Robust control method for asphalt mixing plant batching error

A technology of asphalt concrete and mixing equipment, applied in the field of robust control, can solve problems such as linear model error, and achieve the effect of improving batching accuracy and good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

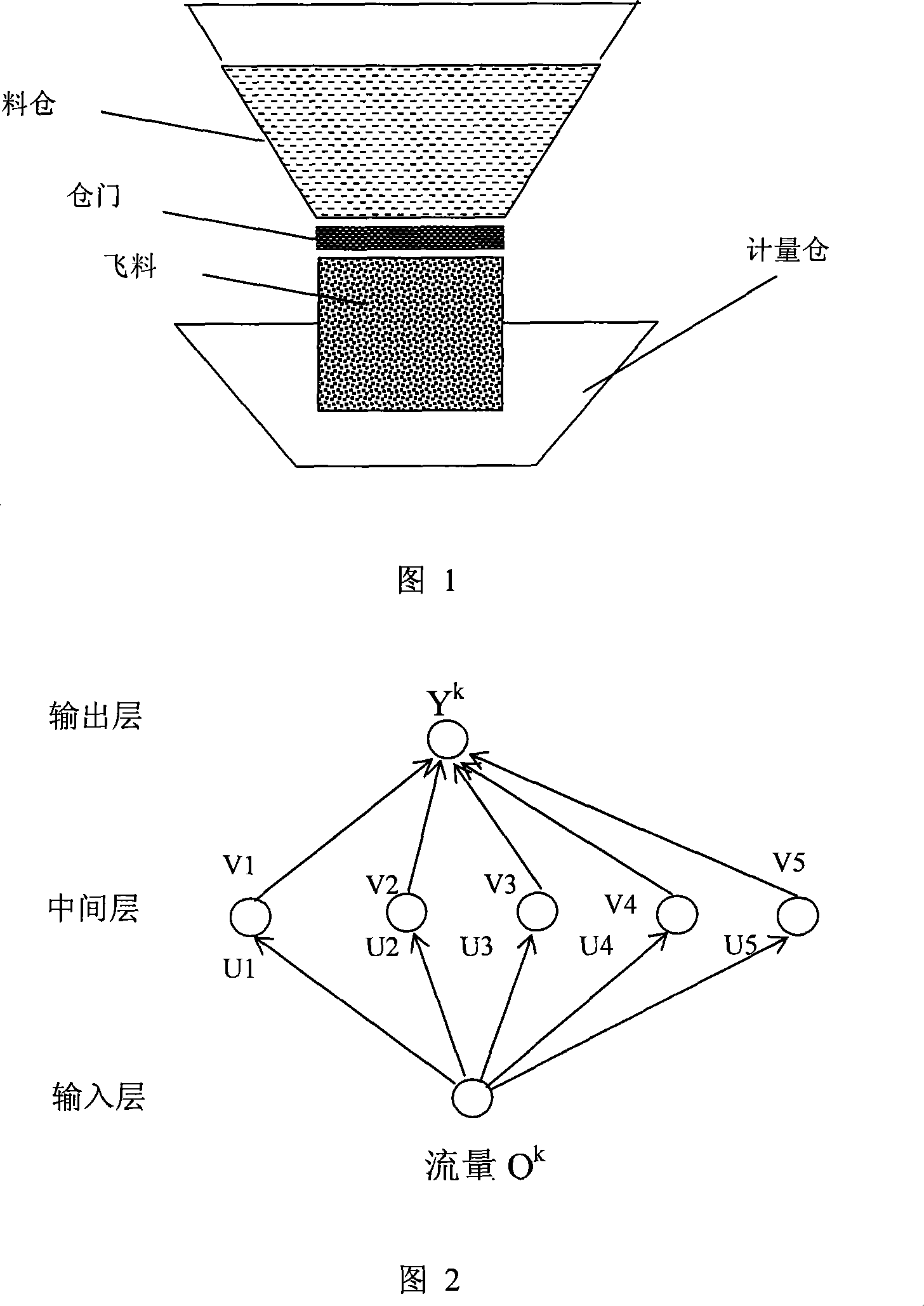

[0014] As shown in Figure 1, the silo is full of materials, and the door can control the opening and closing of the silo. The initial weight of the scale is the tare weight W 0 , after opening the bin door, the material falls into the weighing scale by its own weight, and the dynamic weight W of the scale can be read at this time 1 , and then close the door, and the static weight W can be read after the scale is completely stable, then the weight of the material in the scale after the door is opened to fully closed is W=W 1 +W 2 -W 0 . Where: W 2 is the weight of flying material.

[0015] If the set distribution value is W, it can be known from the above formula that it is ahead of the set value by W 2 Close the door to meet the set requirements. due to W 2 It is related to various factors such as the amount of material in the warehouse, the stability of the warehouse door action, and the composition change of the material, so W 2 It changes drastically all the time. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com