Method for preparing high-temperature NTC heat-sensitive resistance material

A thermistor and high temperature technology, applied in the direction of resistors with negative temperature coefficients, etc., can solve problems such as weak research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

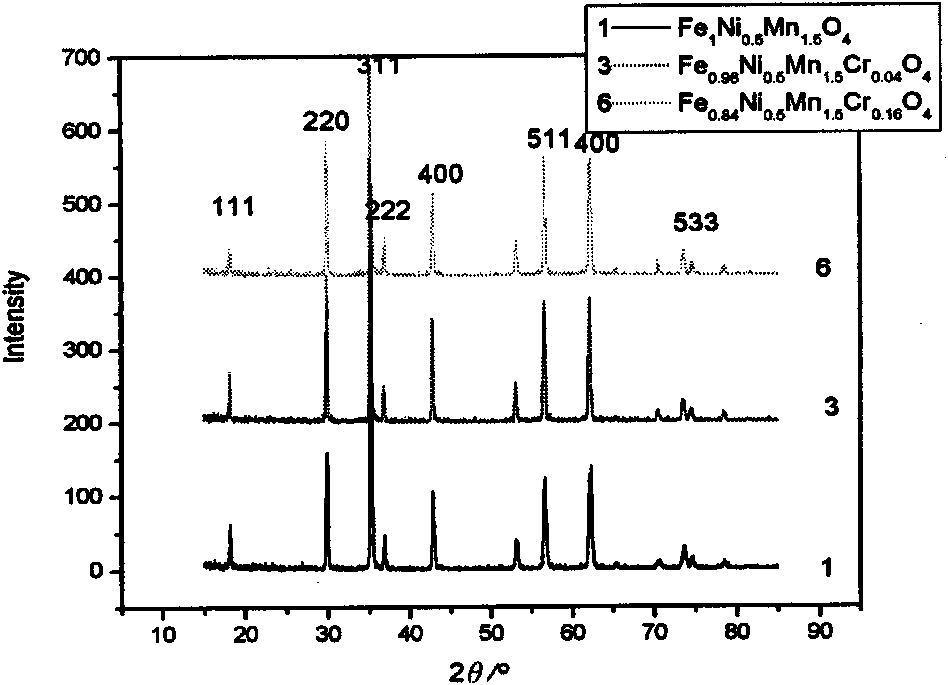

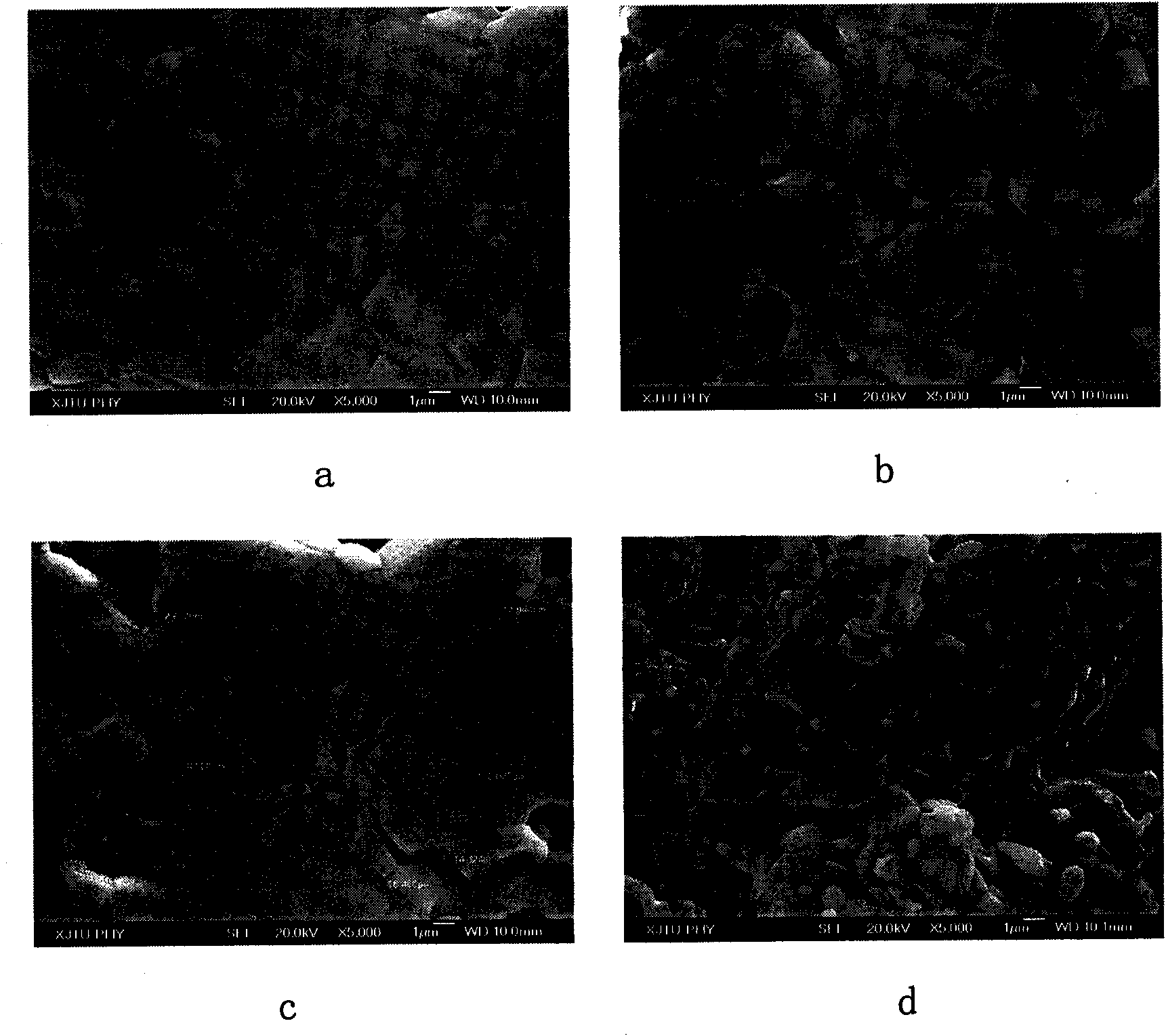

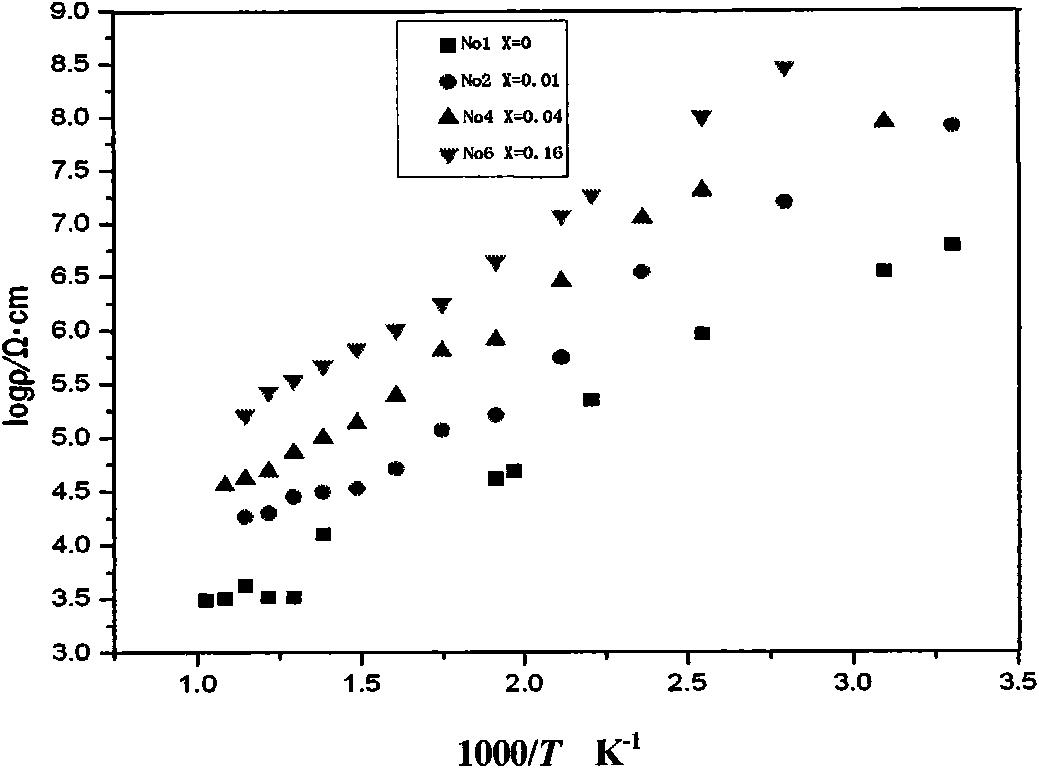

[0017] Embodiment 1, 1) at first, press FeNi 0.5 mn 1.5 o 4 The chemical formula will analyze pure Fe 2 o 3 , NiO, MnO 2 and Cr 2 o 3 Put the powder into a plastic tank, and add ethanol: FeNi to the plastic tank 0.5 mn 1.5 o 4 , adding ethanol at a volume ratio of 1:1, and then using agate balls as the grinding medium, ball milling on a high-speed ball mill for 4 hours to obtain the mixture;

[0018] 2) Then, the mixture was dried in an oven at 75° C. for 12 hours and then ground through a 200-mesh sieve, then adding 4% of the mixture mass concentration to it was 5% PVA binder, and pressed it under a pressure of 100 MPa into a disc with a diameter of 10mm and a height of 2mm;

