Crack propagation rate measurement method

A technology of crack growth rate and testing method, which is applied in the field of crack growth rate testing, and can solve problems such as invalid test data, inability to test crack growth rate, asymmetric crack growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

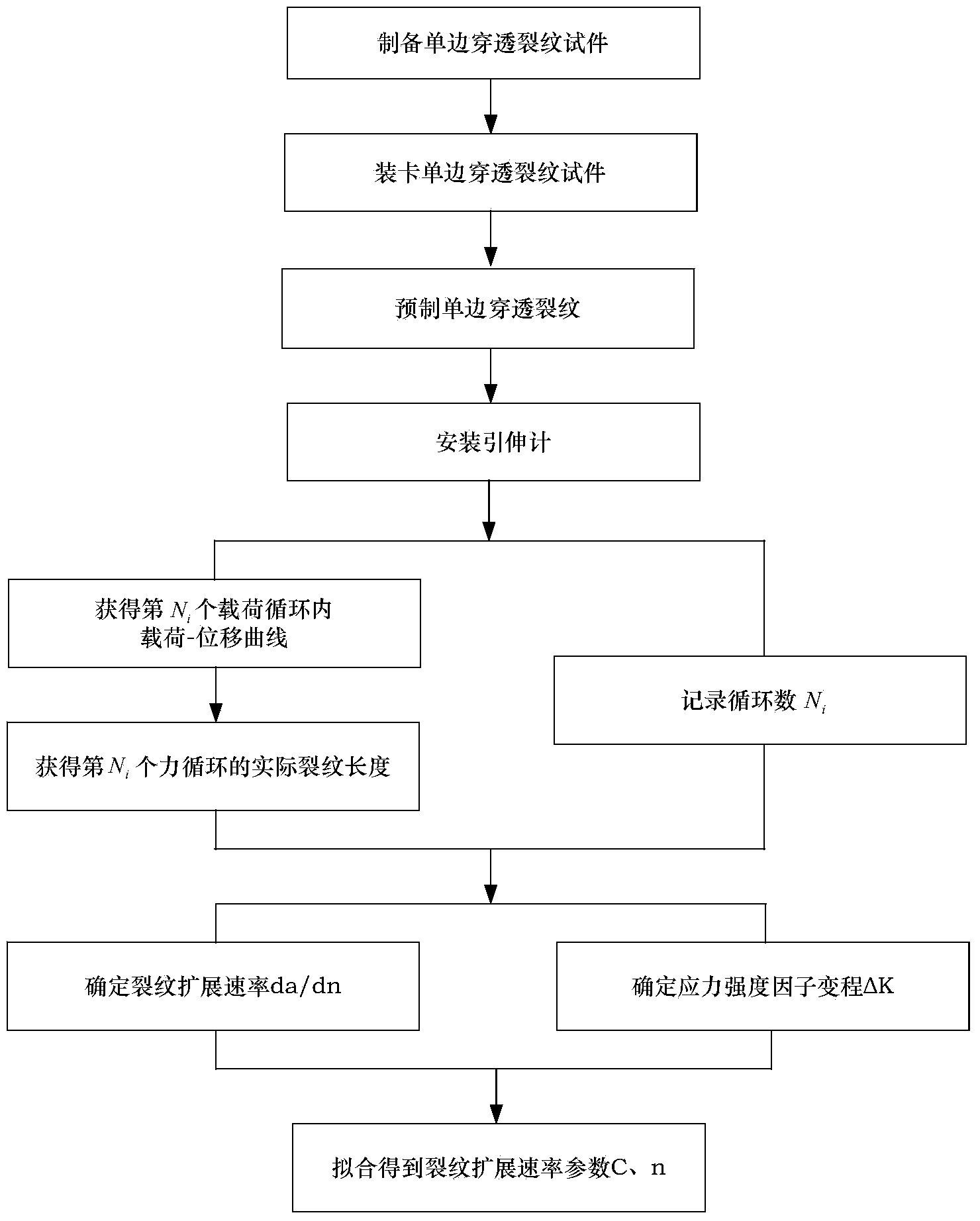

[0043] Crack growth rate test method of the present invention, such as figure 1 shown, through the following steps:

