Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

165 results about "Material constants" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Introduction - Elastic Constants In the science of materials, numbers that quantify the response of a particular material to elastic or non-elastic deformation when a stress load is applied to that material, are known as Elastic Constants.

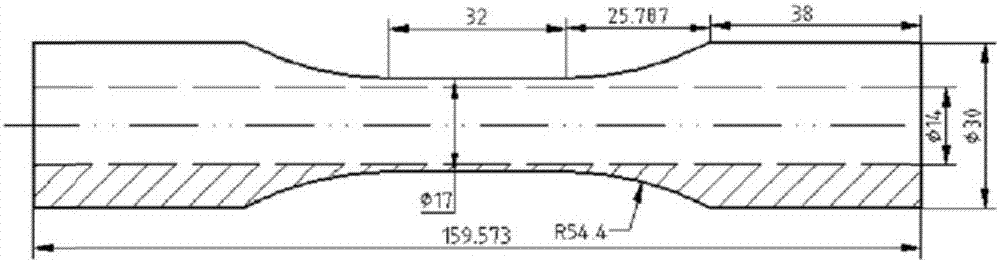

Low-cycle creep and fatigue life evaluation method under conditions of high temperature and multiaxial spectrum load

ActiveCN103926152AEasy accessReduce testing costsMaterial strength using tensile/compressive forcesFatigue damageCreep stress

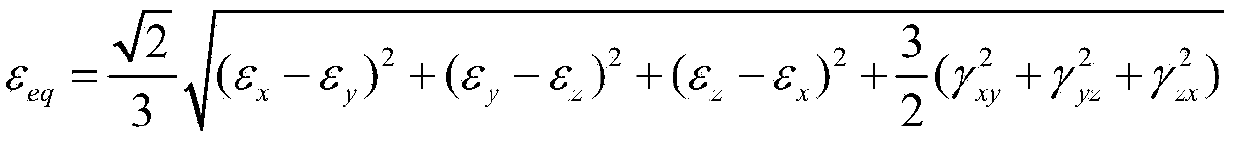

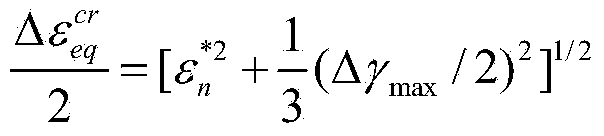

The invention relates to a low-cycle creep and fatigue life evaluation method under the conditions of high temperature and multiaxial spectrum load. The method comprises the following steps of reading a stress strain history in a multiaxial loading spectrum data block, working out equivalent strain, and finishing a loading history; repeatedly extracting by adopting a relative equivalent strain multi-axis counting method; working out all repeated fatigue damage by adopting a unified multiaxial fatigue damage life prediction model; accumulating the fatigue damage to work out the total fatigue damage; working out equivalent creep stress by utilizing the original loading history; working out creep damage Dc according to the equivalent creep stress and the stress history by combining a creep lasting equation; working out the total damage D caused by a multiaxial load spectrum block at the high temperature; and estimating the multiaxial creep and fatigue life. According to the method, the fatigue damage under the multiaxial stress and the creep damage under the multiaxial stress can be respectively calculated in the whole loading spectrum data block, the fatigue material constant at the room temperature is adopted in the calculation of the fatigue damage, and lasting equation material constant recommended by specification is adopted in the calculation of the creep damage; through experimental verification, the method has a good prediction effect.

Owner:BEIJING UNIV OF TECH

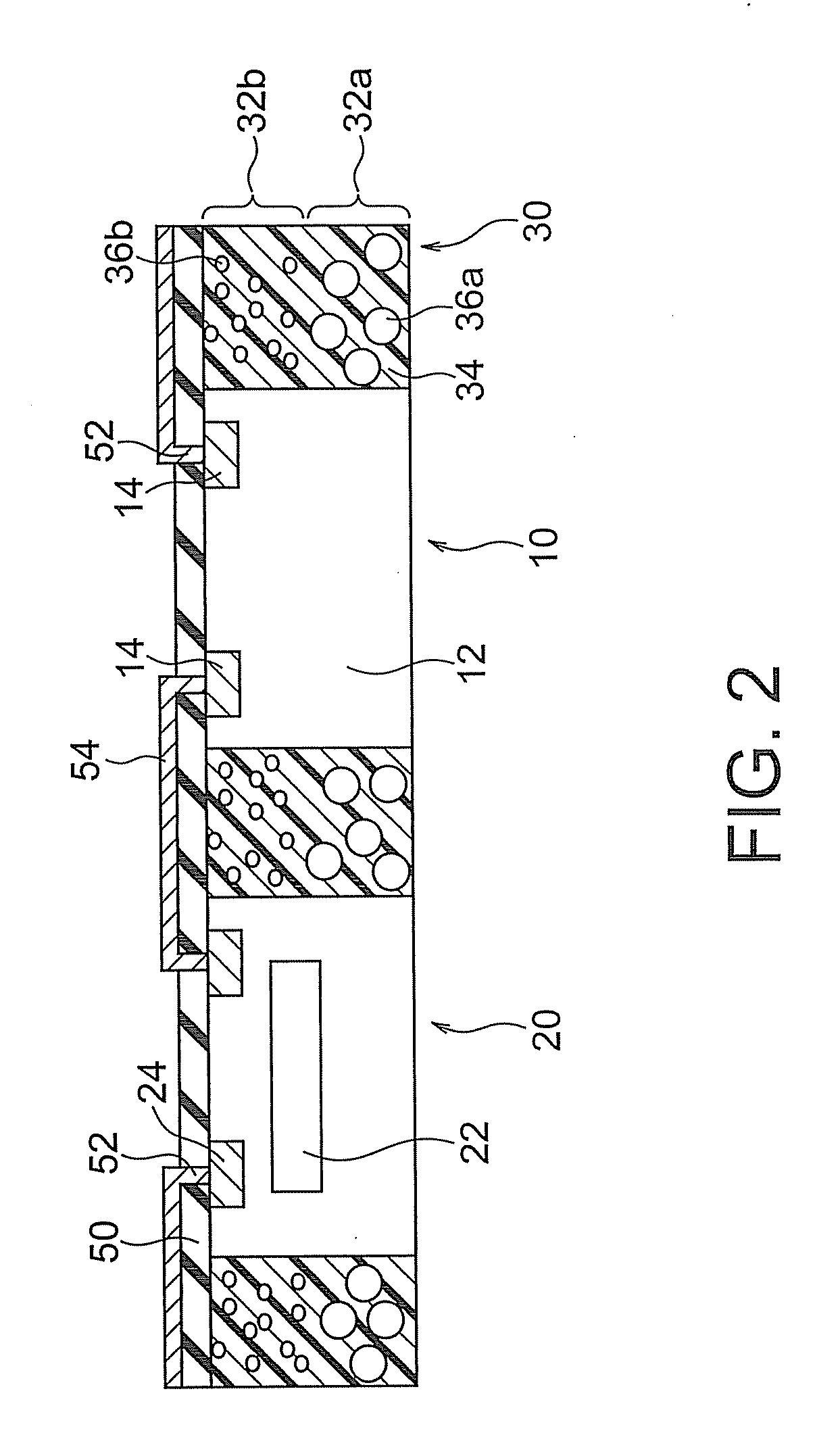

Semiconductor device and method for manufacturing the same

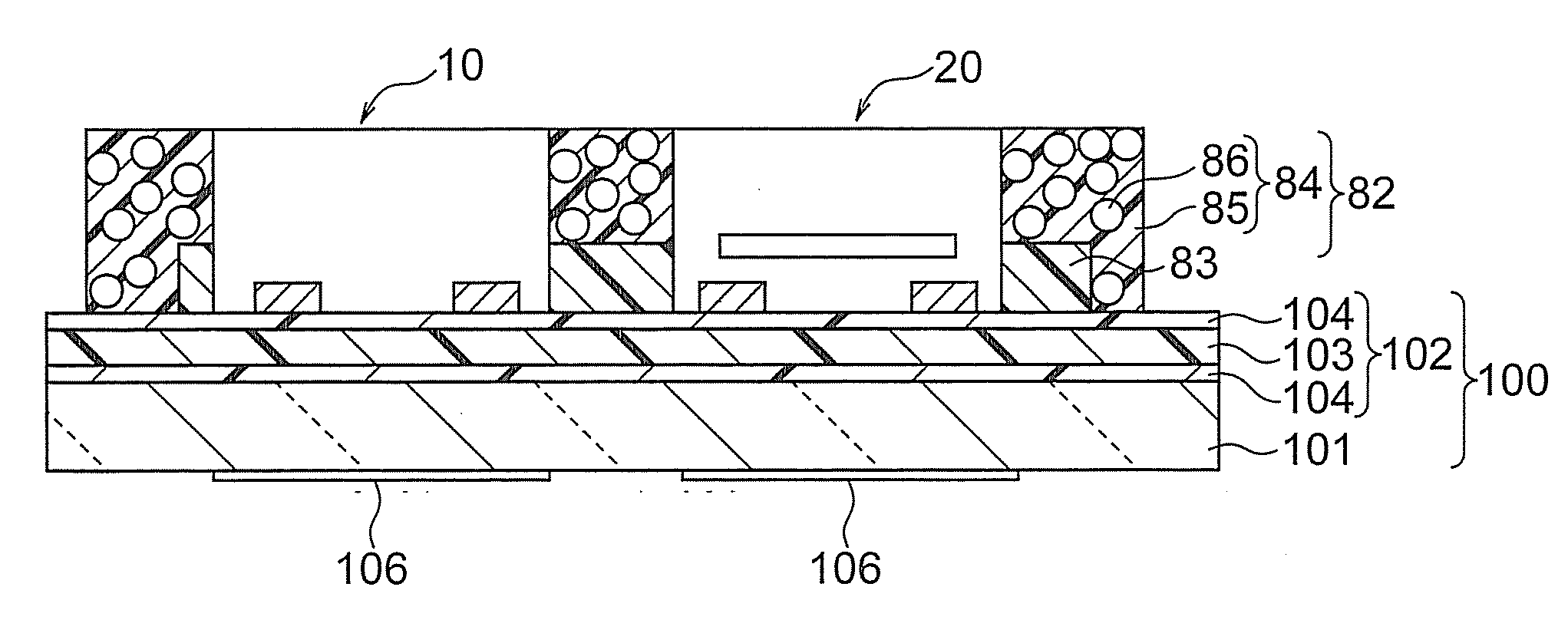

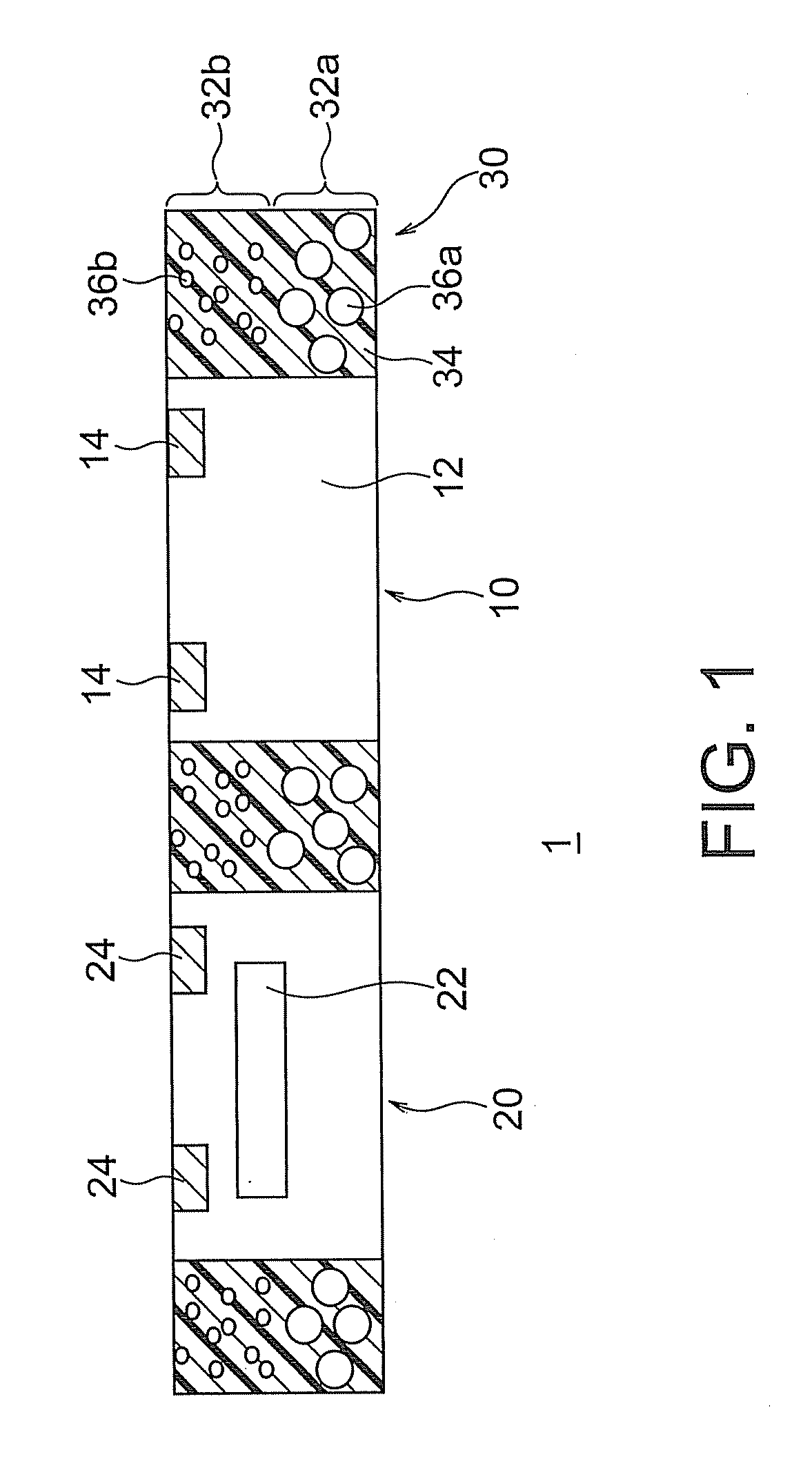

ActiveUS20090179317A1Resists warpageSmall thicknessSemiconductor/solid-state device detailsSolid-state devicesSemiconductorMaterial constants

It is made possible to restrict warpage at the time of resin cure and achieve a smaller thickness. A semiconductor device includes: a first chip including a MEMS device and a first pad formed on an upper face of the MEMS device, the first pad being electrically connected to the MEMS device; a second chip including a semiconductor device and a second pad formed on an upper face of the semiconductor device, the second pad being electrically connected to the semiconductor device; and an adhesive portion having a stacked structure, and bonding a side face of the first chip and a side face of the second chip, the stacked structure including a first adhesive film formed by adding a first material constant modifier to a first resin, and a second adhesive film formed by adding a second material constant modifier to a second resin.

Owner:KK TOSHIBA

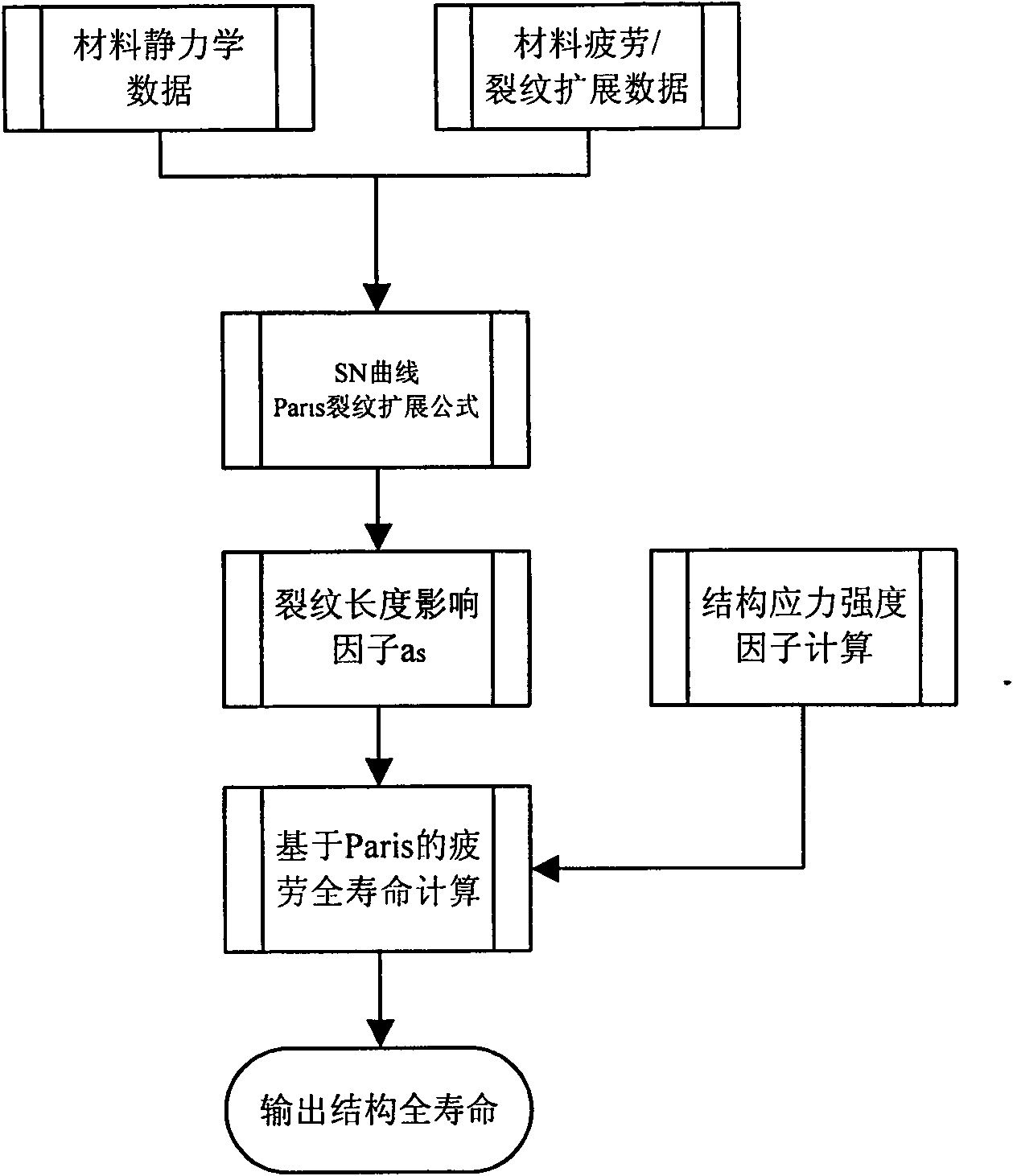

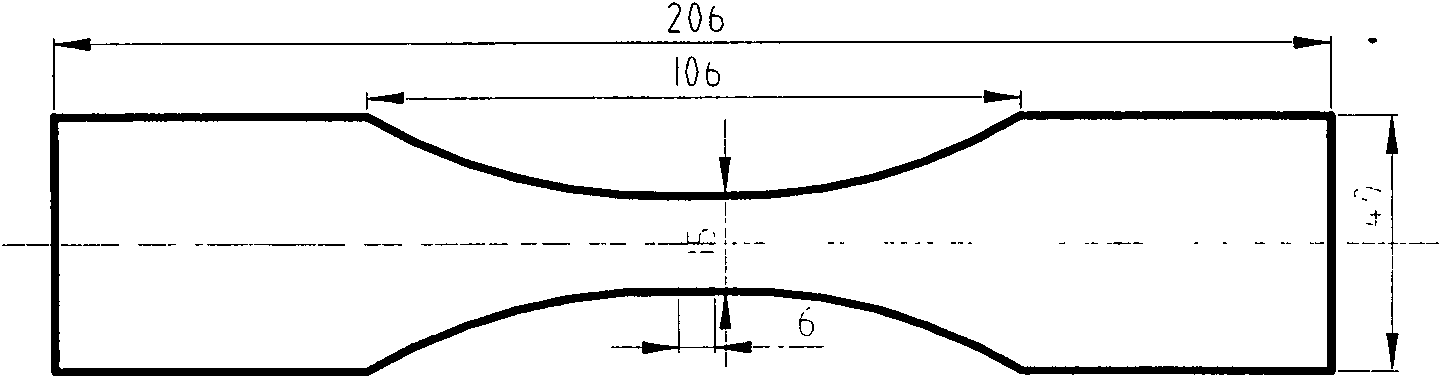

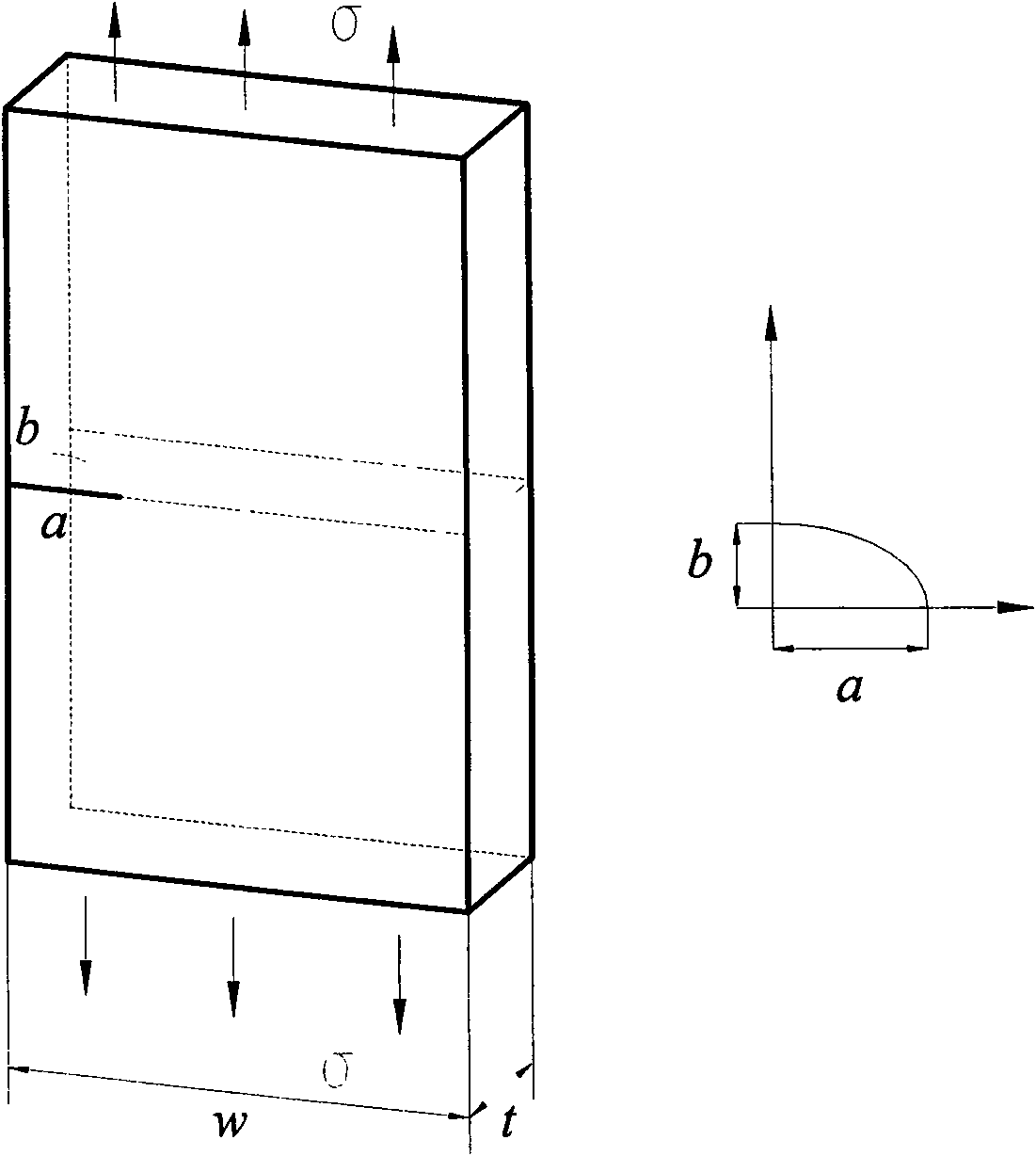

Fatigue life analyzing method based on Paris formula

InactiveCN102129512AAvoid Experimental MeasurementsRealize fatigue life calculationSpecial data processing applicationsStress intensity factorStress ratio

