Structural member crack propagation prediction method based on multi-factor fusion correction

A technology of crack propagation and prediction method, applied in the field of crack propagation prediction of structural parts, can solve the problems of too few factors to consider and low prediction accuracy, and achieve the effect of accurate and effective prediction and improved prediction accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

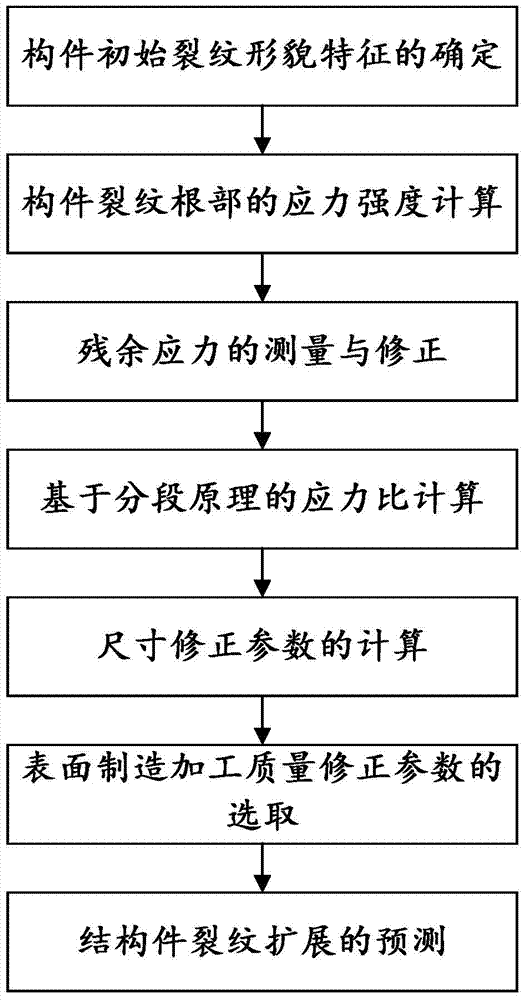

[0024] see figure 1 and figure 2 As shown, the present invention discloses a crack propagation prediction method for structural parts based on multi-factor fusion correction.

[0025] The method includes the following steps:

[0026] S1. Determination of the morphology characteristics of the initial crack of the component

[0027] Scan the crack area of the structural part by means of reverse calculation, and determine the crack morphology characteristics such as the initial crack length of the component according to the scanned data;

[0028] S2. Calculation of stress intensity at the root of component crack

[0029] Establish the 3D model of the analysis component according to the drawings, and correct the 3D model according to the crack region morphology reconstruction characteristic data obtained after S1 scanning and processing, and import the established 3D corrected model into the finite element software, and divide it into meshes , constraint setting, and load a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com