Novel NTC thermistor material suitable for low temperature preparation

A thermistor and raw material technology, applied in the direction of resistors with negative temperature coefficient, resistors, non-adjustable metal resistors, etc., can solve the problems affecting material performance and service life, unstable electrical performance, material aging, etc. Achieve environmental friendliness, low sintering temperature, and simple material composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] This embodiment according to the molecular formula Cu 1-x-y Y x Ti y O was dosed where x=0.008, y=0.01. The initial raw material is selected from copper hydroxide Cu(OH) 2 , tetrabutyl titanate TBT, diyttrium trioxide Y 2 o 3 . Material preparation is carried out according to the technological steps of following experiment:

[0021] (1) Press Cu 0.982 Y 0.008 Ti 0.01 O formula ingredients, take the initial raw material Cu(OH) 2 19.1580g, Y 2 o 3 0.1806g, TBT 0.6806;

[0022] (2) Copper hydroxide, 100 million oxide, and butyl titanate raw materials taken by weighing in the previous step are dissolved in dilute nitric acid respectively;

[0023] (3) Mix the three solutions prepared in the previous step together, and use a magnetic stirring heater to stir and mix evenly, heat and dry;

[0024] (4) Calcining the precursor powder prepared in the previous step at a temperature of 830° C. and keeping it warm for 6 hours;

[0025](5) Granulating and pressing the...

Embodiment 2

[0031] This embodiment according to the molecular formula Cu 0.992-y Y 0.008 Ti y O was dosed where y=0.015. The initial raw material is selected from copper hydroxide Cu(OH) 2 , Oxygen Y 2 o 3 , Butyl titanate TBT. Material preparation is carried out according to the technological steps of following experiment:

[0032] (1) Press Cu 0.977 Y 0.008 Ti 0.01 O formula ingredients, take the initial raw material Cu(OH) 2 19.0605g, Y 2 o 3 0.1806g, TBT 1.0209g;

[0033] (2) The preparation process is the same as steps (2)-(8) in Example 1.