The invention discloses a fatigue life analyzing method based on a Paris formula, comprising the following steps of: acquiring the mechanical property data and a fatigue SN (Serial Number) curve of materials as well as the Paris material constants of the materials when stress ratio R=0 and a stress intensity factor curve of a suture, and then calculating the influence factors of a crack length; and carrying out crack propagation life integral calculation from an initial crack length to a critical crack length by adopting a fatigue life-cycle calculation formula based on the Paris so as to obtain and output a final structure fatigue life-cycle. In the invention, only the basic common material constants are needed, therefore, the test measurement of a large quantity of material constants is prevented; and the prevention of the test measurement of the large quantity of material constants is very important for the structure life-cycle analysis of engineering application.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

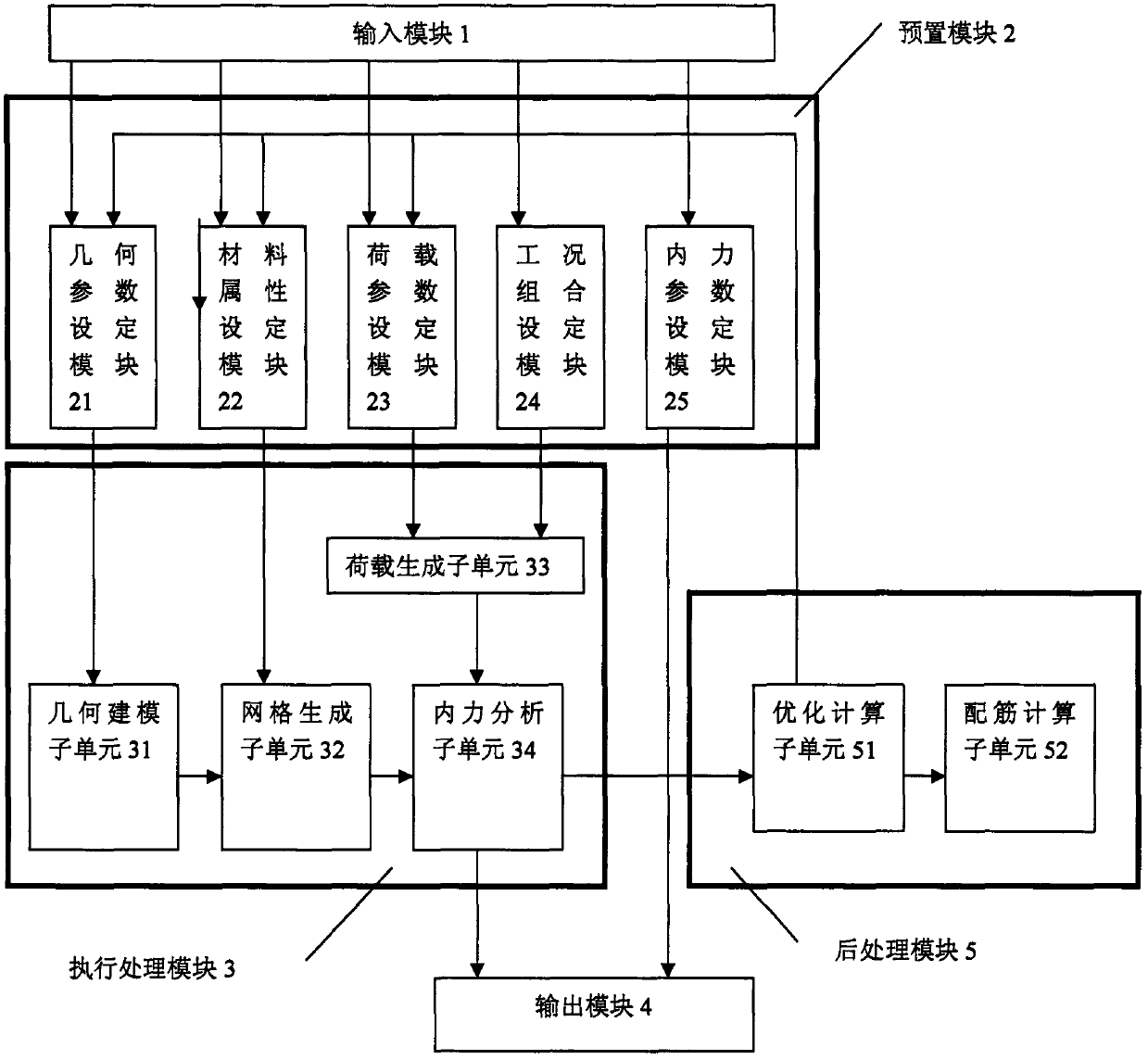

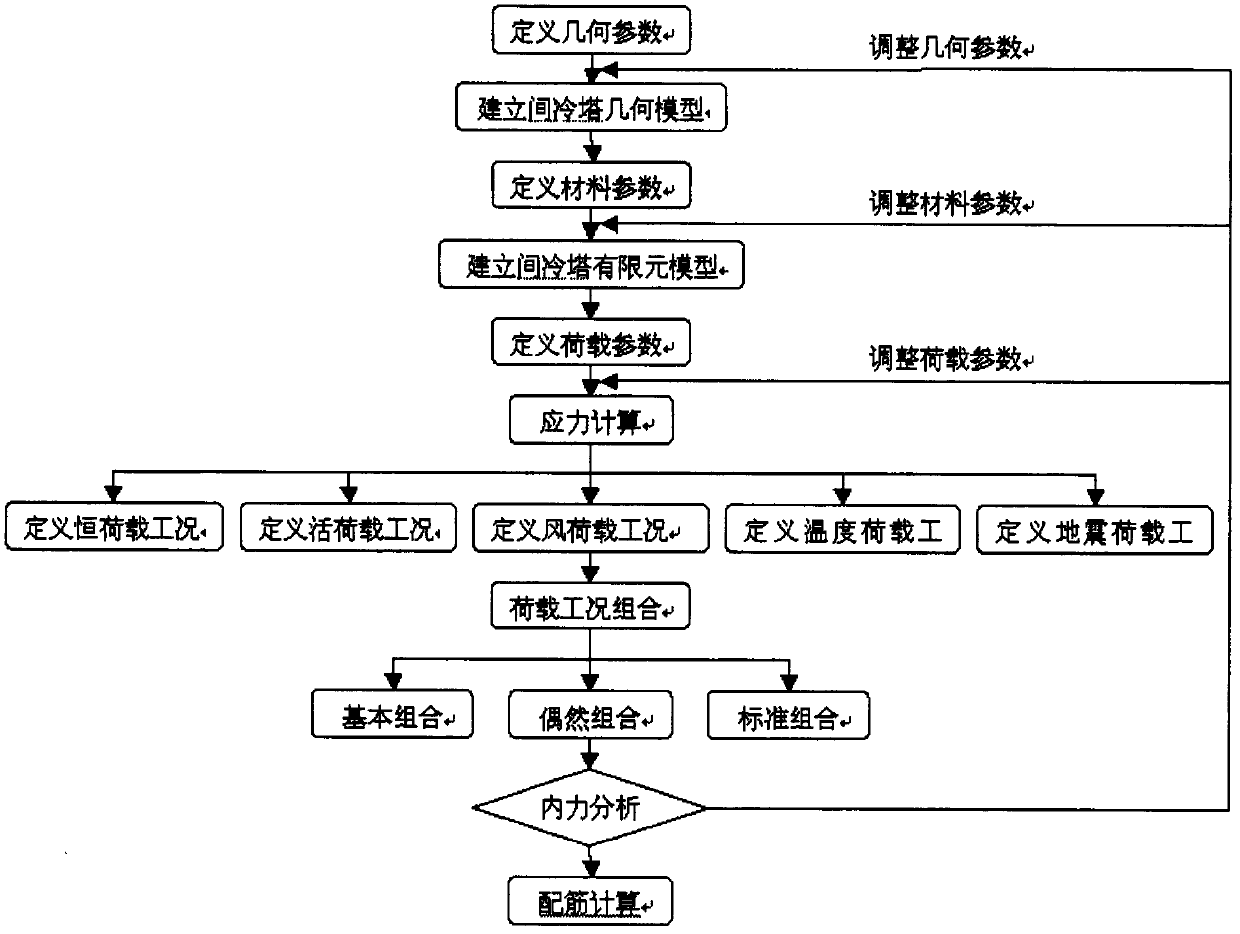

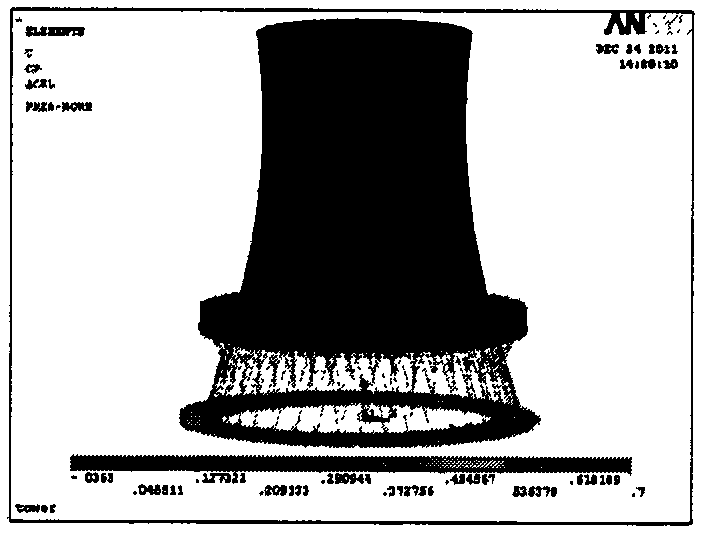

System and method for structural analysis of indirect dry cooling tower

ActiveCN103150460AAvoid duplication of workImprove analysis efficiencySpecial data processing applicationsCooling towerElement model

The invention relates to a power station indirect dry cooling system, and provides a system and a method for structural analysis of an indirect dry cooling tower based on APDL (ANSYS Parametric Design Language). The method comprises the following steps of: 1) according to geometric outside dimension of the indirect cooling tower, defining geometric parameters of the indirect cooling tower, and establishing a parameterized geometric model of the indirect cooling tower; 2) defining the unit type, real constants and material constants of the indirect cooling tower; 3) defining unit meshing size, performing self-adapting meshing division, and establishing a finite element model of the indirect cooling tower; 4) respectively applying parameterized loading for the indirect cooling tower under five loading working conditions (dead load, live load, wind load, temperature load and earthquake load) and performing computational analysis; and 5) performing combination of loading working conditions, and extracting computed results. Through the application of the system, the full process control of the indirect cooling tower from modeling to calculation can be realized. Meanwhile, the indirect cooling tower can be optimally designed by adjusting the value of each parameter. A large amount of repeated work is avoided, and the efficiency of structural analysis and design can be greatly improved.

Owner:DATANG BEIJING ENERGY MANAGEMENT

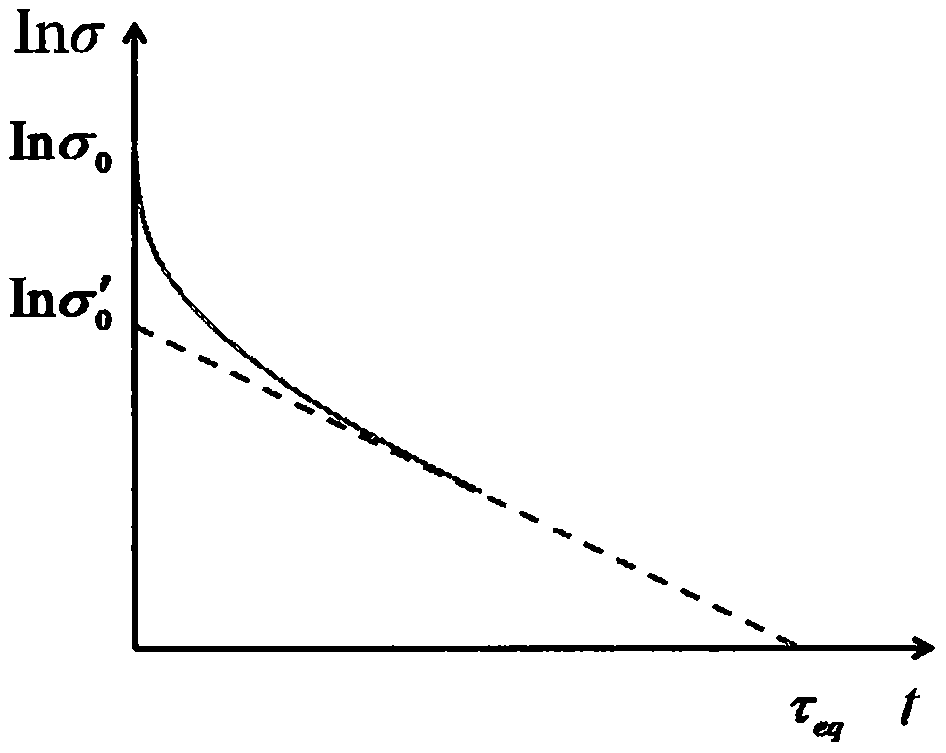

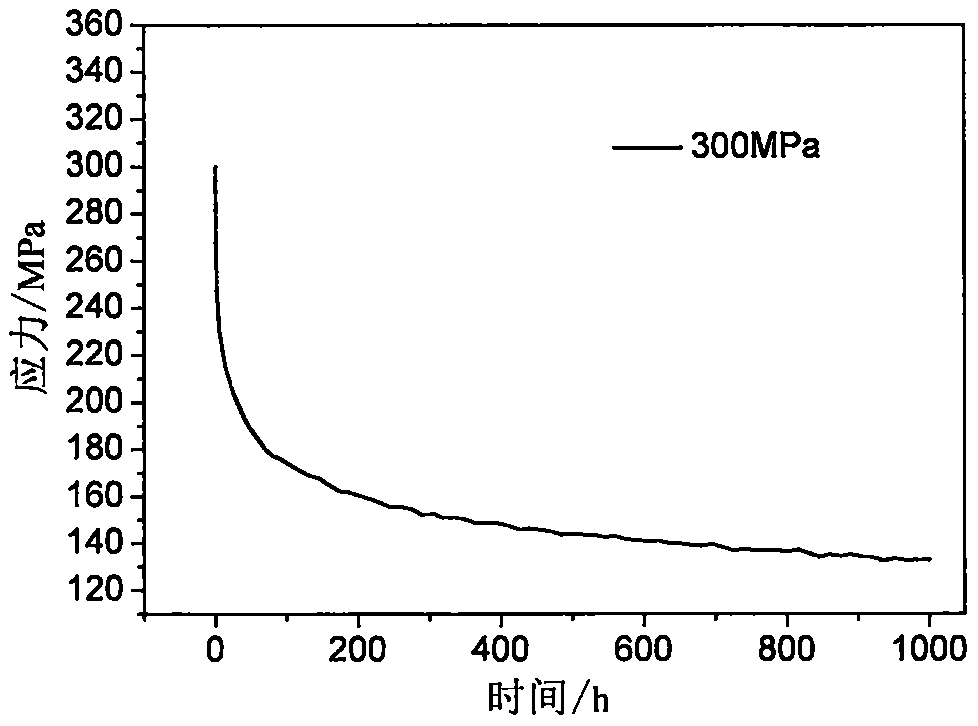

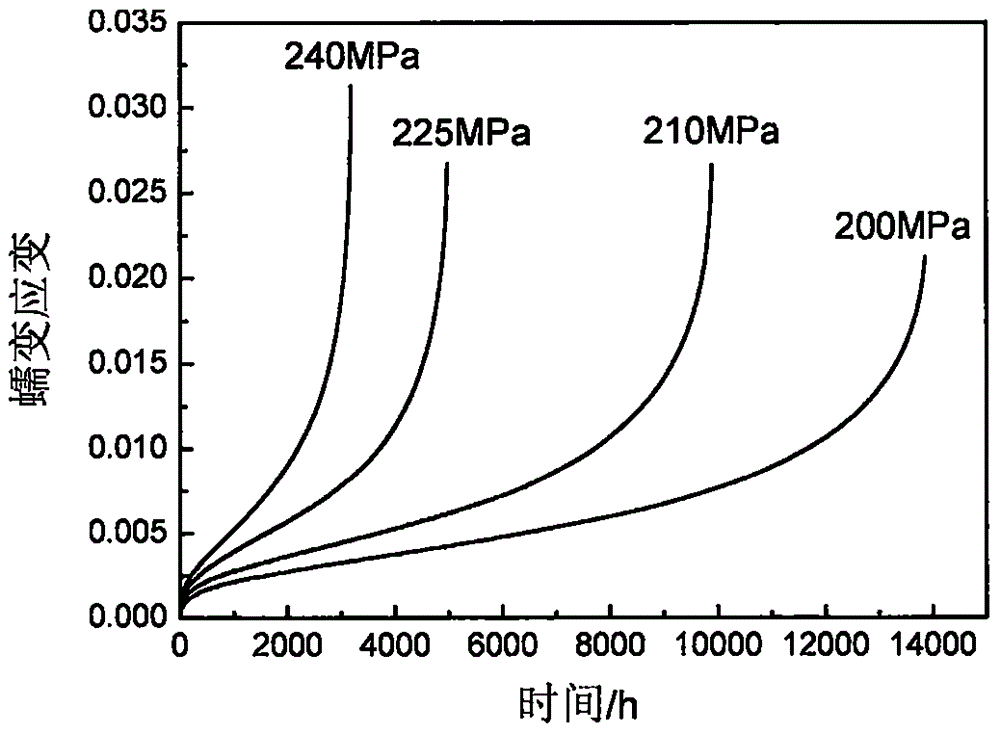

Designing and prediction method for converting high-temperature stress relaxation data into creep data

InactiveCN105842087ALow conversion accuracyReasonable technical pathInvestigating material ductilityComplex mathematical operationsTemperature stressConstant stress

The invention discloses a designing and prediction method for converting high-temperature stress relaxation data into creep data. The method mainly comprises the following steps: establishing a stress relaxation two-stage superposition model; creating the concepts of equivalent full relaxation time and equivalent relaxation creep rates, carrying out simulation of an equivalent relaxation creep rate in two integrated relaxation stages to obtain a steady-state creep rate under constant stress and establishing a stress relaxation-creep conversion model; acquiring stress relaxation performance data of a high-temperature component material; subjecting the data and the stress relaxation two-stage superposition model to fitting so as to obtain a corresponding material constant; and carrying out calculating according to a numerical analysis program, solving the stress relaxation-creep conversion model and eventually converting stress relaxation data into creep data so as to obtain a steady-state creep rate curve and a steady-state creep curve. According to the invention, accurate association between stress relaxation data and creep data behaviors is established; a prediction method for converting single relaxation data into creep data under any stress is constructed; so a novel approach is provided for designing of creep strength of a high-temperature member and for evaluation of the service life of the high-temperature member.

Owner:ANYANG INST OF TECH

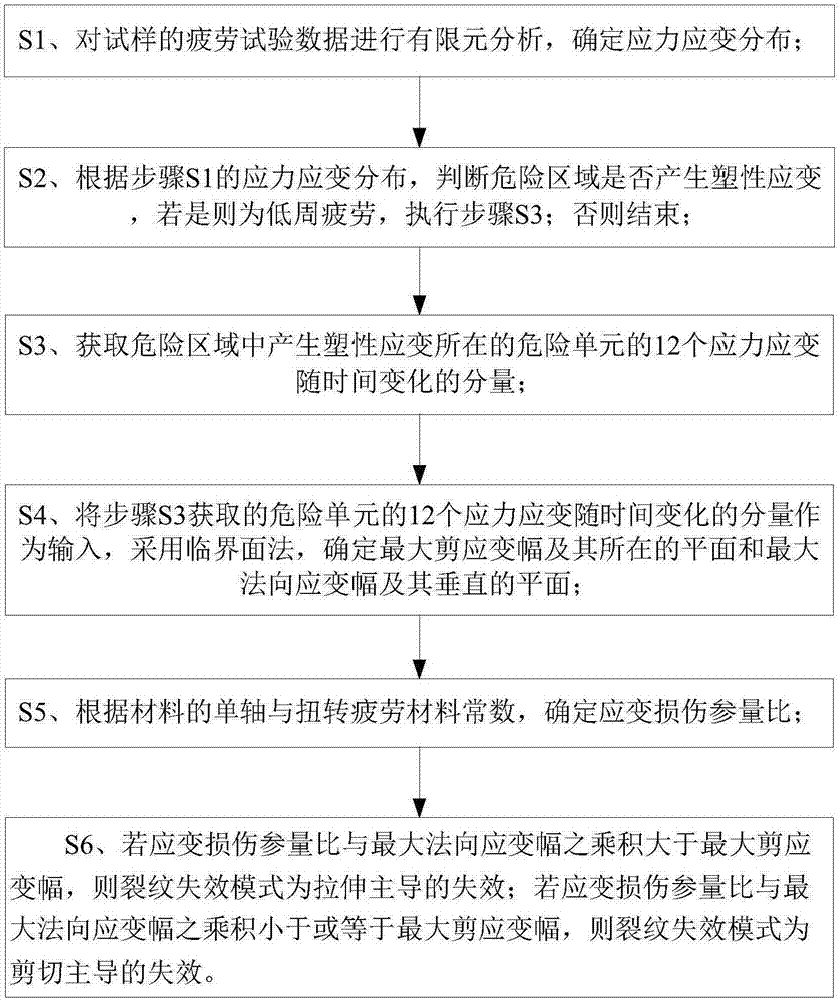

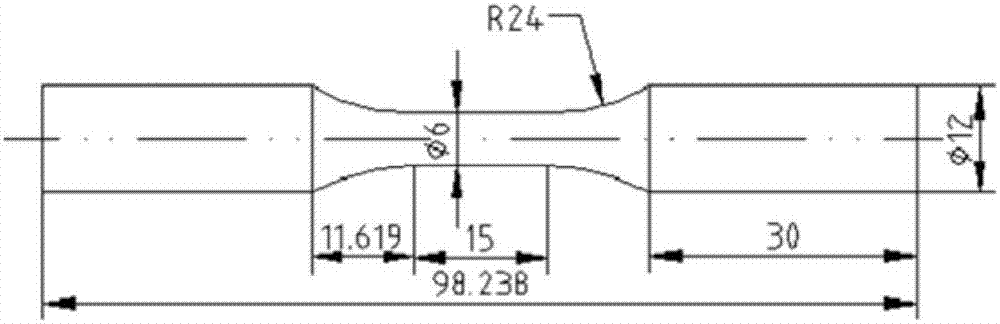

Crack failure mode determination method and fatigue life prediction method based on crack failure mode determination method

ActiveCN107389471AControlling the Problem of Excessive Prediction ErrorsSymmetric fatigue lifeMaterial strength using steady shearing forcesFatigue damageMean stress

The invention discloses a crack failure mode determination method and a fatigue life prediction method based on the crack failure mode determination method and is applied to the field of reliability. A crack failure mode of a part is determined based on contribution made by normal strain and shear strain to fatigue damage, energy and critical plane approach are combined, fatigue life prediction models in two modes such as a stretching dominated failure mode and a shearing dominated failure mode are established, and the problem that the prediction error is too large due to the material dispersion property can be effectively solved, so that the prediction life does not far deviate from experiment life; and moreover, a critical plane stress-strain curve relation and a related material constant are introduced into the model establishing process, the influence on mean stress can be reflected, and the model is capable of predicting the fatigue life under proportional and non-proportional symmetrical or asymmetrical loads.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

