Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105results about How to "Reduce convective heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

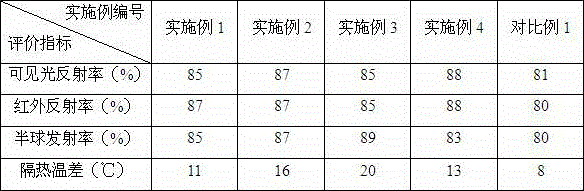

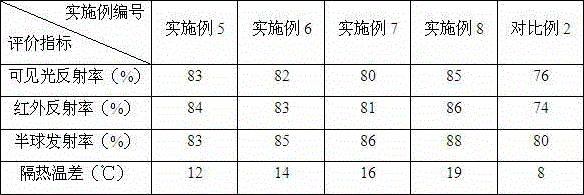

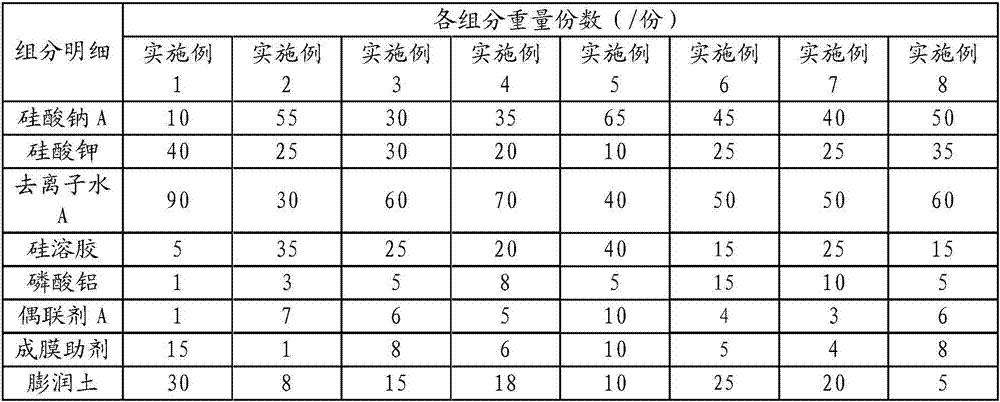

Building coating with heat insulation function and preparation method thereof

InactiveCN106118307AGood thermo-optic comprehensive performanceWith thermal insulation functionReflecting/signal paintsBuilding energyMetallurgy

The invention provides a building coating with a heat insulation function and a preparation method thereof. The building coating with the heat insulation function is divided into an internal wall coating and an external wall coating, wherein each of the internal wall coating and the external wall coating is composed of a basic carrier for film forming of the coating, a heat insulating material, a heat reflecting material, a heat radiating material, filler, an assistant and water. The preparation method comprises the following steps: preparation of heat insulating material slurry, preparation of function material slurry, grinding of slurry, and paint mixing. The film forming thickness of the building coating is 0.2-0.3mm, so that the building coating belongs to a thin building energy-saving coating; the internal and external wall building coatings have higher heat conducting resistance and lower convection heat transfer, so that the building coating has different heat radiating effects under different temperature environments in different seasons and has the heat insulation function; the building coating is high in safety and long in service life; and the preparation method is simple and is suitable for industrial production.

Owner:马承银

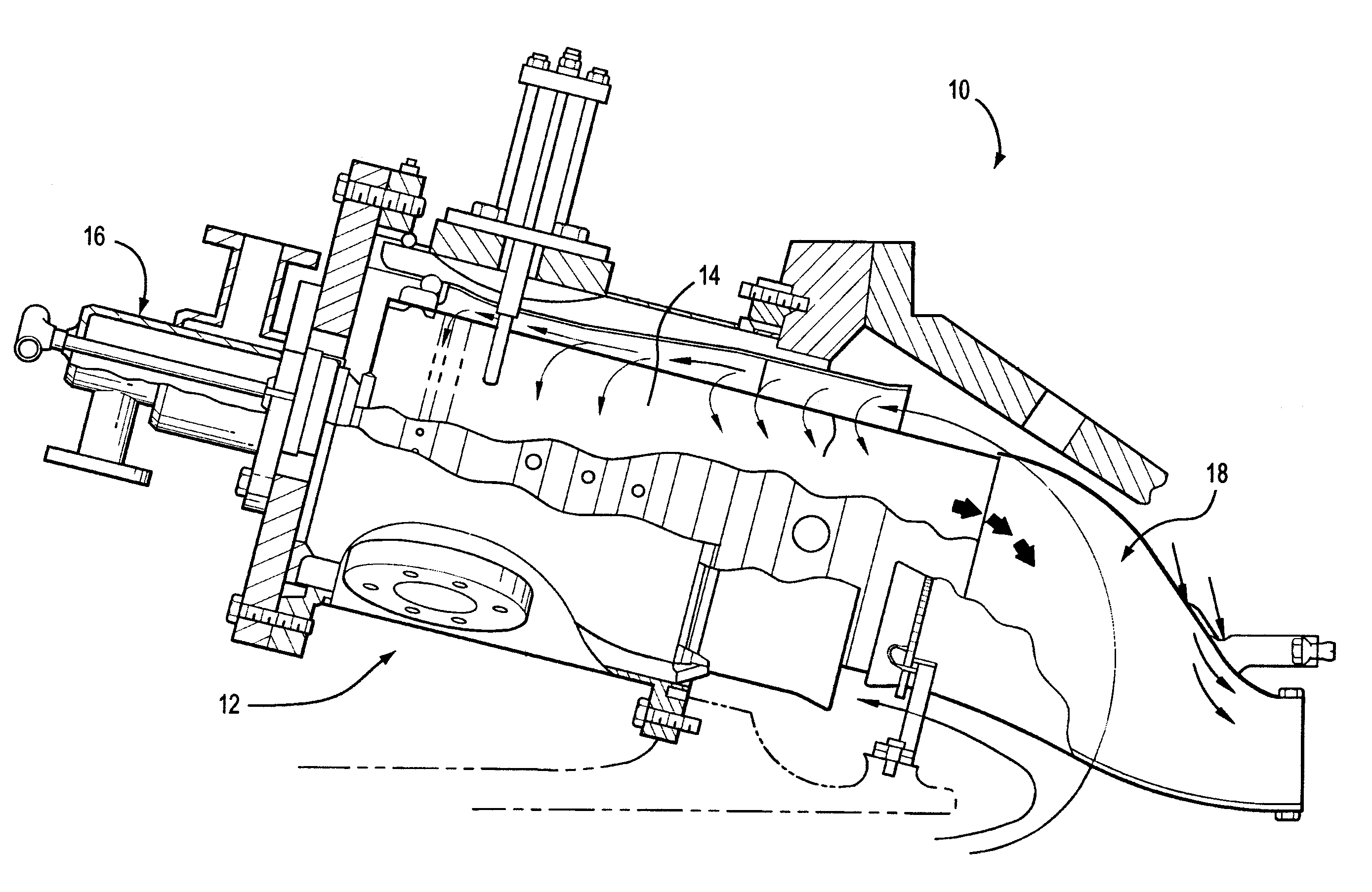

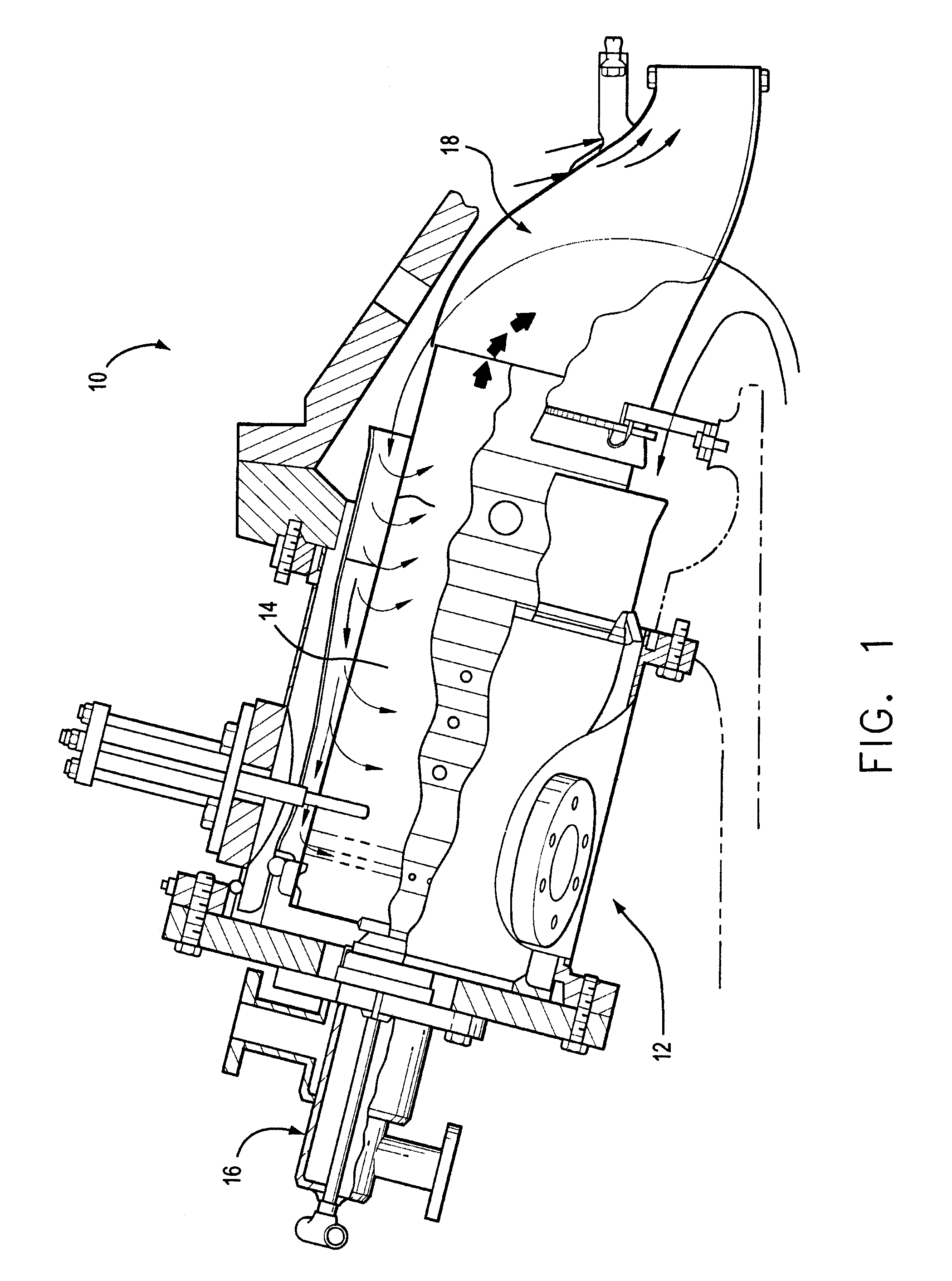

Smooth outer coating for combustor components and coating method therefor

InactiveUS7368164B2Suppresses component temperature riseReduce transferMolten spray coatingPropellersZinc titanateSilica matrix

