Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

106results about How to "Stable performance at high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium carbonate polyamine drilling fluid

InactiveCN101747876AStrong inhibitory abilityReduced tendency to absorb moistureDrilling compositionParaffin waxChemistry

The invention relates to a potassium carbonate polyamine drilling fluid used for the petroleum drilling process. The potassium carbonate polyamine drilling fluid mainly comprises 1-60 percent of potassium carbonate, 0.5-25 percent of calcium oxide, 0.5-5 percent of polyamine shale inhibiting agent, 0-5 percent of bentonite, 0.5-3 percent of filter reducer, 0.1-0.5 percent of coating agent, 0.1-0.8 percent of tackifier, 0.5-5 percent of plugging agent, 0.1-2 percent of lubricating agent and a proper amount of weighing agent (added according to the requirement). The potassium carbonate polyamine drilling fluid can provide K+ with high concentration and has strong inhibiting capability on shale; the potassium carbonate and the calcium oxide react in equal mole ratio to generate micrometer and nanometer calcium carbonate superfine powder, thus CO32-anions generated by dissolving the potassium carbonate can be removed, the mineralization can be reduced and the influence of high mineralization on the action efficiency of other processing agents can be eliminated; and by matching, the calcium carbonate superfine powder can be deformed into asphalt and paraffin particles which can be usedfor plugging a microcrack shale stratum.

Owner:WESTERN DRILLING KELAMAYI DRILLING TECH INST

Drilling fluid for shale hydrocarbon reservoir exploration

InactiveCN104610941AInhibition of hydrationPrevent collapseDrilling compositionWell drillingPotassium silicate

The invention provides a drilling fluid for shale hydrocarbon reservoir exploration. The drilling fluid is based on water, and comprises 4-6wt% of bentonite, 2-5wt% of potassium silicate, 0.2-0.5wt% of a coating inhibitor, 0.2-1.5wt% of a flow pattern regulator, 4-6wt% of a fluid loss additive, 2-3wt% of a shale caving inhibitor, 2-3wt% of a plugging agent, 0.5-1wt% of a filter cake surface modifier, 2-4wt% of a lubricant and 0.4-0.6wt% of a pH value regulator. The drilling fluid has the characteristics of good plugging property, strong inhibition, good lubricity and stable high temperature performances to shale hydrocarbon reservoir stratums, and is suitable for the exploration of shale hydrocarbon reservoirs.

Owner:CHINA PETROCHEMICAL CORP +1

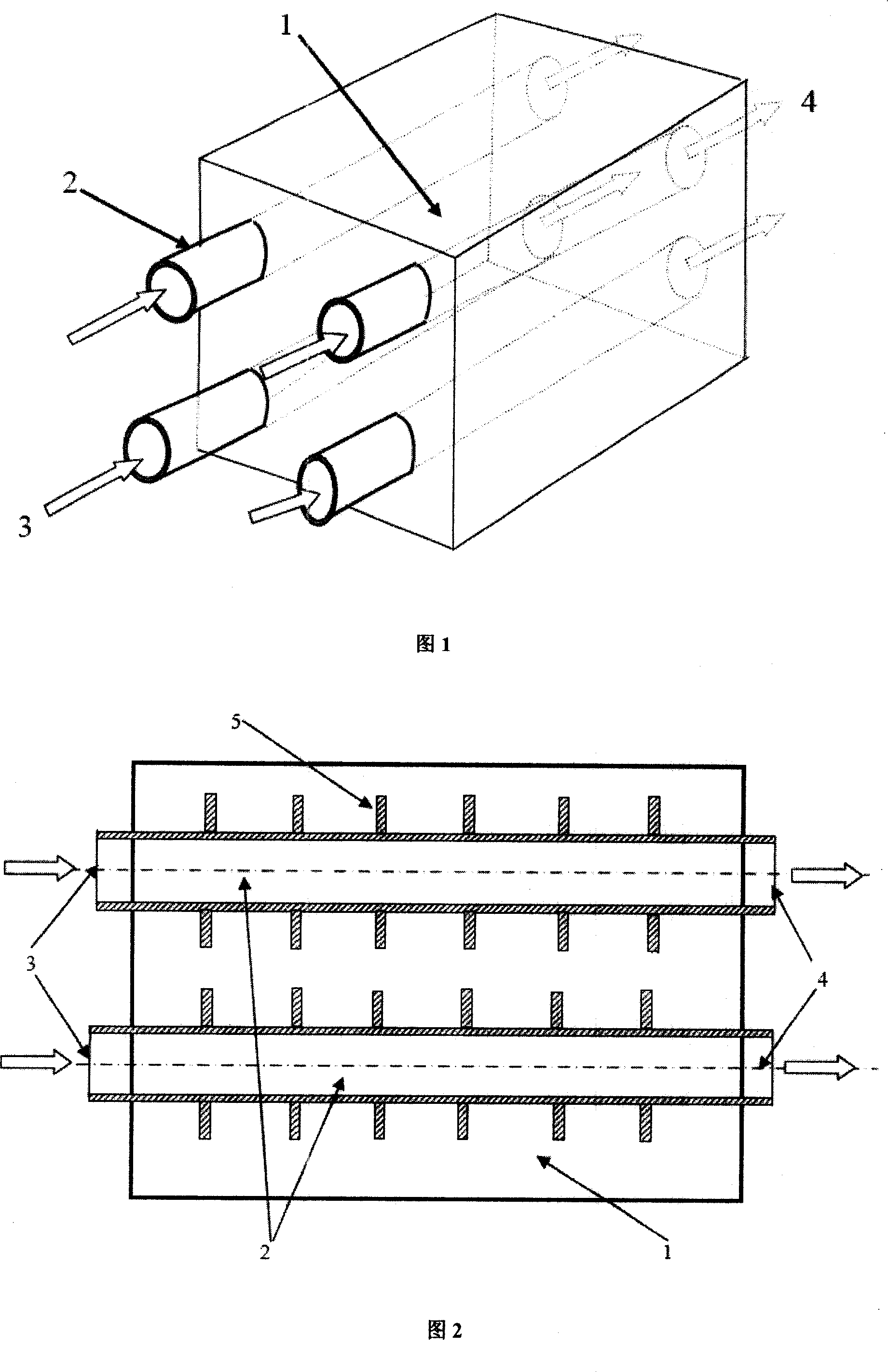

High-temperature heat-storing device using concrete and heat storage method thereof

InactiveCN101135543AImprove heat transfer performanceLarge heat storage capacityHeat storage plantsEngineering

The invention relates to high-temperature heat storage device utilizing concrete and its heat storing method. Its heat exchange pipeline is buried in concrete heat storage block, heat exchange fin is at external wall of the pipe, a valve is mounted at cold fluid inlet, cold fluid outlet is at the other end of cold fluid tank; a valve is mounted at heat fluid inlet, heat fluid outlet is at the other end of heat fluid tank. Heat exchange is carried out utilizing the difference of temperature between the concrete heat storage block and the heat exchange pipeline.

Owner:GUANGDONG FIVESTAR SOLAR ENERGY

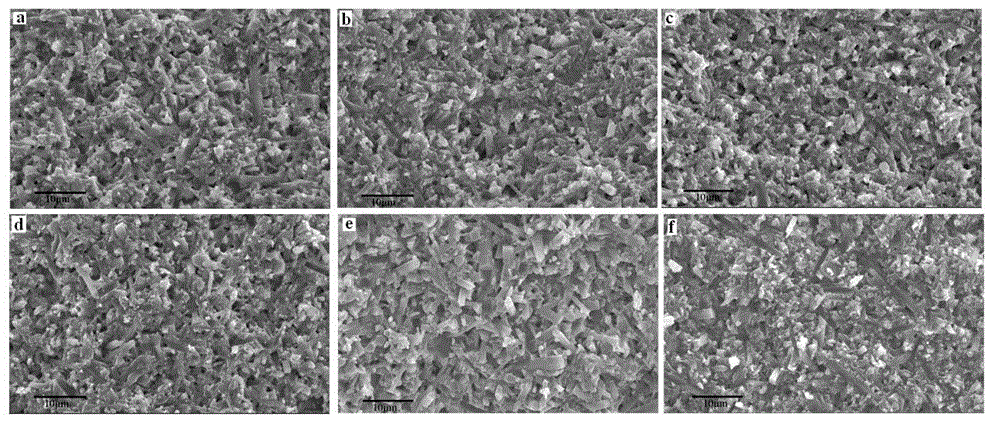

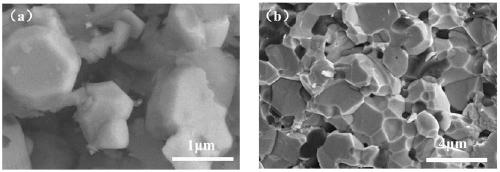

Method for preparing high-thermal-conductivity high-strength silicon nitride ceramic

InactiveCN104098336AMeet application requirementsHigh thermal conductivityThermal conductivityHigh intensity

A disclosed method for preparing high-thermal-conductivity high-strength silicon nitride ceramic comprises: uniformly mixing alpha-Si3N4 powder and a sinter aid according to a ratio, and then successively performing dry-pressing forming and isostatic pressing processing, so as to prepare a blank, wherein the sintering aid is a mixture employing Yb2O3 as a main sintering aid and employing at least one of Y2O3, Lu2O3, Nd2O3, Er2O3 and MgO as an auxiliary sintering aid; and embedding the prepared blank in Si3N4 powder, and performing gas pressure sintering at 1650-1850 DEG C in inert atmosphere, and then cooling to room temperature along with a furnace. The silicon nitride ceramic material prepared by using the method has high thermal conductivity and high strength, and is capable of satisfying application requirements of silicon nitride ceramic to fields such as high-speed circuits and large-power devices. The preparation method is simple in technology and low in cost, is suitable of large-scale production, and has practical value.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