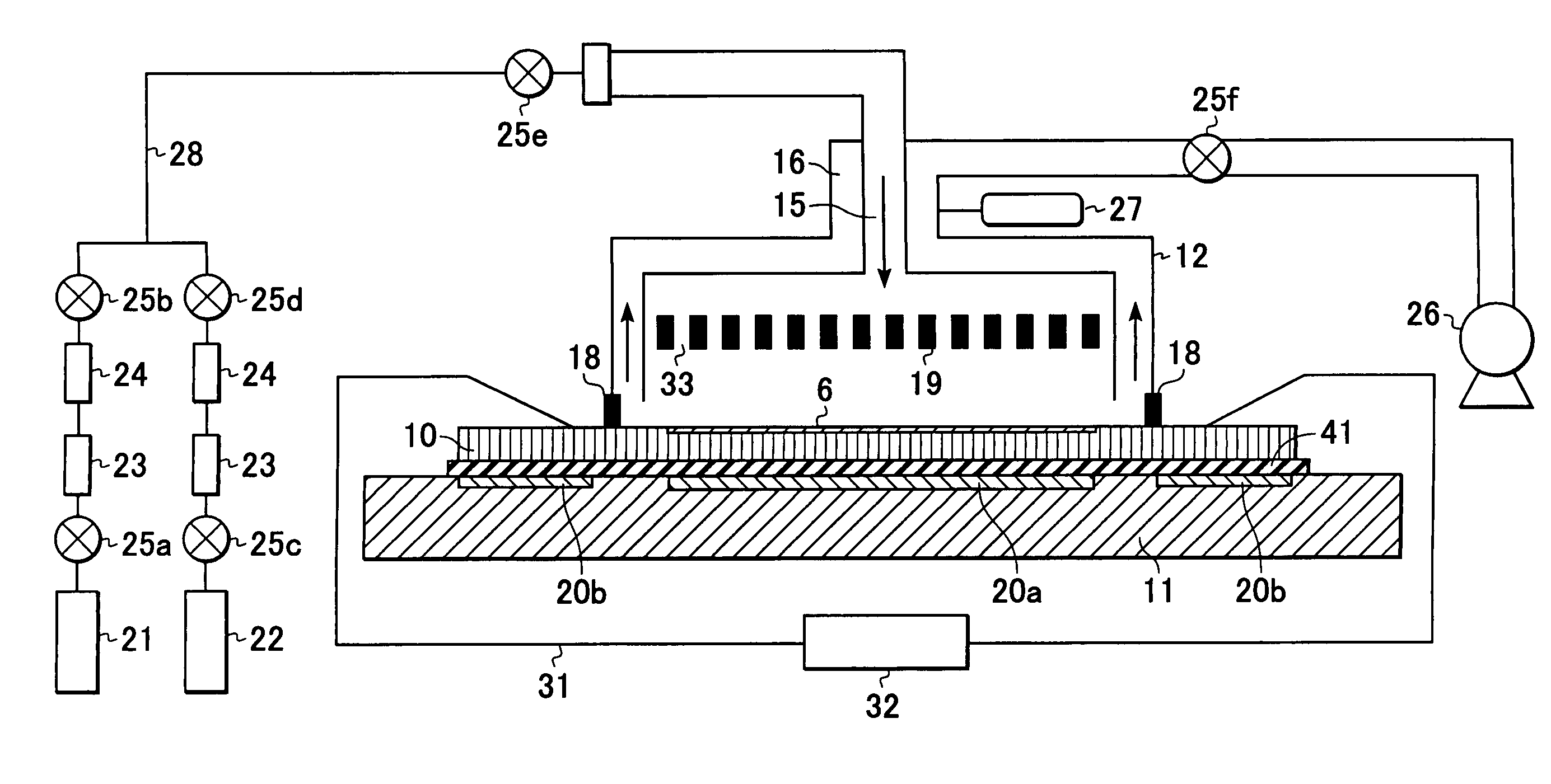

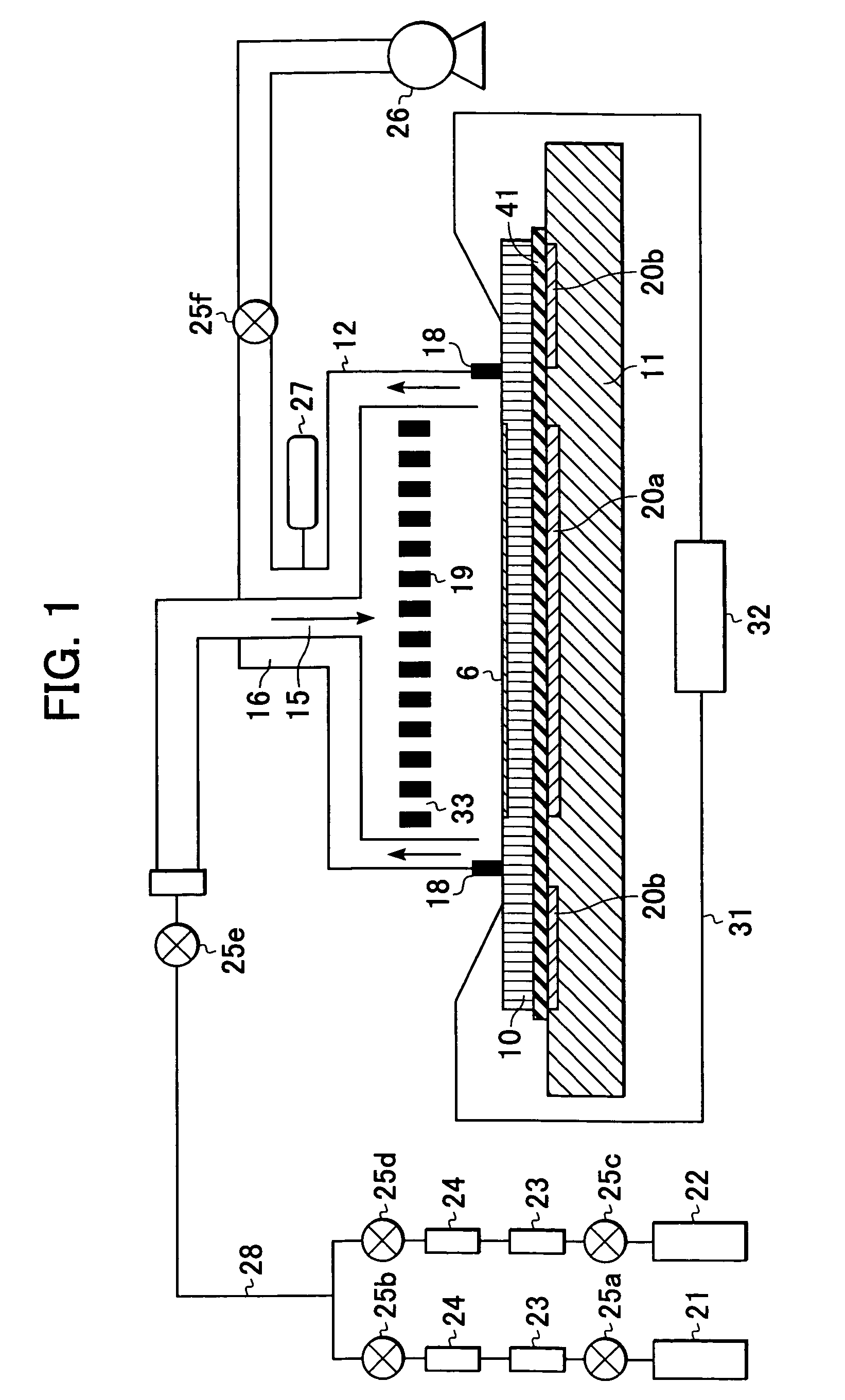

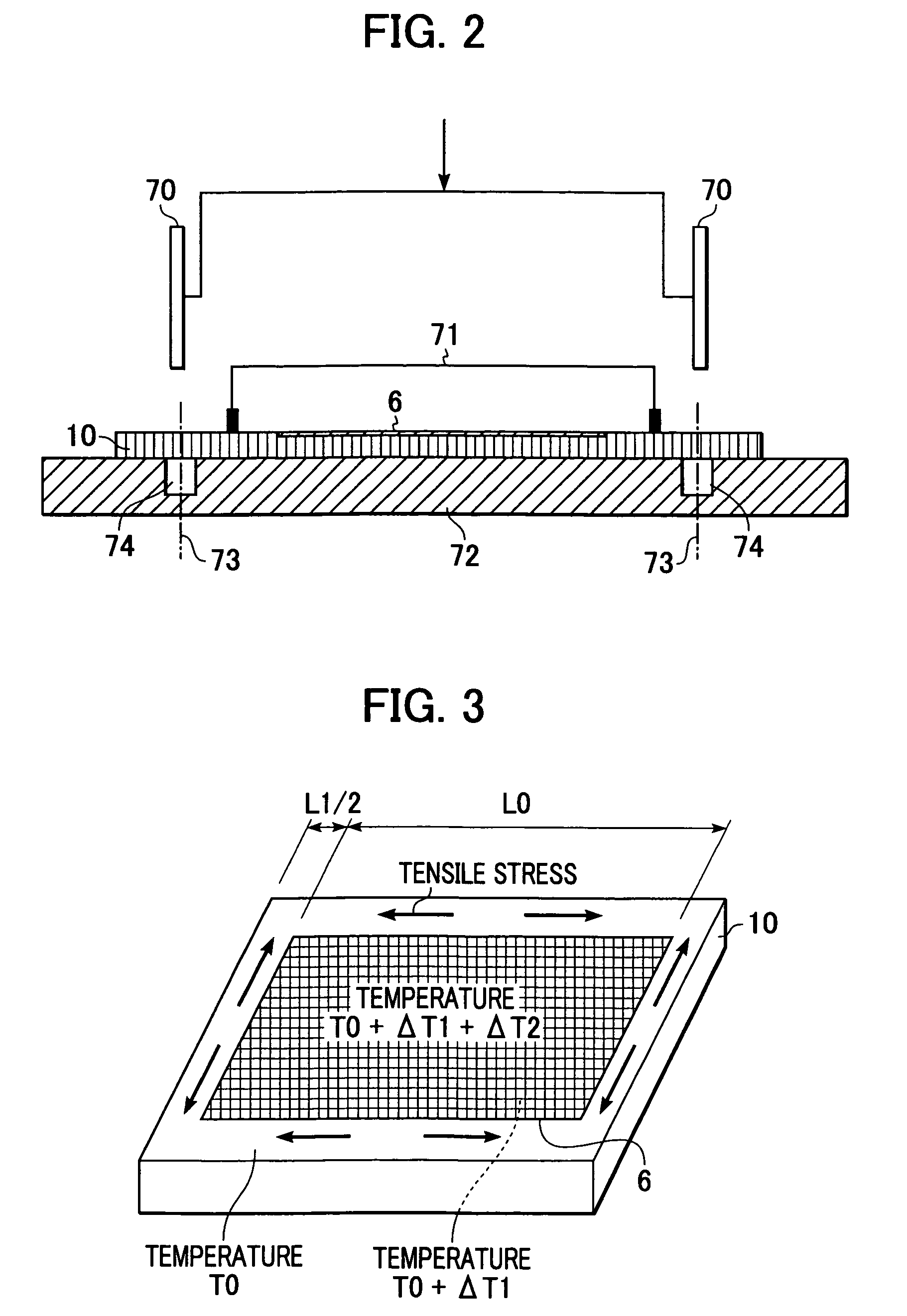

Electrifying method and manufacturing method of electron-source substrate

InactiveUS6972203B2Avoid crackingExcellent characteristicsElectrode assembly support/mounting/spacing/insulationSemiconductor/solid-state device manufacturingElectron sourceYoung's modulus

A method according to the present invention is for electrifying a plurality of electric conductors arranged on a substrate including the step of setting an average temperature difference during electrifying processing between a region S0 in that the plurality of electric conductors on the substrate are arranged and a circumferential region S1 of the region S0 at 15° C. or more, and the substrate satisfies the relational expression:L1 / L0>EαΔT / σth−1.where L0[m]: the width of the region S0 L1[m]: the width of the region S1 ΔT[K]: the average temperature differenceE[Pa]: the Young's modulus of the substrateα[ / K]: the coefficient of linear thermal expansion of the substrateσth[Pa]: the material constant of the substrate.

Owner:CANON KK

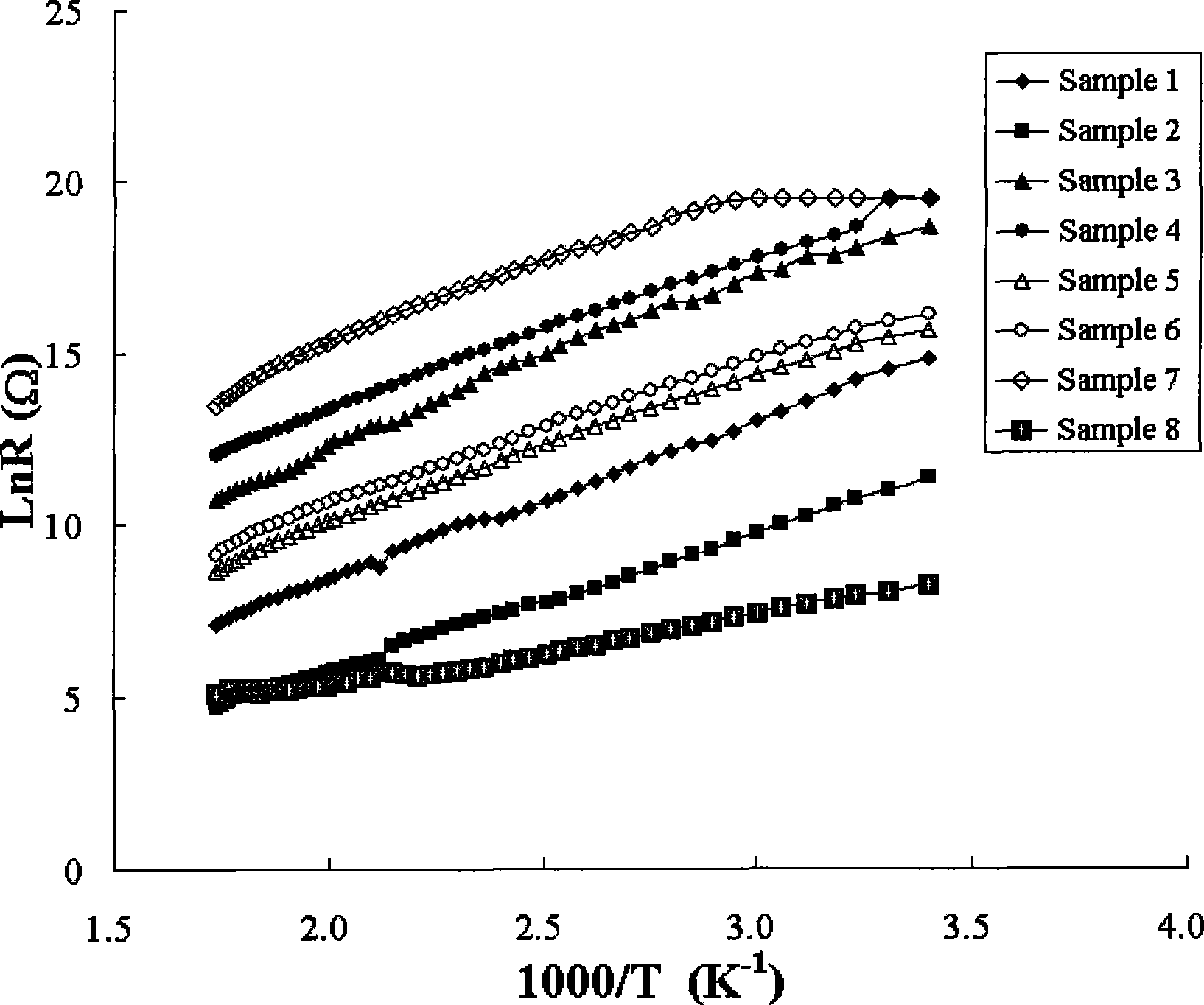

An NTC resistive material and its preparation method

InactiveCN101544493AImprove performance and stabilityAdjustable room temperature resistanceNegative temperature coefficient thermistorsElectrical resistance and conductanceThermistor

The present invention discloses an NTC resistive material and its preparation method. Composition of this material: Ba<1-x>DxTi<1-y-z>Ni<y>MzO3, wherein x=0-0.01; y=0.05-0.5; z=0-0.01, D is a trivalent semiconducting element and contains at least one of the following elements: Bi, La, Sm, Gd, Y, Ho, Nd, Dy and Sc and its content is 0-1% of the total material amount; M is a pentavalent micro-semiconducting element and contains at least one of the following elements: Sb, Nb, Ta and V and its content is 0-1% of the total material amount. The thermistor material of the present invention is characterized by good stability, consistency and repeatability, and controllable resistance value, material constant, resistance temperature coefficient and other electrical properties. The material is applicable to temperature measurement and control and line drop compensation of automobiles, refrigerators and etc.

Owner:CENT SOUTH UNIV

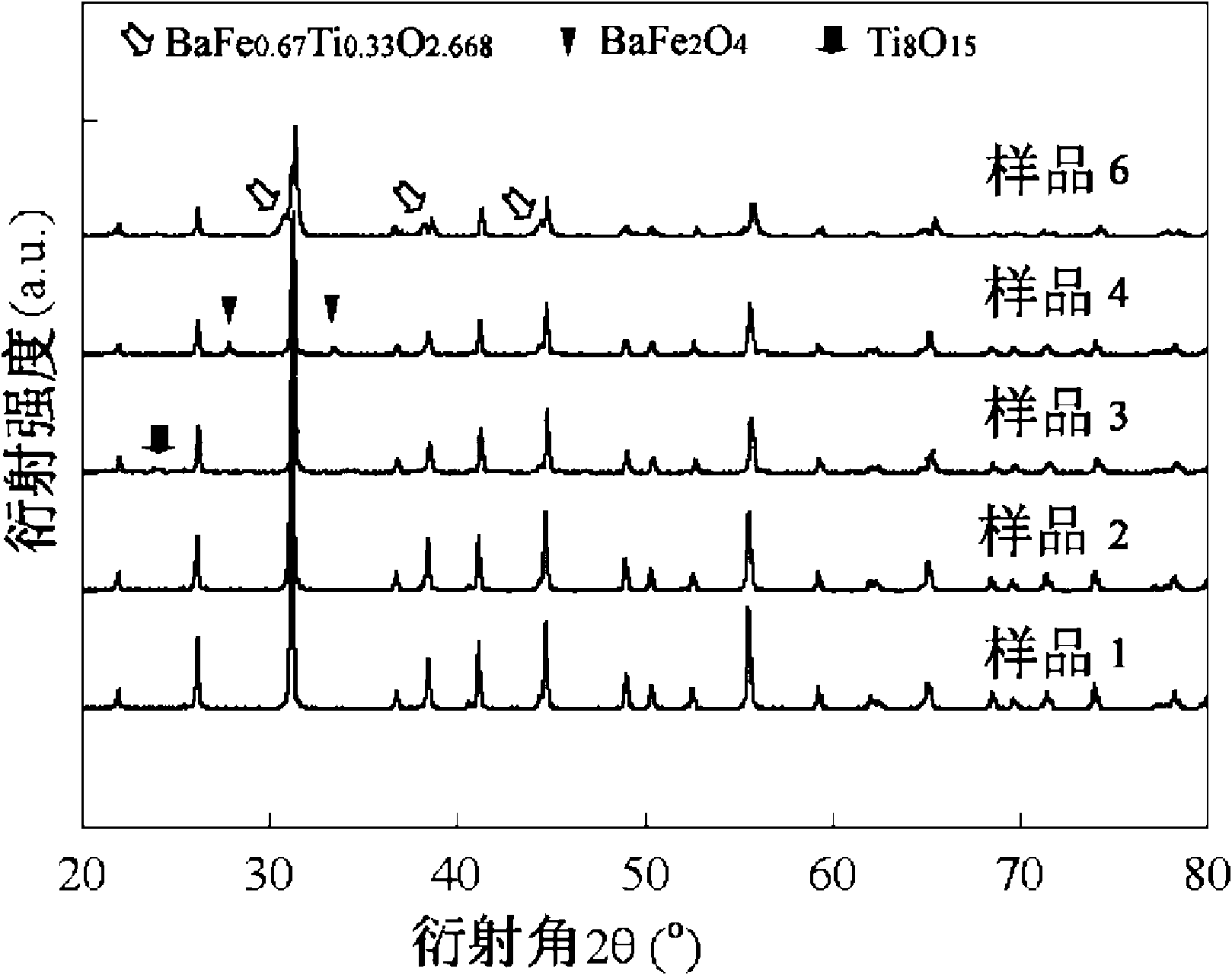

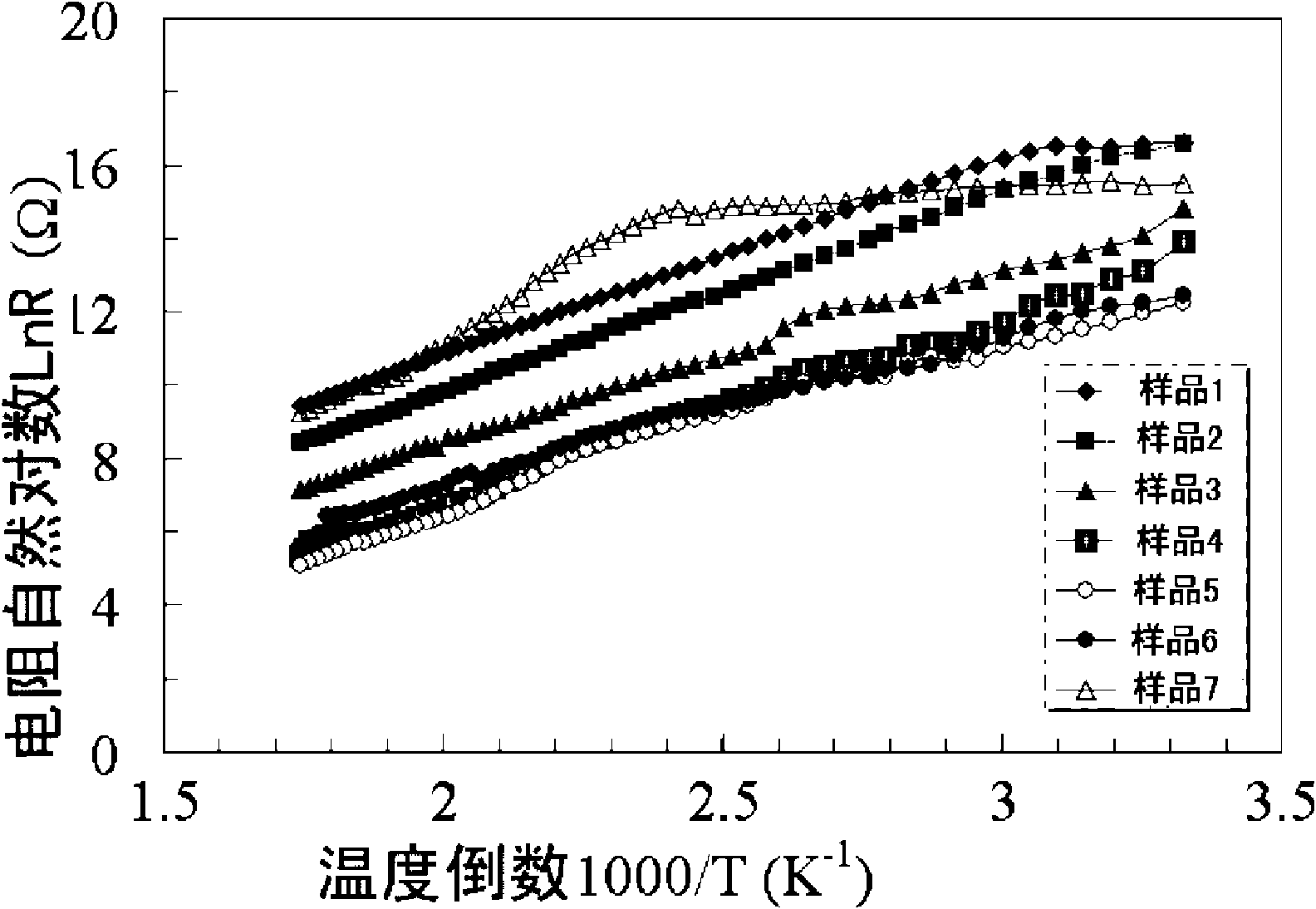

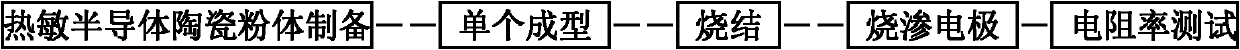

Thermal sensitive ceramic resistance material, resistance element and preparation method of resistance element

InactiveCN101580386AImprove consistencyEase of mass productionNegative temperature coefficient thermistorsSimple componentHeat sensitive

The invention discloses a thermal sensitive ceramic resistance material, a resistance element and a preparation method of the resistance element. The thermal sensitive ceramic resistance material is formed by iron doped with BaTiO3, and the molecular formula is BaTi FeO3; wherein x equals to 0.1 to 1; and the principal crystalline phase of the material is a hexagonal structure. The material of the invention is characterized by simple component design, wide regulating range of components and wide source of raw materials and is suitable for the preparation techniques of multiple ceramic materials; the material only contains one transition metal element of iron and the sintering temperature is lower than the volatilization temperature of the ferriferous oxide, thus effectively avoiding the volatilization problem of the principal component elements at high temperature in the preparation process. The material of the invention has good material constant value, is characterized by good stability, good consistency, good repetitiveness and controllable electrical characteristics such as resistance value, material constant, resistance temperature coefficient and the like, and is applicable to the temperature measurement, control and circuit compensation of automobiles, refrigerators and the like.