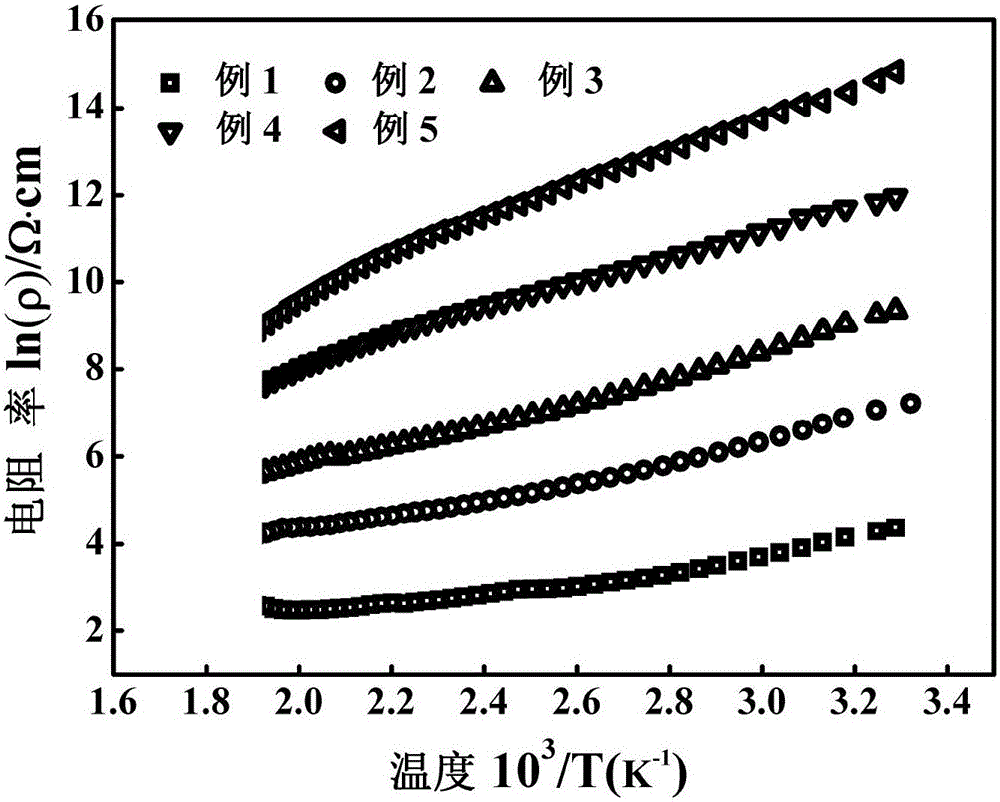

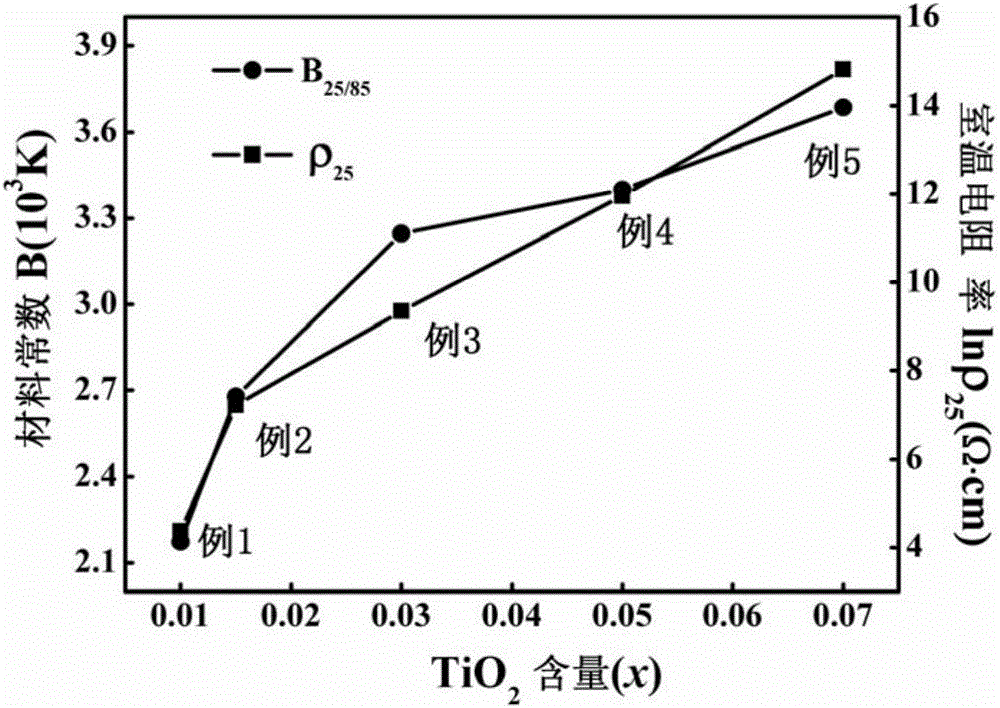

[0034] The properties of the prepared materials are shown in Table 1. figure 1 and figure 2 shown.

Embodiment 3

[0036] This embodiment according to the molecular formula Cu 0.992-y Y 0.008 Ti y O was dosed where y=0.03. The initial raw material is selected from copper hydroxide Cu(OH) 2 , Oxygen Y 2 o 3 , Butyl titanate TBT. Material preparation is carried out according to the technological steps of following experiment:

[0037] (1) Press Cu 0.962 Y 0.008 Ti 0.03 O formula ingredients, take the initial raw material Cu(OH) 2 18.9629g, Y 2 o 3 0.1806g, TBT 2.0418g;

[0038] (2) The preparation process is the same as steps (2)-(8) in Example 1.

[0039] The properties of the prepared materials are shown in Table 1. figure 1 and figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com