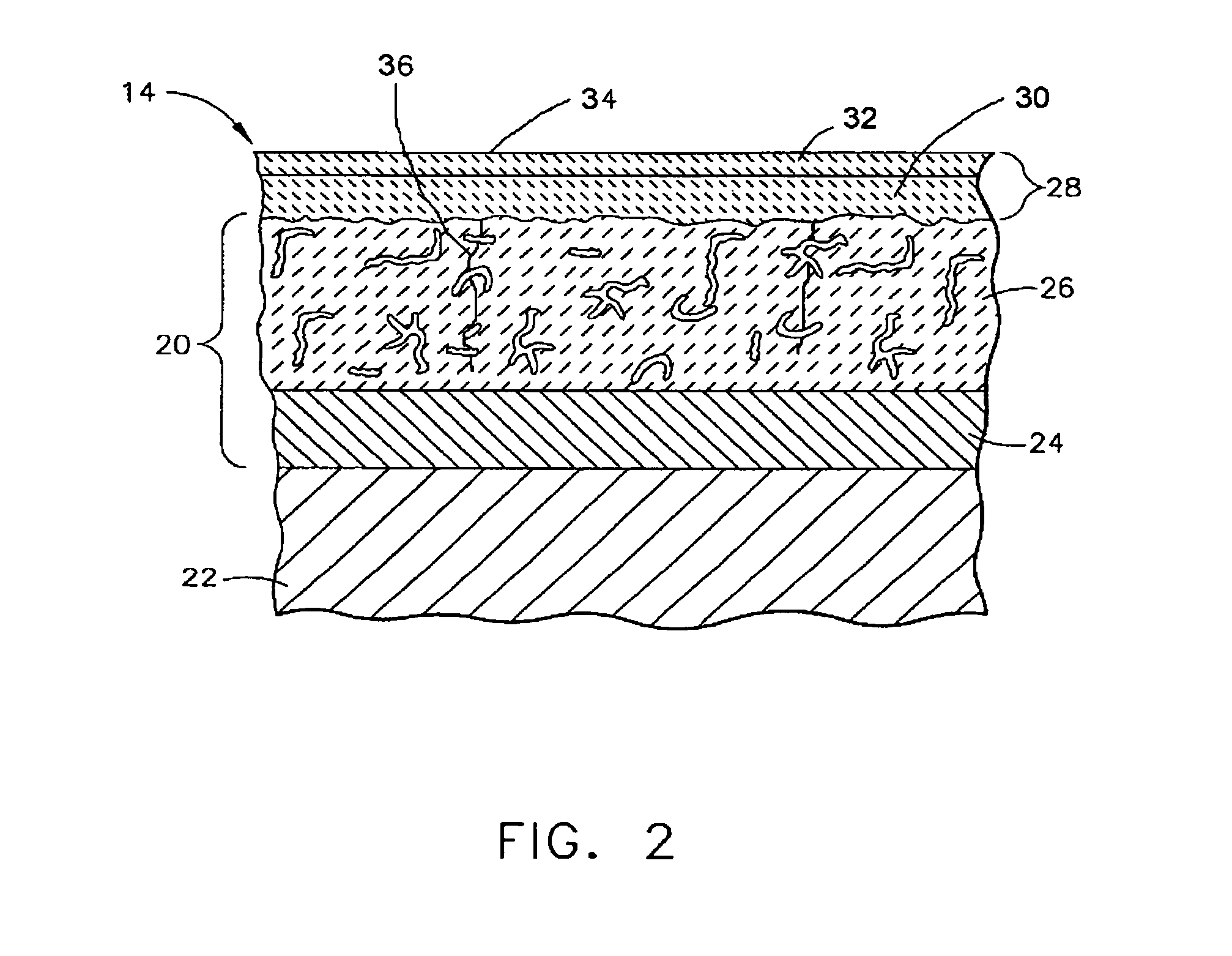

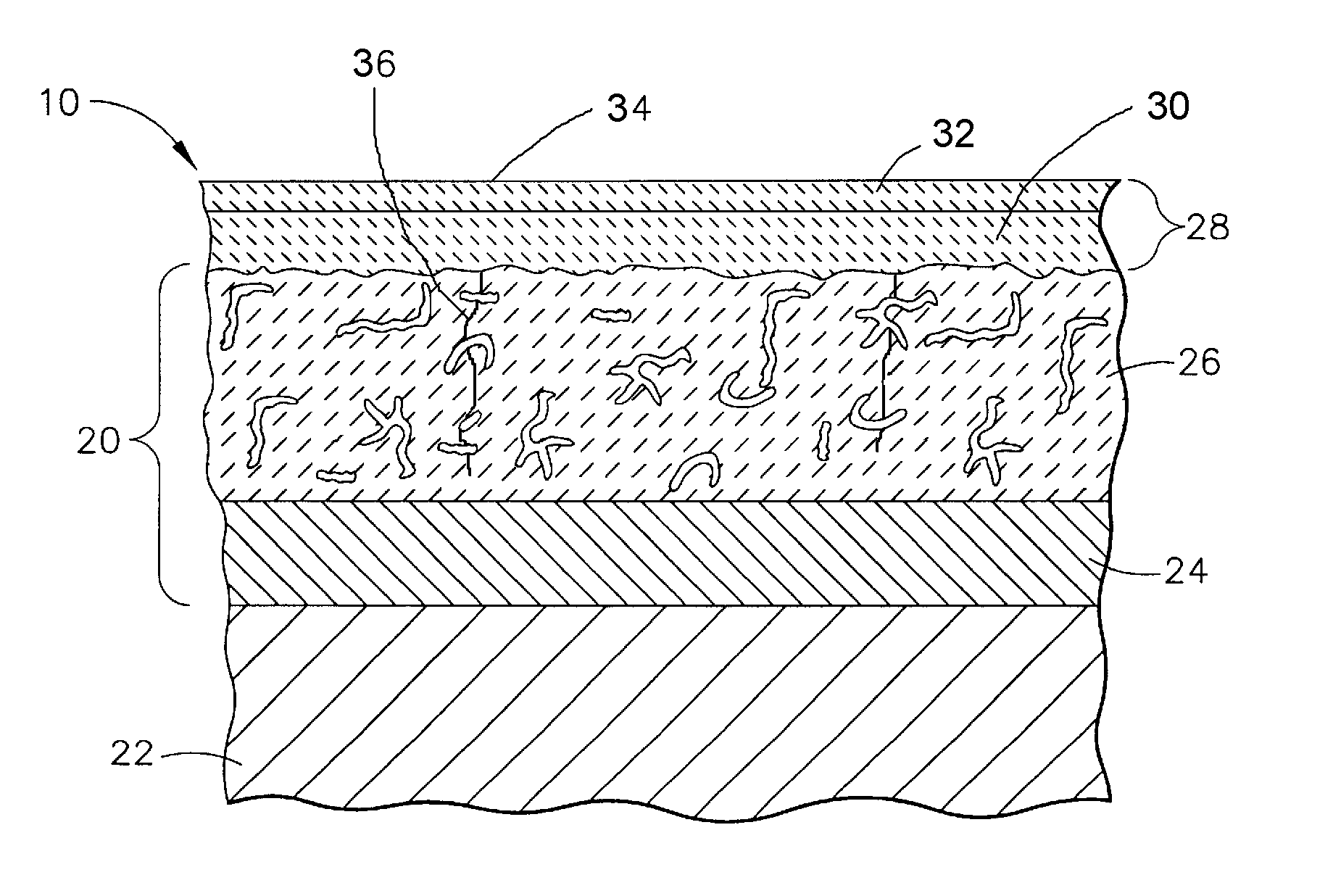

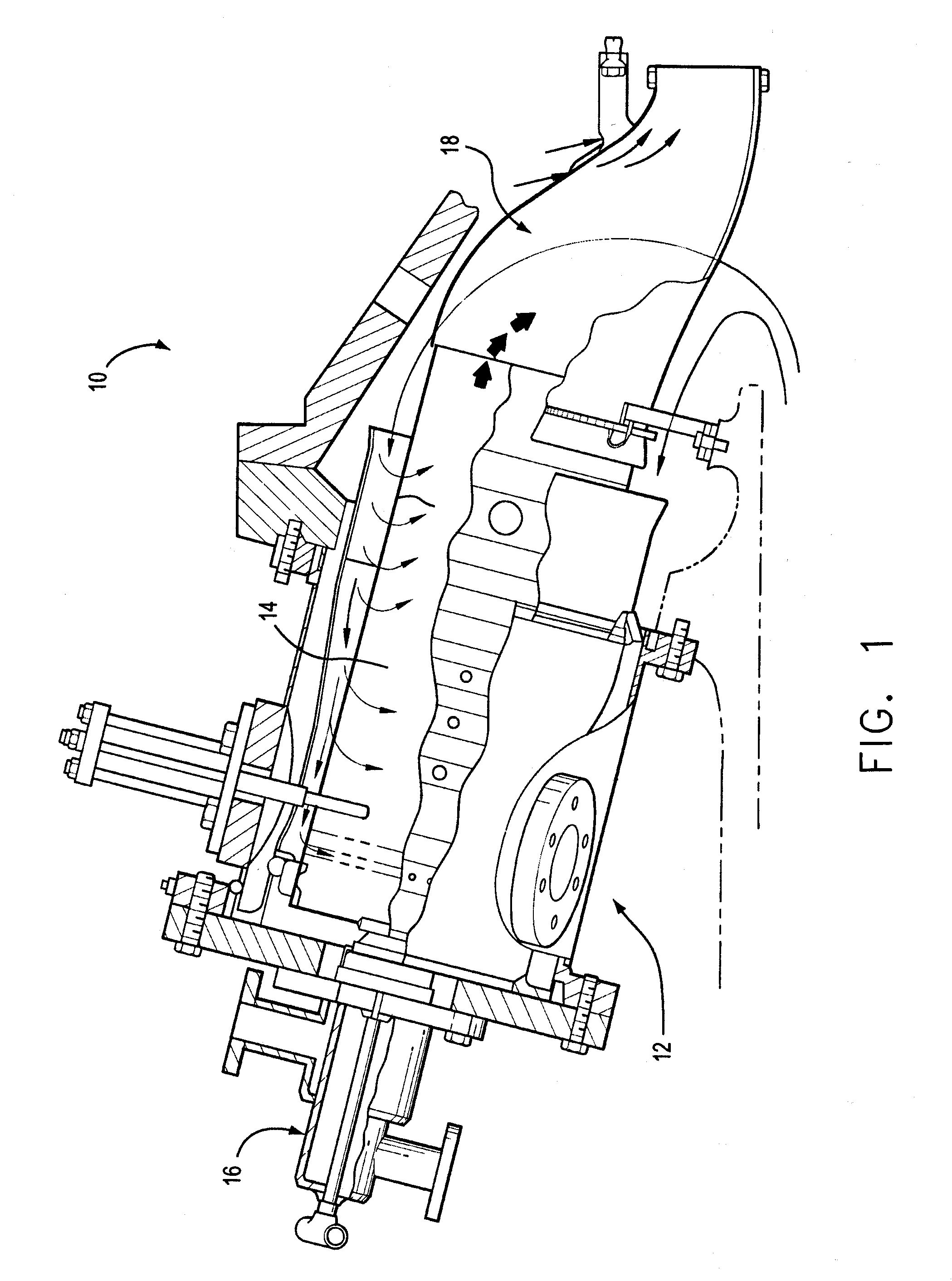

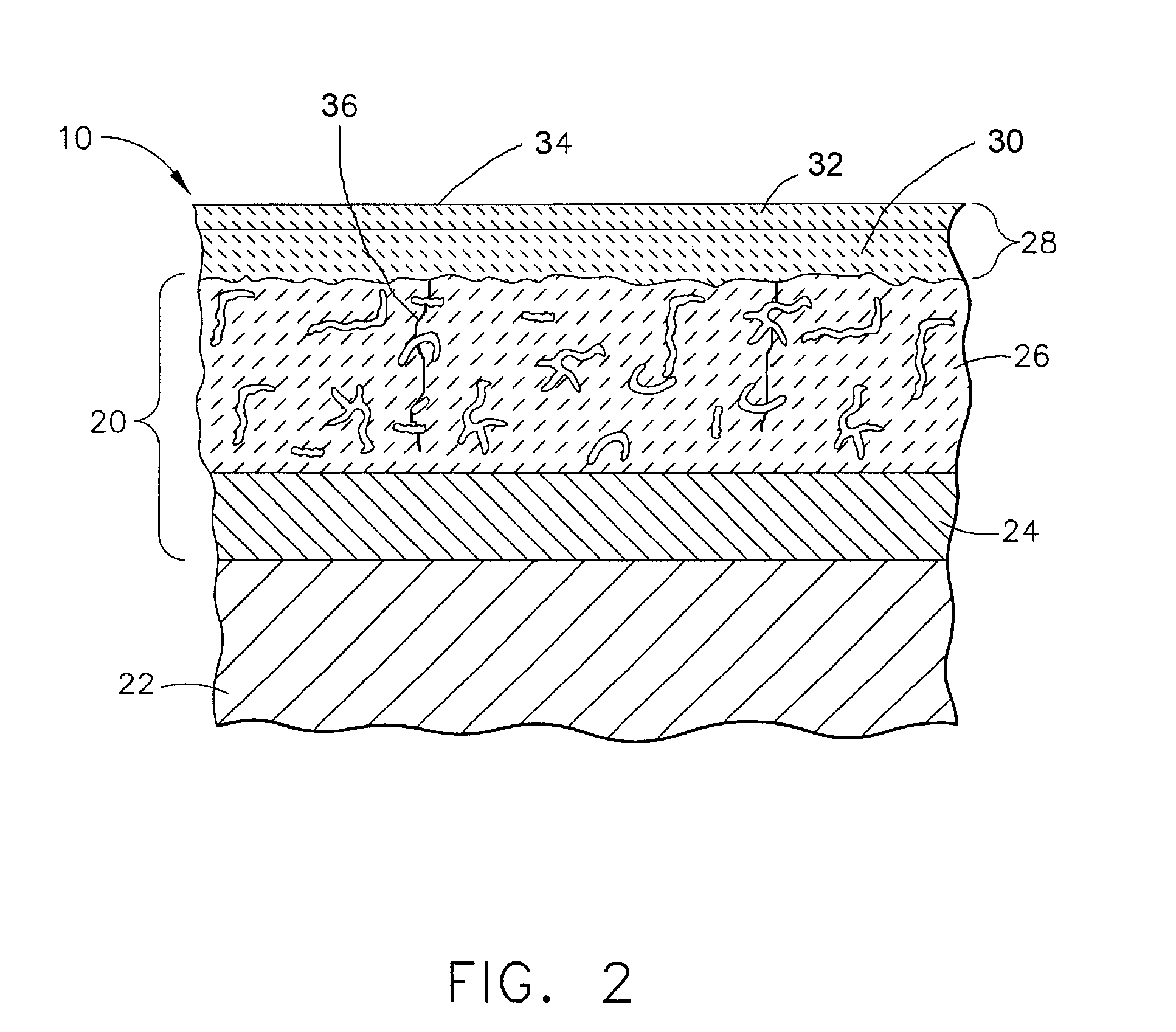

A coating and method for overcoating a TBC on a component used in a high-temperature environment, such as the combustor section of an industrial gas turbine. The coating defines the outermost surface of the component and is formed of at least two layers having different compositions. An inner layer of the coating contains alumina in a first silica-containing matrix material that is free of zinc titanate. An outer layer of the coating contains alumina, a glass material, and zinc titanate in a second silica-containing matrix material. The outer layer of the coating has a surface roughness of not greater than three micrometers Ra and forms the outermost surface of the component. The coating reduces the component temperature by reducing the convective and radiant heat transfer thereto.

Owner:GENERAL ELECTRIC CO

Smooth outer coating for combustor components and coating method therefor

ActiveUS20050282020A1Suppresses component temperature riseReducing convective transferLiquid surface applicatorsMolten spray coatingZinc titanateSilica matrix

A coating and method for overcoating a TBC on a component used in a high-temperature environment, such as the combustor section of an industrial gas turbine. The coating defines the outermost surface of the component and is formed of at least two layers having different compositions. An inner layer of the coating contains alumina in a first silica-containing matrix material that is free of zinc titanate. An outer layer of the coating contains alumina, a glass material, and zinc titanate in a second silica-containing matrix material. The outer layer of the coating has a surface roughness of not greater than three micrometers Ra and forms the outermost surface of the component. The coating reduces the component temperature by reducing the convective and radiant heat transfer thereto.

Owner:GENERAL ELECTRIC CO

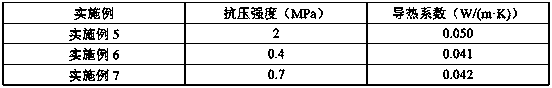

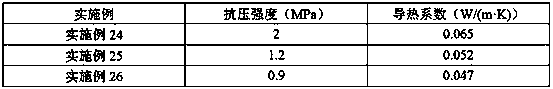

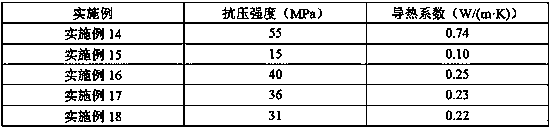

Manufacturing method for microorganism heat-insulation building material

PendingCN108530013ASolve the strength problemSolve insulation problemsBacteriaMicroorganism based processesNutrient solutionMechanical property

The invention discloses a manufacturing method for a microorganism heat-insulation building material. The manufacturing method for the microorganism heat-insulation building material comprises the following steps: taking a bacteria solution which has a mineral deposition function and is prepared from microorganisms and a corresponding nutrient solution as raw materials; directly carrying out mineral deposition on various lightweight aggregates or compounding inorganic or organic cementing materials; and carrying out microorganism