Owner:CENT SOUTH UNIV

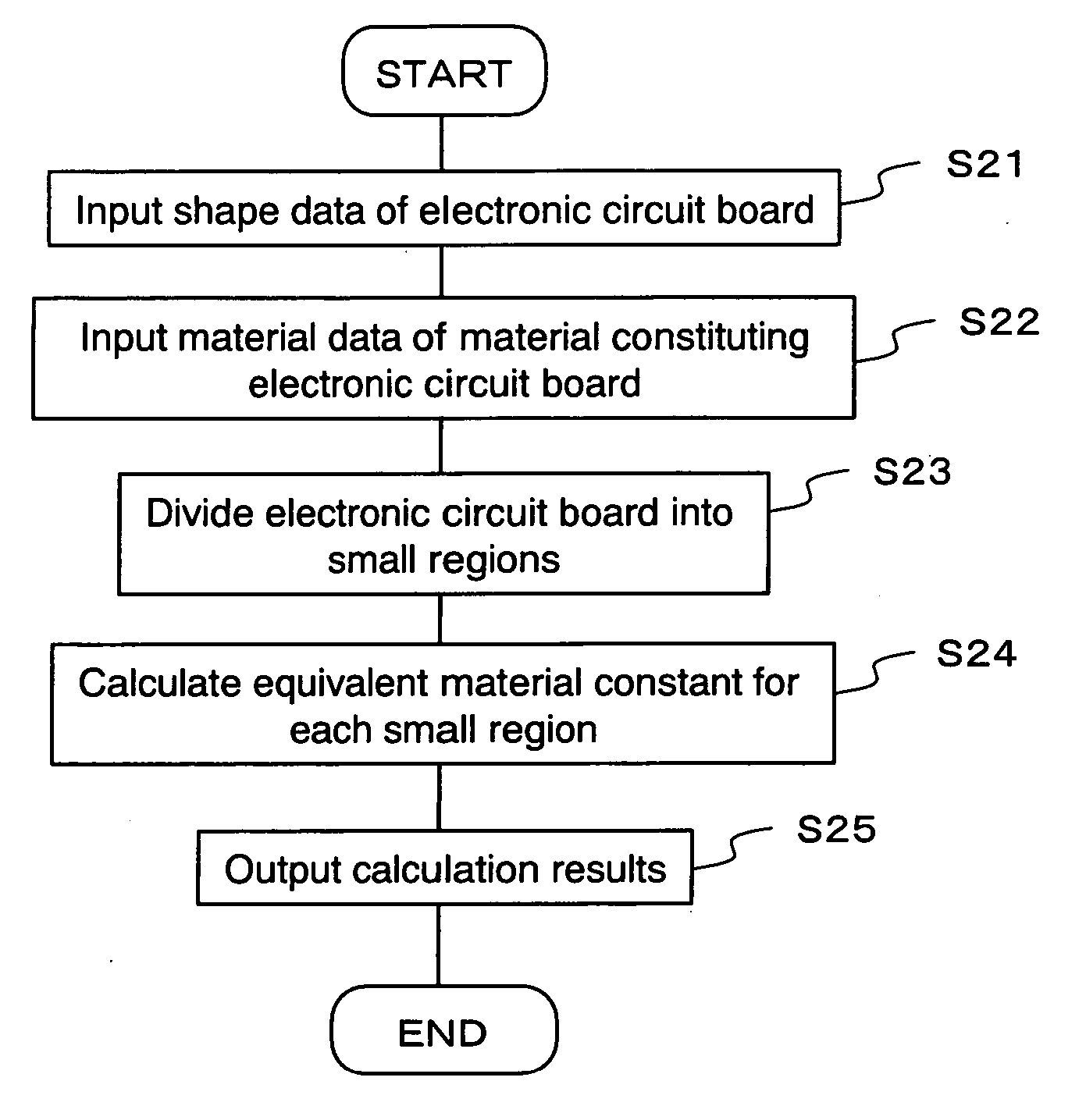

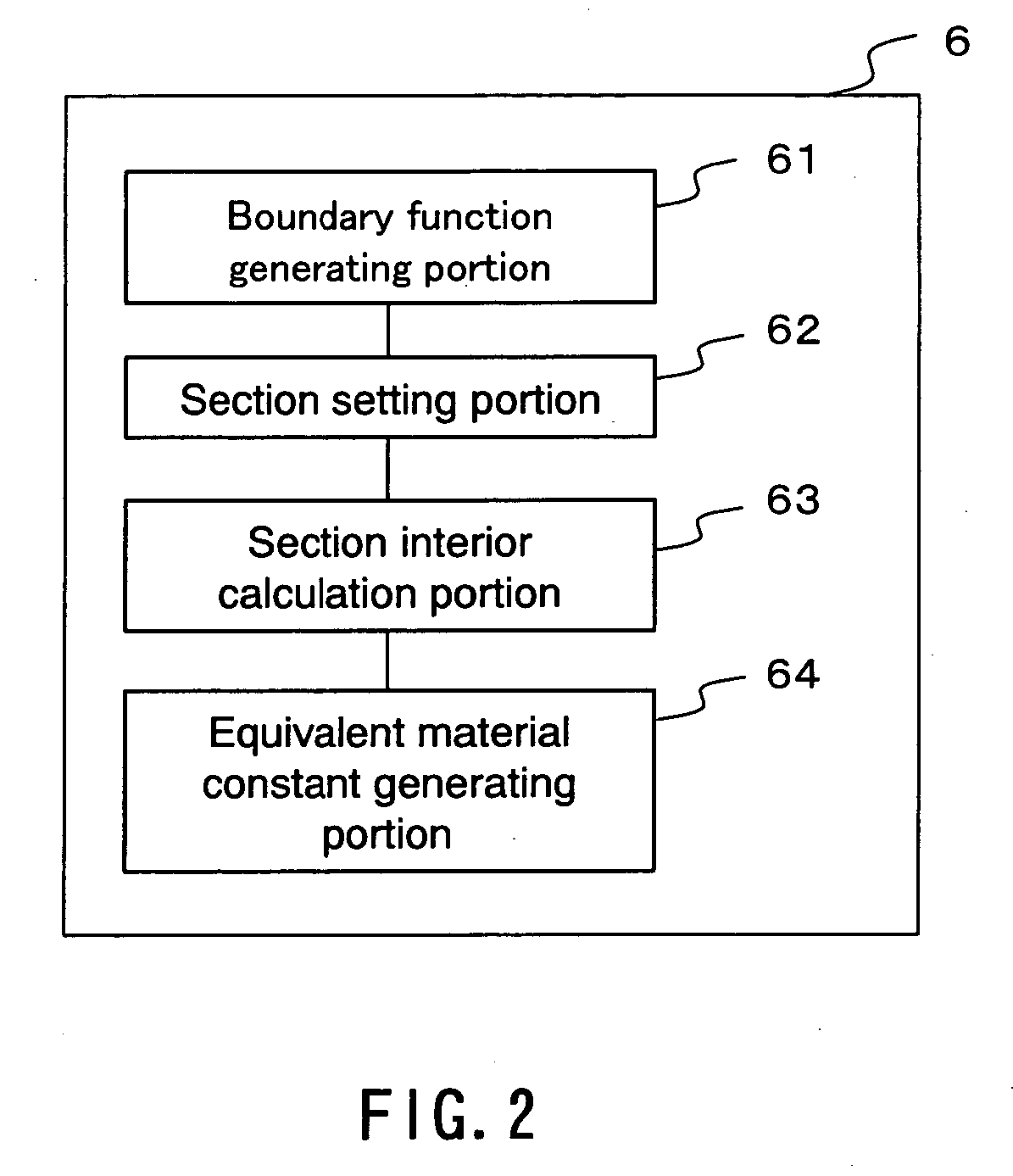

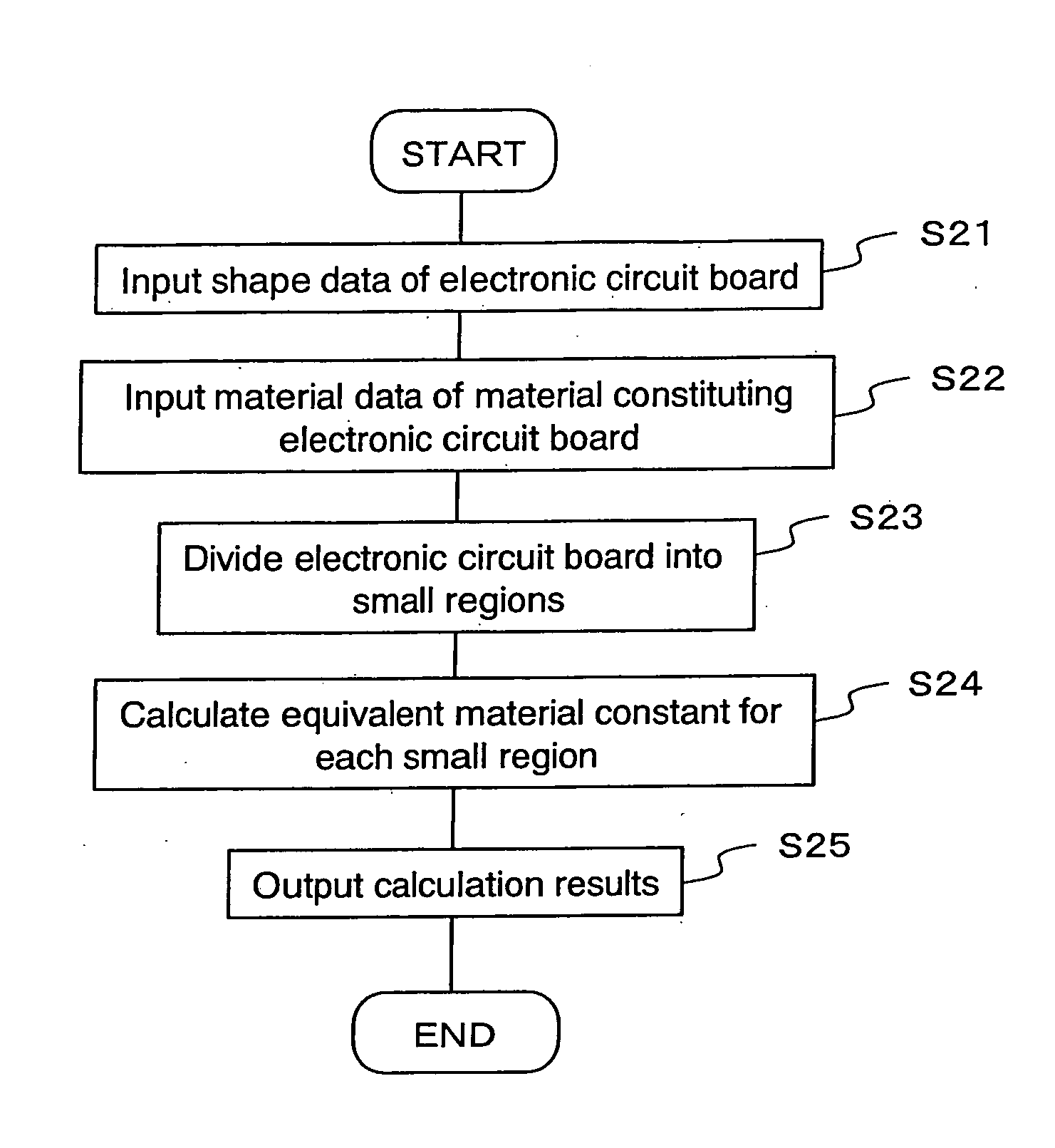

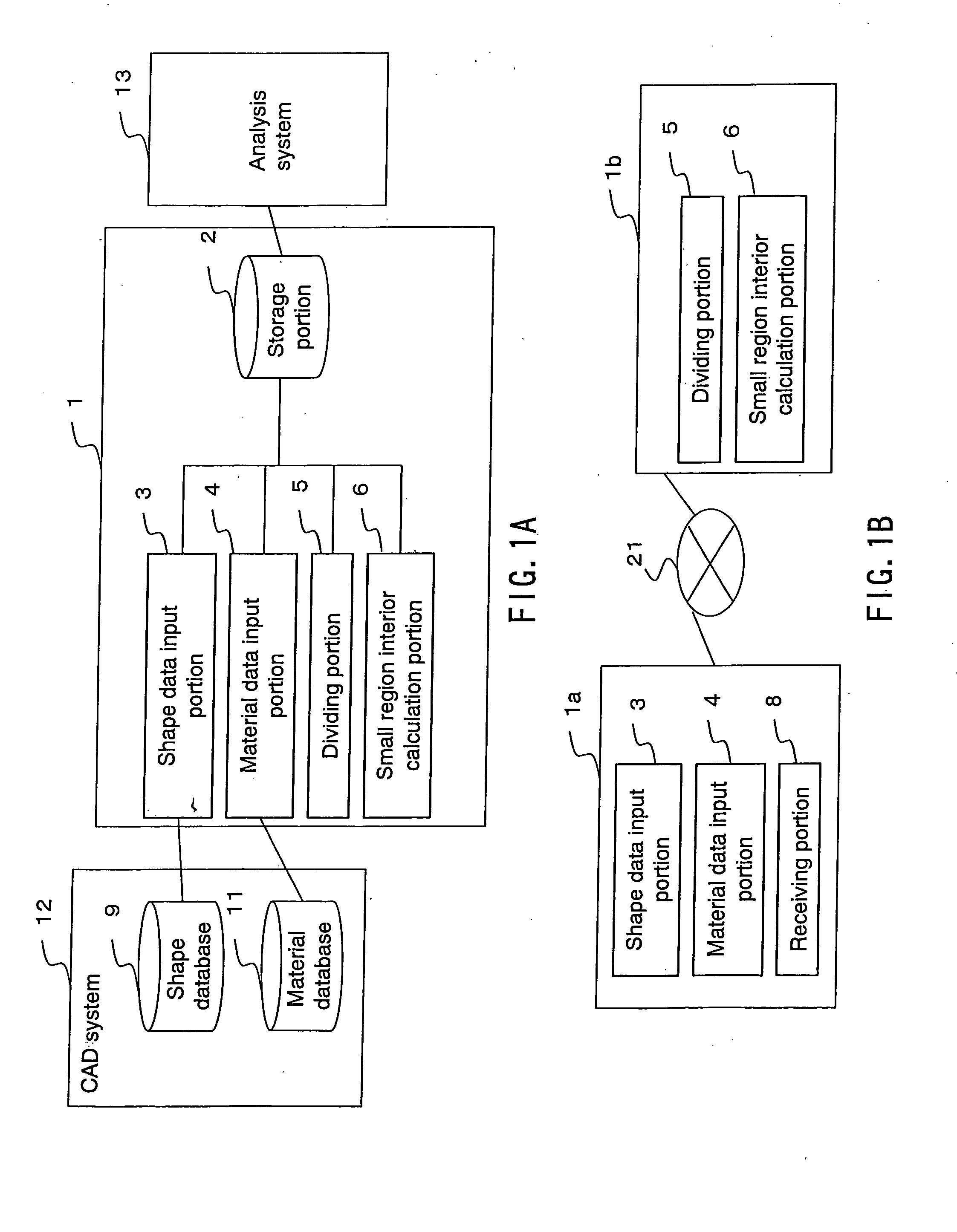

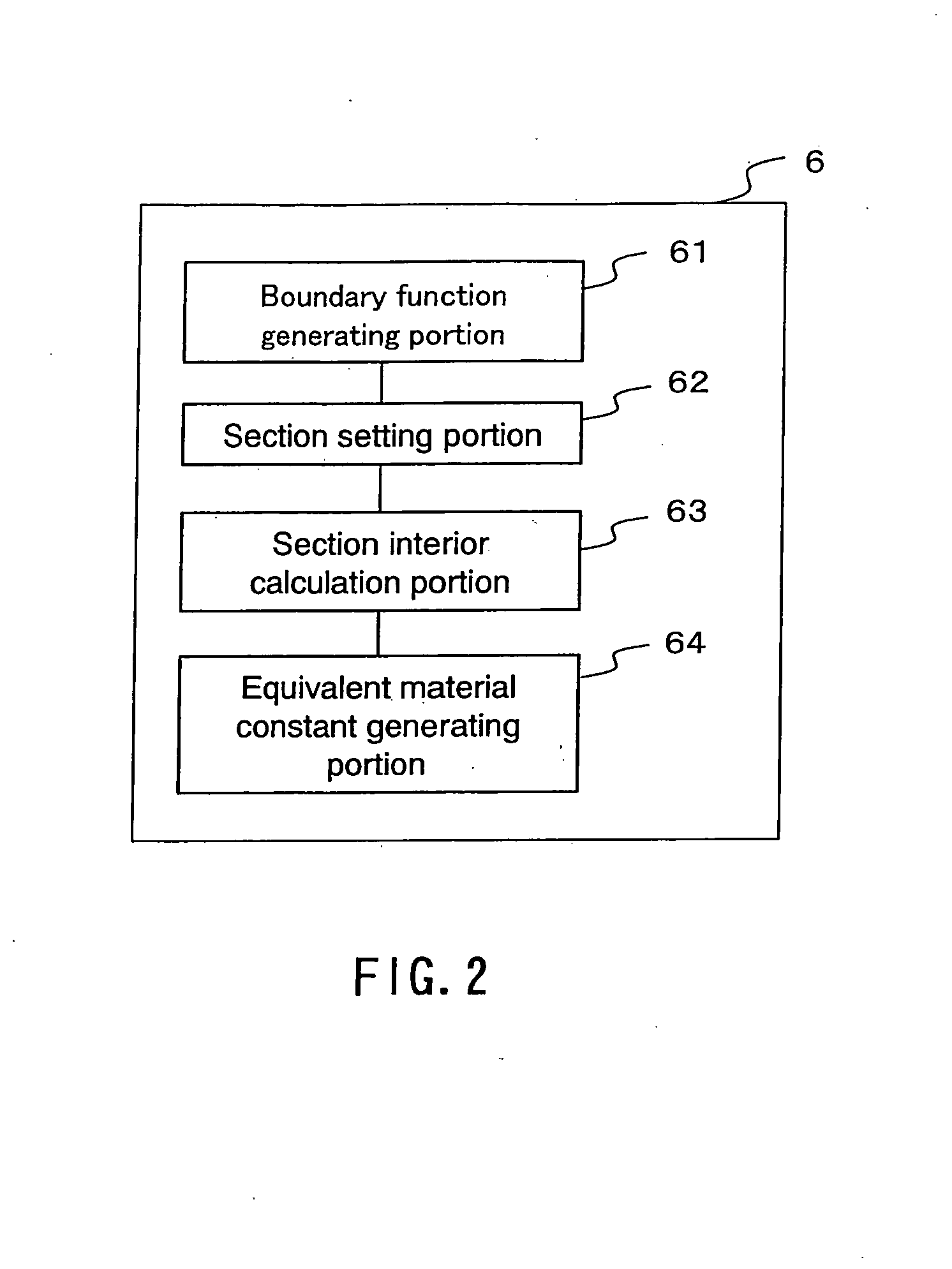

Equivalent material constant calculation system, storage medium storing an equivalent material constant calculation program, equivalent material constant calculation method, design system, and structure manufacturing method

InactiveUS20060095493A1Improve effectivenessImprove accuracyMaterial thermal conductivityCAD circuit designMulti materialComputer science

An equivalent material constant calculation system that calculates an equivalent material constant of a structure constituted by a plurality of materials includes a shape data input portion that inputs shape data, a material data input portion that inputs material constant data, a dividing portion that divides the structure into a plurality of small regions, and a small region interior calculation portion that calculates equivalent material constants in the small regions, in which the small region interior calculation portion, based on the shape data and material constant data, with a function that includes a value in a variable that expresses a position in at least one direction in the small region, expresses an equivalent material constant for a region that is a portion of a small region, and using the function, calculates an equivalent material constant for the small region with respect to the at least one direction.