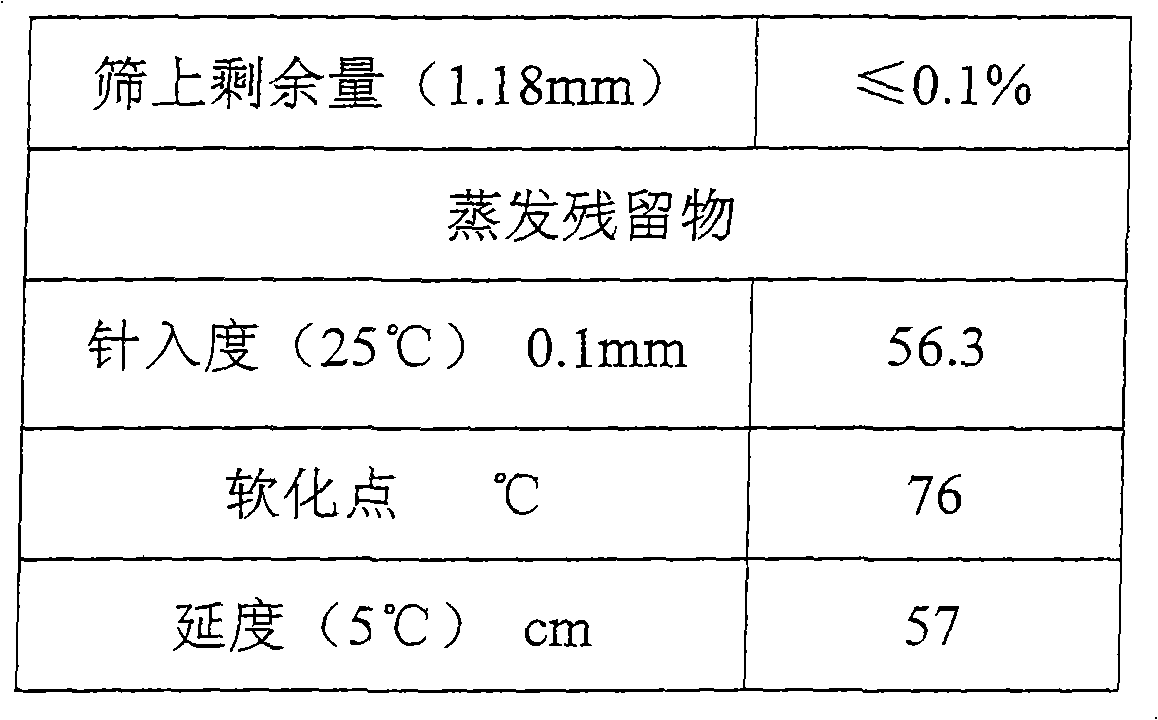

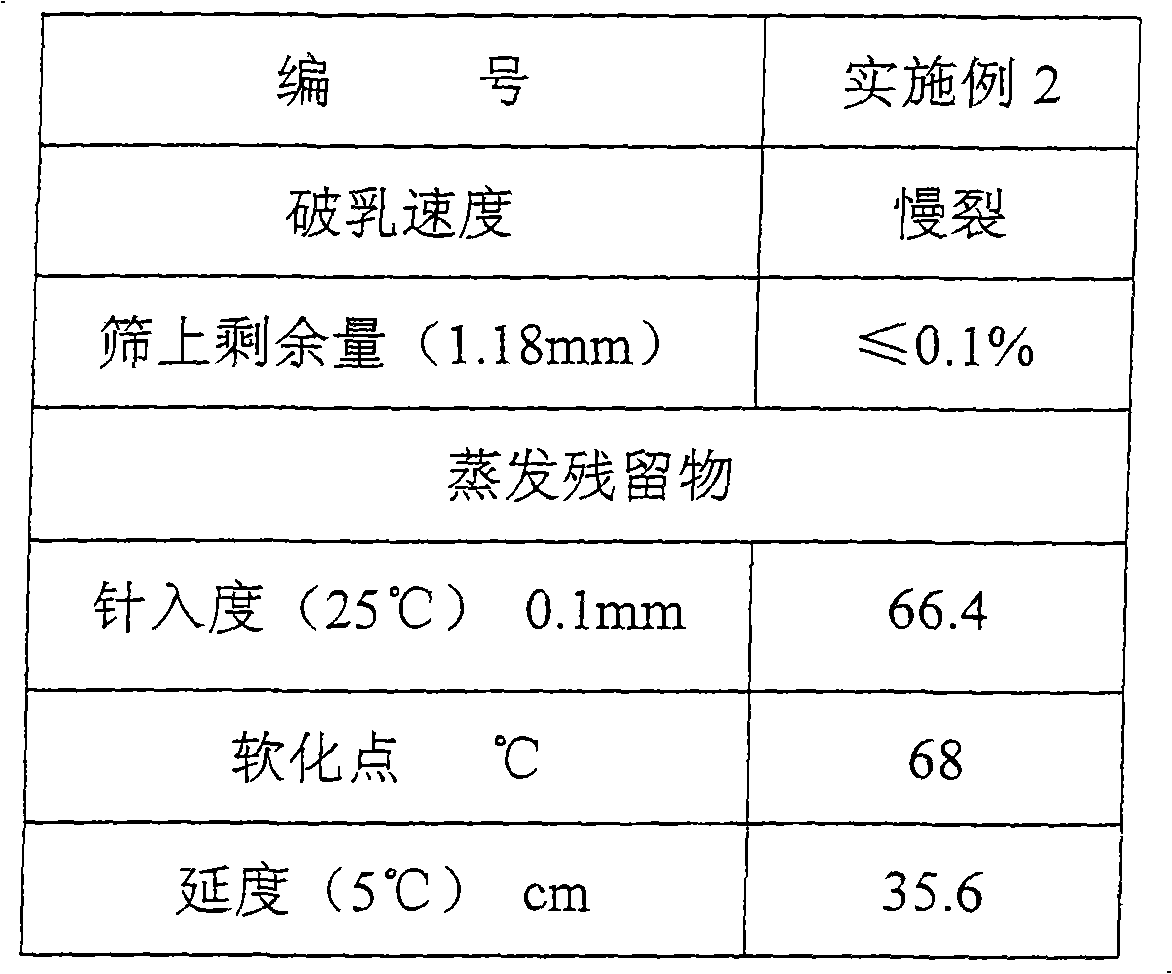

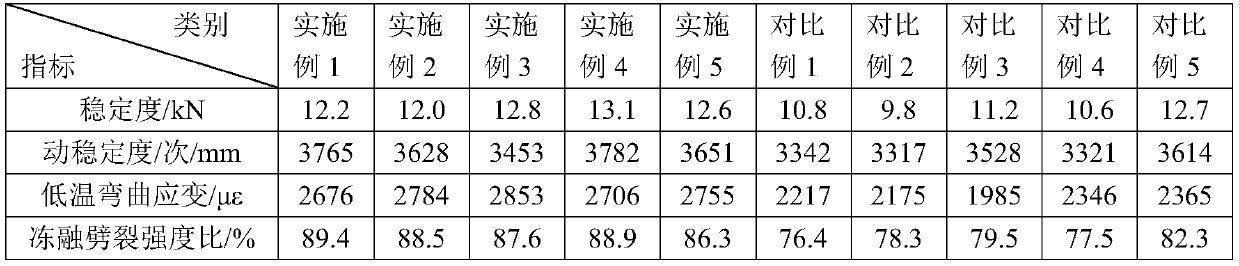

High-temperature behavior stable modified emulsified asphalt and method for preparing the same

InactiveCN101492571AStable performance at high temperatureImprove performanceBuilding insulationsSlurryPyrophosphoric acid

The invention relates to stable high temperature performance modified emulsified asphalt and a preparation method thereof. Based on the weight of matrix asphalt, the mixture of phosphorus-containing compound is 0.1-5%, compound emulsifying agent is 0.5-5%, modifying agent rubber latex is 1-10%. The components and weight percentage of the mixture of the phosphorous-containing compound are: 35%-40% of polyphosphoric acid, 20%-30% of pyrophosphoric acid, and 35%-40% of phosphoric acid. The components and weight percentage of the compound emulsifying agent are: 25%-30% of CAPB, 5%-10% of octadecane DTMAC and 60%-65% of water. And the modified agent rubber latex is styrene butadiene latex. Compared with the prior art, the modified emulsified asphalt prepared by the invention has the following prominent advantages that the softening point of evaporated residue of the modified emulsified asphalt is high; the modified emulsified asphalt has stable high temperature performance, simple processing technique, convenient operation, and high performance and is applicable to the micro-surface treatment of the slurry seal.

