Water-blown warm-mix flame-retardant asphalt mixture, and preparation and design method thereof

A kind of asphalt mixture, water foaming technology, applied in the direction of climate change adaptation, etc., can solve the problems of warm asphalt mixture energy saving and emission reduction effect not fully exerted, large asphalt consumption, etc., to reduce energy consumption, reduce mixing Combined with the construction temperature, reducing the effect of aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] 3.2 Preparation of water-foamed warm-mix asphalt

[0050] Heat the original asphalt to 135°C (base asphalt) or 145°C (modified asphalt) to make the asphalt have sufficient fluidity. Open the air valve and water valve of the water-foamed asphalt foaming machine, adjust the foaming equipment to a temperature of 150-170°C and an air pressure of 100 bar, add a certain amount of water (usually 1.5% to 2% of the original asphalt mass), and Add bitumen into the foaming equipment, start the equipment, and let the bitumen fully foam.

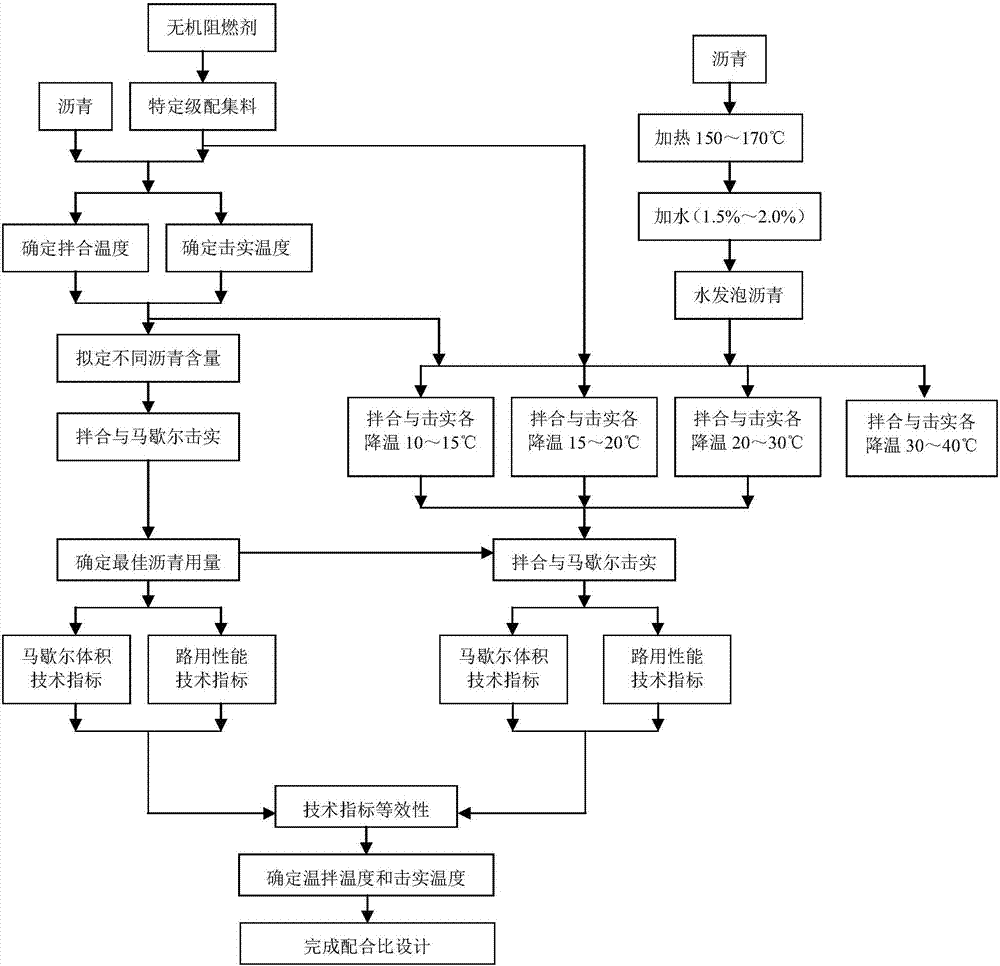

[0051] 3.3 Design of water-foamed warm-mix flame-retardant asphalt mixture

[0052] (1) The composition of the aggregate gradation is the same as the aggregate gradation used in the hot-mix flame-retardant asphalt mixture. The optimal asphalt dosage is the optimal asphalt dosage determined by the design of the hot-mix flame-retardant asphalt mixture. The addition amount of flame retardant is The agreed dosage.

[0053] (2) Determine the mixing temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com