inactivation and pore forming to obtain novel microorganism heat-insulation plates, heat-insulation blocks, heat-insulation concrete, heat-insulation mortar and the like. By the method, the physical and mechanical properties of an existing traditional heat-insulation material can further be improved through a microorganism mineralization function and an inactivation process. Microorganism mineral deposition products are used as cementing material manufacturingand modifying building heat-insulation materials, contradiction between strength and heat insulation of the heat-insulation materials can be solved effectively, cementing materials such as cement arereduced and are even prevented from being used, resource consumption are reduced remarkably, mine excavation frequency is reduced, pollution emission is eliminated, and environment stress and haze influence are relieved. The manufacturing method for the microorganism heat-insulation building material is an environmentally friendly building material manufacturing method, and has good economic benefit, environment benefit and social benefit.

Owner:李珠

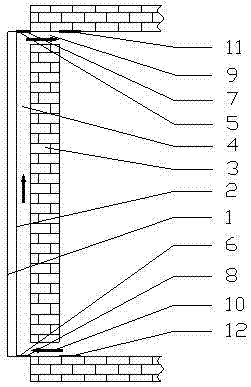

Trombe wall with comprehensive application of solar heat collection and radiation refrigeration

ActiveCN103790244AReduce heat loadSolve the shortcoming of single function only for heatingSolar heating energyWallsFull waveEngineering

The invention relates to a Trombe wall with the comprehensive application of solar heat collection and radiation refrigeration. The Trombe wall comprises a transparent cover plate, a heat collection and storage wall, an air flow channel, upper ventilation openings, lower ventilation openings and baffles. The transparent cover plate is made of full-wave band high transmittance material. A venetian blind is arranged on the inner side face of the transparent cover plate, one side faces of slats of the venetian blind are coated with selective absorbing coatings, and absorptivity of the coatings ranges from 90% to 95% within the solar radiation wave band ranging from 0.2 micrometer to 3 micrometers. The other side faces of the slats of the venetian blind are selective radiation surfaces, emissivity of the selective radiation surfaces ranges from 80% to 90% within the atmospheric window wave band ranging from 8 micrometers to 13 micrometers, and emissivity of the selective radiation surfaces ranges from 60% to 90% within other wave bands. The Trombe wall can heat a room in the daytime and preserve heat of the room at night in winter, and can reduce heat loads of the room in the daytime and refrigerate the room at night in summer, and therefore the problem that a traditional Trombe wall can only heat the room and is single in function is solved; the defect that the appearance of the traditional Trombe wall is not attractive enough is overcome due to the utilization of the venetian blind attractive in appearance.

