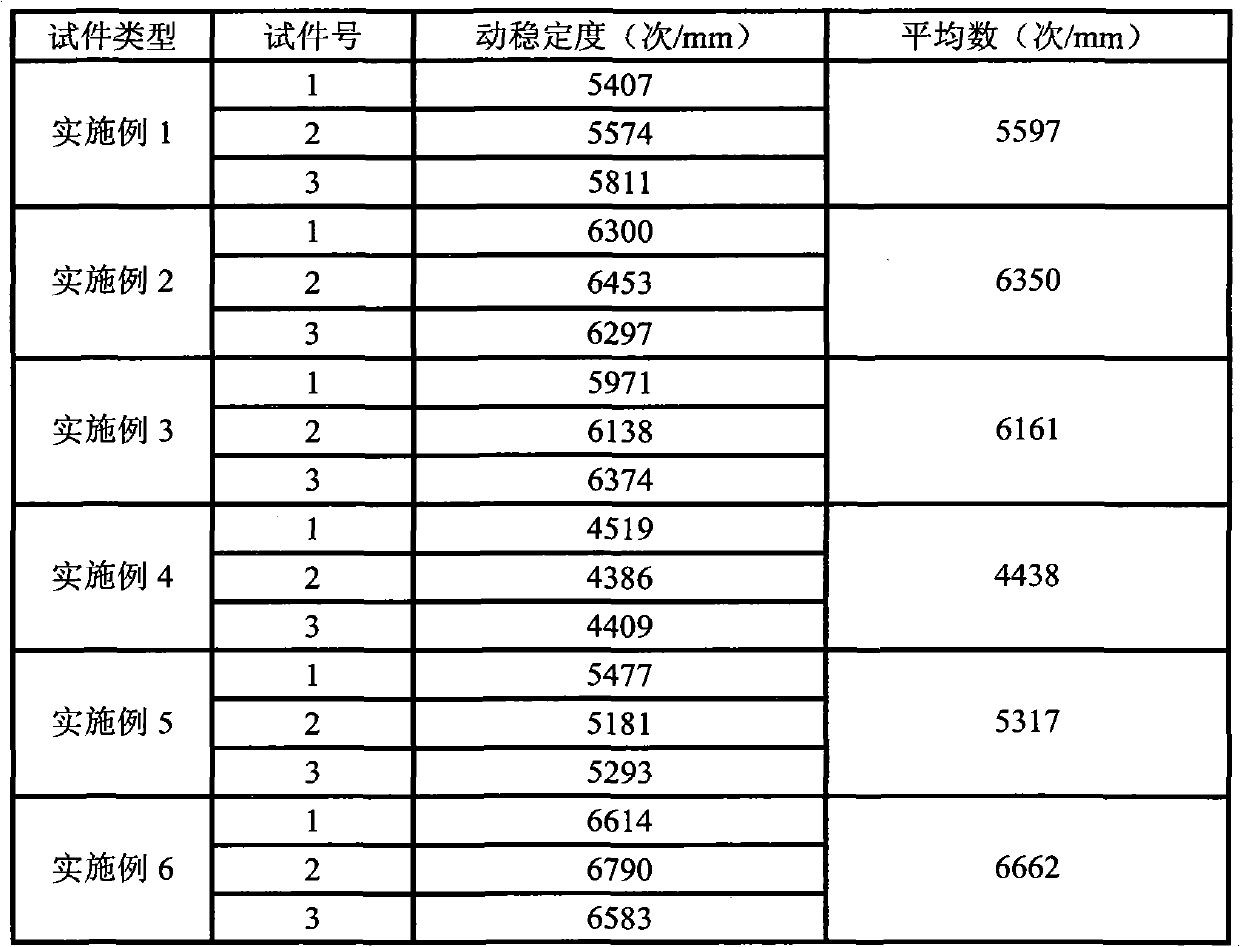

Embodiment 1

[0028] Take 9509g of aggregate, heat it to 145°C and dry it, add it to the mixing pot, keep the temperature in the mixing pot at 140°C, take 594g of SBS modified asphalt and heat it to 165°C, add it to the mixing pot, sprinkle 31.5g of warm mix agent on For the surface of SBS modified asphalt, stir in the mixing pot for 135s, add 396g of mineral powder and 10.5g of fiber into the mixing pot, and stir for 90s, wherein 25% of its weight in the mineral powder is slaked lime, mix the mixed The material is taken out of the pot at 135°C and molded at 125°C to obtain warm mix SMA asphalt mixture.

Embodiment 2

[0030] Take 8750g of aggregates, heat them to 140°C and dry them, add them to the mixing pot, keep the temperature in the mixing pot at 135°C, take 778g of SBS modified asphalt, heat them to 155°C, add them to the mixing pot, sprinkle 31.5g of warm mix agent on For the surface of SBS modified asphalt, stir in the mixing pot for 120s, add 972g of mineral powder and 31.5g of fiber into the mixing pot, stir for 83s, take the mixed material out of the pot at 130°C, and shape it at 115°C , to obtain warm mix SMA asphalt mixture.

Embodiment 3

[0032] Take 10201g of aggregate, heat it to 146°C and dry it, add it to the mixing pot, keep the temperature in the mixing pot at 136°C, take 638g of SBS modified asphalt and heat it to 170°C, add it to the mixing pot, sprinkle 33.8g of warm mix agent on For the surface of SBS modified asphalt, stir in the mixing pot for 148s, add 425g of mineral powder and 33.8g of fiber into the mixing pot, and stir for 97s, wherein 25% of its weight in the mineral powder is slaked lime, mix the mixed The material is taken out of the pot at 136°C and molded at 128°C to obtain warm mix SMA asphalt mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com