[0044] Step 1: Test piece preparation;

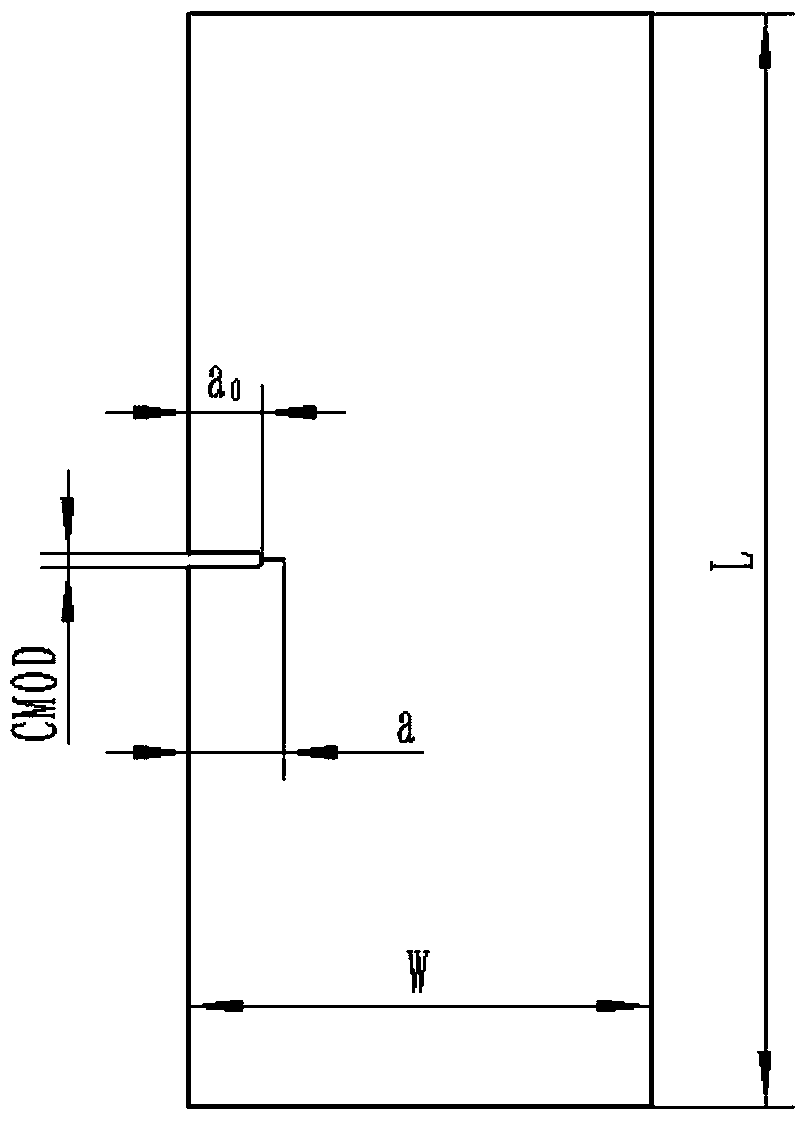

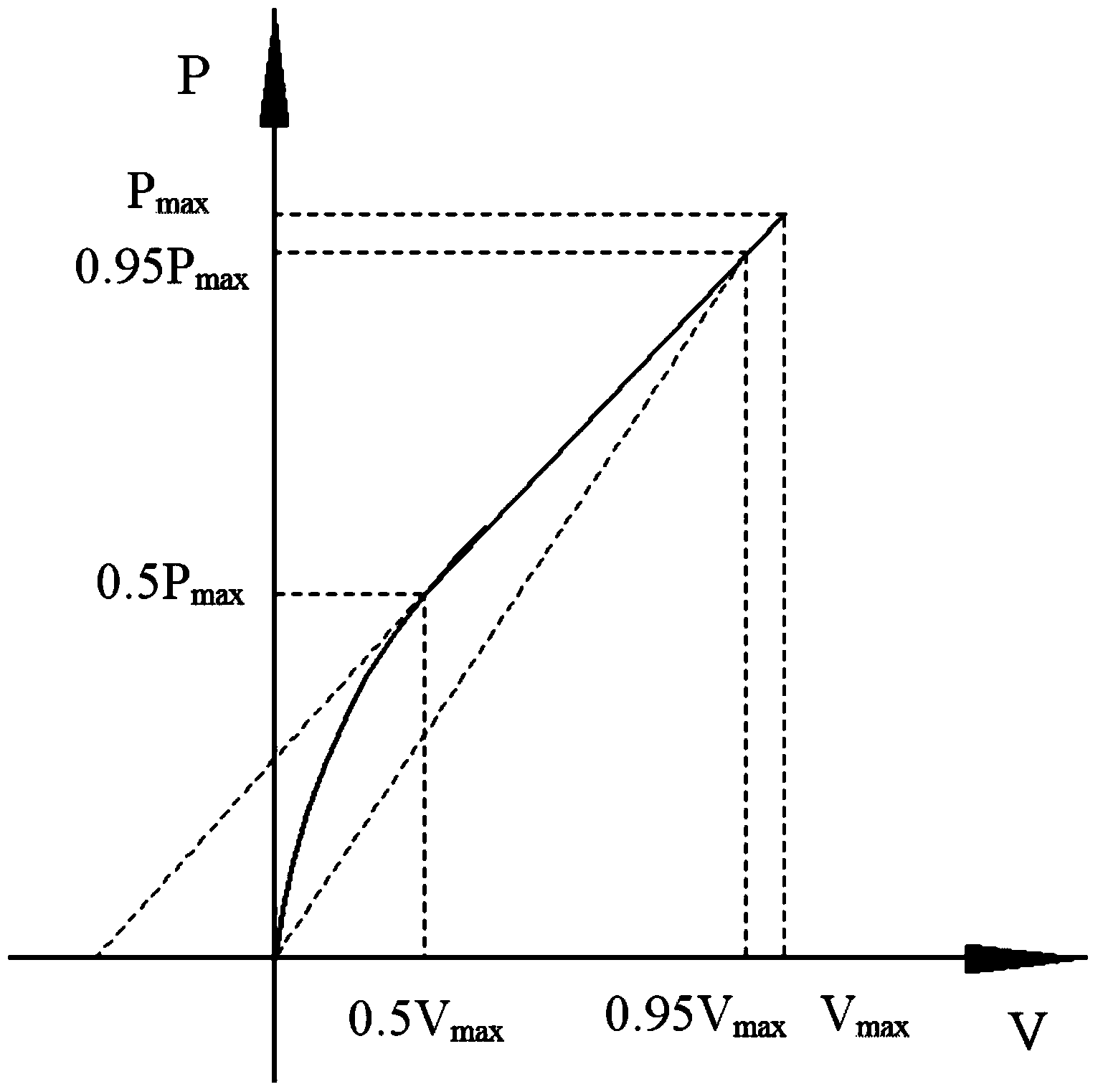

[0045] The horizontal unilateral incision is processed by wire cutting on the test plate, so that the length of the incision is a 0 The ratio to the width W of the specimen is 0.2 to 0.3, such as figure 2 Shown; in order to facilitate subsequent prefabrication of qualified unilateral penetrating cracks, it is required that the radius of curvature at the root of the incision ρ≤0.08mm.

[0046] Step 2: Test the clamping of the board;

[0047] The upper and lower ends of the test plate with unilateral cuts obtained in step 1 are clamped and fixed by the upper and lower chucks of the fatigue testing machine respectively; Both ends of the specimen can be subjected to a uniform cyclic force P applied by the fatig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com