Owner:PANASONIC CORP

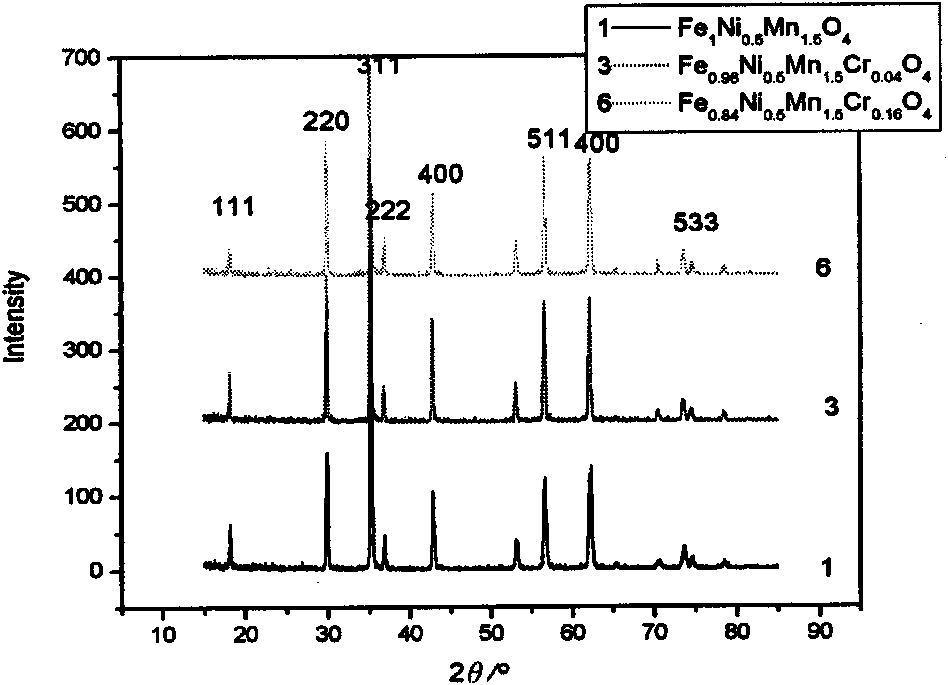

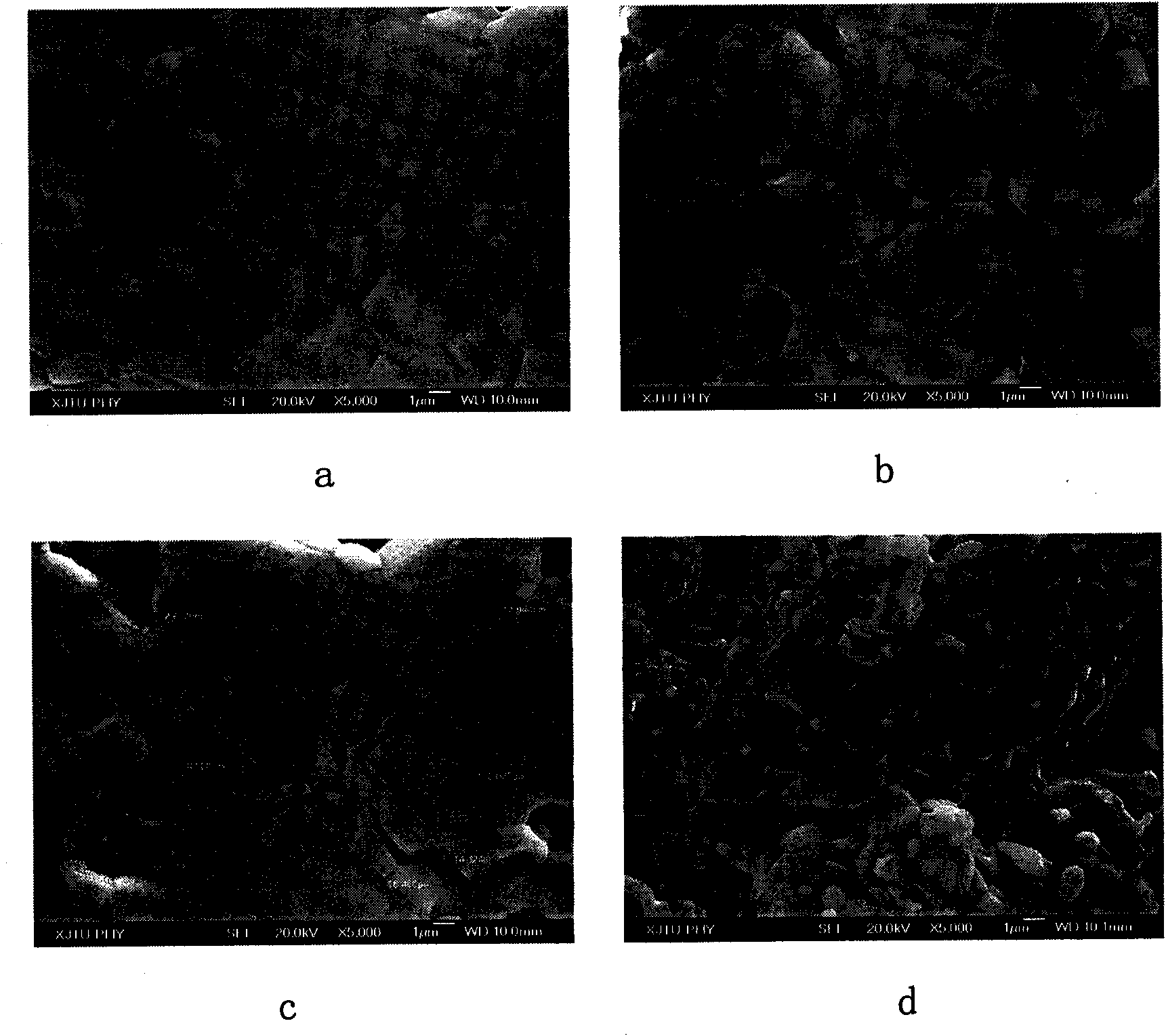

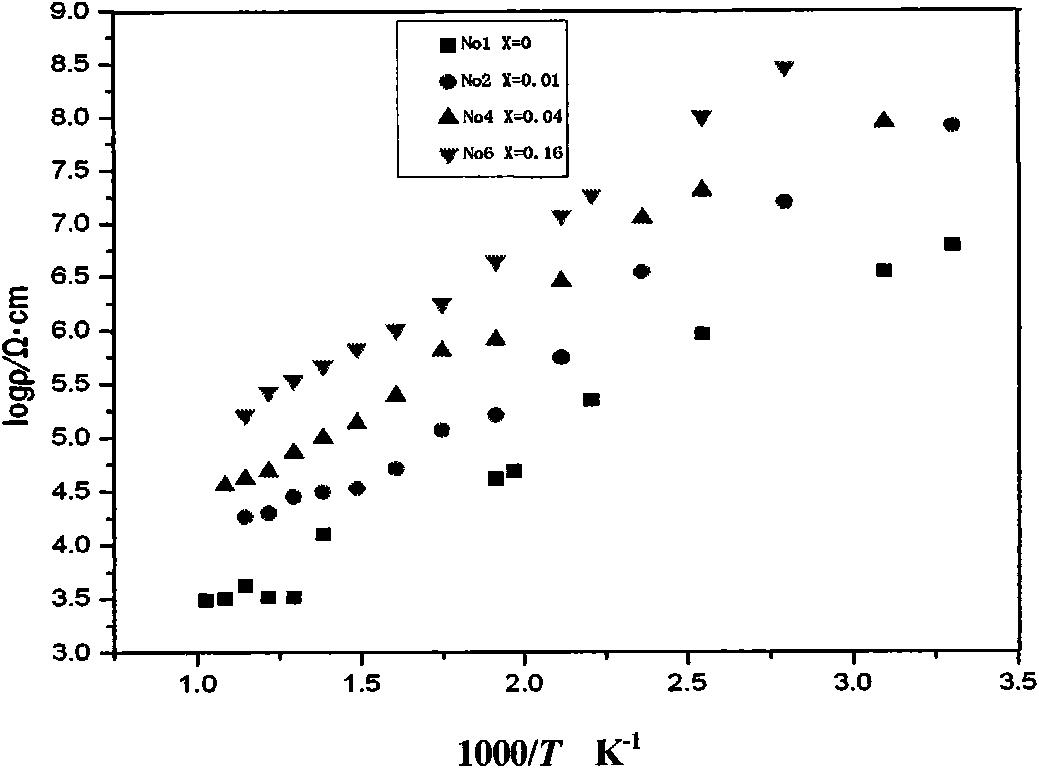

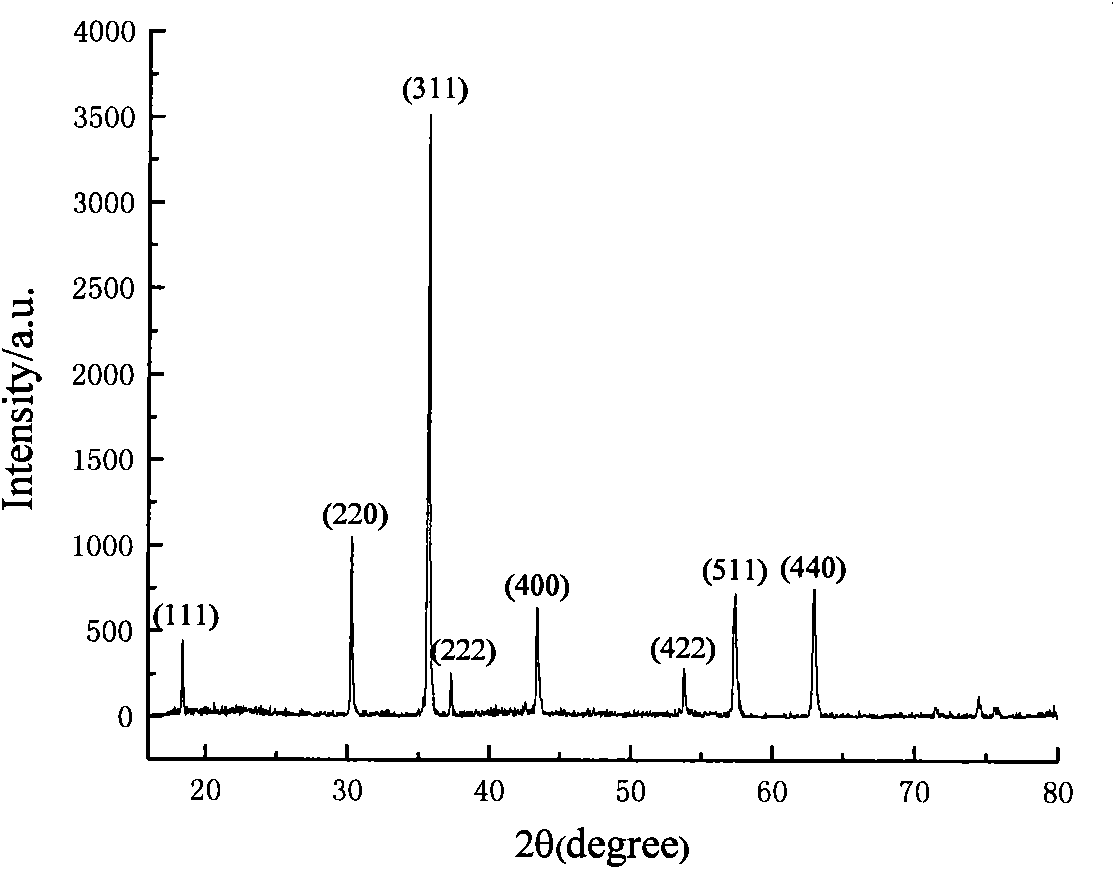

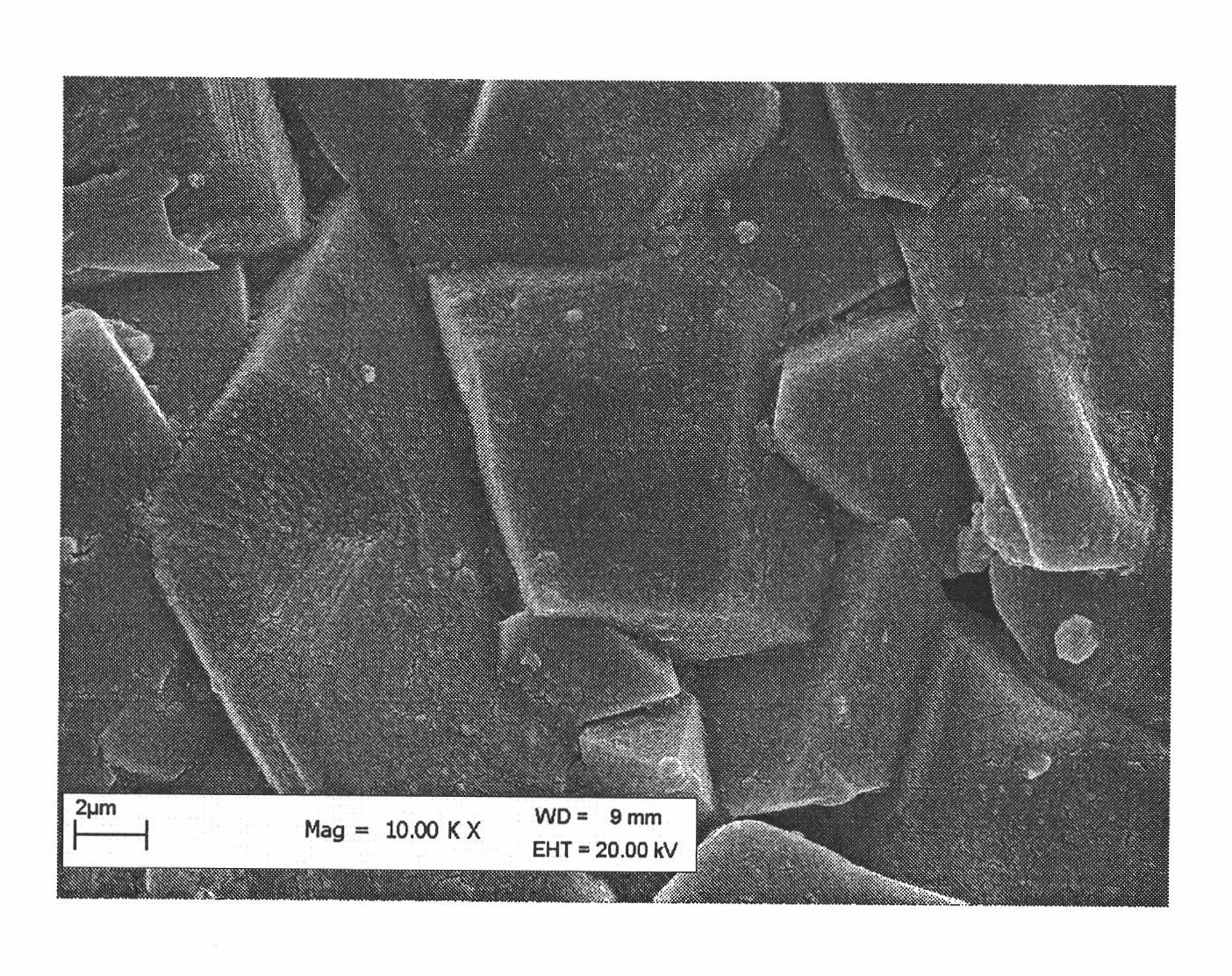

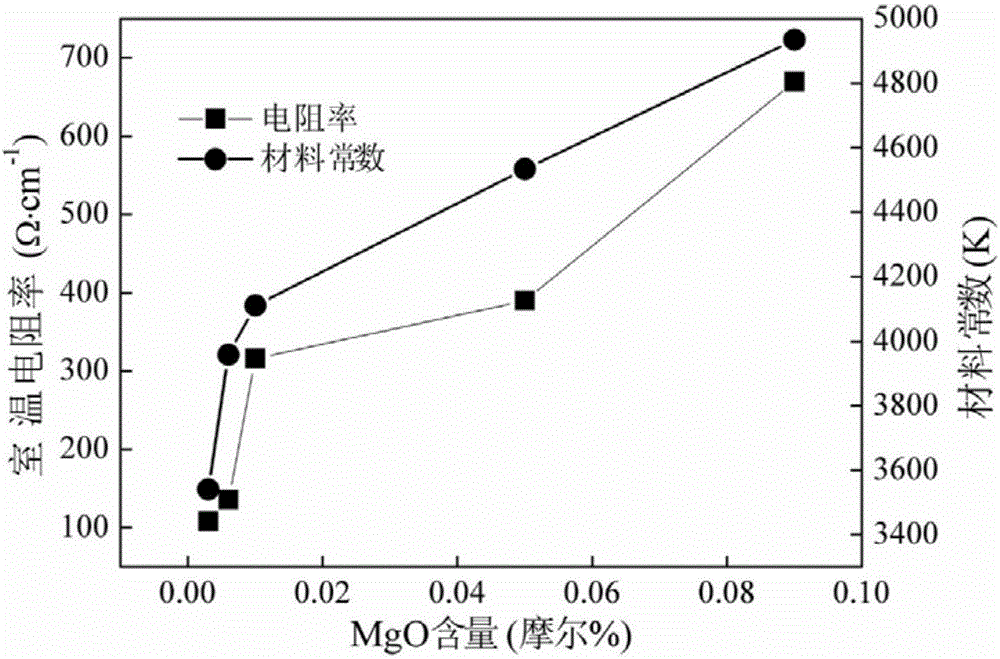

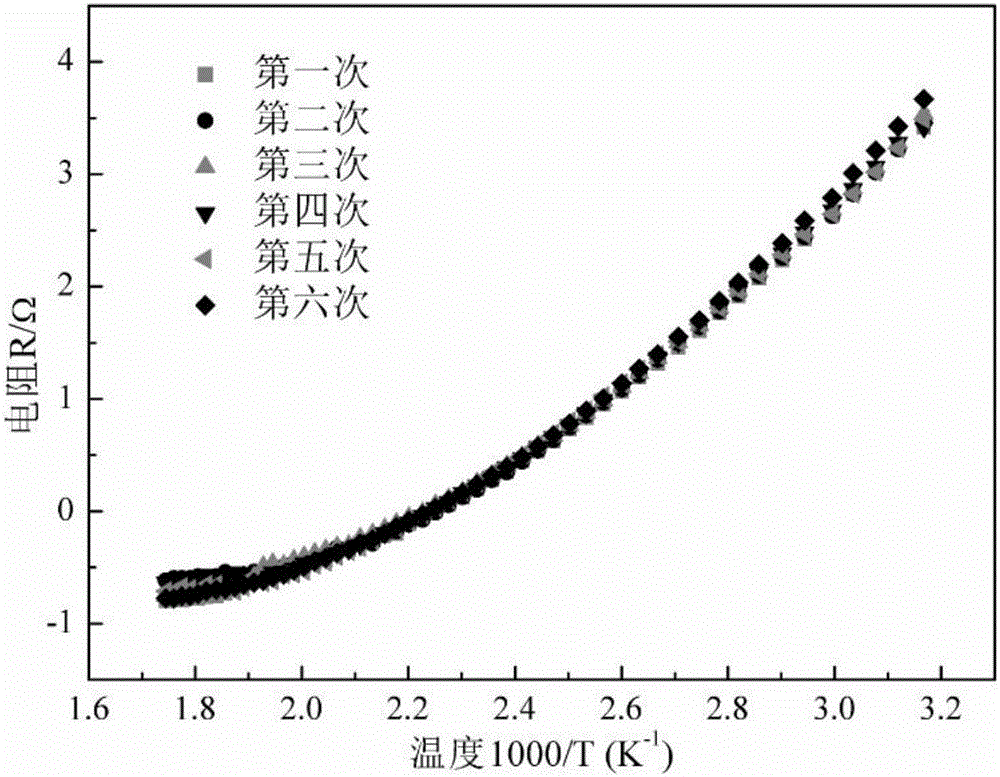

Method for preparing high-temperature NTC heat-sensitive resistance material

InactiveCN101585707AUniform sizeWell-developed grain boundariesNegative temperature coefficient thermistorsElectrical resistance and conductancePorosity

The invention discloses a method for preparing a high-temperature NTC heat-sensitive resistance material. Pure Fe2O3, NiO, MnO2 and Cr2O3 are selected and analyzed, then the materials are sintered according to a chemical formula mixture ratio of Fe[1-x]Ni0.5Mn1.5CrxO4 (x is selected from 0 to 0.16), the unadulterated FeNi0.5Mn1.5O4 basically meets the using requirement as the high-temperature NTC heat-sensitive resistance material, and the adulteration of Cr shows higher material constant B value of about 6,000K and room temperature resistivity change range of 10 to 10 omega / centimeter and achieves the using requirement under high-temperature conditions. The tissue structure characteristics required in the application of the high-temperature NTC material comprise that: the adulteration of little Cr2O3 does not change a phase structure of a matrix, the system with the adulteration amount in a certain range forms a single spinel phase, and no second phase appears; the grain size of the adulterated sample is comparatively even, and the grain boundary growth is comparatively perfect and has no abnormal growing grains; and a sintered sample has low porosity and enough compactness.

Owner:XI AN JIAOTONG UNIV

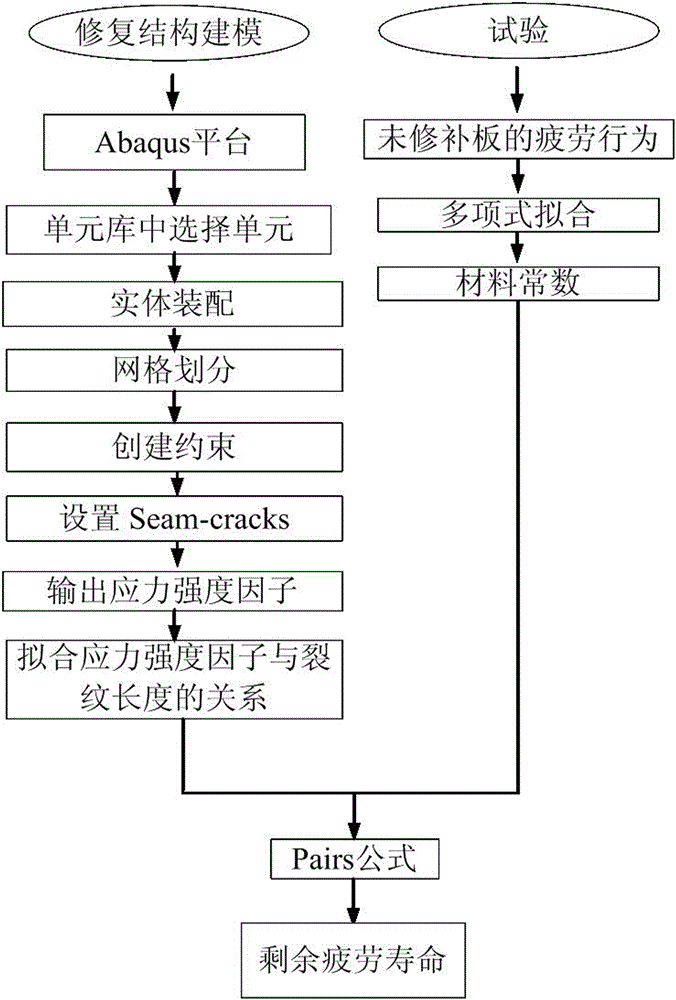

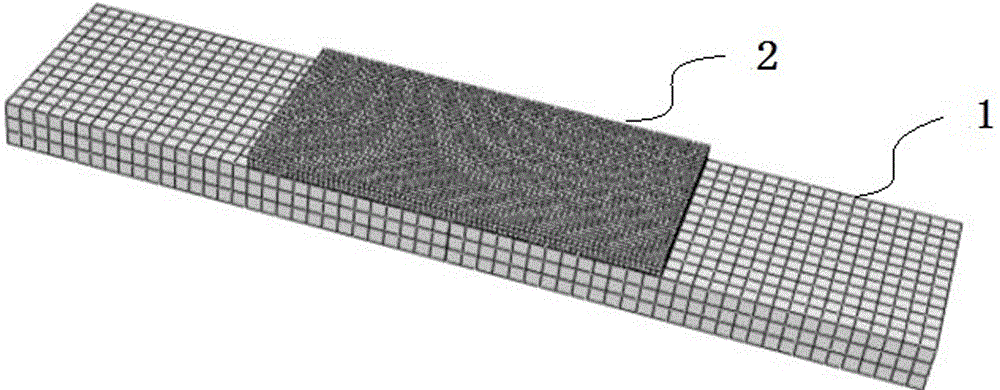

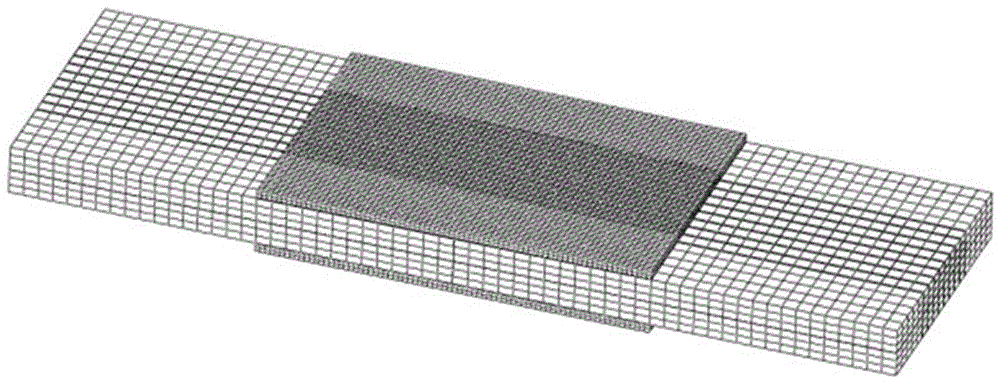

Method for predicting residual fatigue life of composite material adhesive bonding repair structure

ActiveCN106568660AImproving the Prediction Accuracy of Remaining Fatigue LifeImprove forecast accuracyMaterial strength using repeated/pulsating forcesStress intensity factorPredictive methods

The invention provides a method for predicting the residual fatigue life of a composite material adhesive bonding repair structure. The method comprises the following steps: (1) determining the material constants of an unrepaired structure; (2) establishing a model of a repaired structure, after the establishment, assembling entities, dividing grids, and creating constraints; (3) solving the relational expression between the stress intensity factor amplitude and the crack length; (4) according to the breaking tenacity of a metal material, based on the stress intensity factor output by software, determining the final failure crack length of the repaired structure; and (5) substituting the material constants, the final failure crack length, and the relational expression between the stress intensity factor change amplitude and the crack length into Paris formula, and calculating the residual fatigue life of the repaired structure through integration. The calculation steps are simplified, the prediction efficiency on the residual fatigue life of a composite material adhesive bonding repair structure is obviously improved, the calculation cost is reduced, and the development of the composite material adhesive bonding repair technology is promoted.