Owner:SHANGHAI SINOFRA FINE CHEM

Method for preparing high temperature NTC (Negative Temperature Coefficient) thermistor material

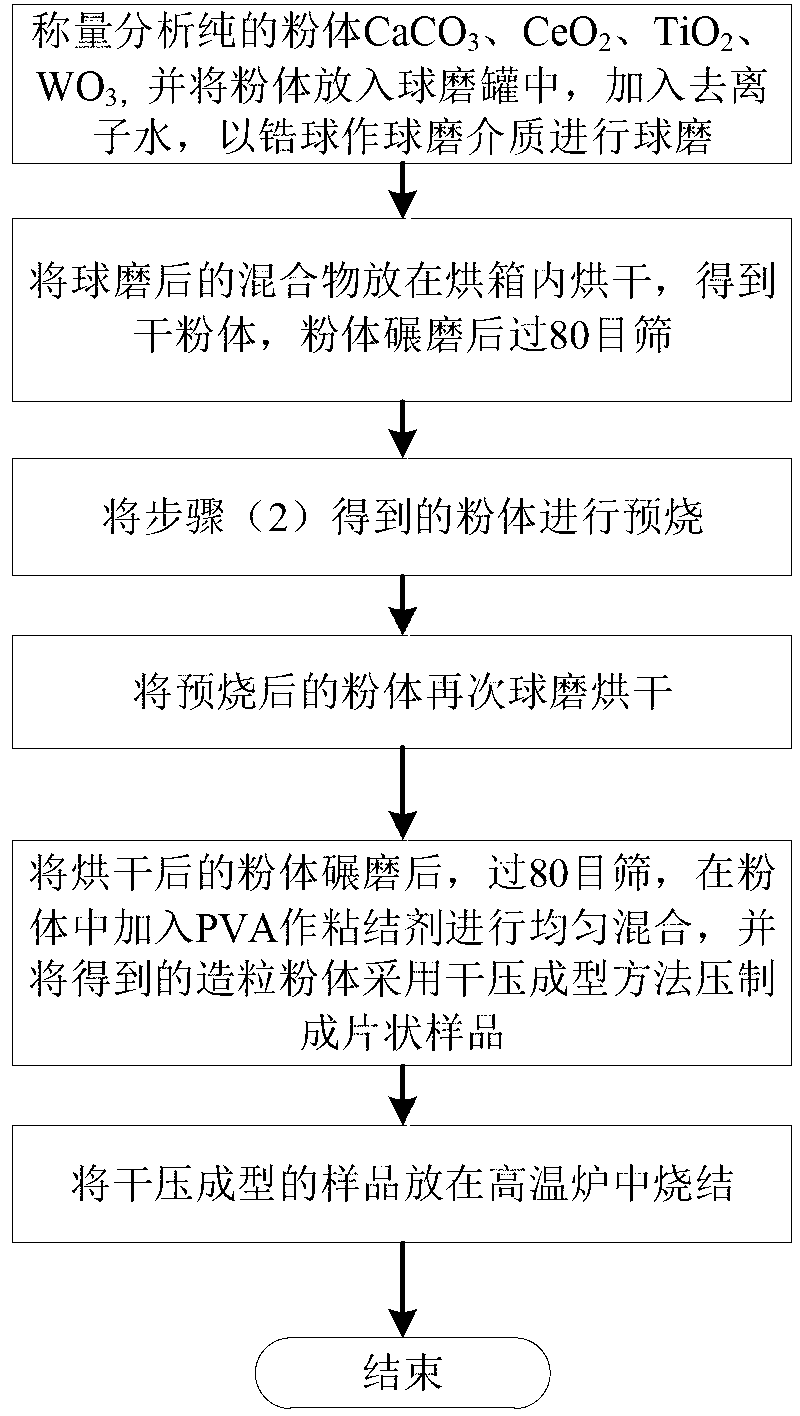

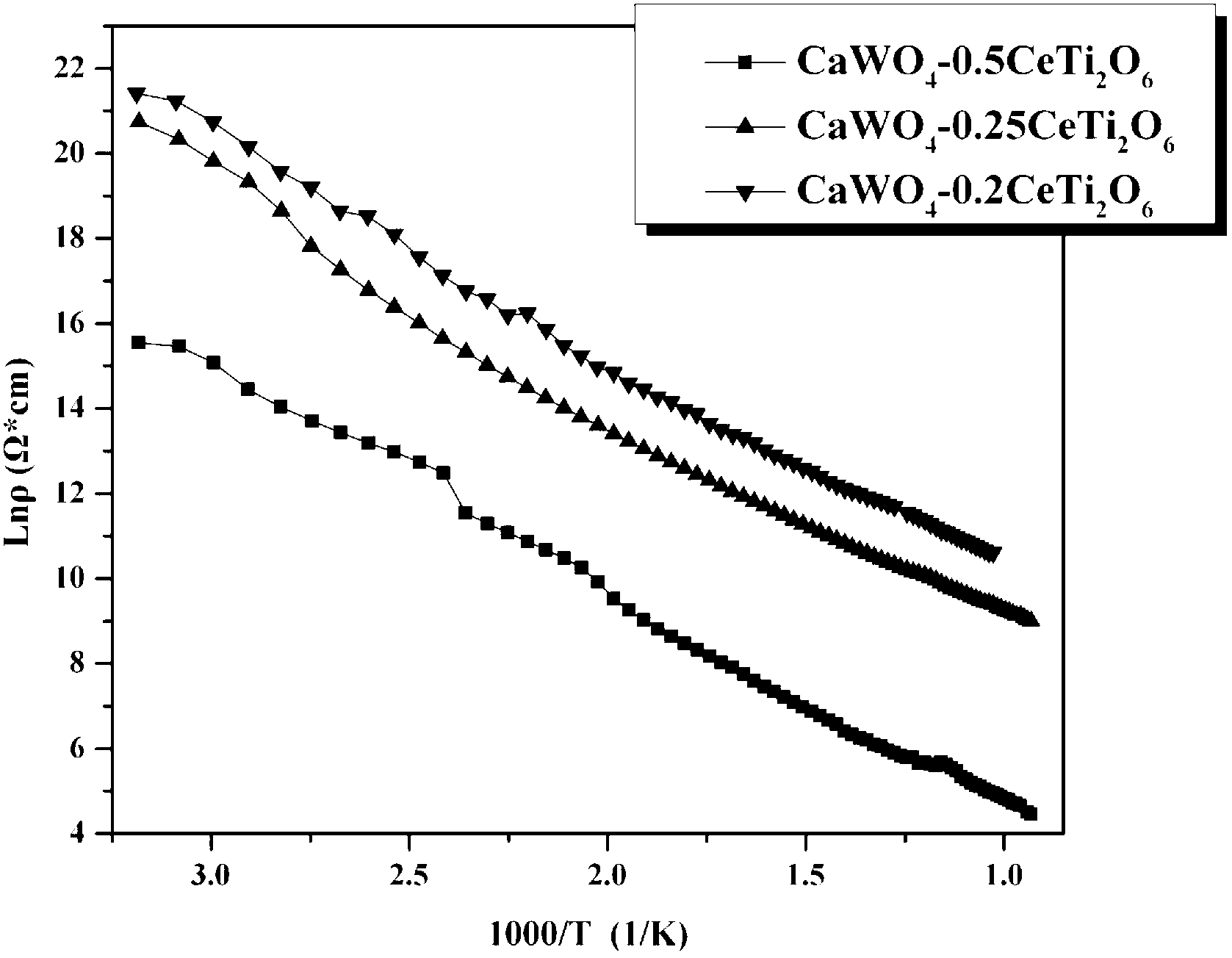

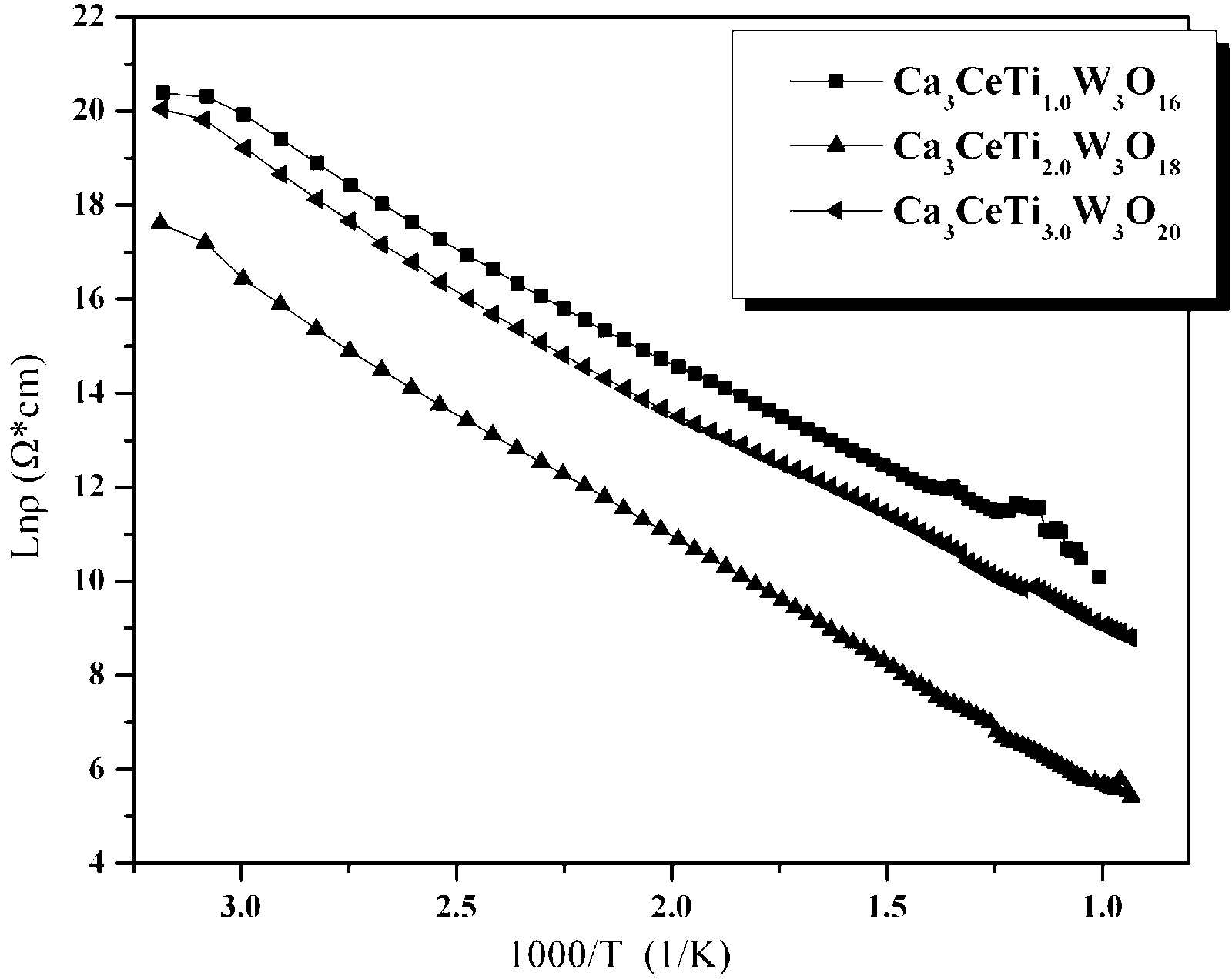

The invention discloses a method for preparing a high temperature NTC (Negative Temperature Coefficient) thermistor material, which comprises the following steps of: according to a formula of CaWO4-xCeTiyO2y+2, weighing and analyzing pure powdered CaCO3, CeO2, TiO2 and WO3, placing the powder into a ball milling tank, adding deionized water and zirconium ball grinding stone and carrying out ball milling for four hours; drying ball-milled slurry, grinding the dried powder and sieving the powder through a 80-mesh sieve; presintering the sieved powder, ball-grinding the presintered powder again, drying and grinding the powder and sieving the power through the 80-mesh sieve to obtain uniform and fine powder; and finally, placing a dry-pressed sample into a high temperature furnace to sinter so as to obtain the thermistor material. A main crystal phase of the thermistor material prepared by the method disclosed by the invention is a scheelite phase; the thermistor material has room temperature resistivity of 5.642*10<6> to 1.982*10<9> ohm.cm and has material constant of 5,077 to 7,275K; in the integral test temperature range, a resistor temperature relation curve LnRho-1000 / T has good linearity; and the method is suitable for temperature measurement in the wide temperature range of room temperature to 1,000 DEG C.

