Anti-rutting modifying agent used for asphalt pavement and asphalt mixture containing anti-rutting modifying agent

A technology of asphalt mixture and asphalt pavement, which is applied in the direction of building insulation materials, building components, buildings, etc., can solve the problems of poor adhesion and water damage resistance, and achieve good deformation resistance and high rutting resistance , High adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] An anti-rutting modifier, comprising by mass percentage:

[0069] High density low pressure polyethylene 80wt%

[0070] Rubber powder 8wt%

[0071] Rock asphalt 12wt%;

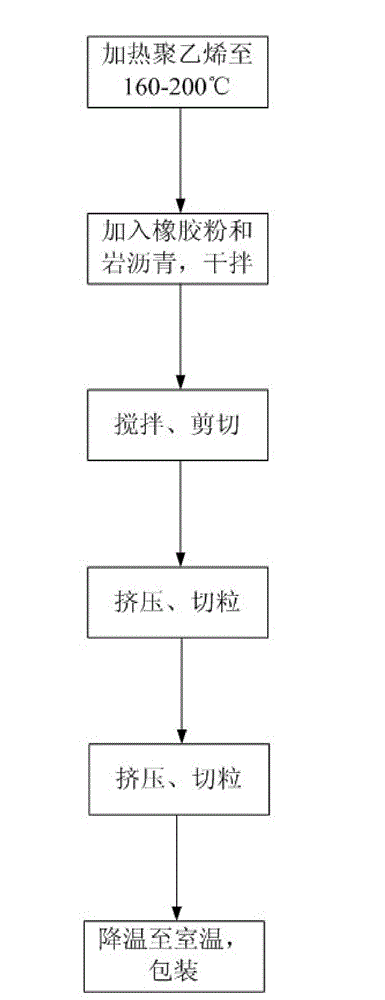

[0072] The preparation method is:

[0073] Heat the high-density low-pressure polyethylene to 200°C, add rubber powder and rock asphalt, shear, stir, extrude, and pelletize through a plastic extruder to obtain a granular mixture with a particle size of 1.8-2.4mm, that is Anti-rutting modifier.

Embodiment 2

[0075] The anti-rutting modifier comprises by mass percentage:

[0076] High density low pressure polyethylene 85wt%

[0077] Rubber powder 9wt%

[0078] Rock asphalt 6wt%;

[0079] The preparation method is:

[0080] Heat high-density and low-pressure polyethylene to 190°C, add rubber powder and rock asphalt, shear, stir, extrude, and pelletize through a plastic extruder to obtain a granular mixture with a particle size of 2.4-3.0mm, that is Anti-rutting modifier.

Embodiment 3

[0082] The anti-rutting modifier comprises by mass percentage:

[0083] High density low pressure polyethylene 92wt%

[0084] Rubber powder 3wt%

[0085] Rock asphalt 5wt%;

[0086] The preparation method is:

[0087] Heat high-density and low-pressure polyethylene to 180°C, add rubber powder and rock asphalt, shear, stir, extrude, and pelletize through a plastic extruder to obtain a granular mixture with a particle size of 3.0-3.6mm, that is Anti-rutting modifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com