Owner:UNIV OF SCI & TECH OF CHINA

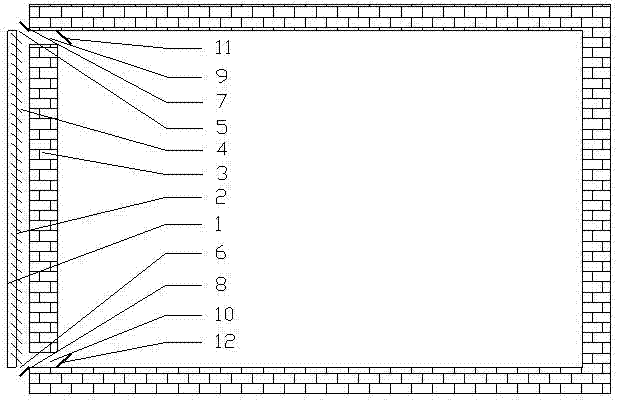

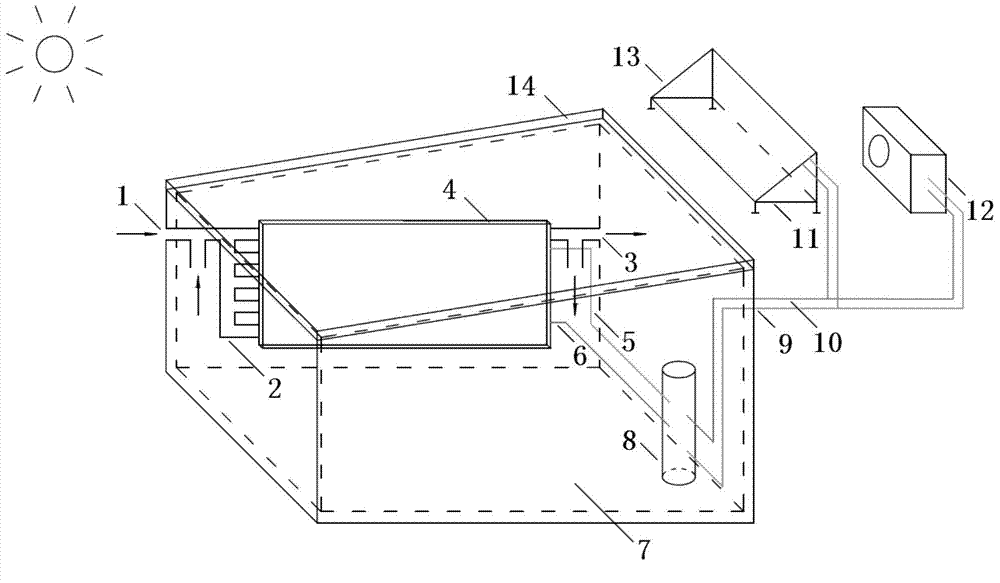

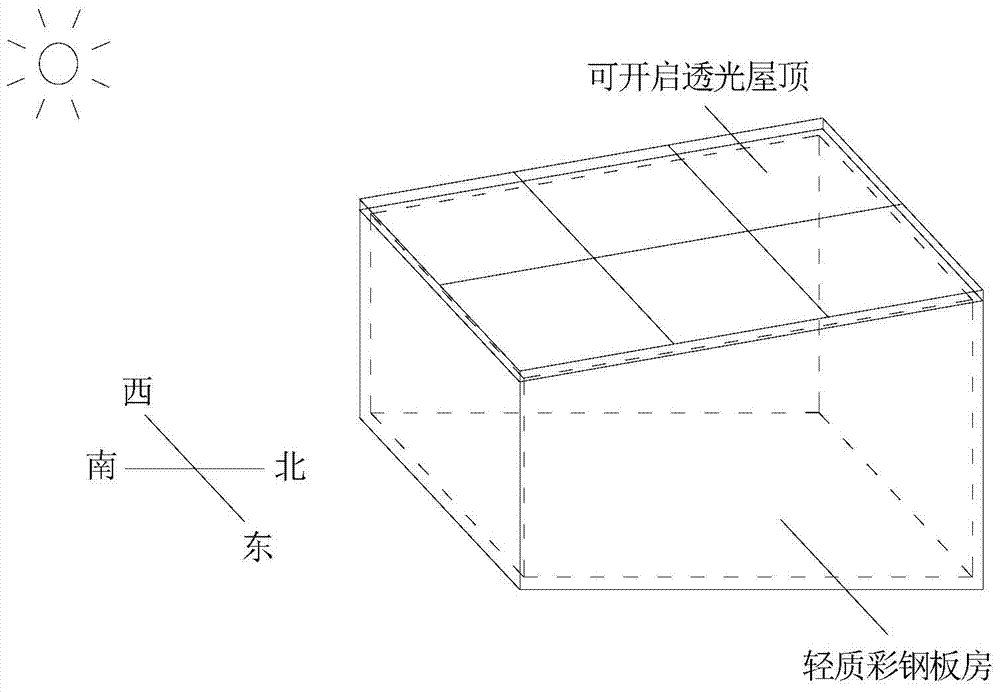

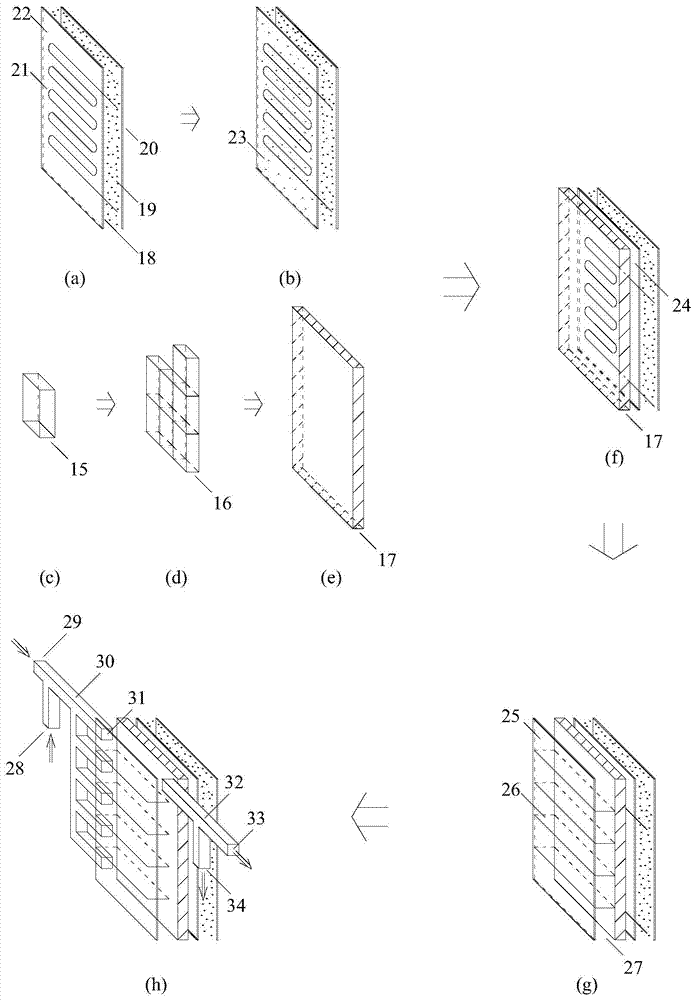

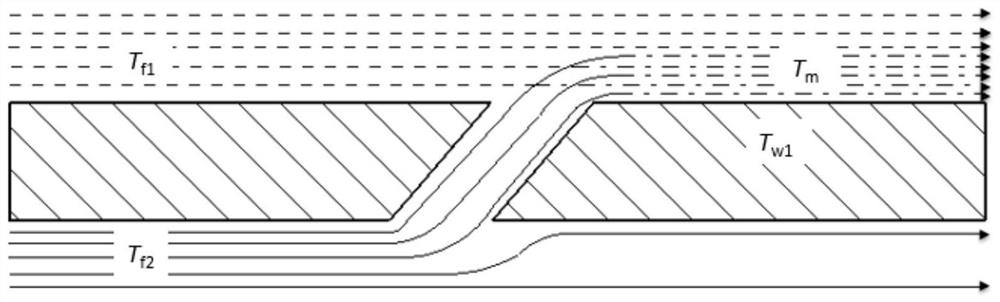

Active and passive combined annual phase-change energy storage room capable of being used all year around

ActiveCN104746647AAchieve year-round adjustmentIncrease the light areaBuilding roofsRoof covering using slabs/sheetsCapillary networkGlass cover

The invention provides an active and passive combined annual phase-change energy storage room capable of being used all year around, wherein the energy storage room aims to enable a building applying phase-change materials to operate in an energy-saving mode, enable the wall body of the building to adjust the air in a room all year around and extract natural cooling capacity actively, improve the storage and efficiency, heat storage and discharge and heat storage efficiency and cooling efficiency of a phase-change wall board and improve the air quality in the room and the indoor comfort. The active and passive combined annual phase-change energy storage room capable of being used all year around comprises a roof lighting room body, a phase-change combined wall body, a water system and a ventilation system. The roof lighting room body comprises a wall body with the four light-proof faces and a light-transmitting roof for collecting light. The phase-change combined wall body comprises the phase-change wall board, mortar made of phase-change materials, a capillary network, a glass cover plate, an air flue and air inlet. The water system comprises a water cooling and heating device, a water storage device and a tail end device. The ventilation system comprises an air supply device, the air flue, the air opening and a corresponding sealing device. By means of the scheme, great significance is provided for increase of the utilization rate of new resources and the phase-change materials in the building.

Owner:BEIJING UNIV OF TECH

Novel heat insulating plate and manufacturing method thereof

ActiveCN104058630AImprove thermal insulationHigh mechanical strengthActive componentMembrane configuration

The invention provides a novel heat insulating plate. Active components of the novel heat insulating plate comprise 70-95 parts by weight of inorganic heat insulating particles and 5-30 parts by weight of an organic coating membrane material, wherein the outer surfaces of all inorganic heat insulating particles are coated with the organic coating membrane material to form 'capsule' type inorganic-organic composite heat insulating units, subsequently the 'capsule' type inorganic-organic composite heat insulating units are connected together by using a curing agent, and then a plate is formed in a mold, namely the novel heat insulating plate is obtained. The novel heat insulating plate disclosed by the invention can be used for improving the mechanical strength, also preventing exposure and water absorption of the inorganic heat insulating particles and limiting the air inside the 'capsule' type inorganic-organic composite heat insulating units as well so as to effectively reduce air motion inside the plate and reduce convective heat transfer, thus the heat conductivity coefficient is relatively as low as 0.032W / (m.K) to 0.040W / (m.K) and A-grade non-ignition can be truly realized, and therefore the novel heat insulating plate has both excellent fireproof performance and relatively-good heat insulation performance.

Owner:合肥候鸟新型材料有限公司

Ultrathin steel structure waterproof coating and preparation method thereof

ActiveCN105838171AImprove fire resistanceImprove insulation performanceFireproof paintsFiberSodium Bentonite

Ultrathin steel structure waterproof coating is characterized by being made from the following materials according to parts by weight: 5-20 parts of nano silicon dioxide aerosol, 15-45 parts of acrylic emulsion, 30-80 parts of melamine, 30-60 parts of pentaerythritol, 50-80 parts of ammonium polyphosphate, 10-15 parts of titanium dioxide, 5-15 parts of sepiolite fiber, 5-15 parts of talc, 5-15 parts of expansible graphite, 0.2-0.8 part of a waterborne wetting dispersant, 0.02-0.08 part of modified organic bentonite, and 0.05-0.2 part of a waterborne leveling agent. The preparation method comprises: weighing the components according to their ratio; adding the components sequentially into a high-speed dispersing machine for mixing and dispersing; standing and aging for 10-15 h; metering and packaging. The fireproof coating of the invention can reduce the increase in the steel structure loading to the coating and has no influence in the expanding and foaming process, expansion rate of a coating layer is high, heat isolating capacity of the fireproof coating can be improved greatly, and fire resistance of a steel structure can be improved greatly.

Owner:SICHUAN TIANFU FIRE MATERIAL

Composite foamed cement insulation board and production technology thereof

The invention relates to an insulation board and a production technology thereof, in particular to a composite foamed cement insulation board and a production technology thereof. The insulation board consists of the following components in percentage by weight: 55 to 60 percent of No. 525 cement, 30 to 35 percent of fly ash, 0.4 to 0.7 percent of stable master batch, 0.015 to 0.020 percent of lithium carbonate, 0.3 to 0.5 percent of fiber, 3 to 5 percent of foam stabilizer, and 5 to 8 percent of hydrogen peroxide. The production technology comprises the following steps of: (1) stirring the components in a stirring machine in a ratio till the components are stirred uniformly; (2) adding a foaming agent into the uniformly stirred mixture, stirring uniformly, pouring the mixture into a mold, and performing natural foaming; (3) sizing the foamed cement board passing foaming for 6 to 12 hours; (4) shifting the sized foamed cement board out of the mold; (5) after the foamed cement board is shifted out of the mold, performing air drying maintenance on the foamed cement board; and (6) after the foamed cement board is in accordance with the cutting conditions, cutting the foamed cement board into a finished product by using a cutting machine, and packing. The insulation board has the advantages of excellent fireproof and waterproof performance, insulation performance, stability, environment friendliness, energy conservation, heat insulation, sound insulation, light weight and compression resistance.

Owner:ZHENJIANG ZHONGRUI ENERGY SAVING TECH

Modified PET polyester as well as preparation method and application thereof

ActiveCN107312166AFree from destructionShorten the replacement periodFlame-proof filament manufactureSilicon compoundsPolyethylene terephthalateSlurry

The invention relates to modified PET (Polyethylene terephthalate) polyester as well as a preparation method and application thereof, and belongs to the field of modified polyester. The modified PET polyester comprises aerogel particles and polyethylene terephthalate; the aerogel particles are dispersed between the molecular chains of the polyethylene terephthalate uniformly; the particle size of the aerogel particles is 2 to 3 microns; the content of the aerogel particles in the modified PET polyester is 1 to 10 percent by weight. Modified PET is prepared by the steps of adding the aerogel powder into glycol, putting into a grinding machine, grinding to prepare mixed slurry, mixing the mixed slurry and terephthalic acid, and performing esterification reaction and polymerization reaction. Modified PET fiber is prepared by slicing the modified PET, metering, spinning, cooling, applying oil, stretching, performing heat setting and performing winding formation. The aerogel particles are introduced before polymerization of the PET polyester, so the prepared PET has high spinnability, can produce modified PET fibers with various thickness, has wide application range and can meet the production requirement of various fabrics.