Owner:HUAZHONG UNIV OF SCI & TECH

Ceramic connection method by using high-temperature interlayer material

The invention belongs to the field of ceramic material preparation and provides a ceramic connection method by using a high-temperature interlayer material. Ti3SiC2 is used as a high-temperature interlayer material, the high-temperature interlayer material and a ceramic material are loaded in a graphite die in a sequence of the ceramic material, the high-temperature interlayer material and the ceramic material, the connection of the ceramic material is realized through a spark plasma sintering technology, and excellent connection effect is achieved during the connection of carborundum ceramic. The high-temperature interlayer material can be directly used for connecting the ceramic material and a ceramic-based composite material without conducting surface pre-coating or other modification treatments to the surface of the ceramic material before connection. The ceramic material connected by the high-temperature interlayer material has high connection strength and stable high-temperature property.

Owner:INNER MONGOLIA UNIV OF TECH

Calcium oxide foam ceramic and preparation method thereof

The invention relates to calcium oxide foam ceramic and a preparation method thereof. The preparation method thereof is technically characterized by comprising the following steps of mixing 90 to 99.5wt% of calcium hydroxide powder and 0.5 to 10wt% of other hydroxides, so as to obtain mixed powder; adding 0.1 to 3wt% of additive and 30 to 100wt% of water into the mixed powder, and mixing in a wet way, so as to obtain slurry; soaking a polyurethane sponge into the slurry for 2 to 20min, fetching out the polyurethane sponge containing the slurry, and extruding; drying the extruded polyurethane sponge at the temperature of 110 DEG C for 12 to 24h, so as to obtain a prefabricated block of the calcium oxide foam ceramic; finally, putting the prefabricated block of the calcium oxide foam ceramic into a heating furnace, heating to 1400 to 1700 DEG C, insulating heat for 1 to 5h, and naturally cooling, so as to obtain the calcium oxide foam ceramic. The calcium oxide foam ceramic has the advantages that the technology is simple, the cost is low, and the energy consumption is low; the prepared calcium oxide foam ceramic has high use temperature, stable high temperature property and good anti-hydration property, and is suitable for using as a high-temperature material for smelting high-purity melts.

Owner:WUHAN UNIV OF SCI & TECH

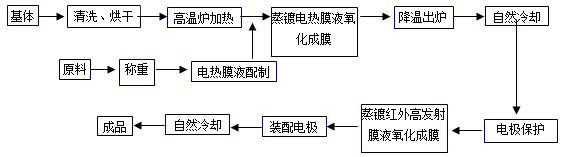

Infrared electric heating film heating tube with double-film layer structure as well as preparation method and application thereof

InactiveCN102036433AEnhanced Radiation Heat TransferReduce convective heat transferHeater elementsHeating element shapesIonElectric heating

The invention discloses an infrared electric heating film heating device with a double-film layer structure, which structurally comprises an electric heating film substrate and electrodes arranged on the two ends of the electric heating film substrate, wherein an electric conduction film layer and an infrared high emission film layer are sequentially evaporated on the surface of the electric heating film substrate. A preparation method of the infrared electric heating film heating device comprises the steps of: sequentially evaporating the electric conduction film layer and the infrared high emission film layer to the electric heating film substrate by using a high-temperature evaporation furnace, wherein an electric heating film solution comprises the components in parts by weight: 45-58 parts of stannic chloride, 0.3-2.0 parts of antimony butter, 0.4-1.2 parts of nickel trichloride, 0.3-1.0 part of indium chloride, 5-15 parts of ethanol / glycerol, 6-17 parts of inorganic acid, and 20-30 parts of deionized water, and an infrared high emission film solution comprises the components in parts by weight: 35-45 parts of manganous chloride, 15-20 parts of nickel dichloride, 5-10 parts of chromium trichloride, 5-15 parts of ethanol / glycerol and 20-30 parts of deionized water; and finally assembling the electrodes to obtain the infrared electric heating film heating device. In the invention, the double-film layer structure is adopted for the infrared electric heating film heating device, which can greatly enhance radiative heat transfer, reduce convection heat transfer, improve energy efficiency and save energy sources.

Owner:吕一诺

Method for preparing super high temperature zirconia ceramic fiber

ActiveCN103757751AThe synthesis process is simpleNo pollution in the processInorganic material artificial filamentsFiberSpinning

The invention relates to a method for preparing a super high temperature zirconia ceramic fiber. The method mainly comprises the following steps: stirring zirconium carbonate, yttrium nitrate and nitric acid as main raw materials and deionized water as a diluting solvent at the room temperate so as to directly generate a composite polymerization solution with yttrium zirconium ions, depressurizing, distilling and concentrating the solution to finally obtain a yttrium zirconium ion composite sol spinning liquid, performing high speed eccentric wire throwing to obtain a yttrium zirconium containing inorganic hydrate fiber, and performing thermal treatment and super high temperature treatment on the yttrium zirconium containing inorganic hydrate fiber under special atmosphere so as to obtain the yttrium zirconium composite oxide ceramic fiber. The preparation process is simple, and the prepared fiber is simple in preparation process, high in purity, stable in high temperature property and can be used within the temperature range less than 2,250 DEG C for a long time.

Owner:宜兴市恒祥耐火材料有限公司

Zirconium-containing high-temperature silicon carbide fiber and preparation method thereof

ActiveCN108193325AHigh strengthStable performance at high temperatureFilament/thread formingArtifical filament manufactureCross-linkFiber bundle

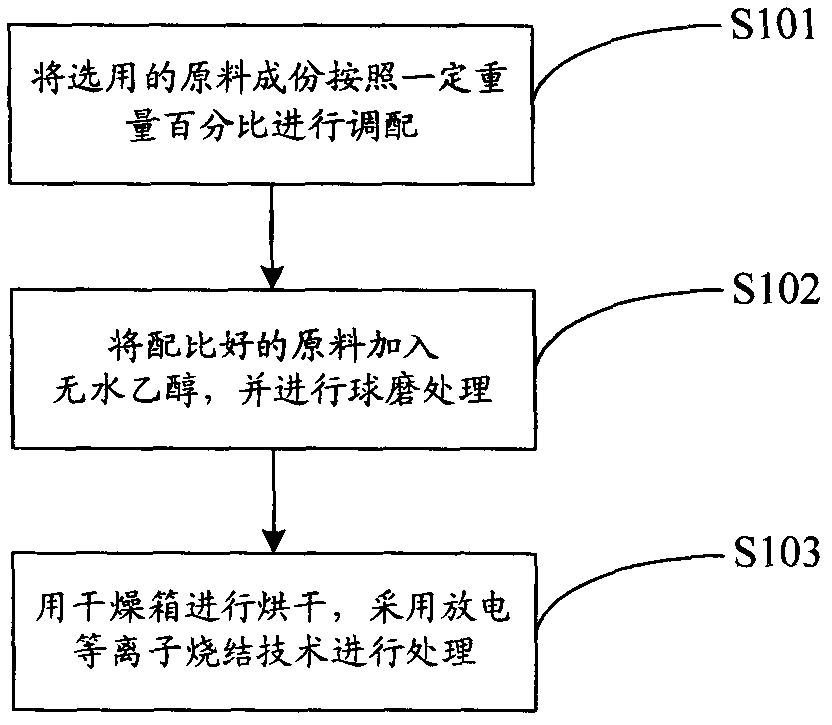

The invention relates to a zirconium-containing high-temperature silicon carbide fiber and a preparation method thereof. The preparation method comprises the following steps: S101, dissolving yttriumoxide into ethanol, heating, and uniformly stirring so as to obtain a first solution; S102, mixing and uniformly mixing the first solution with a nano-zirconia dispersion so as to obtain a second solution; S103, dissolving polycarbosilane into dimethylbenzene, adding a second solution, stirring, heating till a solvent is completely volatized so as to obtain a powder product; S104, performing melting spinning and non-melting treatment on the powder product so as to obtain a cross-linked fiber bundle; and S105, performing high-temperature sintering on the cross-linked fiber bundle in an inert atmosphere, and cooling to the room temperature, thereby obtaining the silicon carbide fiber. Zirconium oxide and yttrium oxide are introduced in the preparation process of the silicon carbide fiber preparation process, by virtue of the phase change size expansion of the zirconium oxide and the high-temperature flowability of the yttrium oxide, the silicon carbide fiber which is high in strength andstable in property at high temperatures is prepared, and the silicon carbide fiber has high application prospects in high-temperature fields such as aerospace.

