Method for preparing high temperature NTC (Negative Temperature Coefficient) thermistor material

A technology of negative temperature coefficient and thermistor, which is applied in the field of preparation of high temperature negative temperature coefficient thermistor materials to achieve the effect of good linearity and stable high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

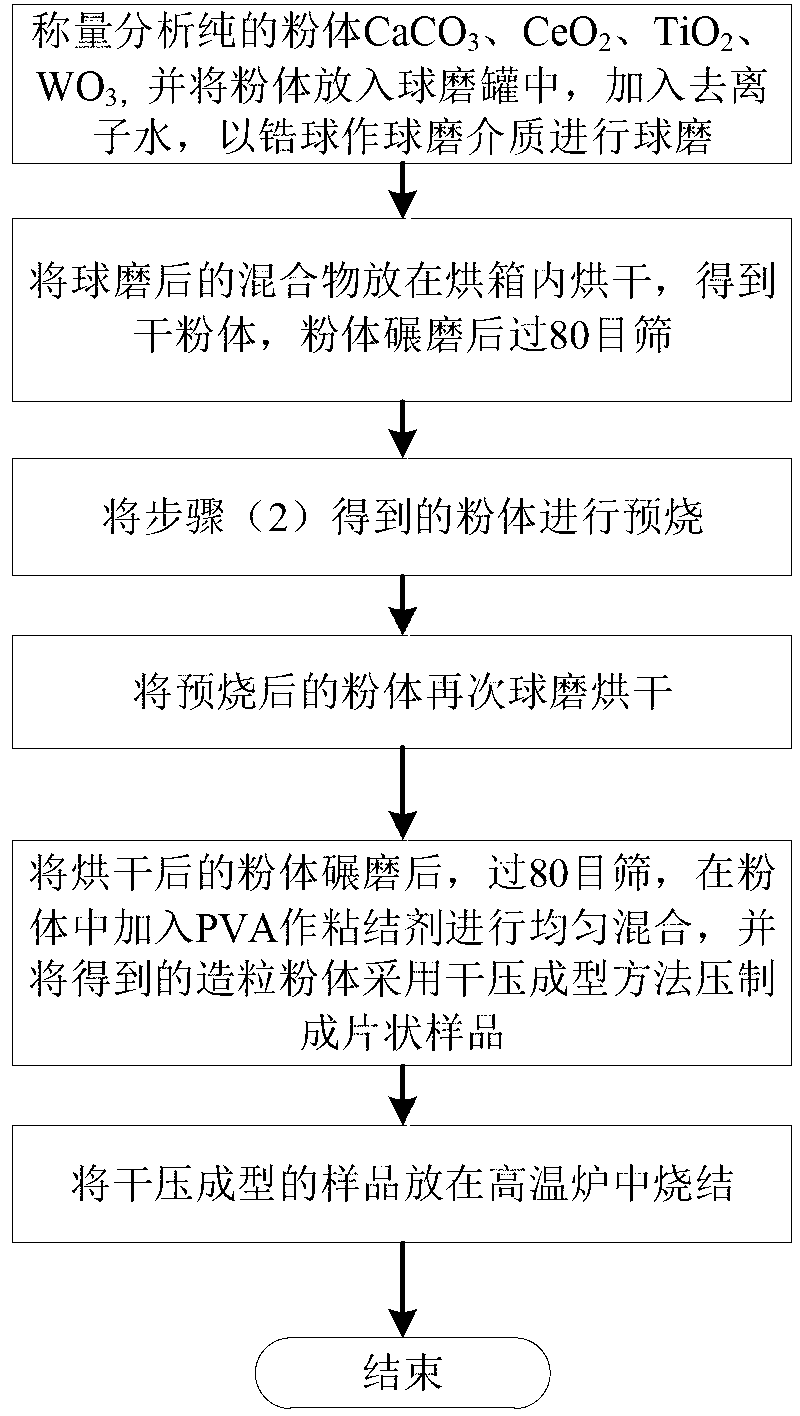

[0022] Such as figure 1 As shown, the preparation method of the high temperature negative temperature coefficient thermistor material of the present invention comprises the following steps:

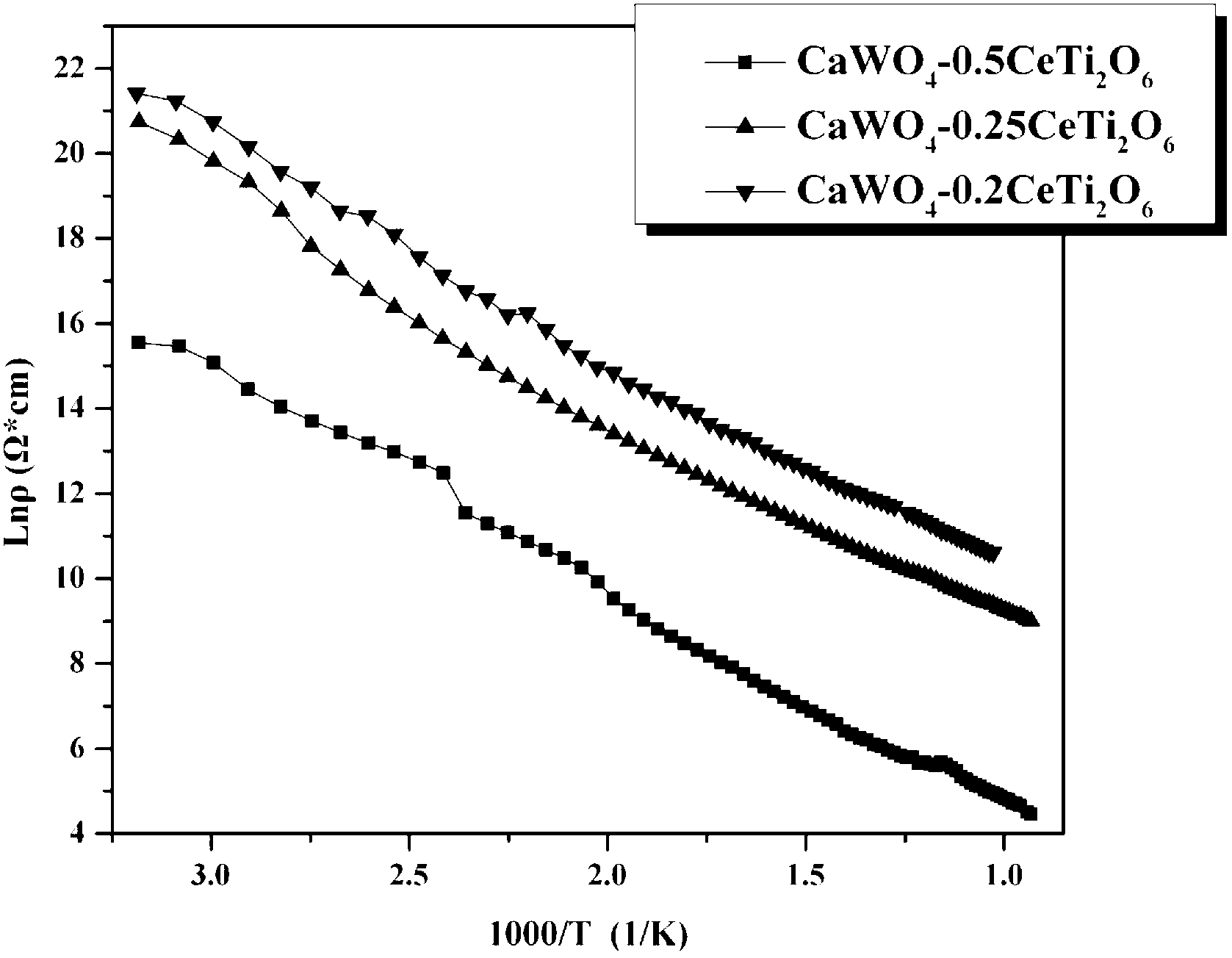

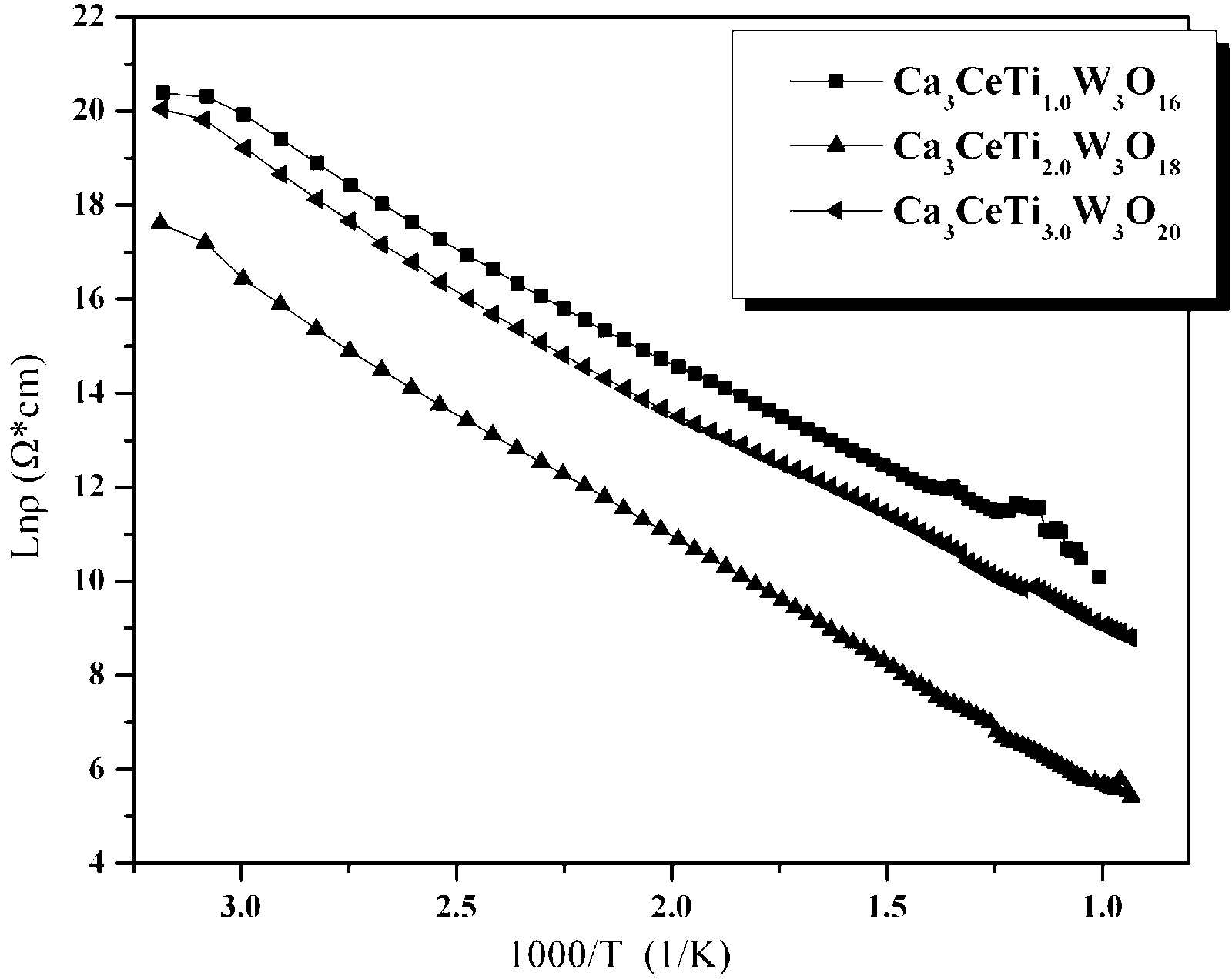

[0023] (1) According to CaWO 4 -xCeTi y o 2y+2 The formulation weighs analytically pure powdered CaCO 3 , CeO 2 、TiO 2 、WO 3, Put the powder into a ball mill tank, add deionized water according to the mass ratio of powder to deionized water at 1:2, add ball millstone at a mass ratio of powder to ball millstone at 1:3, and mill for four hours; where x takes The value range is 0.2 to 0.5, and the value range of y is 1 to 3. Specifically, according to CaWO 4 -xCeTi y o 2y+2 The formula can determine the molar ratio of the four elements Ca, Ce, Ti, and W as 1:x:xy:1, so that the powder CaCO can be further determined according to these four elements 3 , CeO 2 、TiO 2 、WO 3 The molar ratio between;

[0024] (2) Dry the ball-milled mixture in an oven to obtain a dry powder, which is...

Embodiment 1

[0030] (1) According to CaWO 4 -0.2CeTi 1 o 4 The formulation weighs analytically pure powdered CaCO 3 , CeO 2 、TiO 2 、WO 3, Put the powder into a ball mill tank, add deionized water according to the mass ratio of powder to deionized water 1:2, add ball millstone according to the mass ratio of powder to ball millstone 1:3, and mill for four hours;

[0031] (2) Dry the ball-milled mixture in an oven to obtain a dry powder, which is ground and passed through an 80-mesh sieve;

[0032] (3) Pre-burn the fine powder obtained in step (2) at 900-1100°C for 2-5h;