Owner:天津朗华科技发展有限公司

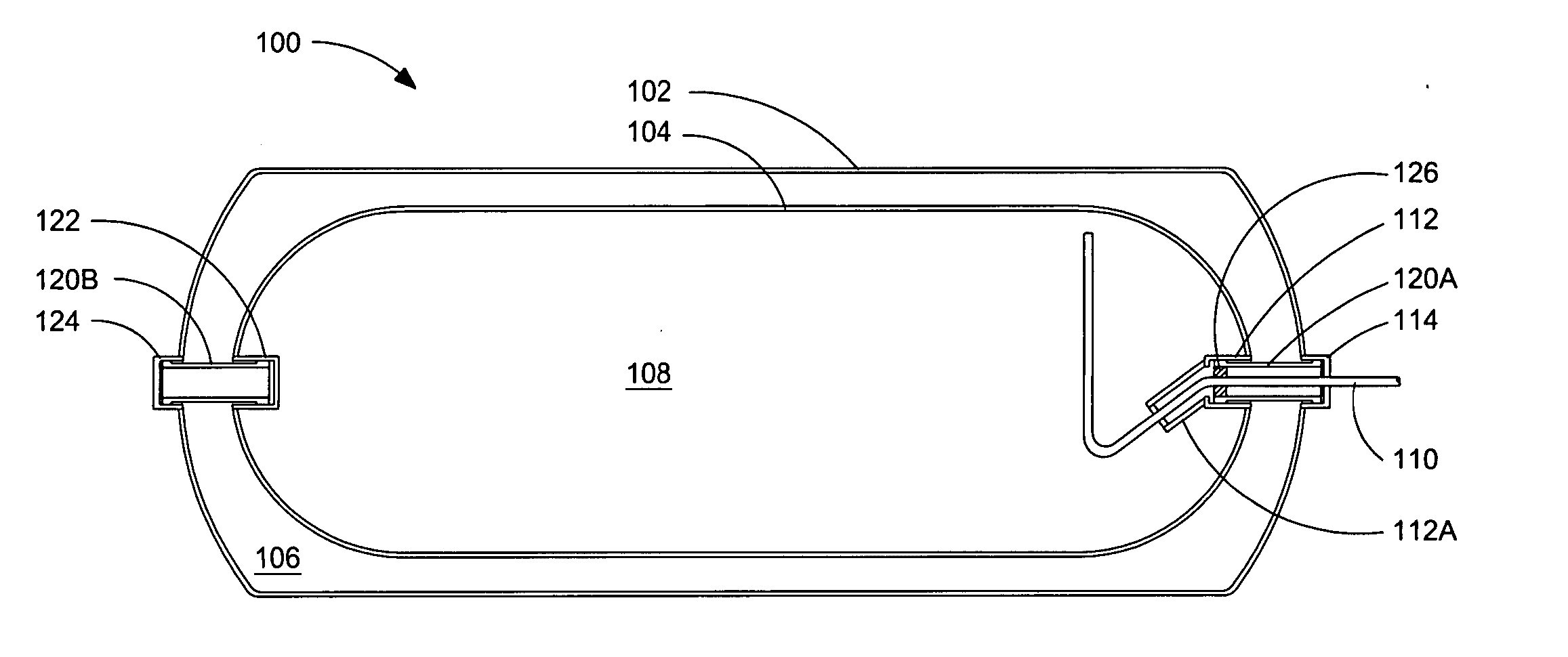

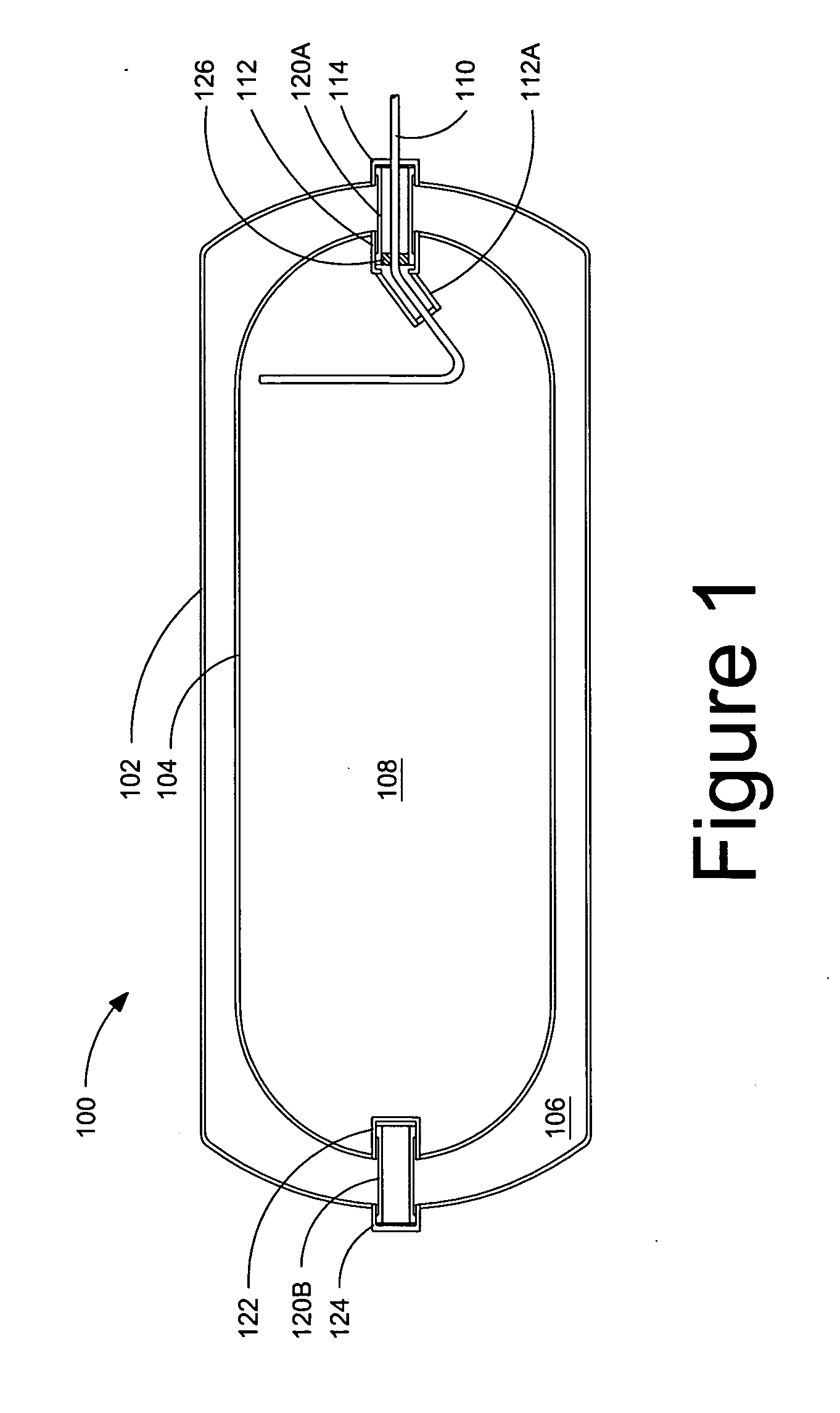

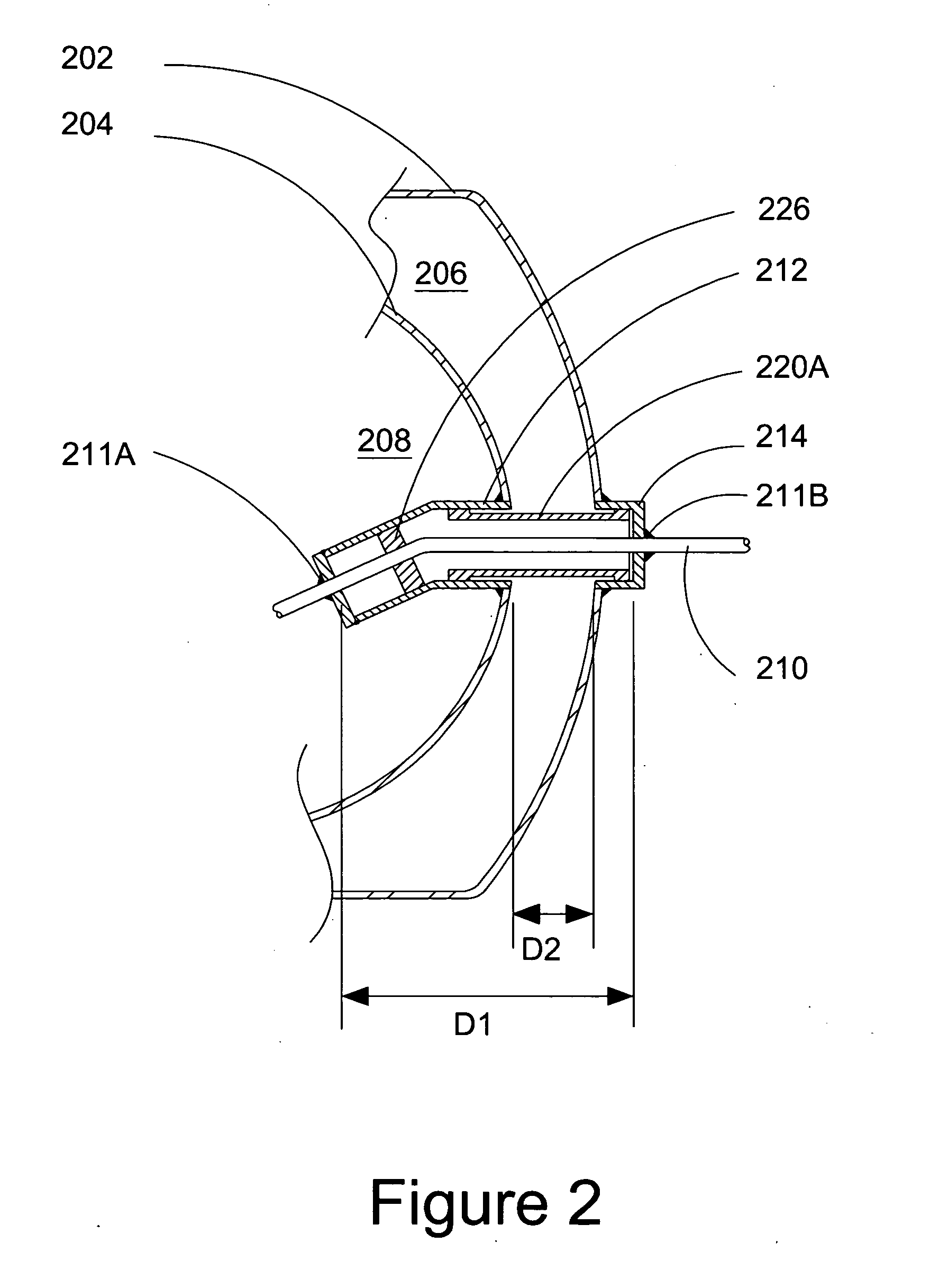

Container for holding a cryogenic fluid

ActiveUS20050139600A1Reduce heat leakageLow thermal conductivityContainer filling methodsSurgeryHorizontal axisDouble wall

A double-walled vacuum-insulated container for holding a cryogenic fluid comprises a support structure for supporting an inner vessel within an outer vessel. The container has an elongated horizontal axis. A conduit extending between the inner and outer vessels has a wall thickness that allows the conduit to carry a substantial portion of axial loads acting on the inner vessel in a direction parallel to the horizontal axis. The support structure further comprises a non-metallic support spanning between the inner and outer vessels, with the non-metallic support capable of transferring substantially all radial loads transverse to said horizontal axis. The non-metallic support is also fixedly attached to the inner and outer vessels so that it is capable of supporting a substantial portion of the axial loads so that the non-metallic support and the conduit cooperate to provide support in the axial direction.

Owner:WESTPORT FUEL SYST CANADA INC

Linear Fresnel reflection type mid-and-low temperature solar energy thermochemical utilization device

InactiveCN103383150ASimple structureManufacturing and running costs are lowSolar heating energySolar heat devicesSystem integrationEnergy transfer

A linear Fresnel reflection type mid-and-low temperature solar energy thermochemical utilization device comprises a linear Fresnel reflection condensing mirror array driven by a solar tracking device to real timely track the sun, and a thermal absorber matched with the condensing mirror array and independently arranged, wherein the thermal absorber is tubular, a selective absorption coating is coated on the surface of the outer wall, and a chemical reactant medium and a catalyst are filled in the tube; a solar energy light-focusing system formed by the Fresnel reflection condensing mirror array and the solar tracking device is adopted and is well matched with the hot grade of thermal chemical reaction of mid-and-low temperature fossil fuel, the structure is simple, the manufacturing and running cost is low and the wing resistance is good when the solar energy thermochemical utilization device is mounted close to the ground; with the chemical reactant medium and the catalyst in the thermal absorber, the solar energy thermochemical utilization device can serve as the thermochemical reaction place while absorbing the solar energy, so that the heat can be directly absorbed and utilized, and the system integration complexity and energy transfer loss can be effectively reduced; as the thermal absorber is independently arranged, the safety and the stability are higher during the heat absorption and reaction process.

