Polyethylene/rubber powder blend modified asphalt and preparation method thereof

A technology of blending modification and rubber powder, which is applied to building components, building insulation materials, construction, etc. It can solve the problems not involved in improving the storage stability of modified asphalt, and achieve short production process, reasonable price and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

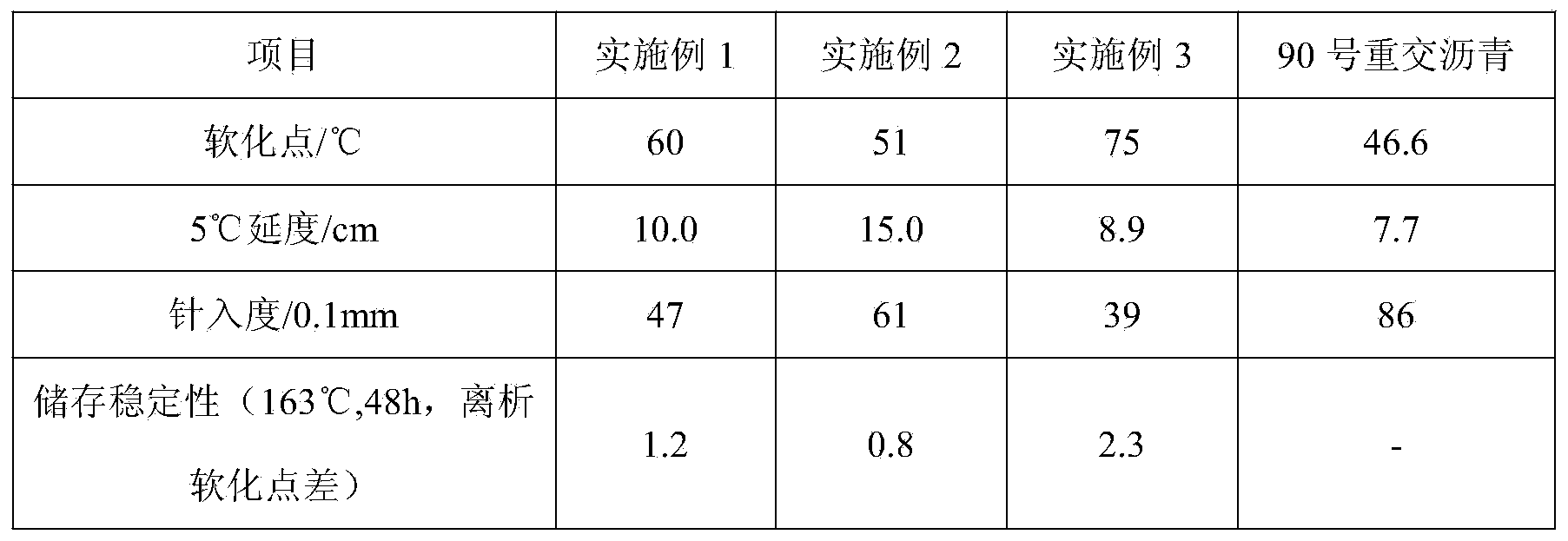

Embodiment 1

[0035] (1) Weigh 98g of low-density polyethylene, 98g of 40 mesh rubber powder, and 4g of crosslinking agent in the experiment, mix them evenly, and melt and extrude them at 170°C to 180°C in a twin-screw extruder to obtain polyethylene / rubber powder blend;

[0036] (2) The experiment weighed 1000g of heavy-duty No. 90 asphalt and 100g of the polyethylene / rubber powder blend prepared in step (1), heated the base asphalt to 180°C, and added the polyethylene / rubber powder blend to the base asphalt After mixing evenly in medium, use a high-speed shearing machine to shear and disperse for 30 minutes to obtain polyethylene / rubber powder blended modified asphalt.

Embodiment 2

[0038] (1) In the experiment, 80g of linear low density polyethylene, 117g of 60 mesh rubber powder, and 3g of crosslinking agent were weighed, mixed evenly, and melted and extruded in a twin-screw extruder at 170°C to 180°C to obtain polyethylene / rubber powder blend;

[0039] (2) The experiment weighed 1000g of heavy-duty No. 90 asphalt and 60g of the polyethylene / rubber powder blend prepared in step (1), heated the base asphalt to 180°C, and added the polyethylene / rubber powder blend to the base asphalt After mixing evenly in medium, use a high-speed shearing machine to shear and disperse for 50 minutes to obtain polyethylene / rubber powder blended modified asphalt.

Embodiment 3

[0041] (1) Weigh 90g of low-density polyethylene, 107g of 80-mesh rubber powder, and 3g of cross-linking agent in the experiment, and mix them evenly, and melt and extrude them in a twin-screw extruder at 170°C to 180°C to obtain polyethylene / rubber powder blend;

[0042] (2) The experiment weighed 1000g of heavy-duty No. 90 asphalt and 130g of the polyethylene / rubber powder blend prepared in step (1), heated the base asphalt to 180°C, and added the polyethylene / rubber powder blend to the base asphalt After mixing evenly in medium, use a high-speed shearing machine to shear and disperse for 50 minutes to obtain polyethylene / rubber powder blended modified asphalt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com