Owner:江西信达航科新材料科技有限公司

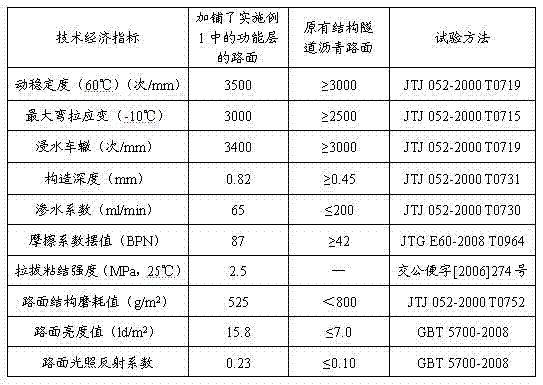

Tunnel bituminous pavement light color functional layer based on light color cement material

InactiveCN102408657AImproves rutting resistanceImproves resistance to water damageIn situ pavingsCrushed stoneRoad surface

The invention aims at providing a tunnel bituminous pavement light color functional layer based on a light color cement material. The functional layer is characterized by comprising the light color cement material and a broken stone material, wherein the light color cement material is formed by mixing a component A and a component B in a mass ratio of 1:1, wherein the component A and the component B have specific compositions. The tunnel bituminous pavement light color functional layer based on the light color cement material has excellent track-resisting capacity and water damage resisting capacity; and the drawing and bonding strength of the light color cement material is obviously improved, the adhesion between the light color cement material and the stone material is improved further, so that the functional layer has more excellent structural integrity and road surface functionality.

Owner:重庆市智翔铺道技术工程有限公司

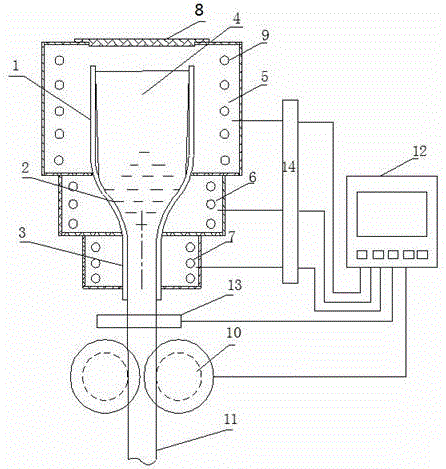

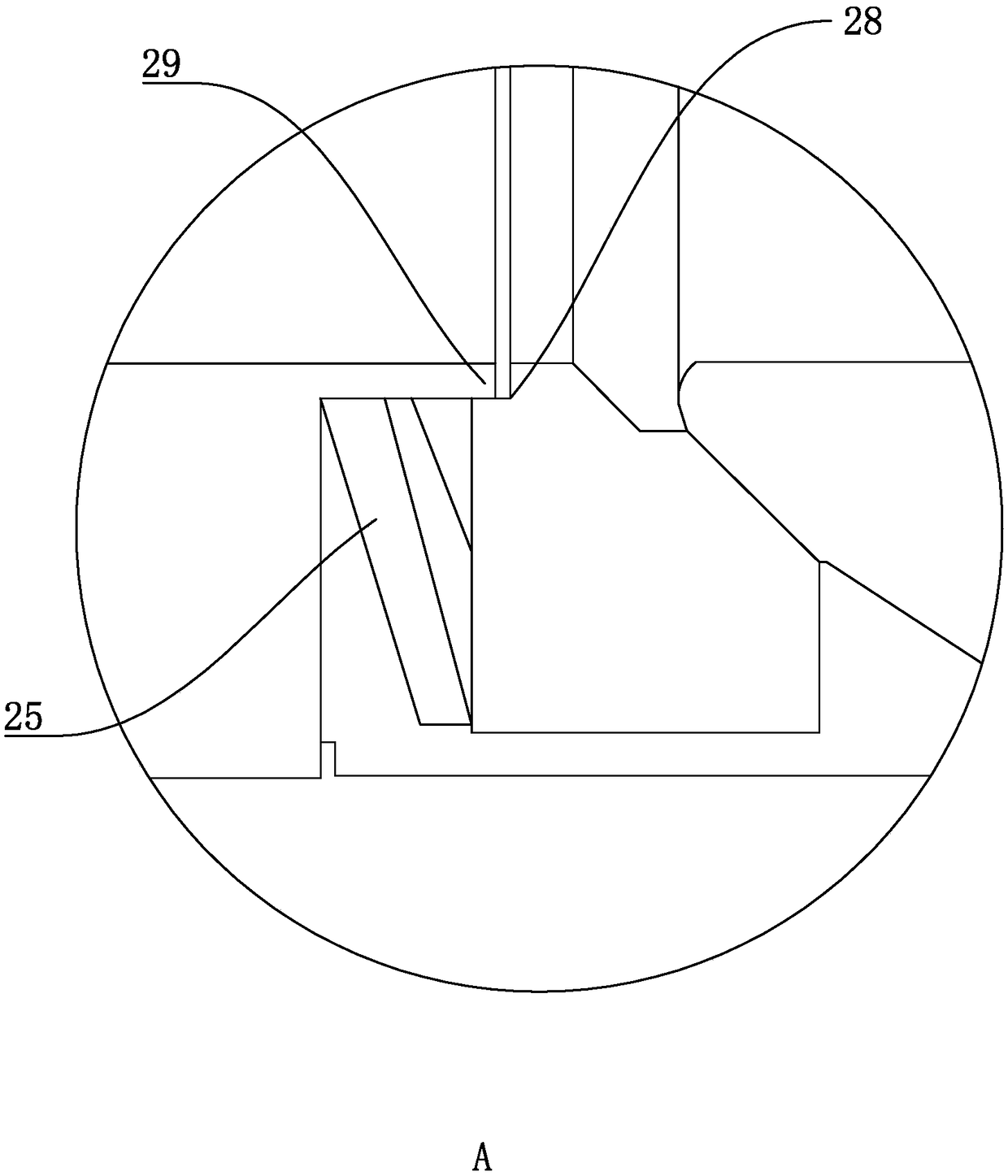

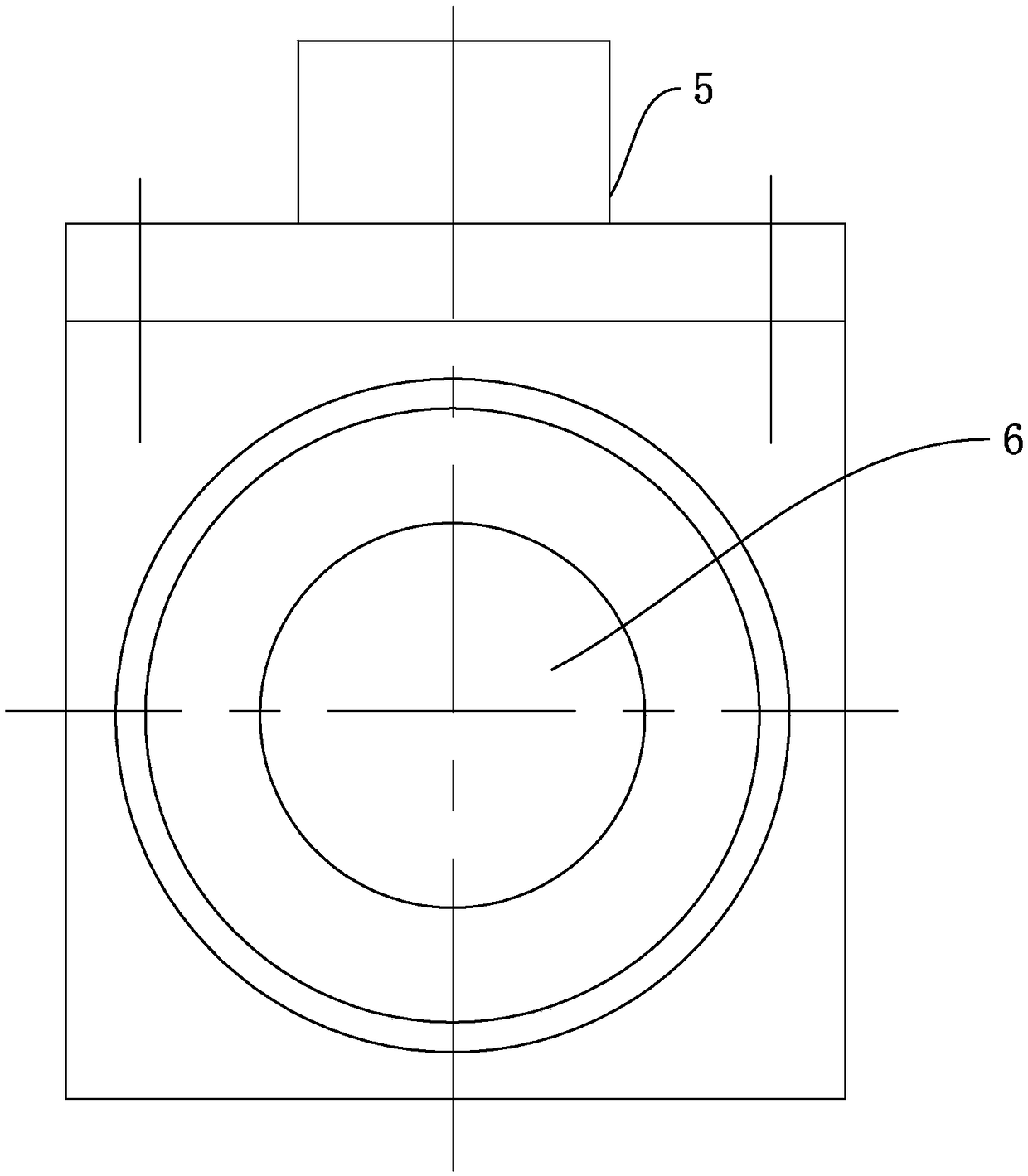

Optical glass rod material drawing device

ActiveCN106082635AGood corrosion resistanceStable performance at high temperatureGlass making apparatusGlass productionDirect productionCrucible