Owner:XI AN JIAOTONG UNIV

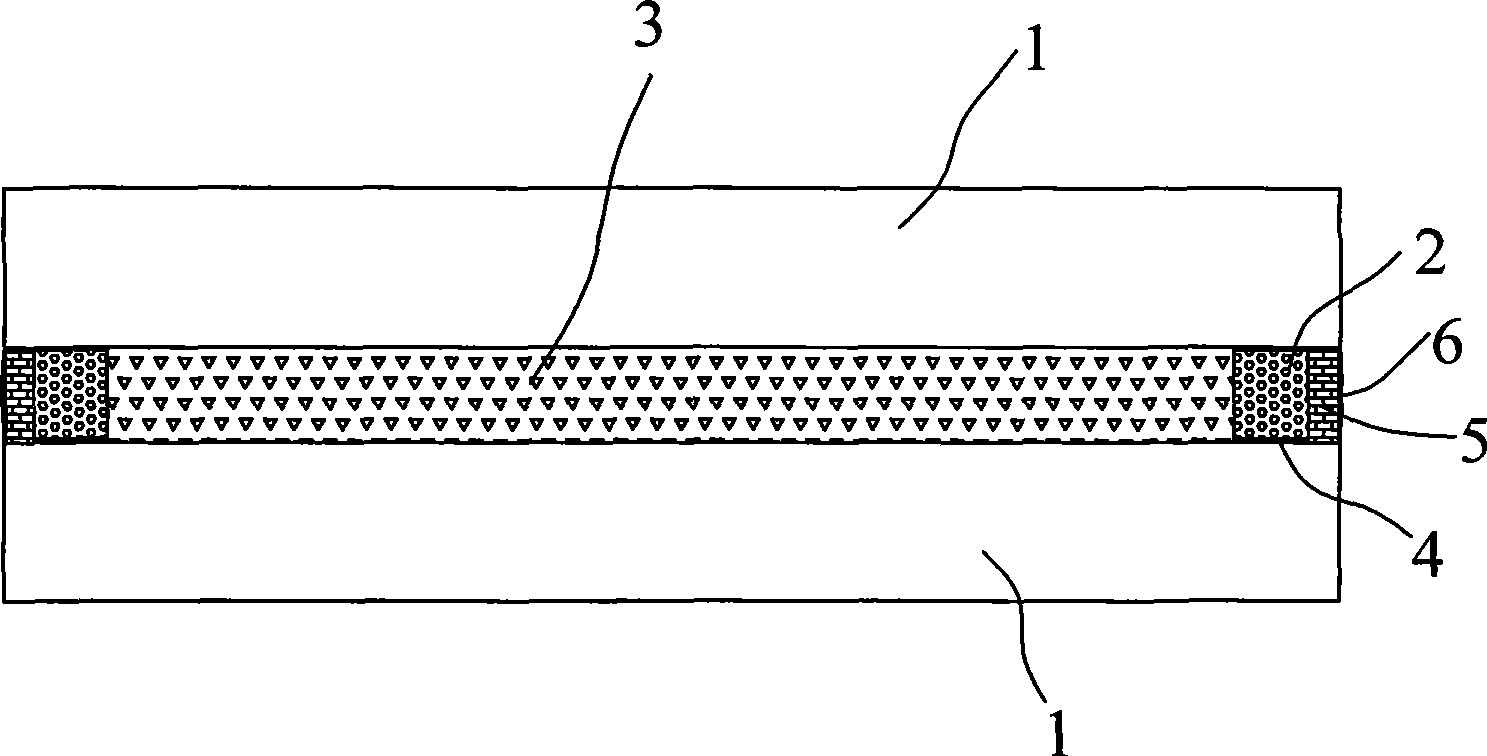

Energy-saving glass window

InactiveCN101481985AGood heat insulationReduce convective heat transferClimate change adaptationWindows/door improvementPorosityFlat glass

The invention discloses an energy-saving glass window, comprising two sheets of plain glass and a sealed spacer, a sealed cavity is formed between the sealed spacer and the plain glass and is filled with silicon dioxide aerogel. Compared with the ordinary insulating glass in the prior art, especially compared with facade wall glass with relatively thick cavity, the energy-saving glass filled with the silicon dioxide aerogel effectively reduces convective heat transfer of air, the superhigh porosity of the silicon dioxide aerogel ensures even lower thermal conduction (normally not more than 0.01W / (m K) ) than the thermal conduction of air, therefore the energy-saving glass window has better heat-insulating property.

Owner:XINYI GLASS ENG (DONGGUAN) CO LTD

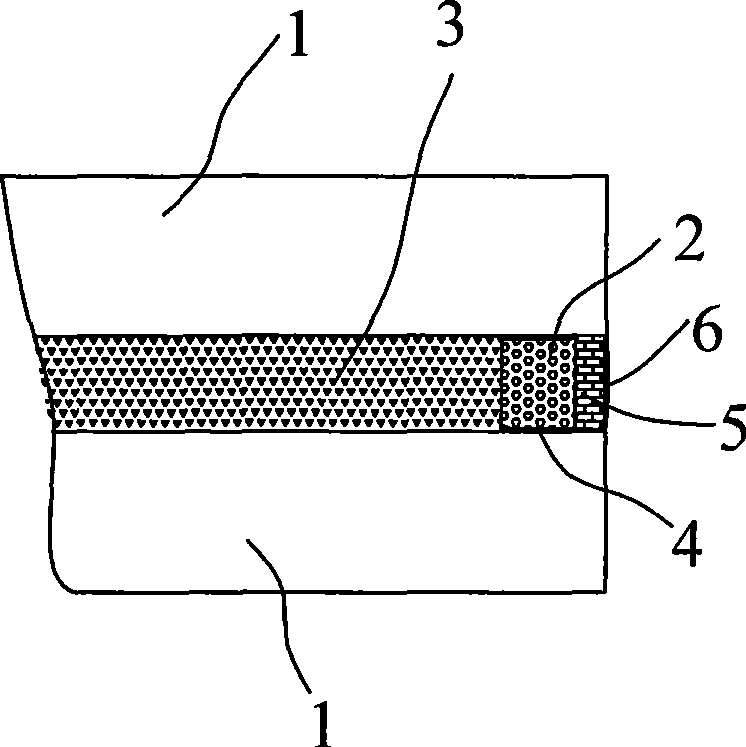

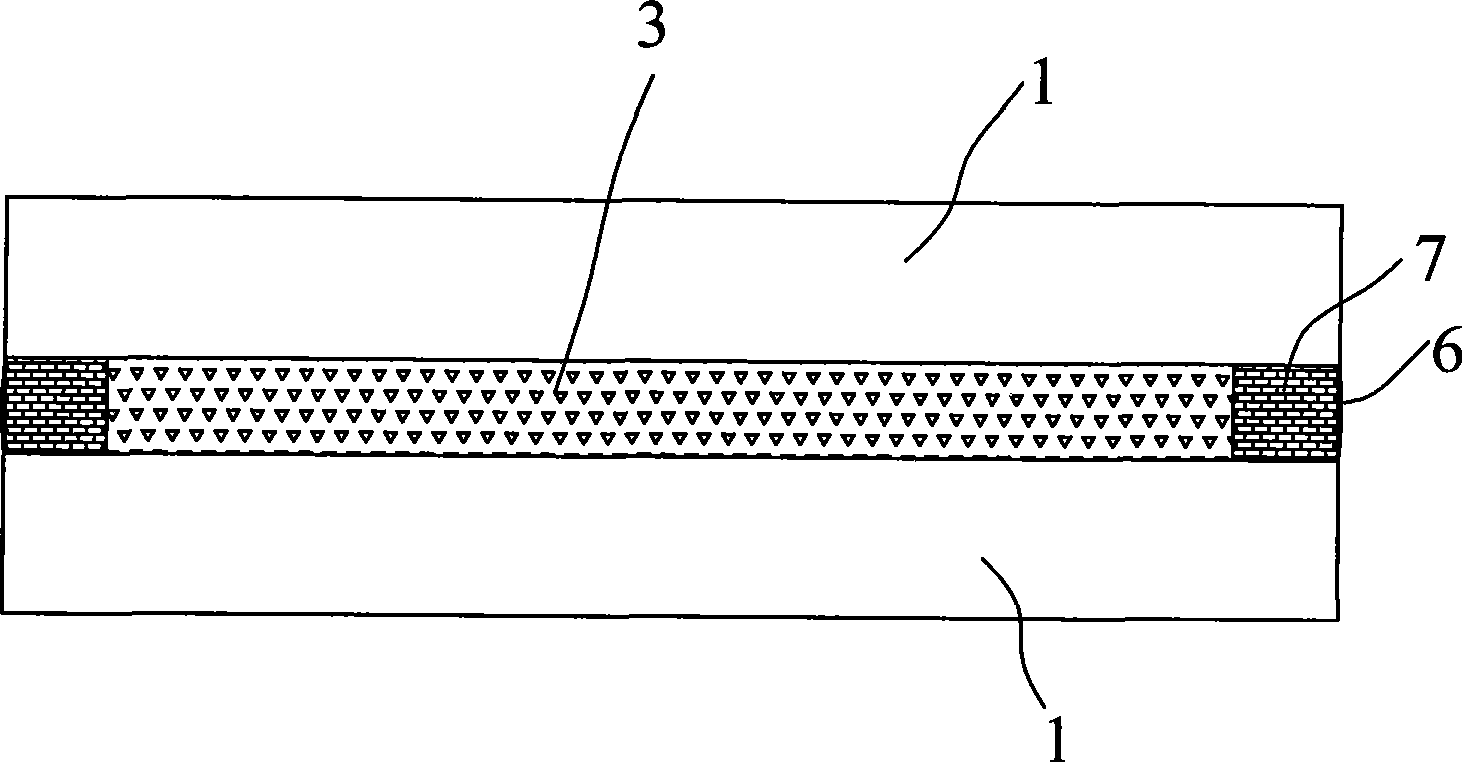

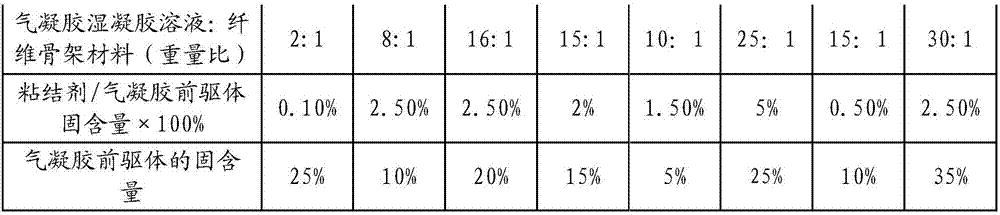

Powder removal prevention aerogel composite insulation felt and preparation method thereof

ActiveCN107140938AShorten the replacement periodImplement reflectionSynthetic fibresCarbon fibresFiberMaterials science

The invention belongs to the technical field of energy-saving and environment-friendly materials, and particularly relates to powder removal prevention aerogel composite insulation felt used for building and industrial energy saving and insulation. The insulation felt comprises an aerogel wet gel solution and a fiber framework material at a weight ratio of (2-30):1. A preparation method of the insulation felt comprises the steps of immersing the fiber framework material into the aerogel wet gel solution according to the aerogel wet gel solution and the fiber framework material at the weight ratio of (2-30):1 to achieve saturation adsorption of the aerogel wet gel solution by the fiber framework material, and then performing drying to obtain the insulation felt. The insulation felt overcomes the problems of high cost and easy powder removal of the existing insulation felt, and is better in performance and more environment-friendly.