Owner:QINGDAO CAMPUS AVIATION ENG COLLEGE OF THE PEOPLES LIBERATION ARMY NAVY

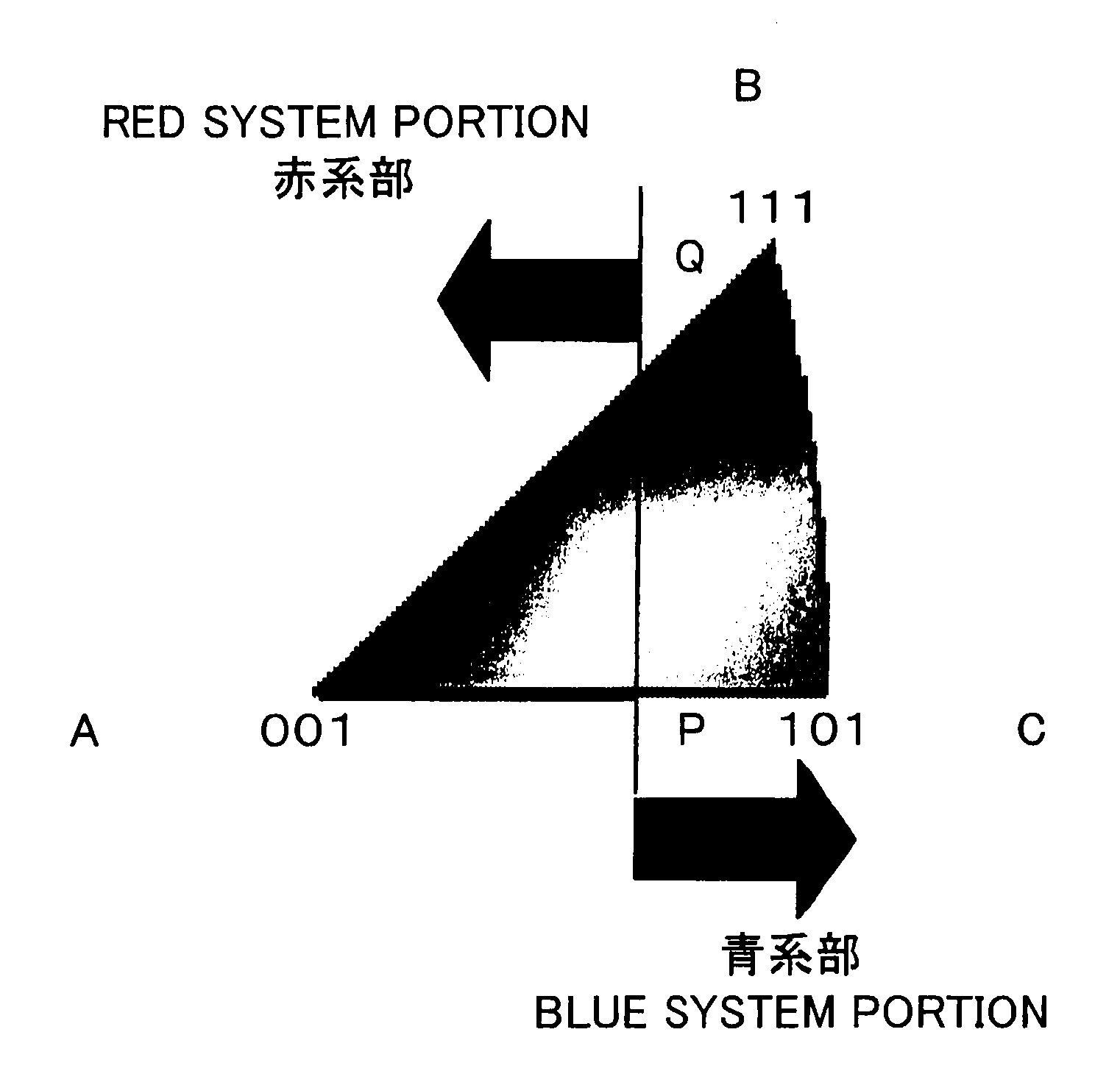

Electrodeposited copper foil and copper clad laminate

InactiveUS20110171491A1Increase flexibilityMaintain good propertiesPig casting plantsPrinted circuit aspectsElectricityX-ray

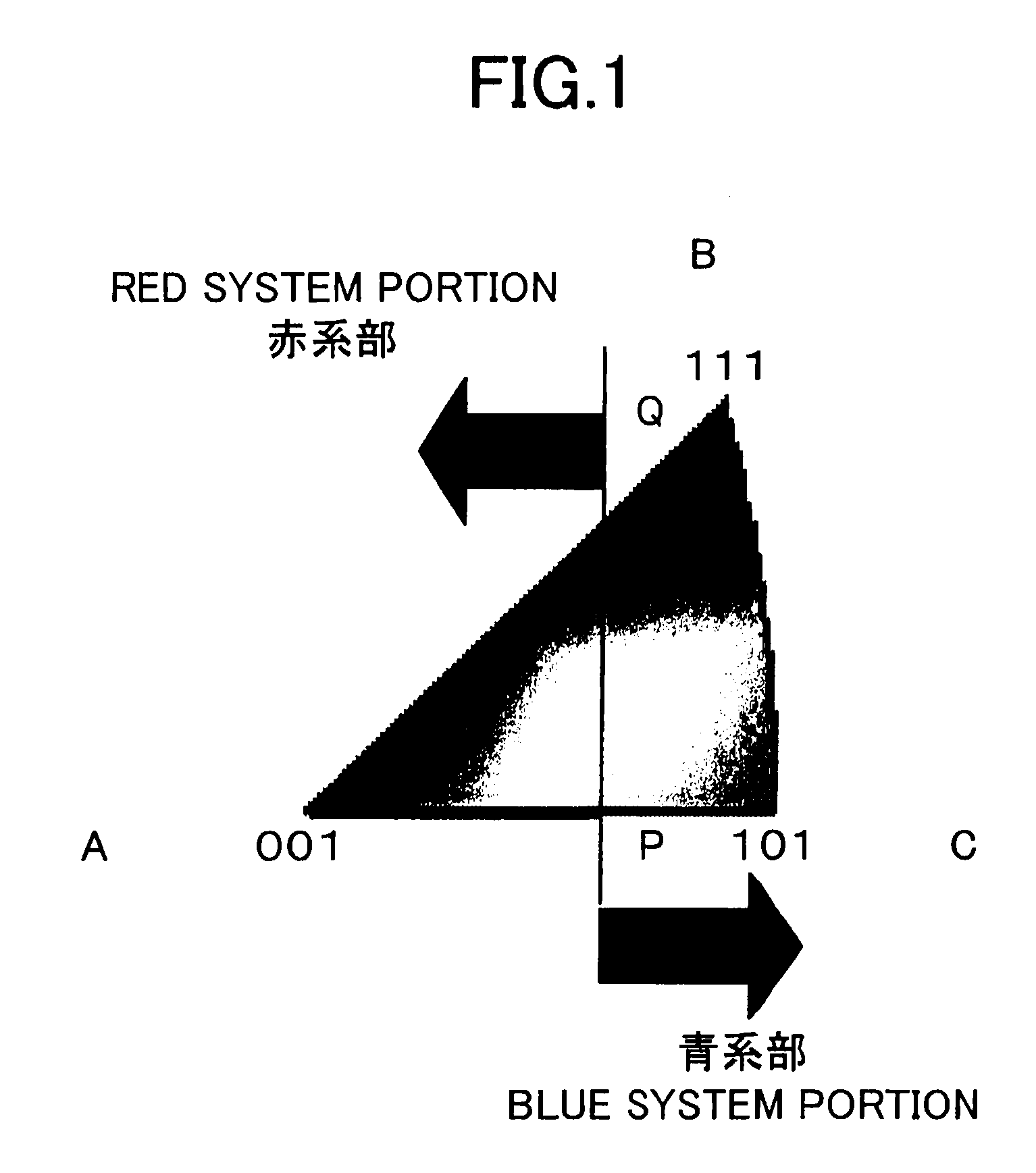

To provide an electrodeposited copper foil having flexibility and bending property equivalent to or better than that of rolled copper foil, an electrodeposited copper foil wherein regarding a crystal structure after heat treatment is applied to the electrodeposited copper foil wherein LMP defined as formula 1 is 9000 or more, either color tone of a red system or a blue system occupies 80% or more in a surface in the EBSP analysis is provided.LMP=(T+273)*(20+Log t) Formula 1wherein 20 is a material constant of copper, T is temperature (° C.), and t is time (Hr).Preferably, relative intensity of (331) face against (111) face is 15 or more in the X-ray diffraction of the electrodeposited copper foil after the heat treatment is applied to the electrodeposited copper foil.

Owner:FURUKAWA ELECTRIC CO LTD

Wide-warm-area negative temperature coefficient thermistor material

InactiveCN102627458AObvious negative temperature coefficient characteristicsImprove performanceNegative temperature coefficient thermistorsNegative temperatureRare earth

The invention relates to a wide-warm-area negative temperature coefficient thermistor material, which uses an analytical pure yttria, ceric oxide, lanthanum oxide, chromium sesquloxide and the manganese dioxide as taw materials. The wide-warm-area negative temperature coefficient thermistor material can be obtained after the raw materials are ground, calcined, formed and sintered at the high temperature. The material is a compound material formed by rare earth oxide of Y2O3 and CeO2 and a perovskite structure of LaCr0.5Mn0.5O3, the material constant is B25 DEG C / 85 DEG C = 2,100K - 2,600 + / - 2%, and a resistance value of 25 DEG C is 3 kliohm - 160 kilohm + / -8%. The thermistor material is stable in performance and good in consistency, has obvious negative temperature coefficient performance at the range of 0 DEG C to 300 DEG C and is suitable for manufacturing wide-warm-area thermal resistors.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Preparation method of laminated chip negative temperature coefficient thermistor

InactiveCN102270531AHigh precisionNegative temperature coefficient thermistorsNegative temperatureCobalt(II,III) oxide

The invention relates to a laminated chip type negative temperature coefficient thermistor and a preparation method thereof. The thermistor uses trimanganese tetroxide, tricobalt tetroxide, nickel trioxide and silicon dioxide as raw materials, and the raw material powder is mechanically The negative temperature coefficient thermal fine powder is synthesized by ball milling method, and then the laminated chip negative temperature coefficient thermistor can be obtained by tape casting (ribbon casting), sintering and coating metal electrode technology, and the obtained laminated negative temperature coefficient thermistor The temperature coefficient thermistor is small in size and high in precision. Its material constant B value is 4030-4105, and the allowable deviation of B value is ±1%. KΩ.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI +1

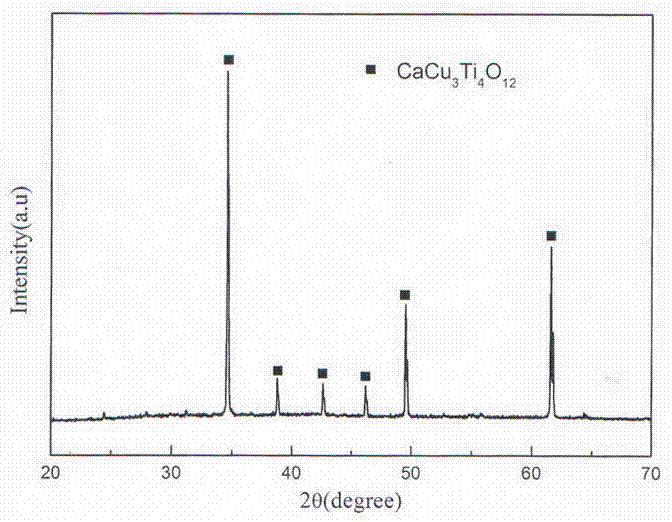

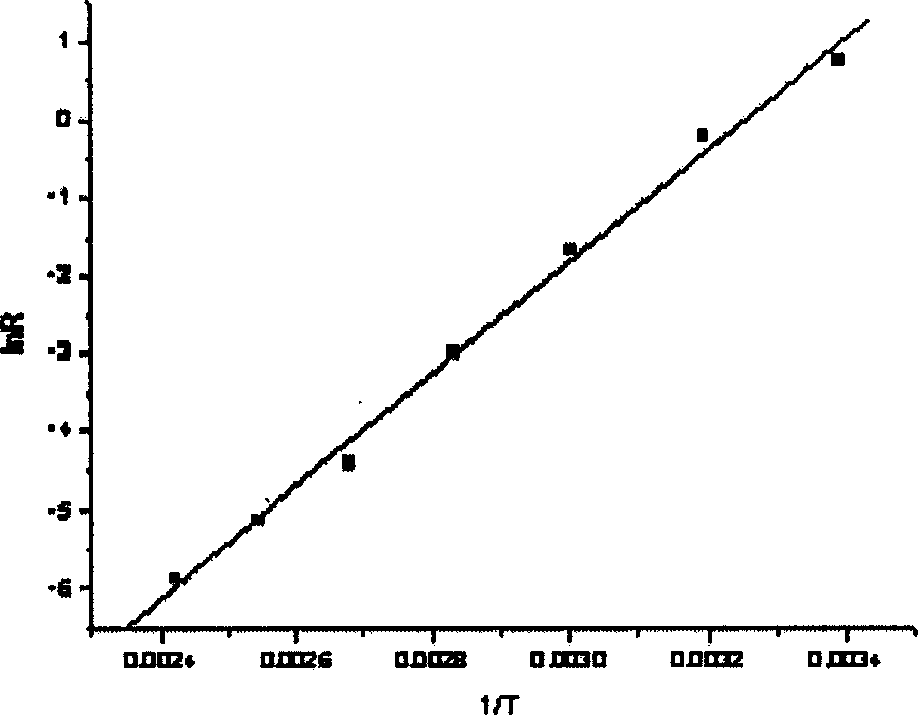

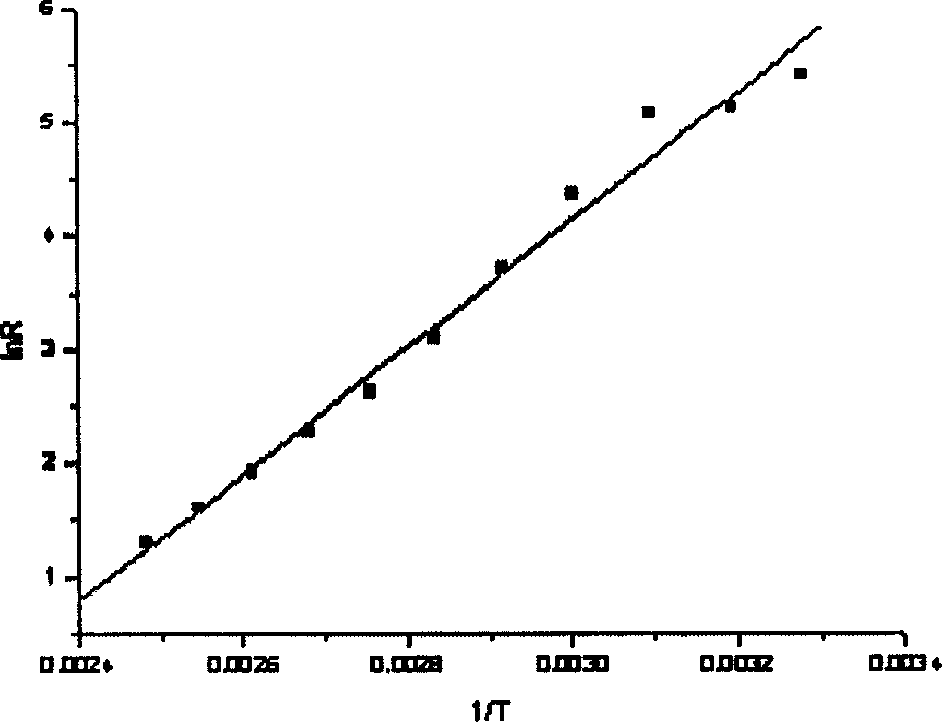

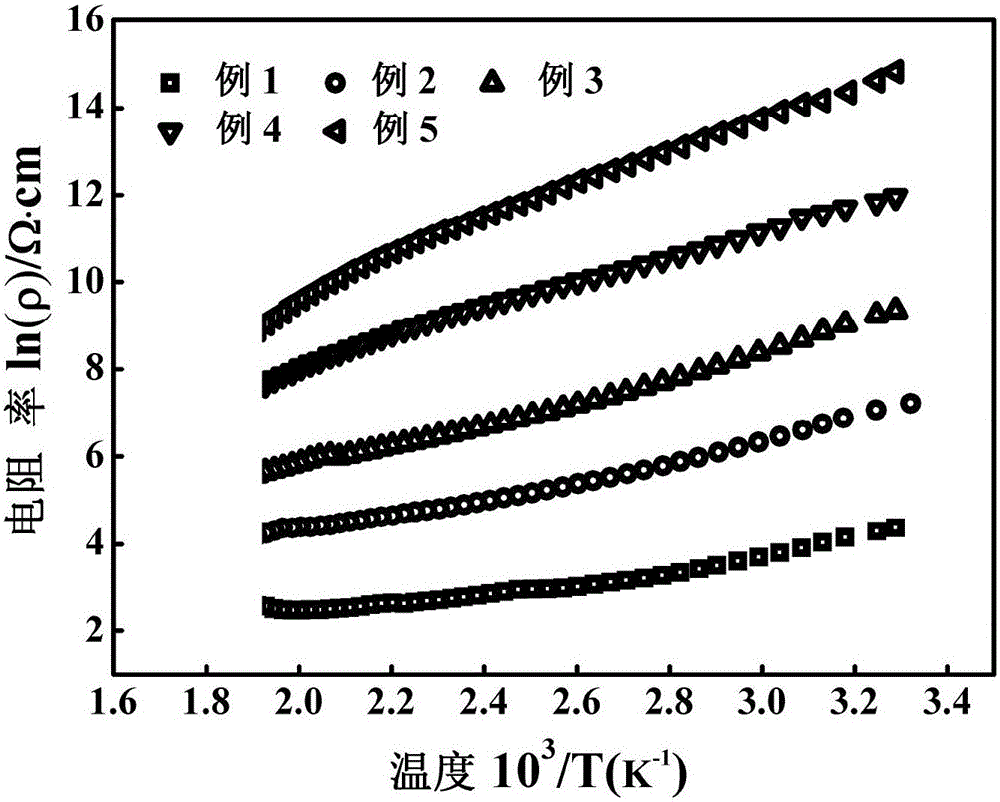

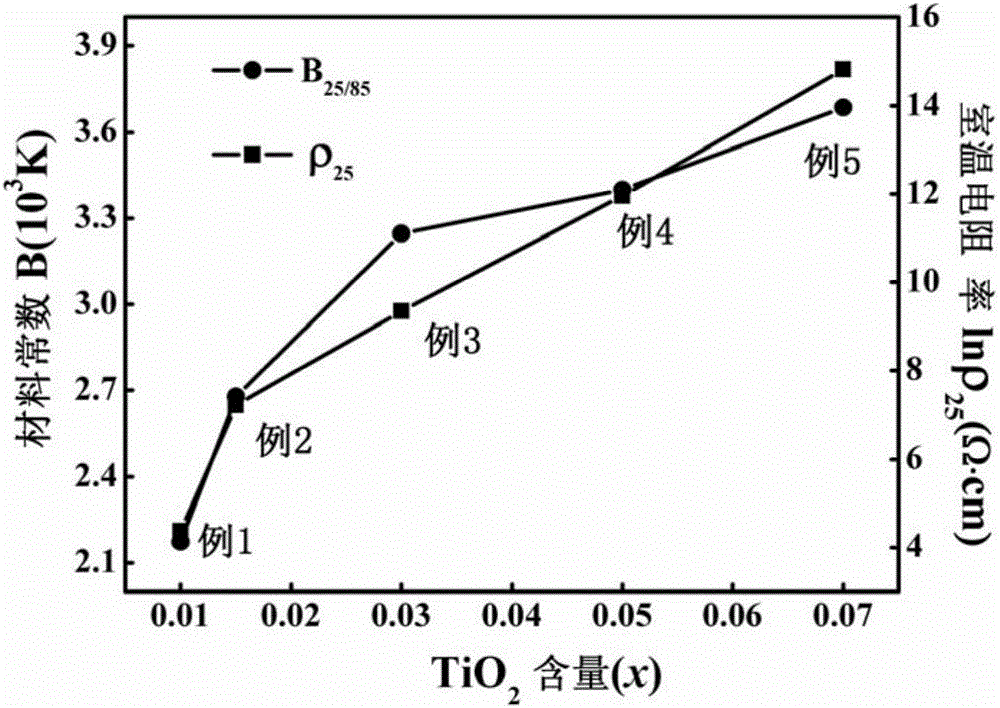

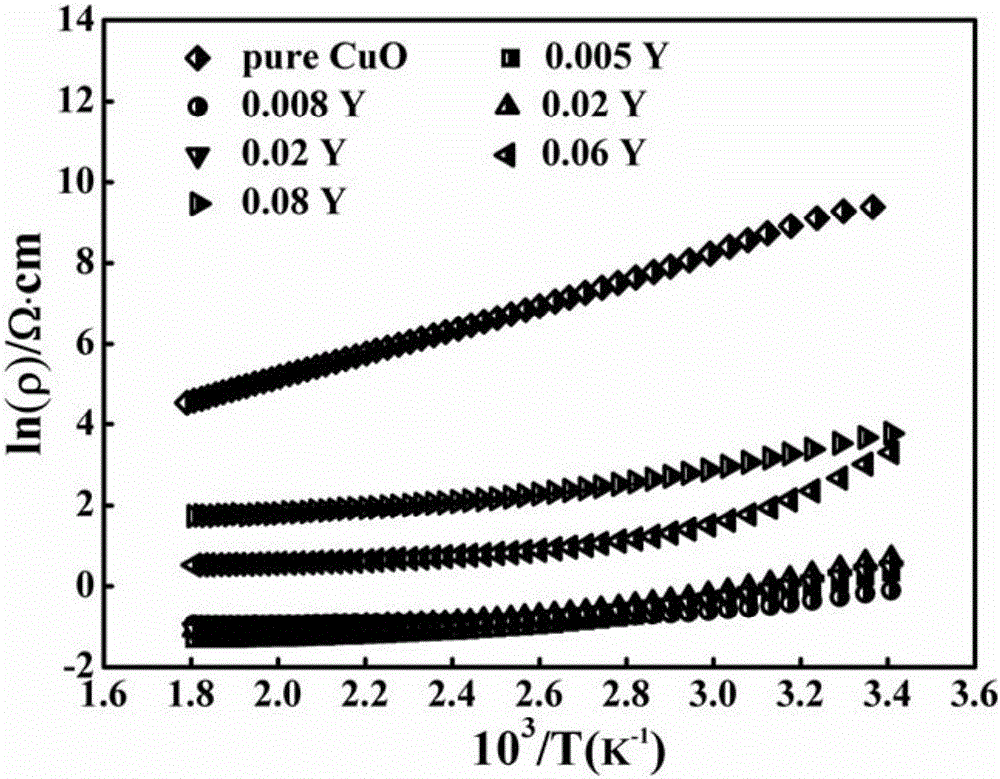

Perovskite type high-temperature thermistor material and preparation method thereof

ActiveCN107324799AImprove performanceImprove consistencyNegative temperature coefficient thermistorsHeat sensitiveCopper oxide

The invention relates to a perovskite type high-temperature thermistor material and a preparation method thereof. The method comprises the following steps: by taking analytically pure calcium carbonate, copper oxide, manganese dioxide, titanium dioxide and yttria as raw materials, mixing and milling; calcining; performing isostatic cool pressing molding; sintering under a high temperature; coating and burning an electrode, thereby acquiring a Ca(1-x)YxCu2.5Mn0.5Ti4O12 (x more than or equal to 0 but less than or equal to 0.1) thermal sensitive ceramic material with a perovskite structure, wherein the material constant is B300 DEG C / 500 DEG C=6800K-7700K and the specific resistance at 25 DEG C is 1.09*10<7>omegacm-3.60*10<7>omegacm. The thermistor material prepared according to the invention has an obvious negative temperature coefficient characteristic within the scope of 25 DEG C-800 DEG C; the electrical property of the material system is stable; and the material is consistent and is suitable for the manufacturing of a high-temperature thermistor.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Negative temperature coefficient (NTC) thermosensitive resistor material

InactiveCN102682944AAvoid the needImprove linearityNegative temperature coefficient thermistorsHigh resistanceMetallurgy

The invention discloses a negative temperature coefficient (NTC) thermosensitive resistor material which comprises, by weight, 20-40% of Mn2O3, 15-20% of Co2O3, 5-15% of Ni2O3, 20-50% of MgO and 2-8% of Al2O3. The ingredients of the NTC thermosensitive resistor material are mixed, and then ethanol, a binding agent and a dispersing agent are added into a mixture to prepare slurry. The slurry is sequentially subjected to casting molding, drying, separation, cutting, glue ejection and sintering to obtain a ceramic chip, and NTC thermosensitive resistors with 450-600 (kilohm.mm) of resistivity rho and 3800 K-3900 K of material constant B are obtained after electrode manufacture. The NTC thermosensitive resistor material has the advantages of being good in linearity, being conveniently applied to the temperature measuring industry, being capable of being manufactured into the high-resistance-value low-B-value thermosensitive resistors, being used simultaneously at high temperature and at low temperature, and capable of meeting the using requirements of special customers so as to avoid the situation that the resistors are required to be connected in series when a high temperature section has a small resistance value and a weak signal.

