Temperature sensing material with negative temperature coefficient effect and method for preparing same

A technology with negative temperature coefficient and effect, applied in the fields of chemical industry and electronics, it can solve the problems of high use cost and high material cost, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

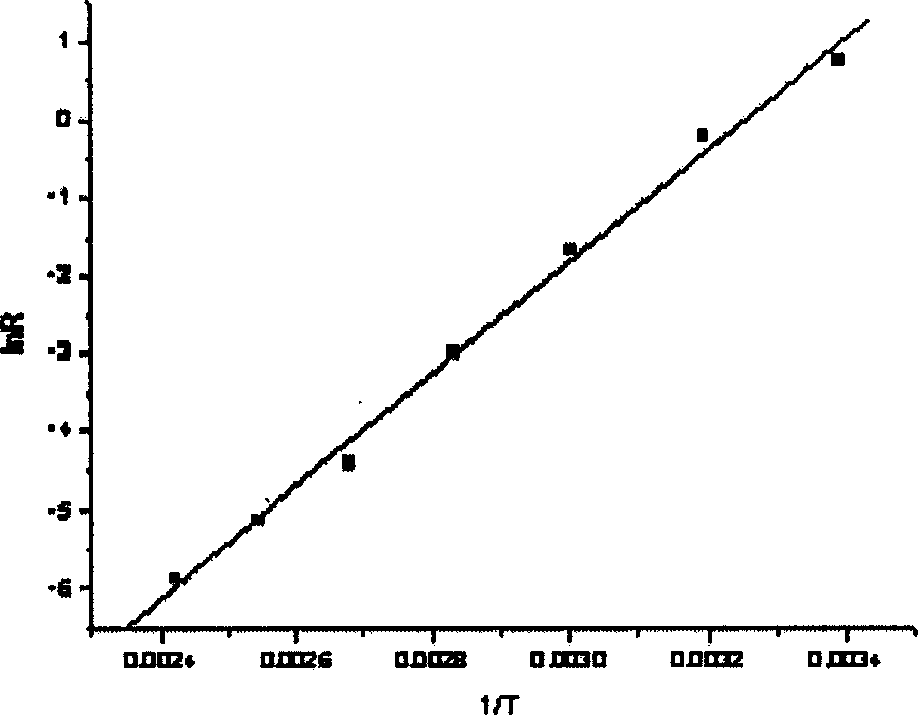

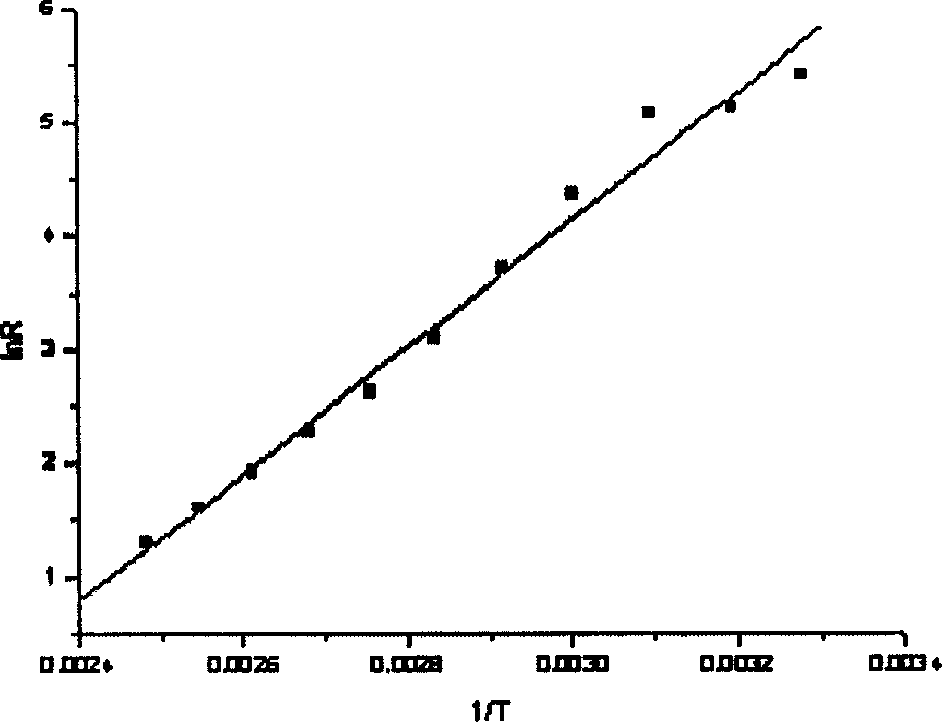

Image

Examples

Embodiment 1

[0020] In a high-speed mixer, add 5 parts of heat-sensitive organic-inorganic composite powder, 50 parts of dibutyl phthalate, 20 parts of epoxy soybean oil, mix at 500 rpm for 5 minutes, add 100 parts of polyvinyl chloride, 5 parts of tribasic lead sulfate, 5 parts of dibasic lead phthalate, 2 parts of oxidized polyethylene wax, 5 parts of ACR, mixed at 80°C and 2500 rpm for 15 minutes, masticated with an internal mixer for 10 minutes, Granulating and extruding to obtain a temperature-sensitive material with a negative temperature coefficient effect.

Embodiment 2

[0022] In a high-speed mixer, add 45 parts of heat-sensitive organic-inorganic composite powder, 60 parts of trimellitate, and 20 parts of dioctyl maleate, mix at a low speed of 1000 rpm for 5 minutes, add polyethylene / 10 parts of vinyl acetate EVA, 90 parts of polyvinyl chloride, 10 parts of tribasic lead sulfate, 8 parts of dibasic lead phosphite, 2 parts of oleic acid amide, 3 parts of chlorinated paraffin, 2 parts of talcum powder, at 100 ℃ 2500 R / M mixing for 10 minutes, masticating with an extruder for 20 minutes, granulation and extrusion molding to obtain a temperature-sensitive material with a negative temperature coefficient effect.

Embodiment 3

[0024] In a high-speed mixer, add 20 parts of heat-sensitive organic-inorganic composite powder, 40 parts of dibutyl phthalate, and 10 parts of epoxy dioctyl soybean oil, mix at 1500 rpm for 3 minutes, add chloroprene 100 parts of rubber, 2 parts of dibutyltin lauryl mercaptide, 3 parts of zinc stearate, 3 parts of calcium laurate, 1 part of butyl stearate, 3 parts of chlorinated paraffin, 1 part of erucamide, 8 parts of AMS, carbonic acid 8 parts of calcium, mixed at 120°C and 3500 rpm for 12 minutes at high speed, masticated with an internal mixer for 10 minutes, granulated and extruded to obtain a temperature-sensitive material with a negative temperature coefficient effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com