The invention provides an optical glass rod material drawing device and belongs to the technical field of secondary forming of optical glass. The problem of low master rod material utilization rate caused by secondary rod material surface defects at present is mainly solved. The optical glass rod material drawing device is mainly characterized by comprising a softening crucible, a viscosity adjusting crucible and a rod material forming mold which are connected from top to bottom to form a whole. Heating rods are arranged in a heat-preserving furnace body outside the softening crucible, the viscosity adjusting crucible and the rod material forming mold. A rod material traction device is arranged below the rod material forming mold. The rod material forming mold is smaller than the softening crucible in cavity cross section area. The surfaces of the inner cavities of the softening crucible, the viscosity adjusting crucible and the rod material forming mold are continuously smooth. A charging port is formed in the top of the softening crucible. The optical glass rod material drawing device has the advantages that glass master rod materials which have forming defects on the surfaces or are not suitable for direct secondary rod material production can be directly drawn into required sub-rod materials and the product yield is improved, and is mainly used for secondary draw-forming of optical glass rod materials.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

High-temperature heat-storing device using concrete and heat storage method thereof

InactiveCN100578133CImprove heat transfer performanceLarge heat storage capacityHeat storage plantsThermodynamicsMechanical engineering

The invention relates to high-temperature heat storage device utilizing concrete and its heat storing method. Its heat exchange pipeline is buried in concrete heat storage block, heat exchange fin is at external wall of the pipe, a valve is mounted at cold fluid inlet, cold fluid outlet is at the other end of cold fluid tank; a valve is mounted at heat fluid inlet, heat fluid outlet is at the other end of heat fluid tank. Heat exchange is carried out utilizing the difference of temperature between the concrete heat storage block and the heat exchange pipeline.

Owner:GUANGDONG FIVESTAR SOLAR ENERGY

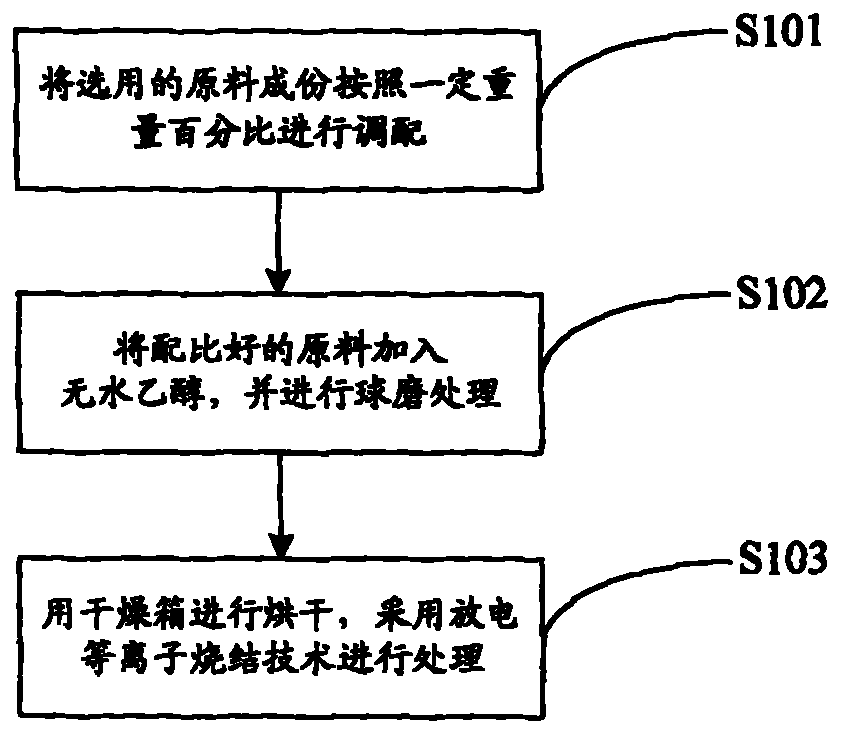

Superhigh-temperature SiC-HfB2 composite ceramic and preparation method and application thereof

InactiveCN109665848AStable performance at high temperatureImprove antioxidant capacityComposite ceramicSolvent

The invention belongs to the technical field of ceramic materials and discloses superhigh-temperature SiC-HfB2 composite ceramic and a preparation method and application thereof. The superhigh-temperature SiC-HfB2 composite ceramic is prepared by: adding a solvent and a ball milling medium into SiC powder, HfO2 powder, Ta2O5 powder and amorphous boron powder, mixing, drying to obtain mixed powder,die-pressing the mixed powder to obtain a mixed powder blank, thermally treating in vacuum, heating to 900-1300 DEG C, carrying out temperature holding I, heating to 1500-1800 DEG C, carrying out temperature holding II, thermally treating in vacuum to obtain SiC-HfB2 powder, performing discharge plasma sintering to heat the SiC-HfB2 powder to 1000-1400 DEG C, injecting a protective atmosphere, heating to 1800-2200 DEG C, and calcining. The superhigh-temperature SiC-HfB2 composite ceramic has good resistance to high temperature.

Owner:GUANGDONG UNIV OF TECH

Light granular calcium oxide material and preparation method thereof

ActiveCN106186021ALow costReduce energy consumptionCalcium/strontium/barium oxides/hydroxidesCalcium hydroxideThermal insulation

The invention relates to a light granular calcium oxide material and a preparation method thereof. According to the technical scheme, the preparation method comprises the following steps: firstly, putting calcium hydroxide powder into a bucket of a pelletizer; adding water which accounts for 10-30wt% of the calcium hydroxide powder under the condition that the rotation speed of a rotor is 1000-3000rpm; adjusting the rotation speed of the rotor to be 500-1000rpm, and after calcium hydroxide granules are formed, discharging the calcium hydroxide granules; putting the calcium hydroxide granules into a heating furnace, keeping the temperature for 1-5 hours at 600-1300 DEG C, and introducing nitrogen or argon into the furnace at a flowing speed of 0.5-5 liters per minute till the temperature is 35 DEG C, thereby obtaining the light granular calcium oxide material. The preparation method has the characteristics of being simple in process, low in cost and low in energy consumption; the prepared granular calcium oxide material is high in use temperature, stable in high-temperature property, low in volume density, light in weight and good in thermal insulation.

Owner:WUHAN UNIV OF SCI & TECH

Nitrided steel base plate with excellent corrosion resistance and production method

A nitrided steel base plate with excellent corrosion resistance comprises, by weight percent, 0.010%-0.10% of C, 0.10%-1.00% of Mn, 0.010%-0.10% of Si, smaller than or equal to 0.02% of P, smaller than or equal to 0.01% of S, 0.50%-1.50% of Als, smaller than or equal to 0.005% of N, 0.10%-1.50% of Cr, 0.01%-1.00% of Cu and 0.01%-1.00% of Ni. A production method comprises the preparing steps of melting and continuous casting blank forming, cast blank heating, hot rolling, reeling, cold rolling, annealing and flattening. Steel used for a traditional iron pan serves as a base body, and rusting can be effectively avoided after nitriding treatment; the surface hardness is high, the corrosion resistance is excellent, the high-temperature performance is stable, and the fatigue resisting strength is high. After the low-carbon steel plate is subjected to the nitriding treatment, the low-carbon steel plate can replace stainless steel and functional coating steel plates to be used for manufacturing woks, corrosion resisting containers and the like.

Owner:武汉钢铁有限公司

Titanium coated calcium oxide material and preparation method thereof

The invention relates to a titanium coated calcium oxide material and a preparation method thereof. The preparation method has the technical scheme that calcium hydroxide fine powder is used as raw materials; water accounting for 0.2 to 4 weight percent of raw materials is externally added; mixing, formation and drying are performed to obtain a calcium hydroxide blank body; then, the blank body isput into a container; pressure maintaining is performed for 4 to 6 minutes under the condition of 1 to 2kPa; a titanic acid ester solution is injected into the container at uniform speed until the calcium hydroxide blank body is submersed; then, pressure maintaining is performed for 4 to 6 minutes under the condition of 1 to 2kPa; the container injected with the titanic acid ester solution is taken out; still standing is performed for 20 to 40 minutes in air; the calcium hydroxide blank body soaked in the titanic acid ester solution is taken out; still standing is performed for 20 to 24h. Finally, heat treatment is performed for 1 to 8h under the temperature of 1300 to 1700 DEG C; natural cooling is performed; the titanium coated calcium oxide material is prepared. The process is simple;the prepared titanium coated calcium oxide material has high use temperature, stable high-temperature performance and good anti-hydration performance; high-temperature melts can be purified; the titanium coated calcium oxide material is suitable for being used as a high-temperature material for high-purity melt smelting.

Owner:WUHAN UNIV OF SCI & TECH

Dense granule magnesia-calcia material and preparation method thereof

The invention relates to a dense granule magnesia-calcia material and a preparation method thereof. According to the technical scheme, lightly burnt dolomite is hydrated, filtered and dried and then magnesium-calcium hydroxide powder is obtained; the magnesium-calcium hydroxide powder and an additive are prepared in the mass ratio being 1:(0.002-0.05), subjected to wet grinding, filtered, dried and ground; the magnesium-calcium hydroxide mixture powder obtained through grinding is put into granulation equipment, water accounting for 8-30wt% of the magnesium-calcium hydroxide mixture powder is added under the condition of 1,000-3,000 rpm, and when granules are formed, the granulation equipment is adjusted to run at the speed of 500-1,000 rpm and is stopped after all the magnesium-calcium hydroxide mixture powder is made into magnesium-calcium hydroxide granules; the magnesium-calcium hydroxide granules are put into a heating furnace and kept at the temperature of 1,400-1,800 DEG C for 1-5 h, nitrogen or argon is introduced at the speed of 0.5-5 l / min until the temperature reaches 35-70 DEG C, and the dense granule magnesia-calcia material is obtained. According to the dense granule magnesia-calcia material, the process is simple, the cost is low and the energy consumption is low; the prepared dense granule magnesia-calcia material can be used at a high temperature and has stable high-temperature performance and good hydration resistance.