Owner:天津朗华科技发展有限公司

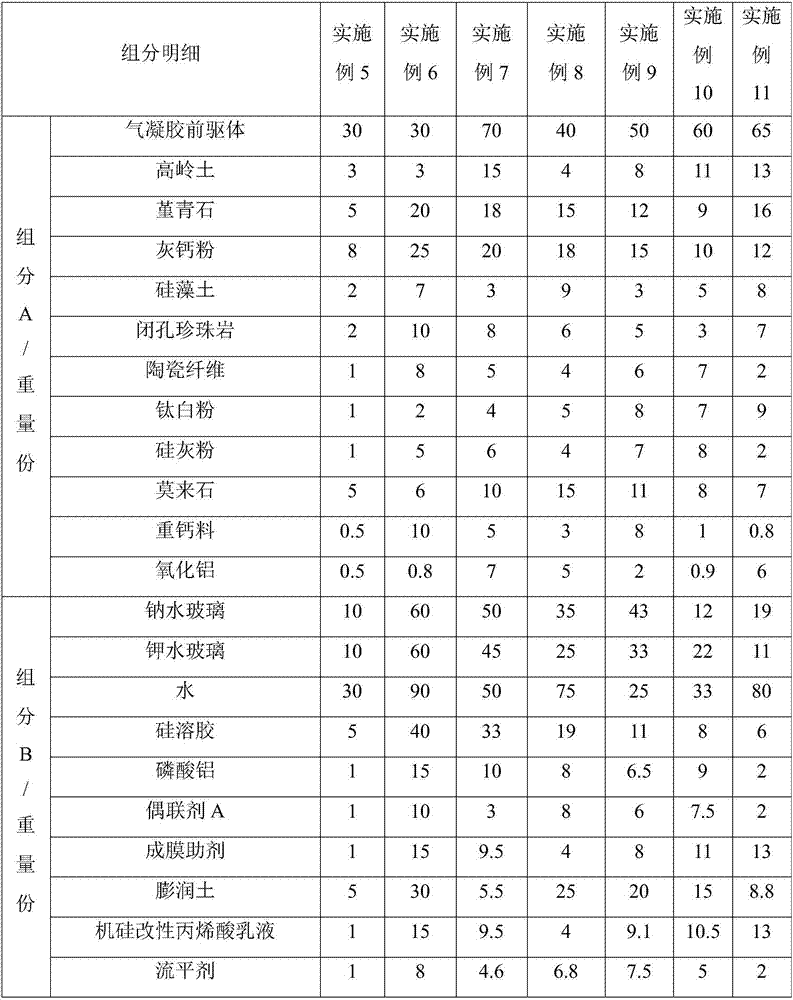

Ultrathin fireproof aqueous coating and preparation method thereof

ActiveCN107254204ADelay the heating processEnhanced Fire DurabilityFireproof paintsAlkali metal silicate coatingsThermal insulationThermal radiation

The invention belongs to the field of aqueous coatings and in particular relates to an ultrathin fireproof aqueous coating and a preparation method thereof. When the ultrathin fireproof aqueous coating is prepared, a component A and a component B are added, the component A comprises an aerogel precursor, stepless powder and the like, and the component B is used as a binding agent. The aerogel precursor is adopted as a core raw material to prepare the fireproof aqueous coating; as an aerogel material is of a nano three-dimensional structure and has characteristics that a solid heat conduction route is effectively prolonged, gas convective heat transfer is inhibited and thermal radiation is reduced, an aerogel fireproof coating made of the aerogel material has a thermal insulation property which is incomparable by conventional materials; after being applied to a steel material and dried, the ultrathin fireproof aqueous coating provided by the invention is relatively high in mechanical strength, achieves a fireproof grade A1, additionally has relatively good advantages of being waterproof and low in cost, and provides a novel material for buildings, environmental protection and industrial energy conservation.

Owner:天津朗华睿博科技有限公司

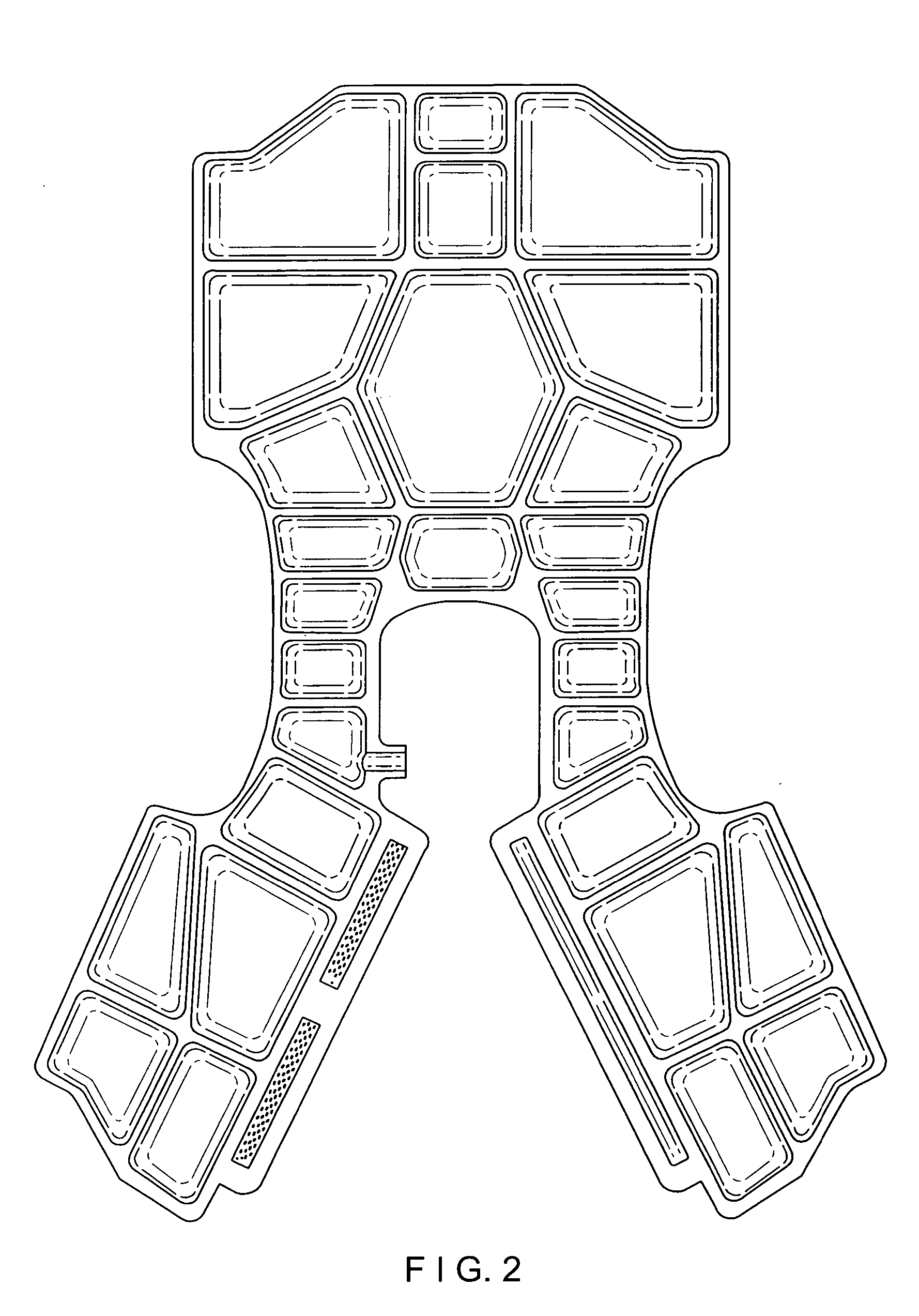

Emergency anti-hypothermia system and highly portable, inflatable emergency vest therefor

InactiveUS20050278823A1Reduce convective heat transferImprove portabilityGarment special featuresProtective garmentThermal insulationEngineering

An emergency anti-hypothermia system has a thermally insulating vest that is sufficiently portable to be carried for emergency use in a pocket, purse, backpack, compartment of a vehicle, ski pole or other location. The vest provides thermal insulation by being made with thermally insulating air impervious material that also provides for its inflation. The inflating air also provides insulation as, preferably, does thermal radiation reflective material on inwardly facing surfaces of the vest, preferably inwardly facing surfaces of outer layers of inflated chambers about the vest, the multiplicity of the chambers about the vest reducing convection heat transfer therewithin. The vest thus preferably provides thermal insulation by anti-conduction, anti-radiation and anti-convection in a highly portable system.

Owner:SOLATEC

Vacuum low-temperature ball valve

The vacuum low temperature ball valve comprises the clamping part, seal part and the drive part, with the clamping part composed of inlet flange, outlet flange and the outside shell connected in the middle, the seal structure composed of the valve inside the jacket with both ends fixed on the inlet and outlet flanges, fixed on the spring valve base at the inlet end of the valve through the screw bolt and nut and two seal bases with seal cushion embedded at both sides, with one connected to the spring valve base and the other connected to the valve. The drive part comprises the ball floating inside the valve, both sides of the ball contacting with two seal base, sliders on the top of the ball, with spring base and spring connected to the valve at the bottom of the ball. There are valve bar, guide sleeve and drive mechanism on the slider. It has good seal feature, high reliability, less cold loss, and long working cycle.

Owner:中国航天科技集团公司第一研究院第一〇一研究所

Infrared electric heating film heating tube with double-film layer structure as well as preparation method and application thereof

InactiveCN102036433AEnhanced Radiation Heat TransferReduce convective heat transferHeater elementsHeating element shapesIonElectric heating

The invention discloses an infrared electric heating film heating device with a double-film layer structure, which structurally comprises an electric heating film substrate and electrodes arranged on the two ends of the electric heating film substrate, wherein an electric conduction film layer and an infrared high emission film layer are sequentially evaporated on the surface of the electric heating film substrate. A preparation method of the infrared electric heating film heating device comprises the steps of: sequentially evaporating the electric conduction film layer and the infrared high emission film layer to the electric heating film substrate by using a high-temperature evaporation furnace, wherein an electric heating film solution comprises the components in parts by weight: 45-58 parts of stannic chloride, 0.3-2.0 parts of antimony butter, 0.4-1.2 parts of nickel trichloride, 0.3-1.0 part of indium chloride, 5-15 parts of ethanol / glycerol, 6-17 parts of inorganic acid, and 20-30 parts of deionized water, and an infrared high emission film solution comprises the components in parts by weight: 35-45 parts of manganous chloride, 15-20 parts of nickel dichloride, 5-10 parts of chromium trichloride, 5-15 parts of ethanol / glycerol and 20-30 parts of deionized water; and finally assembling the electrodes to obtain the infrared electric heating film heating device. In the invention, the double-film layer structure is adopted for the infrared electric heating film heating device, which can greatly enhance radiative heat transfer, reduce convection heat transfer, improve energy efficiency and save energy sources.

