Scrap aluminum regeneration type heat-resistant aluminum alloy and preparation method thereof

A technology for aluminum alloy and aluminum regeneration, applied in the field of aluminum alloy preparation, can solve the problems of waste of resources, not being effectively utilized, etc., and achieve the effects of slowing down the decomposition speed, small size and large quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

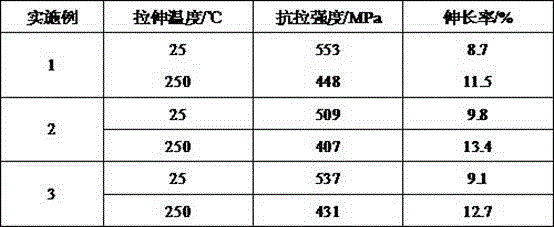

Embodiment 1

[0025] The raw material composition of heat-resistant aluminum alloy is: 60.5% waste aluminum profiles (chemical composition and mass percentage are: Mg 1.2%, Si 0.8%, Fe 0.5%, Cu 0.6%, Mn 0.4%, Zn 0.3%, The balance is Al), 10.5% waste aluminum castings (chemical composition and mass percentage: Si 3.5%, Mn 1.5%, Cu 0.2%, Fe 0.9%, Cr 0.45%, Zn 0.3%, the balance is Al), 7.5% waste aluminum plate (chemical composition and mass percentage: Mg 7.5%, Mn 0.7%, Cr 0.05%, Si0.4%, Fe 0.6%, Cu 0.2%, the balance is Al), 16.0% waste aluminum wire (Chemical composition and mass percentage: Zr1.5%, Fe 0.3%, Mg 0.4%, Si 0.25%, Ti 0.015%, B 0.006%, the balance is Al) and 5.5% waste copper wire (chemical composition and quality The percentages are: Bi 0.009%, Sb 0.007%, Fe 0.01%, Ni 0.04%, Pb 0.002%, Sn 0.001%, and the balance is Cu). The preparation steps of the heat-resistant aluminum alloy are as follows:

[0026] (1) Heat and melt waste aluminum profiles, waste aluminum castings, waste a...

Embodiment 2

[0031] The raw material composition of heat-resistant aluminum alloy is: 63.0% waste aluminum profiles (chemical composition and mass percentage are: Mg 0.9%, Si 0.6%, Fe 0.7%, Cu 0.2%, Mn 0.5%, Zn 0.1%, The balance is Al), 10.5% waste aluminum castings (chemical composition and mass percentage: Si 4.0%, Mn 1.9%, Cu 0.3%, Fe 0.5%, Cr 0.4%, Zn 0.2%, the balance is Al), 7.0% waste aluminum plate (chemical composition and mass percentage: Mg 6.5%, Mn 0.7%, Cr 0.45%, Si0.34%, Fe 0.6%, Cu 0.2%, the balance is Al), 15.0% waste aluminum wire (Chemical composition and mass percentage: Zr0.5%, Fe 0.2%, Mg 0.2%, Si 0.5%, Ti 0.01%, B 0.005%, the balance is Al) and 4.5% waste copper wire (chemical composition and quality The percentages are: Bi 0.001%, Sb 0.009%, Fe 0.01%, Ni 0.02%, Pb 0.02%, Sn 0.01%, and the balance is Cu). The preparation steps of the heat-resistant aluminum alloy are as follows:

[0032] (1) Heat and melt waste aluminum profiles, waste aluminum castings, waste alumi...

Embodiment 3

[0037]The raw material composition of heat-resistant aluminum alloy is: 61.5% waste aluminum profiles (chemical composition and mass percentage are: Mg 0.3%, Si 0.3%, Fe 0.2%, Cu 0.8%, Mn 0.55%, Zn 0.2%, The balance is Al), 11.0% waste aluminum castings (chemical composition and mass percentage: Si 5.5%, Mn 3.5%, Cu 0.1%, Fe 0.1%, Cr 0.4%, Zn 0.3%, the balance is Al), 7.5% waste aluminum plate (chemical composition and mass percentage: Mg 4.5%, Mn 0.4%, Cr 0.45%, Si0.4%, Fe 0.2%, Cu 0.4%, the balance is Al), 15.0% waste aluminum wire (Chemical composition and mass percentage: Zr0.5%, Fe 0.2%, Mg 0.7%, Si 0.15%, Ti 0.005%, B 0.001%, the balance is Al) and 5.0% waste copper wire (chemical composition and quality The percentages are: Bi 0.03%, Sb 0.01%, Fe 0.04%, Ni 0.04%, Pb 0.01%, Sn 0.001%, and the balance is Cu). The preparation steps of the heat-resistant aluminum alloy are as follows:

[0038] (1) Heat and melt the above-mentioned waste aluminum profiles, waste aluminum c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com