[0019] 3) Finally, put the pressed disc into a high-temperature sintering furnace for sintering. The sintering temperature control program is: (1) Low-temperature stage: from room temperature to 300°C at a heating rate of 75°C / h, and then to 300°C Keep warm for 2 hours; (2) Decomposition and ...

Embodiment 2

[0020] Embodiment 2, 1) at first, press Fe 0.99 Ni 0.5 mn 1.5 Cr 0.01 o 4 The chemical formula will analyze pure Fe 2 o 3 , NiO, MnO 2 and Cr 2 o 3 Put the powder into a plastic tank, and add ethanol: Fe 0.99 Ni 0.5 mn 1.5 Cr 0.01 o 4 Add ethanol at a volume ratio of 1:1, then use agate balls as the grinding medium, and ball mill on a high-speed ball mill for 4 hours to obtain the mixture;

[0021] 2) Then, the mixture is dried in an oven at 75° C. for 12 hours and then ground through a 200-mesh sieve, then adding 2% of the mixture mass concentration to it is 5% PVA binder, and pressing it under a pressure of 100 MPa into a disc with a diameter of 10mm and a height of 2mm;

[0022] 3) Finally, put the pressed disc into a high-temperature sintering furnace for sintering. The sintering temperature control program is: (1) Low-temperature stage: from room temperature to 300°C at a heating rate of 75°C / h, and then to 300°C Keep warm for 2 hours; (2) Decomposition and...

Embodiment 3

[0023] Embodiment 3, 1) at first, press Fe 0.96 Ni 0.5 mn 1.5 Cr 0.04 o 4 The chemical formula will analyze pure Fe 2 o 3 , NiO, MnO 2 and Cr 2 o 3 Put the powder into a plastic tank, and add ethanol: Fe 0.96 Ni 0.5 mn 1.5 Cr 0.04 o 4 Add ethanol at a volume ratio of 1:1, then use agate balls as the grinding medium, and ball mill on a high-speed ball mill for 4 hours to obtain a mixture;

[0024] 2) Then, the mixture is dried in an oven at 75° C. for 12 hours and then ground through a 200-mesh sieve, then adding 5% of the mixture mass concentration is 5% PVA binder, and pressing it under a pressure of 100 MPa into a disc with a diameter of 10mm and a height of 2mm;

[0025] 3) Finally, put the pressed disc into a high-temperature sintering furnace for sintering. The sintering temperature control program is: (1) Low-temperature stage: from room temperature to 300°C at a heating rate of 75°C / h, and then to 300°C Keep warm for 2 hours; (2) Decomposition and oxidati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com