Owner:WUHAN UNIV OF SCI & TECH

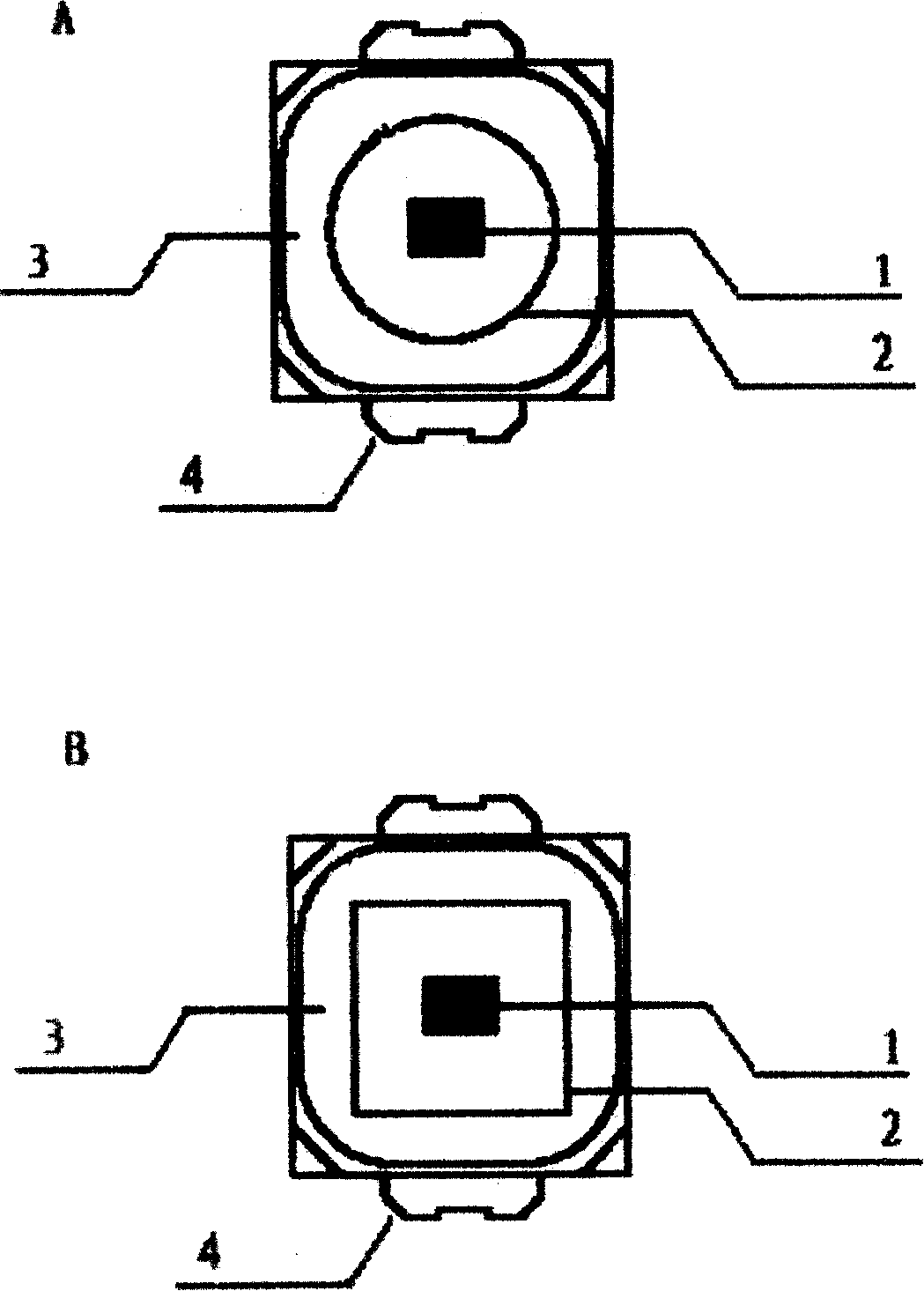

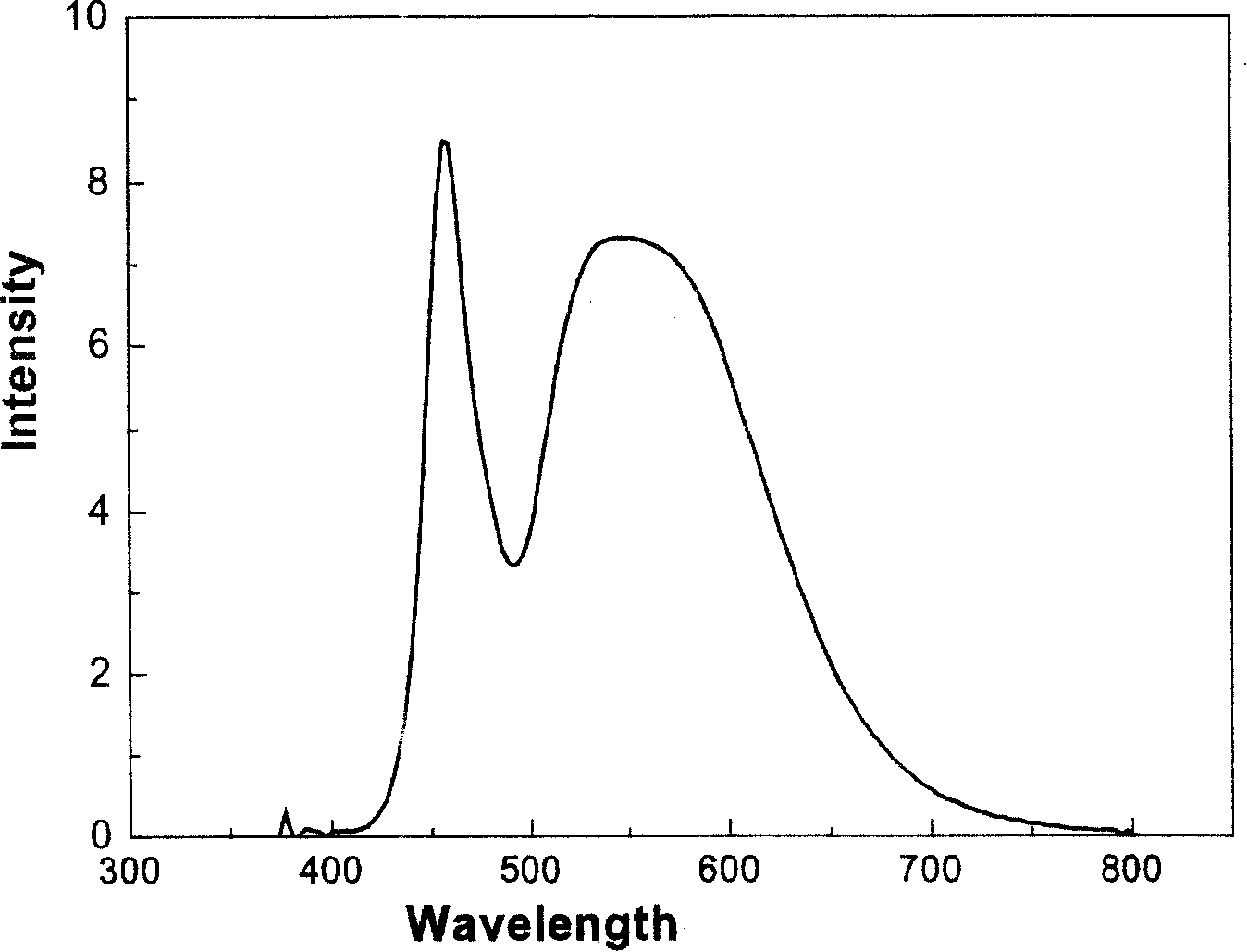

YAG chip-type white-light light-emitting-diode and its packing method

ActiveCN100389504CStable chemical propertiesStable performance at high temperatureSolid-state devicesSemiconductor devicesSingle crystalSealant

Using YAG single crystal body converts part of blue light sent from GaN based semiconductor LED crystal grain to another light in one or more ideal wave bands. Then, not converted remanent blue light sent from LED crystal grain is mixed with the converted light in ideal wave band to generate white light. Through controlling each parameter of fluorophor of single crystal chip, the method adjusts and controls proportion between yellow light converted by the fluorophor of single crystal and not converted blue light. At the same time, using evenness of single crystal chip obtains even white light in high quality. Comparing with traditional technique, the invention solves difficult issue of controlling dispersivity of powder of fluorophor in sealant in silicone greases or resins. After wafer is cut to chips in desired size, packaging operation is full automatic so as to raise degree of mechanization.

Owner:SUN YAT SEN UNIV +2

Copper alloy and manufacturing process thereof

InactiveCN102230102AHigh tensile strengthImprove wear and corrosion resistanceHigh resistanceRare earth

The invention discloses copper alloy and a manufacturing process thereof. The manufacturing process comprises the following steps of: preparing an intermediate copper alloy block and a rare-earth alloy block; adding the prepared intermediate copper alloy block into refined copper liquid in a tilting refining furnace, and homogenizing copper alloy; and adding the weighed rare-earth alloy block at the initial end of a sealing trough, and smelting to obtain the copper alloy. The copper alloy has the hightensile strength, high wear resistance and high corrosion resistance, has the stable high-temperature performance at high temperature, namely a high-temperature softening initial point is high, and has the high conductive performance.