Owner:JURONG BOYUAN ELECTRONICS

Thermistor with low resistance value, high B value and negative temperature coefficient

ActiveCN102682942AMeet the needs of useImprove linearityNegative temperature coefficient thermistorsNegative temperatureThermistor

The invention discloses a thermistor with a low resistance value, a high B value and a negative temperature coefficient, comprising the following components in percentage by weight: 30-50% of Mn2O3, 20-40% of Co2O3, 5-8% of CuO, 1-5% of La2O3, 1-5% of MgO, 1-5% of CaO, 1-5% of ZrO2 and 2-3% of SiO2. The thermistor has the advantages that (1) the thermistor is better in linearity and is conveniently applied to a temperature measurement industry; (2) the low resistance value and the high B value can be realized by using the formula, i.e., the resistivity rho can be up to 15-40 (kohm.mm) when a material constant B value is up to 4500-4700K; (3) the thermistor can be used within a wide low-temperature and high-temperature range; and (4) because of large material constant B value and high sensitivity, the thermistor can also be used by a special customer requiring low temperature, high temperature and a resistance value.

Owner:JURONG BOYUAN ELECTRONICS

Temperature sensing material with negative temperature coefficient effect and method for preparing same

InactiveCN1629215AHas resistance valueHas a temperature coefficient of resistanceHeat-exchange elementsTemperature controlElectrical resistance and conductance

The invention provides a temperature sensing material with negative temperature coefficient effect and method for preparing process, wherein the NTC material comprises polymer, temperature-sensitive organic-inorganic composite powder and auxiliary agent, wherein the temperature on certain spot of the temperature-sensitive material changes, the resistance will be lowered substantially, thus the value of resistance of the detecting circuit will be changed greatly. The conductivity process of the temperature-sensitive material is realized through carrier supply by the temperature-sensitive organic-inorganic composite powder.

Owner:FUDAN UNIV

Equivalent material constant calculation system, storage medium storing an equivalent material constant calculation program, equivalent material constant calculation method, design system, and structure manufacturing method

InactiveUS20080183322A1Improve effectivenessImprove accuracyMaterial thermal conductivityCAD circuit designMulti materialComputer science

An equivalent material constant calculation system that calculates an equivalent material constant of a structure constituted by a plurality of materials includes a shape data input portion that inputs shape data, a material data input portion that inputs material constant data, a dividing portion that divides the structure into a plurality of small regions, and a small region interior calculation portion that calculates equivalent material constants in the small regions, in which the small region interior calculation portion, based on the shape data and material constant data, with a function that includes a value in a variable that expresses a position in at least one direction in the small region, expresses an equivalent material constant for a region that is a portion of a small region, and using the function, calculates an equivalent material constant for the small region with respect to the at least one direction.

Owner:PANASONIC CORP

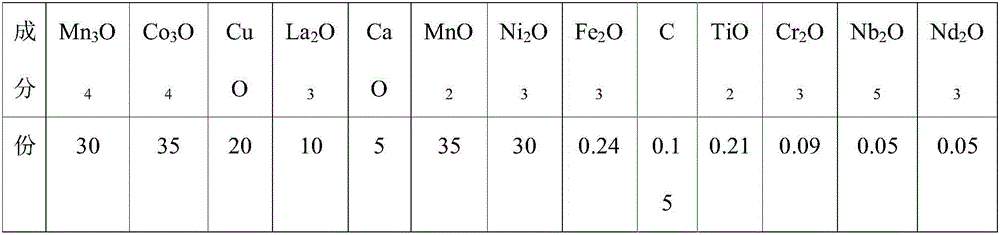

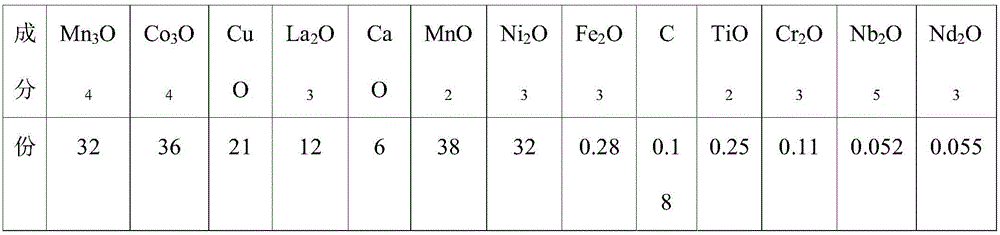

Thermal sensitive ceramic material with low electrical resistivity and negative temperature coefficient and preparation method thereof

InactiveCN105753454ALow resistivityImprove stabilityNegative temperature coefficient thermistorsPorosityPower flow

The invention discloses a thermal sensitive ceramic material with low electrical resistivity and a negative temperature coefficient and a preparation method thereof. The thermal sensitive ceramic material is prepared from the following raw materials in parts by weight: 30-40 parts of Mn3O4, 35-40 parts of Co3O4, 20-25 parts of CuO, 10-20 parts of La2O3, 5-10 parts of CaO, 35-45 parts of MnO2, 30-40 parts of Ni2O3, 0.24-0.4 part of Fe2O3, 0.15-0.25 part of C, 0.21-0.35 part of TiO2, 0.09-0.15 part of Cr2O3, 0.05-0.06 part of Nb2O5 and 0.05-0.07 part of Nd2O3. The obtained thermal sensitive ceramic material is capable of achieving relatively small electrical resistivity under a condition of slightly influencing a material constant B value, reducing the porosity, and improving the pulse performance of the material in a situation of inhibiting a surge current field.

Owner:刘操

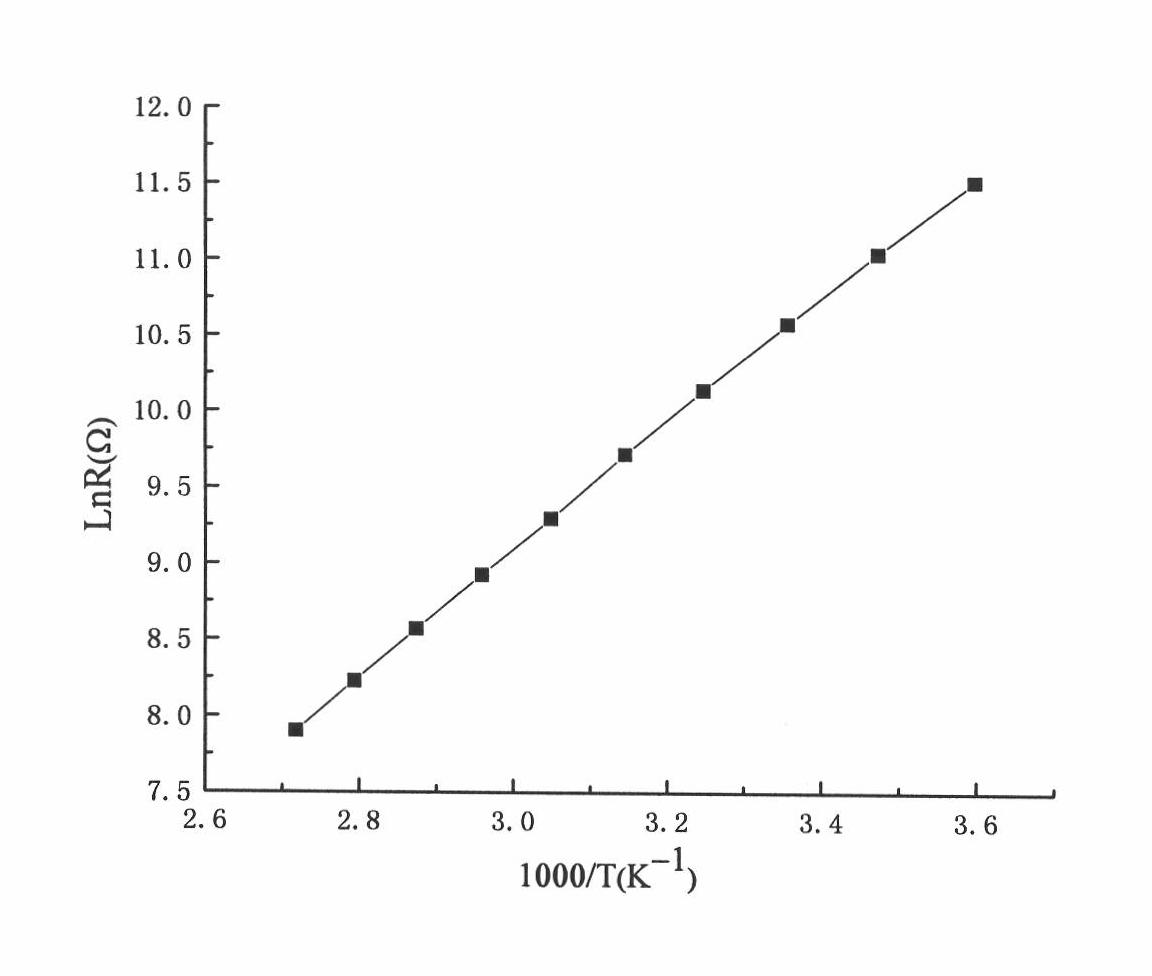

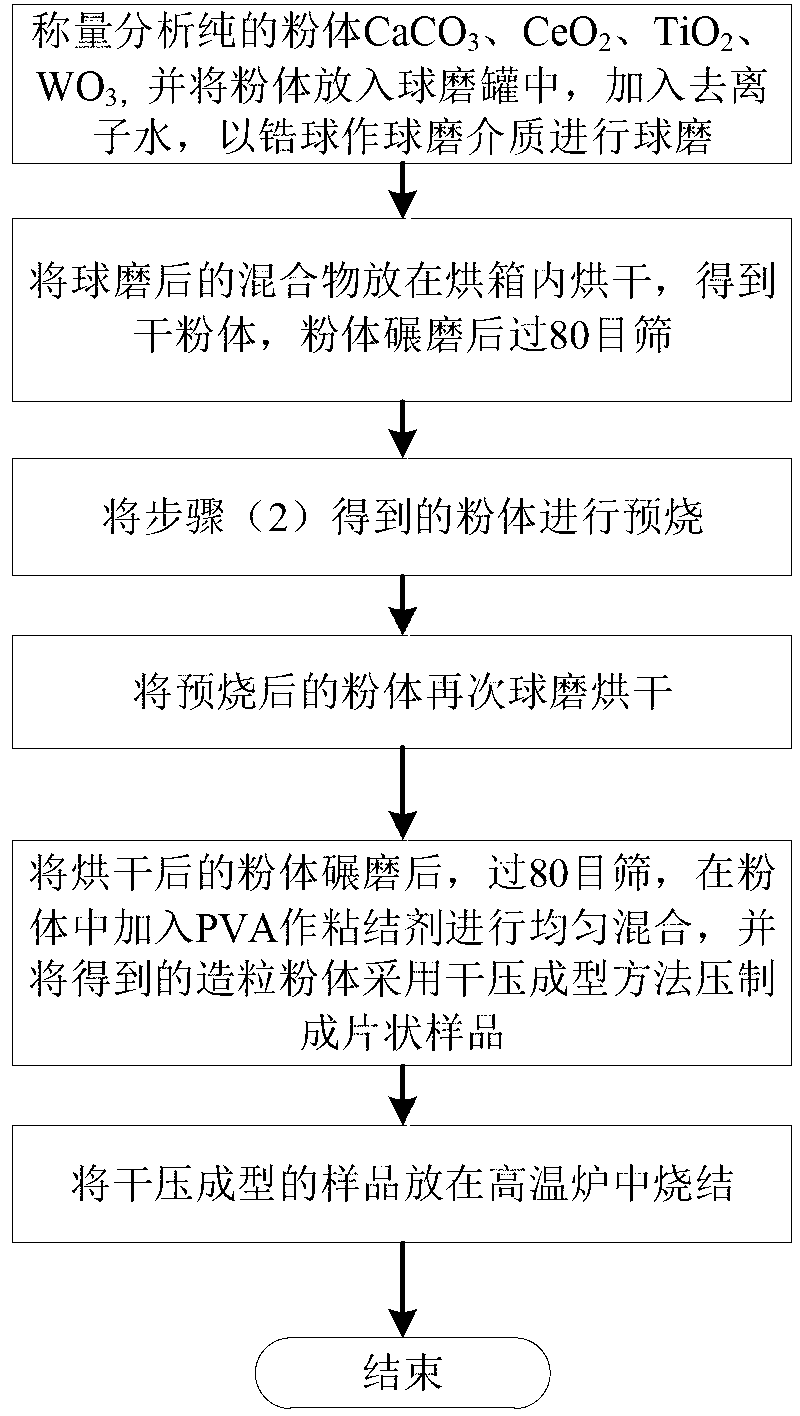

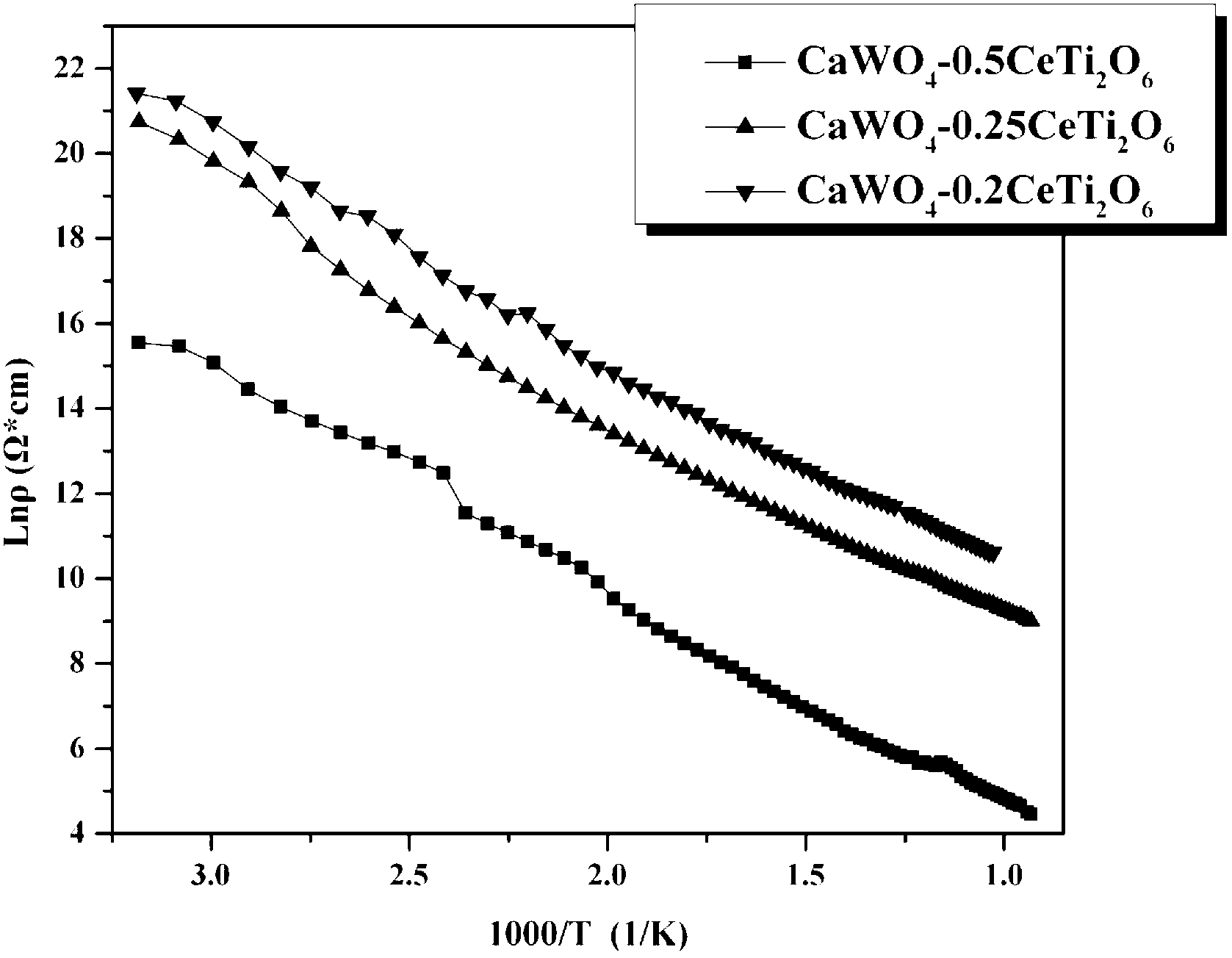

Method for preparing high temperature NTC (Negative Temperature Coefficient) thermistor material

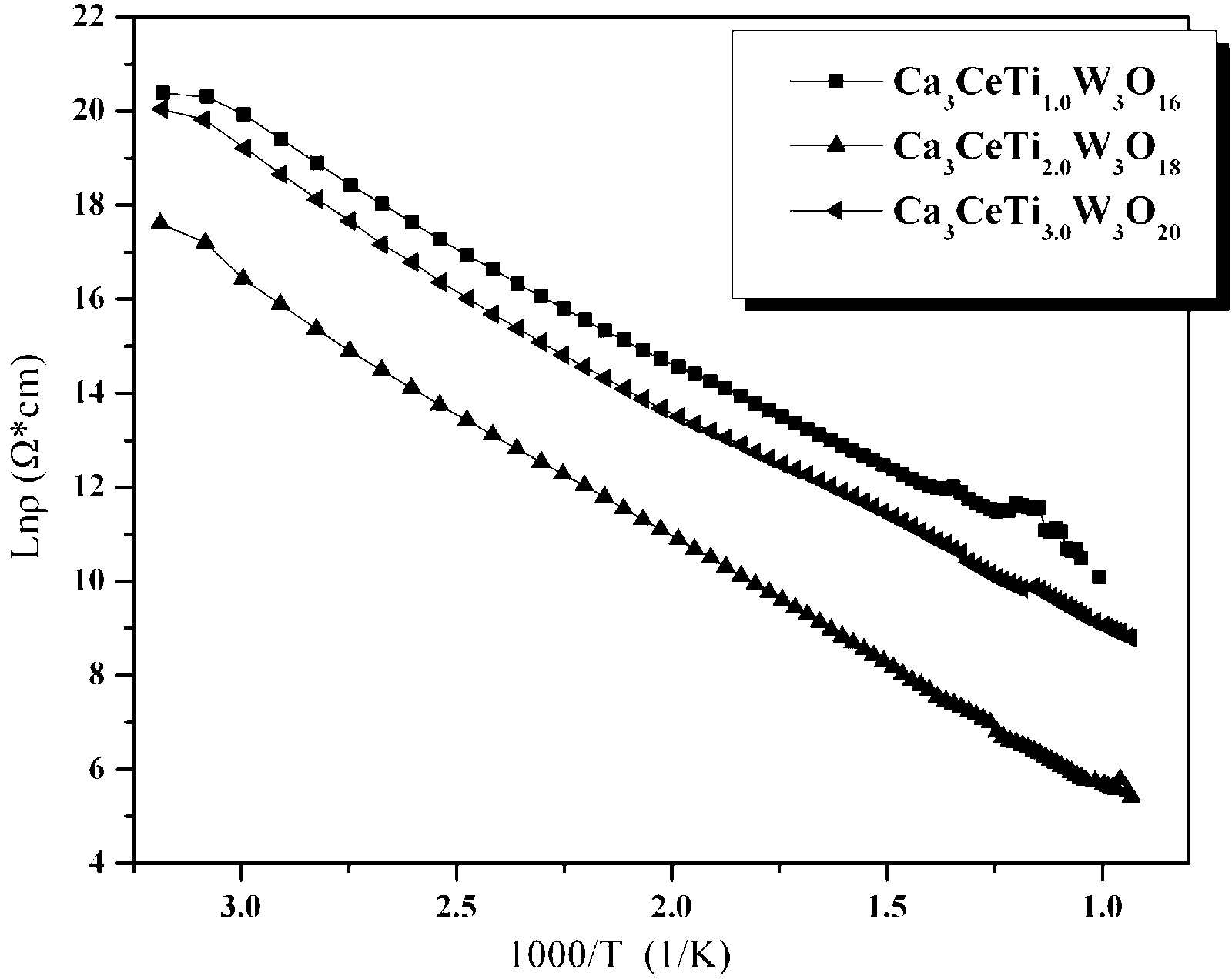

The invention discloses a method for preparing a high temperature NTC (Negative Temperature Coefficient) thermistor material, which comprises the following steps of: according to a formula of CaWO4-xCeTiyO2y+2, weighing and analyzing pure powdered CaCO3, CeO2, TiO2 and WO3, placing the powder into a ball milling tank, adding deionized water and zirconium ball grinding stone and carrying out ball milling for four hours; drying ball-milled slurry, grinding the dried powder and sieving the powder through a 80-mesh sieve; presintering the sieved powder, ball-grinding the presintered powder again, drying and grinding the powder and sieving the power through the 80-mesh sieve to obtain uniform and fine powder; and finally, placing a dry-pressed sample into a high temperature furnace to sinter so as to obtain the thermistor material. A main crystal phase of the thermistor material prepared by the method disclosed by the invention is a scheelite phase; the thermistor material has room temperature resistivity of 5.642*10<6> to 1.982*10<9> ohm.cm and has material constant of 5,077 to 7,275K; in the integral test temperature range, a resistor temperature relation curve LnRho-1000 / T has good linearity; and the method is suitable for temperature measurement in the wide temperature range of room temperature to 1,000 DEG C.

