System and method for structural analysis of indirect dry cooling tower

A technology of structural analysis and air-cooling towers, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as poor interaction ability, achieve the effect of improving efficiency and avoiding a lot of repetitive work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

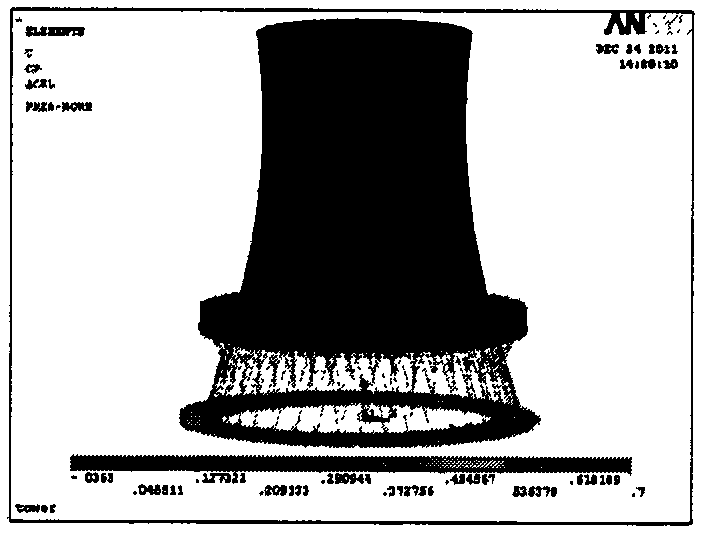

Image

Examples

Embodiment Construction

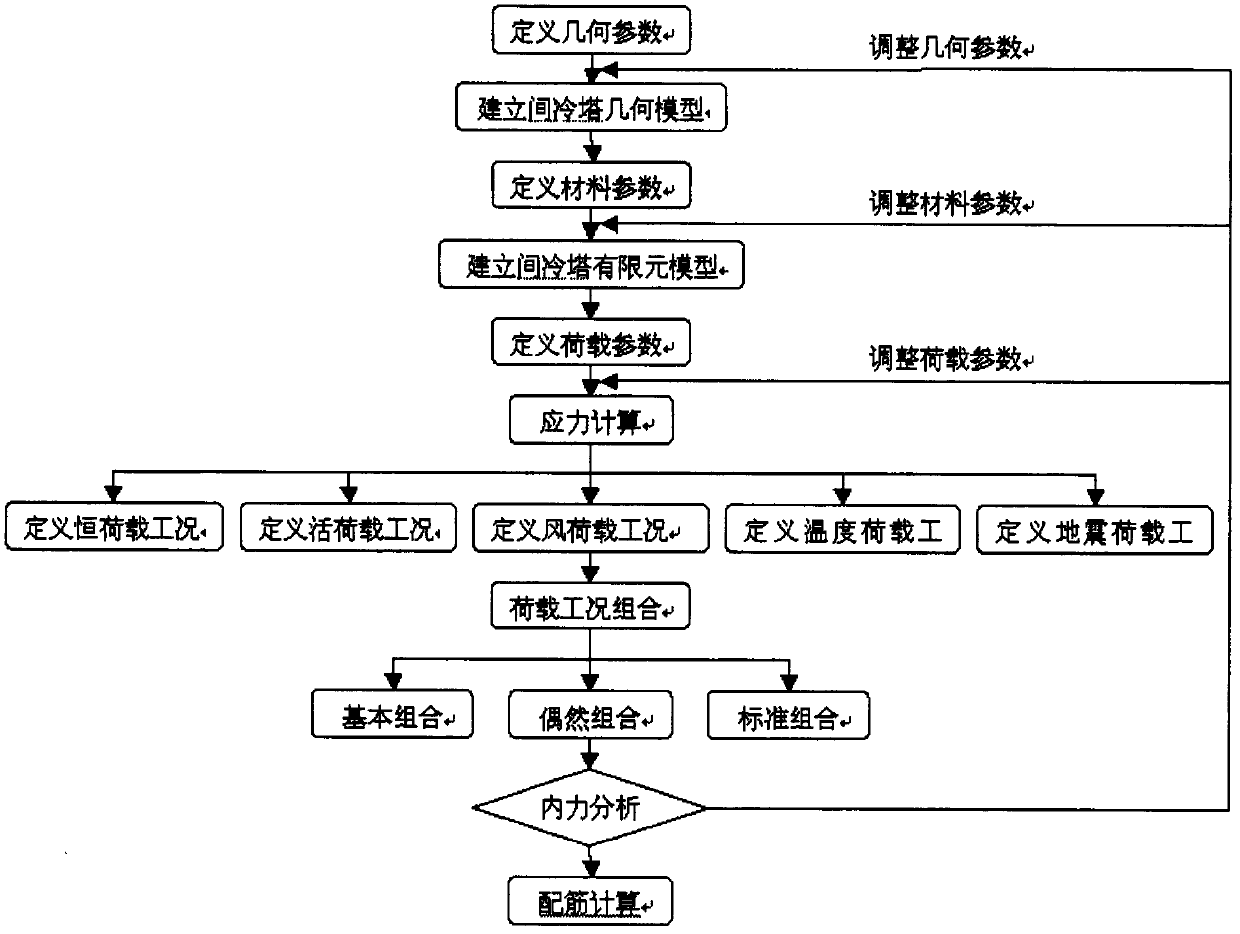

[0032] The present invention will be described in further detail below in conjunction with accompanying drawing, attached table and concrete engineering example:

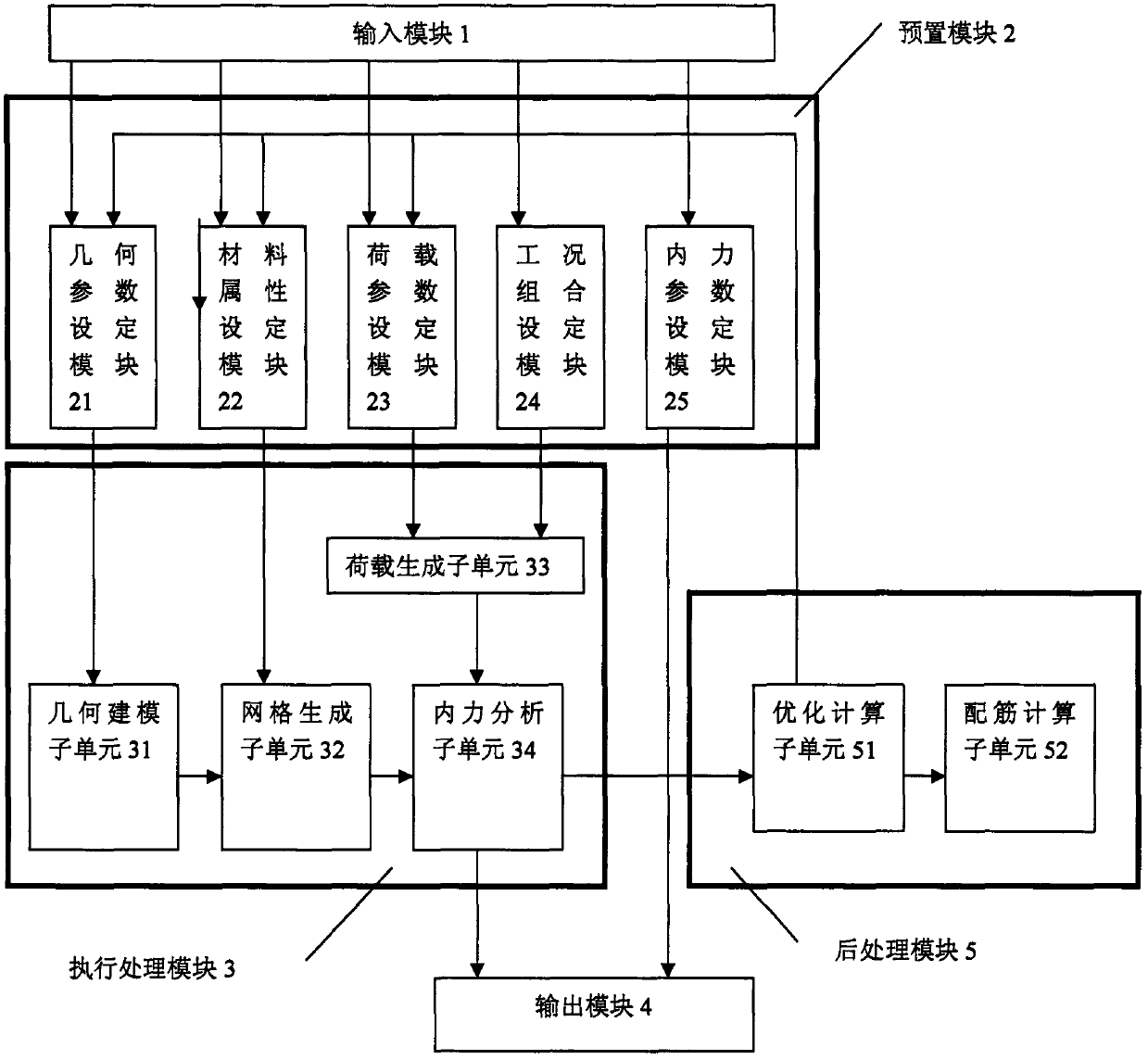

[0033] figure 1 Shown in is an APDL-based structure finite element analysis system of an indirect air-cooling tower of the present invention, including an input module 1 , a preset module 2 , an execution processing module 3 , an output module 4 , and a post-processing module 5 . The input module 1 is used to realize the man-machine interface, and the user inputs commands according to the page display;

[0034] The preset module 2 is used to predefine various required parameter variables and set corresponding parameter values, including a geometric parameter setting module 21, a material property setting module 22, a load parameter setting module 23, working conditions Combination setting module 24 and internal force parameter setting module 25 . Send the geometric modeling command to the geometric parameter setti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com