Chromatic bituminous cement and preparation method thereof

A technology of colored asphalt and binder, which is applied in the field of asphalt binder, which can solve the problems of high energy consumption, limitation of high temperature stability of colored asphalt binder, and difficulty in construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0018] Raw materials used:

[0019] Refined lubricating oil, viscosity at 40°C: 3.5Pa.S, flash point: 335°C, aromatic content: 68wt%, density at 15°C: 0.98g / cm3

[0020] Petroleum resin, produced by Korea Kolon Company, trade name: Hikotack P140, softening point 145°C, average molecular weight (GPC method) 2200

[0021] Polyethylene wax, molecular weight 3000-6000, softening point 120-150℃

[0022] SBR, the grade produced by Qilu Petrochemical is 1502

[0023] Heat the extracted lubricating oil to 175°C, then add petroleum resin, polyethylene wax and SBR, and stir with a stirrer at a speed of 200 rpm for 60 minutes to prepare the finished colored asphalt binder. The specific composition ratio (percentage by weight), and the performance results of the binder and the mixture tested by the testing method specified in the JTJ052-2000 standard "Testing Procedures for Asphalt and Asphalt Mixtures in Highway Engineering" of the Ministry of Communications of China are shown in Table...

Embodiment 4

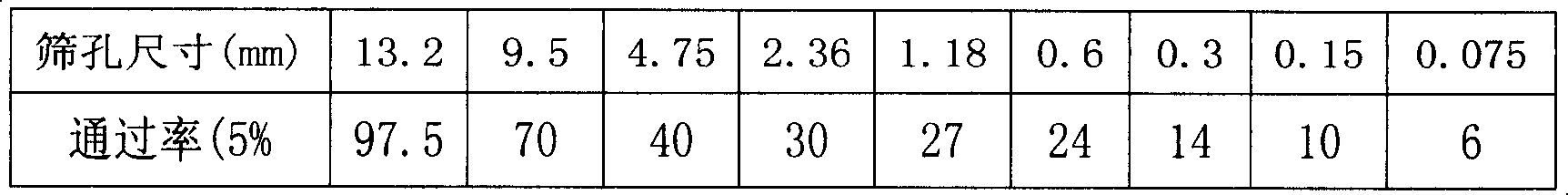

[0030] The colored asphalt cement and aggregates are mixed into Marshall specimens and rut specimens to form, among which the stones above 2.36mm are made of diabase, and the stones of 2.36mm-0.075mm are made of quartzite, and the following gradation is adopted:

[0031]

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com