Owner:HUAZHONG UNIV OF SCI & TECH

Novel NTC thermistor material suitable for low temperature preparation

InactiveCN105967675ASimple ingredientsAdjust material constantsNegative temperature coefficient thermistorsThermistorTemperature sensitive

The invention relates to a semiconductor ceramic material, and especially relates to a thermistor material which can prepare a thermistor element with negative temperature coefficient (NTC) resistance. Simple oxides are used as main components in the NTC thermistor material; the material can be sintered into a ceramic body below 1000 DEG C, and is adapted to be sintered and moulded into temperature-sensitive ceramic elements, film temperature-sensitive elements, and low temperature co-sintered laminated temperature-sensitive elements. Contents of trace doped elements can be changed in order to adjust room temperature resistivity and NTC material constant of the thermistor element. The thermistor material has the characteristics of good stability, good consistency, and good repeatability, and has controllable resistance value, material constant, resistance temperature coefficient and other electrical characteristics; the thermistor material is suitable for temperature measurement, temperature control and line compensation, as well as protection of circuits and electronic components, and the fields of apparatus and application of measurements of flow velocity, flow, and ray.

Owner:CENT SOUTH UNIV

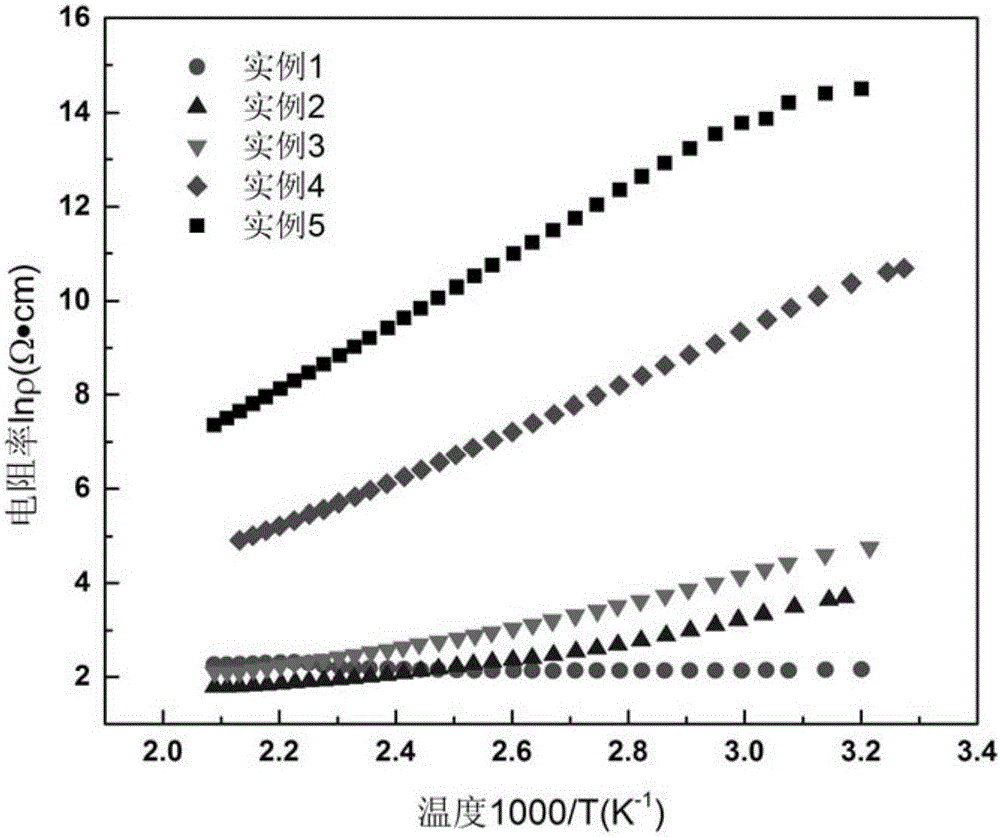

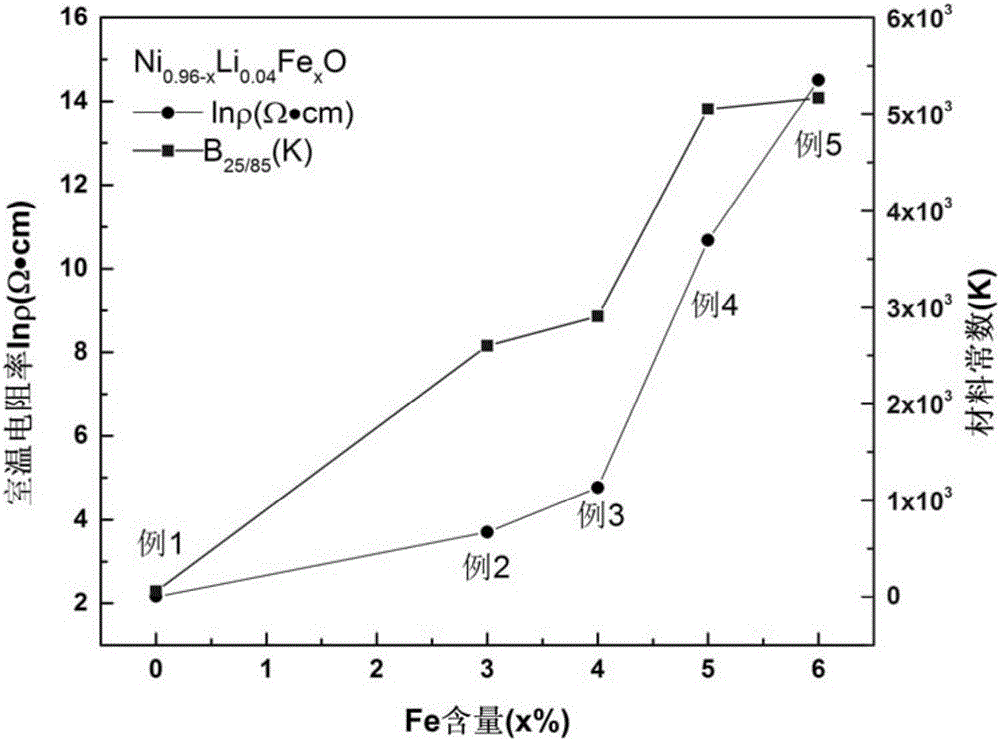

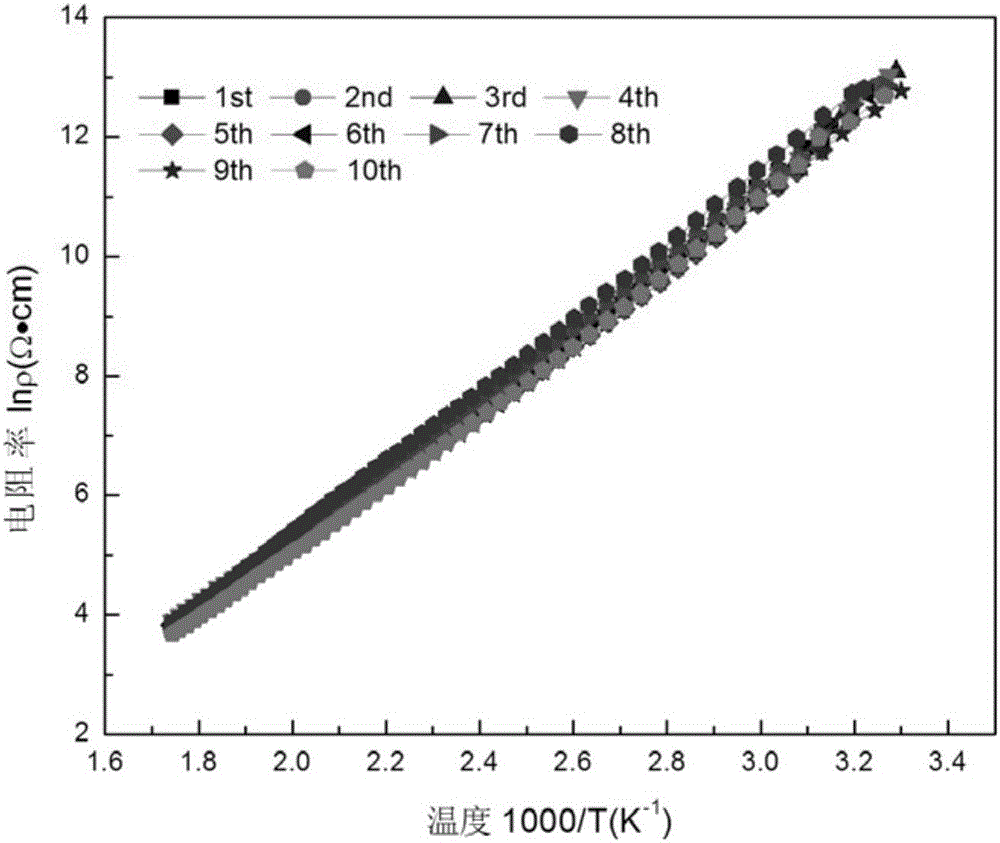

Lithium-iron-doped nickel oxide negative temperature coefficient (NTC) thermistor material

ActiveCN105967655AImprove reliabilitySimple ingredientsNegative temperature coefficient thermistorsHeat sensitiveThermistor

The invention relates to a semiconductive ceramic material and especially relates to a negative temperature coefficient (NTC) thermistor material. The material can adjust a room temperature resistance value and a material constant value of a thermistor element through change of doped microelement content. The NTC thermistor material mainly comprises a simple oxide, can be sintered to form ceramic at a temperature of about 1200 DEG C and is suitable for sintering molding of a thermal sensitive ceramic element, a film thermal sensitive element and a low temperature co-fired laminated heat sensitive component. The heat sensitive thermistor material has the characteristics of good stability, good consistency and good repeatability, has controllability of electric characteristics such as a resistance value, a material constant and a resistance temperature coefficient, is suitable for temperature measurement, temperature control and line compensation and can be used in the field of circuit and electronic component protection and flow velocity, flow and ray measurement apparatus and application.

Owner:CENT SOUTH UNIV

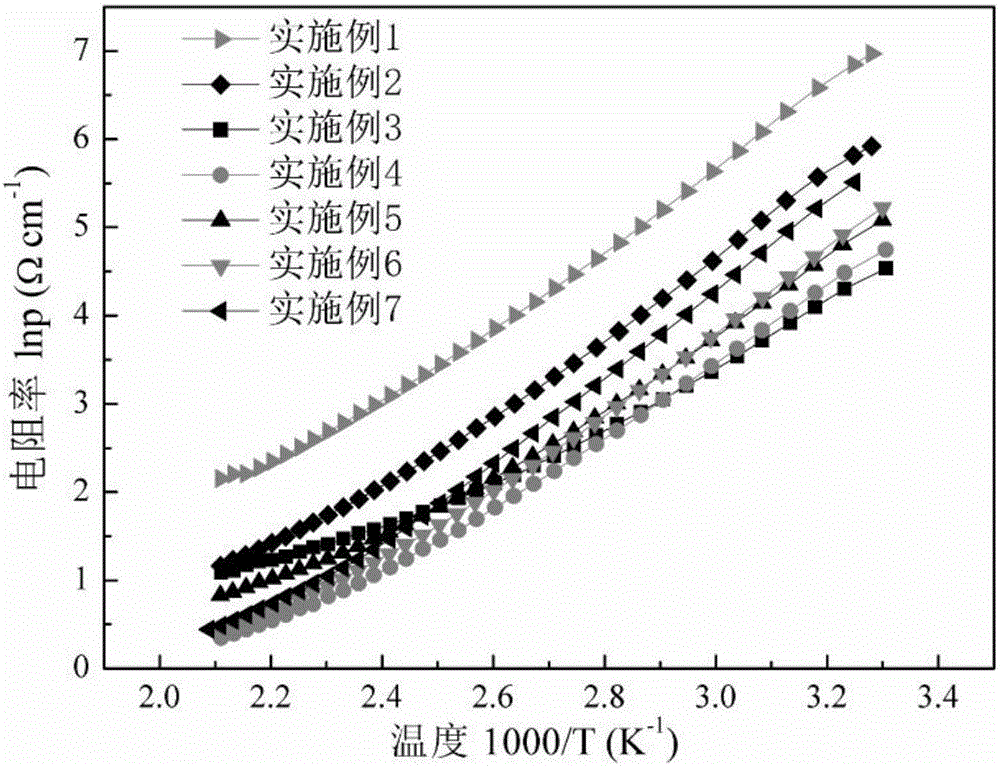

Novel NTC thermistor material based on nickel oxide

InactiveCN105967656AImprove reliabilityImprove performanceNegative temperature coefficient thermistorsThermistorTemperature sensitive

The invention relates to a semiconductor ceramic material, and especially relates to a thermistor material which can prepare a thermistor element with negative temperature coefficient (NTC) resistance. The NTC material employs NiO as a base of main compositions, room temperature resistance value and material constant value of the thermistor element are adjusted by adding a trace amount of doping elements. Simple oxides are used as main components in the NTC thermistor material; the material can be sintered into a ceramic body at 1100 DEG C, and is adapted to be sintered and moulded into temperature-sensitive ceramic elements, film temperature-sensitive elements, and low temperature co-sintered laminated temperature-sensitive elements. The thermistor material has the characteristics of good stability, good consistency, and good repeatability, and has adjustable room temperature resistance value, material constant, resistance temperature coefficient and other electrical characteristics; the thermistor material is suitable for temperature measurement, temperature control and line compensation, as well as protection of circuits and electronic components, and the fields of apparatus and application of measurements of flow velocity, flow, and ray.

Owner:CENT SOUTH UNIV

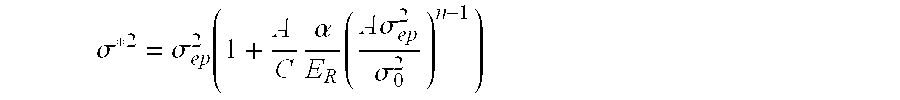

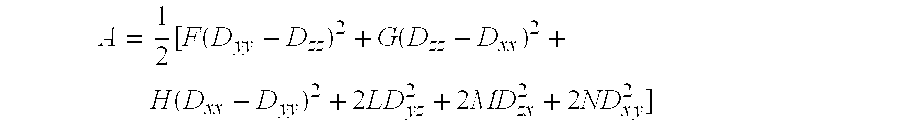

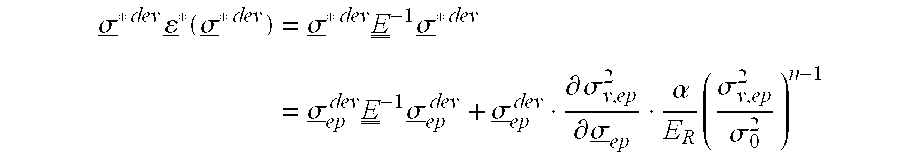

Method of determining the elastoplastic behavior of components consisting of anisotropic material and use of the method

InactiveUS20050065749A1Thermometer detailsThermometers using material expansion/contactionElastic anisotropyCrystalline materials

A method of determining the elastoplastic behavior of components, in particular of gas turbine plants, at high temperatures. First of all, the linear-elastic behavior is determined and the inelastic behavior is taken into account on the basis of the linear-elastic results by using the Neuber rule, the anisotropic characteristics of the components, as occur in particular through the use of single-crystalline materials, are taken into account in a simple manner by using a modified anistropic Neuber rule in the form σ*2=σep2(1+A CαER(A σep2σ02)n-1)where A=inelastic anisotropic correction term, A=12[F(Dyy-Dzz)2+G(Dzz-Dxx)2+H(Dxx-Dyy)2+2L Dyz2+2 MDz x2+2 NDx y2] where F, G, H, L, M and N are the Hill constants, C=elastic anisotropic correction term, C=D•E−1•Dσ*=determined linear stress, σep=estimated inelastic stress, D=direction vector of the elastic and inelastic stresses E−1=inverse stiffness matrix, ER=reference stiffness, σ0=reference stress, and σα, n=material constants.

Owner:GENERAL ELECTRIC TECH GMBH

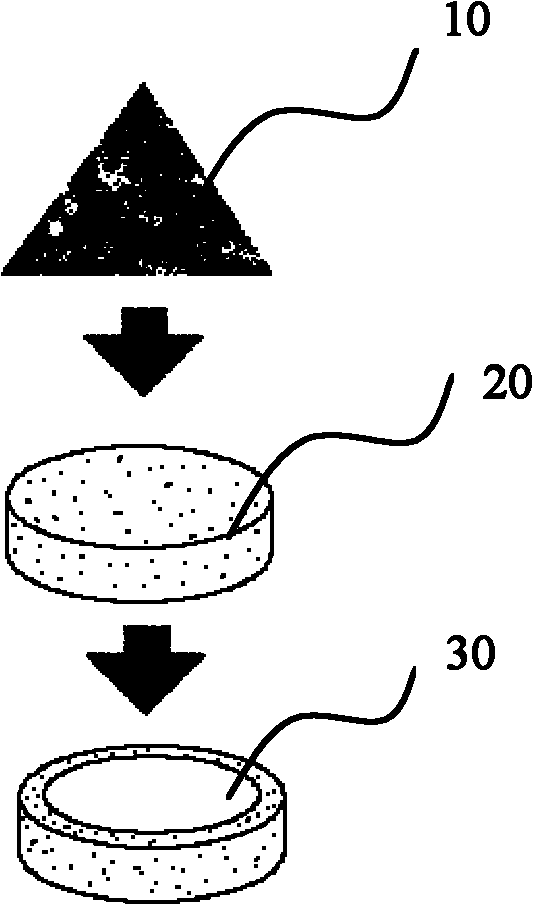

Method for manufacturing negative temperature coefficient (NTC) thermosensitive chip for high-precision temperature sensor

ActiveCN101995306AImprove hit rateSmall impactThermometers using electric/magnetic elementsUsing electrical meansElectrical resistance and conductanceElectricity

The invention belongs to the technical field of electronic parts and components, in particular to a method for manufacturing a negative temperature coefficient (NTC) thermosensitive chip for a high-precision temperature sensor, comprising the following steps: (1) preparing NTC thermosensitive semiconductor ceramic powder; (2) forming / sintering into a strip shape; (3) encapsulating by utilizing glass; (4) testing the resistivity; (5) cutting based on the size; and (6) adding terminal electrodes. As for the NTC thermosensitive chip manufactured by the method in the invention, in high-precision temperature measuring application occasions, the precision of the resistance R and the precision of the material constant B are controlled within 0.3%, namely the temperature precision can be controlled at 0.1% DEG C, and the annual drift rate of electric properties ( the resistance R and the material constant B) is less than 0.1% after the chip is utilized in an application circuit, thus the NTC thermosensitive chip can preferably ensure that high-precision resistance adjustments is realized, and has good stability preferably.

Owner:ZHUHAI EXENSE MEDICAL TECH

Negative temperature coefficient thermistor

InactiveCN102693795AMeet the needs of useImprove linearityNegative temperature coefficient thermistorsNegative temperatureHigh resistivity

The invention discloses a negative temperature coefficient thermistor and a manufacturing method thereof. The thermistor is manufactured by mainly mixing a metal oxide and a solvent, wherein the metal oxide comprises the following components in percentage by weight: 10 to 30 percent of Mn2O3, 40 to 65 percent of Ni2O3, 10 to 25 percent of Fe2O3, 10 to 30 percent of CuO, 0.5 to 2.5 percent of Al2O3 and 1 to 5 percent of MgO. The negative temperature coefficient thermistor and the manufacturing method thereof have the advantages that the negative temperature coefficient thermistor has high linearity, and can be conveniently applied to the temperature measurement industry; due to the adoption of the formula of the metal oxide, the combination of high resistivity and a low B value can be obtained, namely a material constant B is 2,800 to 2,900K when resistivity rho is 10 to 20 (kOhm.mm); the negative temperature coefficient thermistor can be used for a wide temperature range, namely the negative temperature coefficient thermistor can be used at high temperature and low temperature; and the negative temperature coefficient thermistor can be used for a special customer, and the series-connection of a resistor is avoided when the resistivity is low and a signal is weak in a high-temperature section.

Owner:佛山市顺德区晶铭电子有限公司

Preparation method of high-TCR low square resistance linear NTC resistance paste

ActiveCN105321642AWith linear NTC effectHigh TCRNegative temperature coefficient thermistorsManganeseThermistor

The invention discloses a preparation method of a high-TCR low square resistance linear NTC resistance paste. According to the method, nonlinear manganese, nickel and copper NTC ceramic reaction precursors are taken as main body function materials of the linear NTC paste, and the addition amount of precious metals can be effectively reduced by preparing a nonlinear NTC material with suitable B values (material constants) and specific resistance; and moreover, the value of resistance and the influence of temperature on the value of resistance are reduced by using an appropriate amount of nonlinear NTC powder to be mixed with ruthenium powder or ruthenium oxide powder, the linear relation between the value of resistance and the temperature is achieved, and the method is extremely stable in application. The method accords with the miniaturization and lamination development direction of current electronic components, key electronic pastes are independently researched and developed and are produced in large scale, the development of domestic electronic components can be quickened, and the cost of components and parts such as thermistors can be greatly reduced by preparing the low-cost and high-performance linear NTC paste, so that great economic benefits can be brought.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

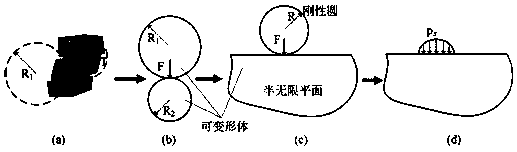

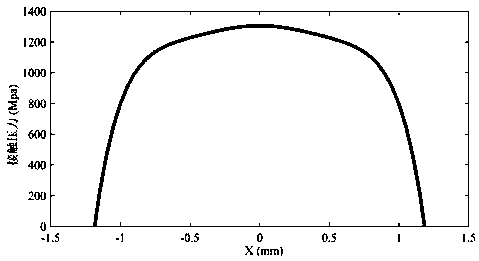

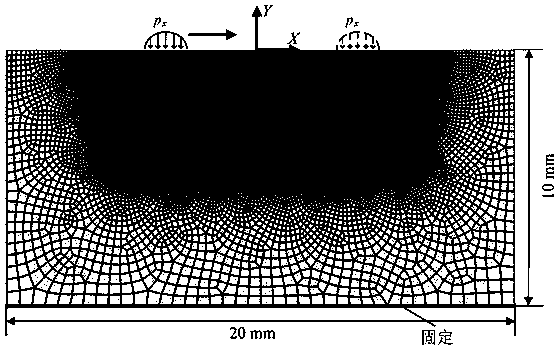

Prediction method for crack initiation of secondary surface of heavy-load gear

InactiveCN108256241ASolve long-standing technical problemsPredicted positionGeometric CADDesign optimisation/simulationContact pressurePredictive methods

The invention discloses a prediction method for crack initiation of a secondary surface of a heavy-load gear. The method comprises the following steps that 1, based on a hertz contact theory, the contact of a gear pair is simplified, a meshed position parameter is calculated according to geometric kinematics, and a contact analysis model is established; 2, based on the contact analysis model of the gear pair, by using a value calculation method, the surface contact pressure of the analysis model under the heavy-load condition is obtained; 3, a material constant related to the service life of crack initiation is solved; 4, based on a continuous damage mechanics theory, by using critical damage amount, whether or not a crack occurs on the secondary surface is judged, and a gear contact elastic-plastic constitutive equation of coupling damage is established; 5, the service life of crack initiation is calculated, and the position of crack initiation is obtained. According to the predictionmethod, the technical difficult problem which exists for a long time in the machinery industry is solved, the position and service life of crack initiation of the secondary surface of the heavy-loadgear can be effectively predicted, and the basis is provided for design, manufacturing and use of the gear.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com