Owner:华瀚管道系统科技有限公司

Calcium oxide particle and preparation method thereof

The invention relates to a calcium oxide particle and a preparation method thereof. The preparation method comprises the following steps: mixing 20-95 wt% of limestone powder with 5-80 wt% of calciumoxide powder to obtain a mixed powder; adding the mixed powder and water accounting for 10-30% of the weight of the mixed powder into a material barrel for a granulating device, starting the granulating device, performing granulation at a rotating speed of a rotor of 500-2000 rpm, and taking out obtained particles after the mixed powder in the material barrel are completely converted into the particles; and adding the particles into a heating furnace, performing heat insulation at 1500-1800 DEG C for 1-5 h, and cooling the particles to prepare the calcium oxide particle. The particle size of the calcium oxide particle is 0.1-8 mm, and the content of CaO in the calcium oxide particle is equal to or more than 95 wt%. The preparation method has the advantages of simple process and low preparation cost, and the prepared calcium oxide particle has the characteristics of high use temperature, stable high temperature performances and good hydration resistance, and is an optically selected rawmaterial for calcium oxide ceramic, refractive materials and other high-grade materials.

Owner:WUHAN UNIV OF SCI & TECH

Low-density oil-well cement

InactiveCN108059401ALow densityImprove liquiditySolid waste managementDrilling compositionPhosphateLow density

The invention belongs to the technical field of construction materials and discloses high temperature resistant low-density oil-well cement. The low-density oil-well cement is prepared from the following substances in parts by weight: 40 to 60 parts of G-grade oil-well cement, 2 to 5 parts of phosphorus gypsum, 10 to 20 parts of waste glass powder, 30 to 40 parts of fly ash, 0.5 to 3 parts of a plastic expanding agent, 0.05 to 1 part of a stabilizer, 0.5 to 1 part of a retarder, 0.01 to 0.03 part of an enhancing agent, 1 to 3 parts of a dispersant and 0.5 to 2 parts of aluminum dihydrogen phosphate. The low-density oil-well cement disclosed by the invention has the advantages of small density, good flowability, stable high-temperature performance and the like, and is very suitable for requirements of cementing engineering of deep wells and long shut-in wells.

Owner:毕言铎

Aluminiferous silicon carbide fiber and preparation method thereof

The invention relates to an aluminiferous silicon carbide fiber and a preparation method of the silicon carbide fiber. The method comprises the following steps of: S101: grinding aluminum isopropoxide, heating to a molten state, S102: adding aluminum isopropoxide in the molten state into hot water for uniform stirring and standing, regulating a pH (potential of hydrogen) value of a solution afterthe standing to 2.0-3.0, and performing backflow ageing to form aluminum collosol, S103: soaking a melt spinning product in the aluminum collosol, and then taking out and drying the product, S104: performing infusibility treatment on a product obtained in S103, and S105: performing high-temperature sintering on a product obtained in S104, and obtaining the aluminiferous silicon carbide fiber at last. In a preparation process of the silicon carbide fiber, an Al element is introduced by a physical method; the method is simple in technology, has no adverse effect on an environment; and the prepared aluminiferous silicon carbide fiber is high in strength, large in modulus and stable in high temperature property, and has good application prospects in the high temperature field of aerospace, weaponry and the like.

Owner:江西信达航科新材料科技有限公司

Low-cost ramming material for RH and preparation method thereof

The invention discloses a low-cost ramming material for RH and a preparation method thereof and belongs to the technical field of smelting refractory materials. The low-cost ramming material for RH comprises, by mass, 20-25% of a used waste refractory material with particle sizes of greater than 3mm and less than or equal to 5mm, 20-25% of a used waste refractory material with particle sizes of greater than 1mm and less than or equal to 3mm, 25-30% of a used waste refractory material with particle sizes of less than or equal to 1mm, 20-25% of magnesia, 2-5% of a binding agent and 0.1-0.5% of additives. After the ramming material is used, refractory material resources are reasonably applied, and environmental pollution caused by solid waste emission is reduced. The ramming material for RH has the characteristics of low cost, stable high-temperature performances and no new pollution.

Owner:PANZHIHUA GANGCHENG GROUP

Scrap aluminum regeneration type heat-resistant aluminum alloy and preparation method thereof

ActiveCN106319274AImprove thermal stabilityImprove high temperature strengthCopper wireUltimate tensile strength

The invention discloses a scrap aluminum regeneration type heat-resistant aluminum alloy and a preparation method of the scrap aluminum regeneration type heat-resistant aluminum alloy. The raw materials of the heat-resistant aluminum alloy comprise, by mass, 60.5%-63.0% of scrap aluminum profiles, 10.5%-11.0% of scrap aluminum castings, 7.0%-7.5% of scrap aluminum plates, 15.0%-16.0% of waste aluminum wires and 4.5%-5.5% of scrap copper wires. According to the scrap aluminum regeneration type heat-resistant aluminum alloy and the preparation method of the scrap aluminum regeneration type heat-resistant aluminum alloy, scrap aluminum is used as the raw material to be directly regenerated for production of the heat-resistant aluminum alloy, the use value of the scrap aluminum is improved, the production cost of the heat-resistant aluminum alloy is lowered, and the produced heat-resistant aluminum alloy has excellent indoor-temperature strength and high-temperature strength, can be applied to the automobile field, the rail transit field, the maritime work facility field, the aerospace field and the like and has broad application prospect.

Owner:广东省科学院工业分析检测中心

High-temperature and high-pressure rigidity seal hydrophobic ball valve

PendingCN108953661AExtended service lifeLong-lasting elasticitySpindle sealingsPlug valvesEngineeringHigh pressure

The invention discloses a high-temperature and high-pressure rigidity seal hydrophobic ball valve, aiming to provides a ball valve resistant to high temperature and high pressure. According to the technical scheme, the high-temperature and high-pressure rigidity seal hydrophobic ball valve comprises a valve body, the valve body is internally provided with a sealing device, and the sealing device comprises the valve body and a channel in the valve body; a fixed valve seat is fixedly welded to the right side of the valve body, and the valve body is further internally provided with a valve ball which forms a main seal with the fixed valve seat; a moving valve seat is arranged on the other side of the channel, and the moving valve seat is further provided with a pressure spring attached to thevalve ball; an adjusting valve seat is further arranged at the end, away from the valve ball, of the pressure spring, and a spring retaining ring is further arranged on the side, away from the pressure spring, of the adjusting valve cover; and an inner hole step is further arranged at the top end of the moving valve seat, and a lip tip for inserting the inner hole step is arranged at one end of the adjusting valve cover.

Owner:KROM WUXI FLUID CONTROL

Method for preparing AlCr2C material based on induction furnace melting

The invention discloses a method for preparing an AlCr2C material based on induction furnace melting. According to the technical scheme, the method comprises the following steps: vacuumizing an induction furnace with an aluminum ingot to be 7*10<-2>Pa or below, and filling argon gas in the induction furnace until the pressure of the argon gas is an atmospheric pressure; melting the aluminum ingot in the induction furnace, continuing to heat to 800-1700 DEG C, adding chromium powder, melting the chromium powder, adding graphite powder, preserving heat for 2-30 minutes, finally cooling to 600-1000 DEG C, casting and cooling to prepare the AlCr2C material. The preparation process is conducted under the condition that the pressure of the argon gas is the atmospheric pressure; the chromium powder and the graphite powder are added according to a molar ratio of the aluminum ingot to the chromium powder to the graphite powder of 1 to 2 to 1; the preparation process is simple; and the prepared AlCr2C material is stable in chemical components, uniform in microscopic structures, good in hydration resistance, stable in high-temperature performance, excellent in corrosion resistance and good in thermal shock resistance.

Owner:WUHAN UNIV OF SCI & TECH

Infrared electric heating film heating tube with double-film layer structure as well as preparation method and application thereof

InactiveCN102036433BReasonable ratioSimple preparation processHeater elementsHeating element shapesInfraredEvaporation

The invention discloses an infrared electric heating film heating device with a double-film layer structure, which structurally comprises an electric heating film substrate and electrodes arranged on the two ends of the electric heating film substrate, wherein an electric conduction film layer and an infrared high emission film layer are sequentially evaporated on the surface of the electric heating film substrate. A preparation method of the infrared electric heating film heating device comprises the steps of: sequentially evaporating the electric conduction film layer and the infrared high emission film layer to the electric heating film substrate by using a high-temperature evaporation furnace, wherein an electric heating film solution comprises the components in parts by weight: 45-58parts of stannic chloride, 0.3-2.0 parts of antimony butter, 0.4-1.2 parts of nickel trichloride, 0.3-1.0 part of indium chloride, 5-15 parts of ethanol / glycerol, 6-17 parts of inorganic acid, and 20-30 parts of deionized water, and an infrared high emission film solution comprises the components in parts by weight: 35-45 parts of manganous chloride, 15-20 parts of nickel dichloride, 5-10 parts of chromium trichloride, 5-15 parts of ethanol / glycerol and 20-30 parts of deionized water; and finally assembling the electrodes to obtain the infrared electric heating film heating device. In the invention, the double-film layer structure is adopted for the infrared electric heating film heating device, which can greatly enhance radiative heat transfer, reduce convection heat transfer, improve energy efficiency and save energy sources.

Owner:吕一诺

High-performance asphalt pavement regenerant and preparation method thereof

ActiveCN111410848AImproved thermal stabilityImprove long-term aging performanceBuilding insulationsChemistryProcess engineering

The invention provides a high-performance asphalt pavement regenerant and a preparation method thereof. The high-performance asphalt pavement regenerant is prepared from, by weight, 60-70 parts of anactivating component, 5-10 parts of a permeating component, 10-15 parts of a plasticizing component, 8-15 parts of a modifying component and 3-6 parts of an anti-aging component, and the sum of the weight parts of the raw materials is 100 parts. According to the invention, the synergistic combination of thermal stability substances is used as an activating component to replace the traditional aromatic hydrocarbon oil activating component, so that the thermal stability of the regenerant can be greatly improved, and the long-term aging performance of the regenerated mixture can be improved. Theselected surfactant enables the asphaltene association structure to be deassociated, and dissolution and dispersion of asphaltene are promoted. The preparation process is simple, raw materials are wide in source, starting from the asphalt aging mechanism, activation and performance blending of aging components are considered, and the prepared regenerant is excellent in pavement performance and wide in application prospect.

Owner:山西省高速公路集团有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com