Oil-resistant road asphalt modifier and preparation method thereof

A technology of road asphalt and modifier, applied in building components, building insulation materials, construction and other directions, can solve the problems of increasing the emission of harmful gases such as smoke, high viscosity of oil-resistant modified asphalt, high mixing and construction temperature, etc. Achieve the effect of improving aging resistance and performance, good compatibility, and reducing hot mixing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

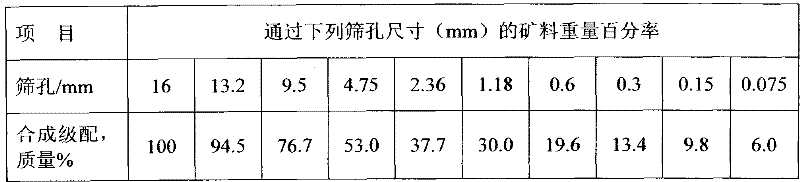

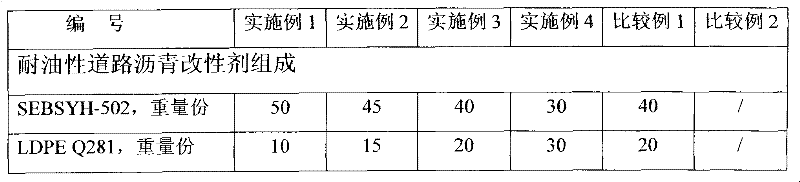

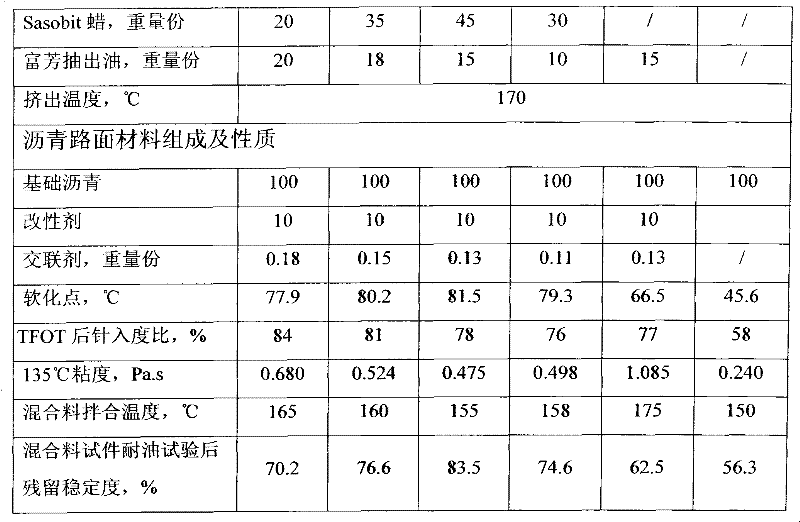

[0022] The oil-resistant road asphalt modifier is prepared according to the ratio of parts by weight in Table 2. The solid materials are pre-mixed uniformly in proportion and added to the feed hopper of the twin-screw extruder. The feed port is used for strand granulation at an extrusion temperature of 170°C.

[0023] Select asphalt with a needle penetration of 92 1 / 10mm and a softening point of 46.2°C as the base asphalt. Take 100 parts of the base asphalt in a molten state, add 10 parts of the modifier in Example 1, and then add 0.18 parts of the cross-linking agent sulfur sublimation to maintain Stir at 160°C for 60 minutes at 400rpm / min to prepare an oil-resistant asphalt pavement material, the properties of which are shown in Table 2. According to the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" JTJ052-2000 of the Ministry of Communications, the asphalt pavement material is used as the binder, and the asphalt mixture standard Marshall test pi...

Embodiment 2

[0025] According to the asphalt pavement material prepared by the method of Example 1, the difference is that the modifying agent is an example 2 modifying agent, and the crosslinking agent sulfur is sublimated to 0.15 parts, and its properties are shown in Table 2. # After soaking in aviation kerosene for 24 hours, the oil resistance results are shown in Table 2.

Embodiment 3

[0027] The asphalt pavement material was prepared according to the method of Example 1, except that the modifier was different. Example 3 was the modifier, and the sulfur sublimation of the crosslinking agent was 0.13 parts, and its properties were shown in Table 2. The mixture specimen was heated at 30°C for 3 # After soaking in aviation kerosene for 24 hours, the oil resistance results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com