[0033] (4) Ball mill and dry the pre-burned powder again;

[0034] (5) After grinding the dried powder, pass it through a 80-mesh sieve, add PVA with a mass ratio of 6%-10% and a concentration of 5-10mol% in the powder as a binder for uniform mixing, and The obtained granulated powder is pressed into a sheet sample by a dry pressing method;

[0035] (6) Put the dry-pressed sample into a high-temperature furnace for...

Embodiment 2

[0037] (1) According to CaWO 4 -0.2CeTi 2 o 6 The formulation weighs analytically pure powdered CaCO 3 , CeO 2 、TiO 2 、WO 3, Put the powder into a ball mill tank, add deionized water according to the mass ratio of powder to deionized water 1:2, add ball millstone according to the mass ratio of powder to ball millstone 1:3, and mill for four hours;

[0038] (2) Dry the ball-milled mixture in an oven to obtain a dry powder, which is ground and passed through an 80-mesh sieve;

[0039] (3) Pre-burn the fine powder obtained in step (2) at 900-1100°C for 2-5 hours;

[0040] (4) Ball mill and dry the pre-burned powder again;

[0041] (5) After grinding the dried powder, pass it through a 80-mesh sieve, add PVA with a mass ratio of 6%-10% and a concentration of 5-10mol% in the powder as a binder for uniform mixing, and The obtained granulated powder is pressed into a sheet sample by a dry pressing method;

[0042] (6) Put the dry-pressed sample into a high-temperature furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com