Owner:吕一诺

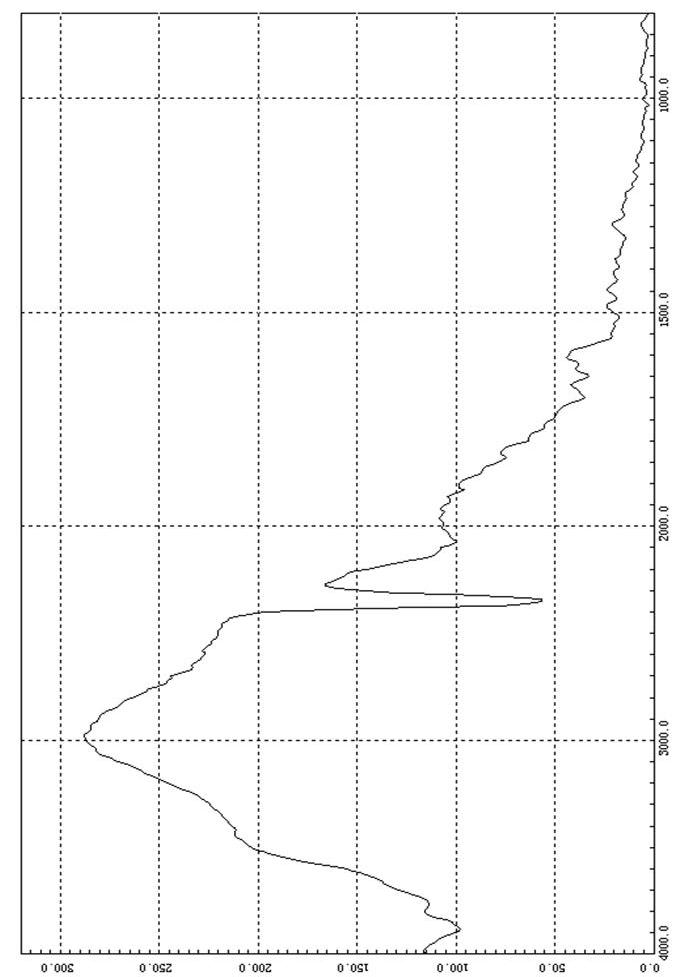

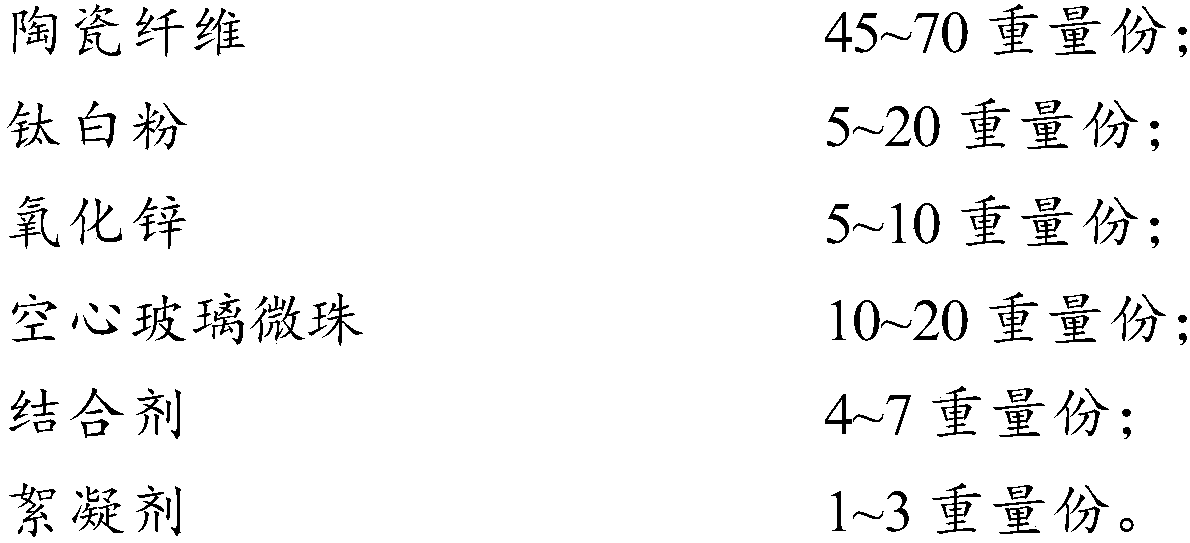

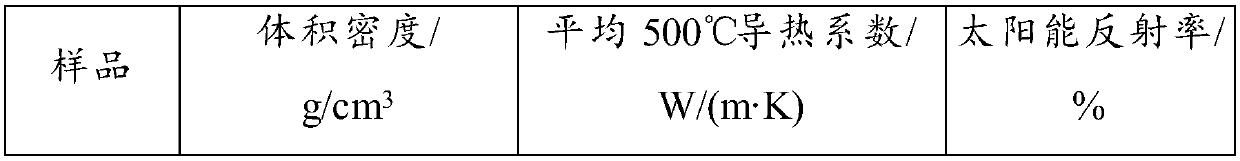

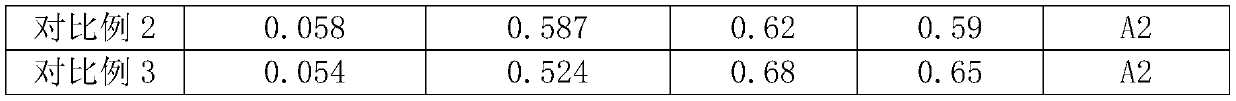

Ceramic fiber board and preparation method thereof

The invention provides a ceramic fiber board. The ceramic fiber board is prepared from, in parts by weight, 45-70 parts of ceramic fiber, 5-20 parts of titanium dioxide, 5-10 parts of zinc oxide, 10-20 parts of hollow glass beads, 4-7 parts of a binding agent and 1-3 parts of a flocculant. The ceramic fiber is used as a base material, a functional additive is selected to endow the ceramic fiber board with high solar reflectance and low heat conductivity coefficient, and the ceramic fiber board has the average heat conductivity coefficient at 500 DEG C lower than 0.11 W / (m.K) and solar reflectance higher than 55% and is applicable to the field of solar-thermal power generation.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

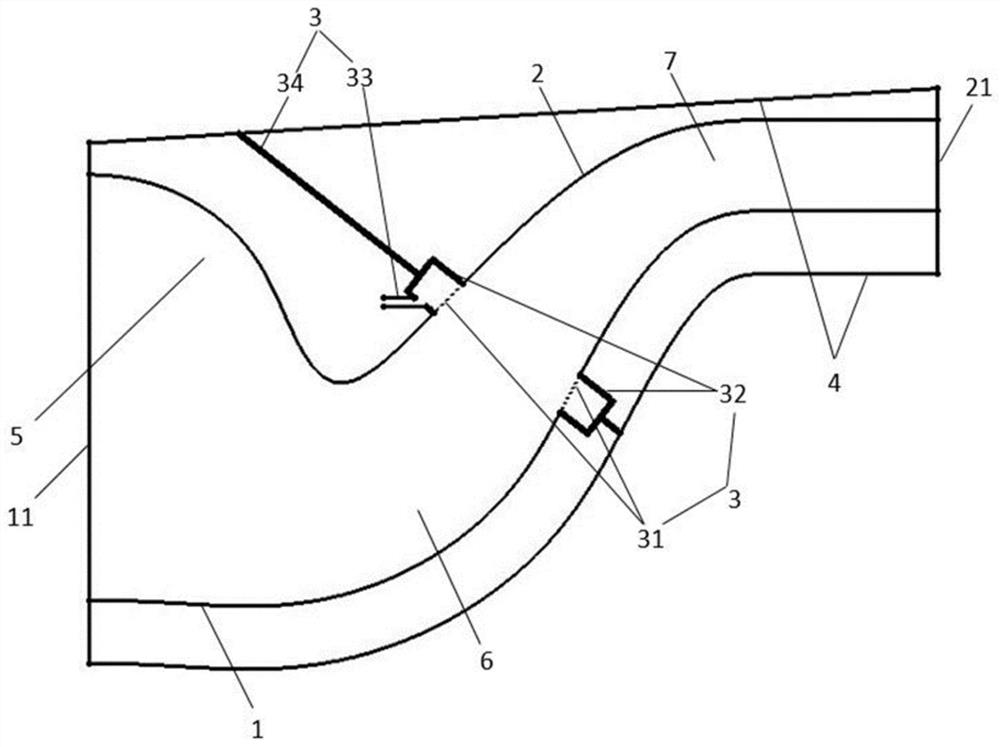

S-shaped invisible spray pipe with cooling structure

ActiveCN112610357AReduce the temperatureAvoid damageEfficient propulsion technologiesJet propulsion plantsAviationEngineering

The invention discloses an S-shaped invisible spray pipe with a cooling structure, and belongs to the field of aero-engines. The S-shaped invisible spray pipe comprises an S-shaped bent spray pipe and an air film cooling and reinforcing device. The air film cooling and reinforcing device is arranged on the outer peripheral surface of the S-shaped bent spray pipe and comprises air film cooling holes, an annular reinforcing device, a cooling air supply device and a reinforcing support column. The annular reinforcing device is an annular cavity with an opening in the inner annular surface and coaxially sleeves the periphery of the S-shaped bent spray pipe, and the opening in the inner annular surface of the annular reinforcing device is attached and fixed to the outer wall surface of the S-shaped bent spray pipe. The air film cooling holes are formed in the wall of the S-shaped bent spray pipe in the annular reinforcing device. The outer annular surface of the annular reinforcing device is connected with an aircraft skin through the reinforcing support column. Cooling air enters the S-shaped bent spray pipe through the cooling air supply device, so that the injected cooling air flow covers the inner wall surface of the spray pipe, and the temperature of the wall surface of the S-shaped bent spray pipe and the infrared radiation of an exhaust system are reduced. Damage caused by the high temperature of the wall surface is prevented, meanwhile, the infrared radiation of the exhaust system can be reduced through the injected cooling airflow, and the hiding performance of the S-shaped bent spray pipe is enhanced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Long-distance cold transfer device based on small cryogenic refrigerator

ActiveCN107727481AReduce convective heat transferSmall low convection heat transferPreparing sample for investigationCompression machinesCold testCold shield

The invention provides a long-distance cold transfer device based on a small cryogenic refrigerator. The device comprises a vacuum chamber and the cryogenic refrigerator fixedly arranged in the vacuumchamber, the lower end of the vacuum chamber is in detachable sealing connection with a test chamber for containing a sample to be tested, a cold shield is arranged in the vacuum chamber, the lower part of the small cryogenic refrigerator is inserted to the cold shield, a first heat exchanger is fixedly arranged at the lower end of the small cryogenic refrigerator, a second heat exchanger capableof exchanging heat with the sample to be tested is arranged in the test chamber, the first heat exchanger and the second heat exchanger are connected by a circulating pipeline, and the circulating pipeline is positioned in the cold shield. The device can meet the installation requirements of a test space, makes the low temperature test of the sample easy, and has a application range.

Owner:TSINGHUA UNIV

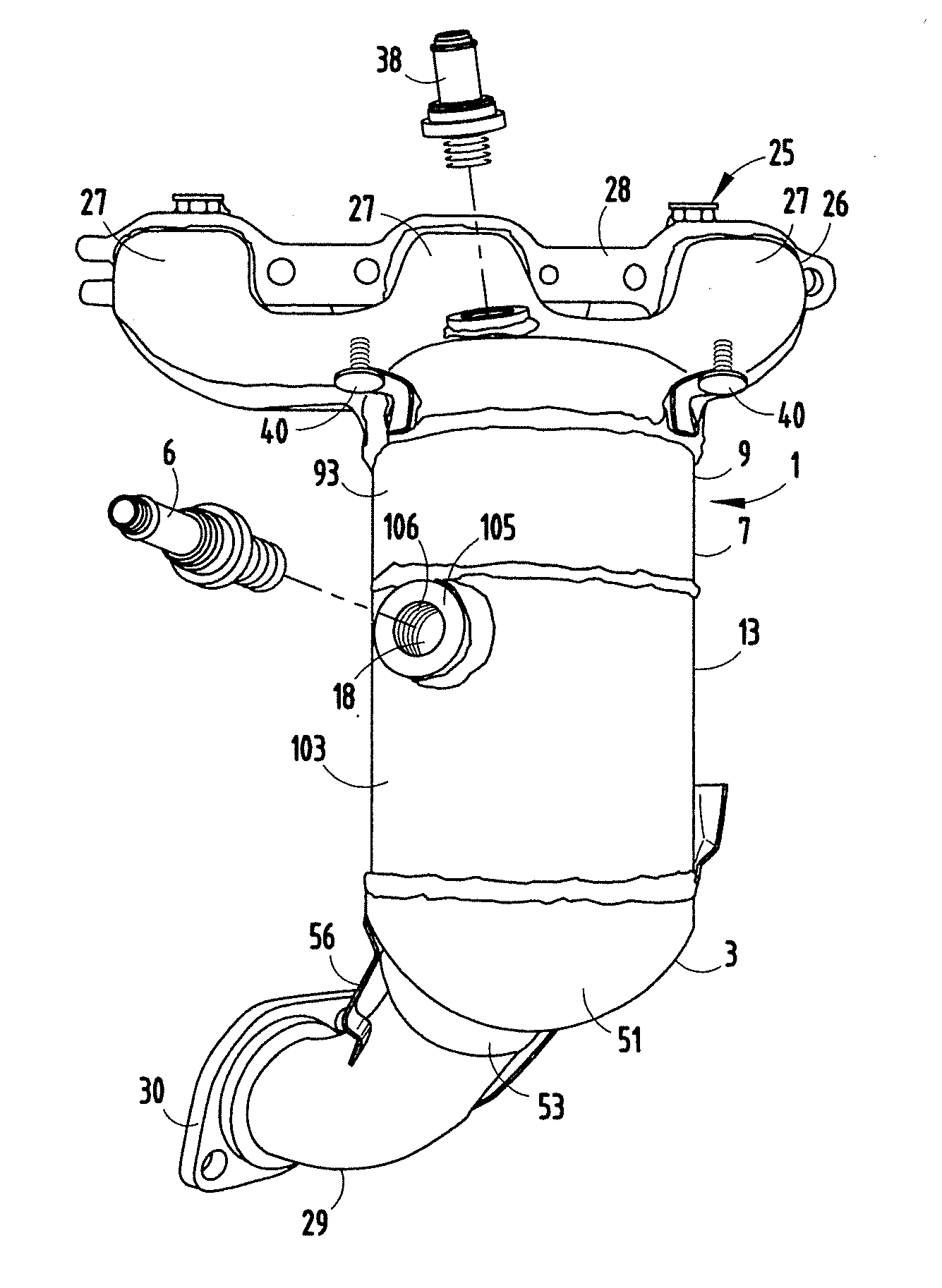

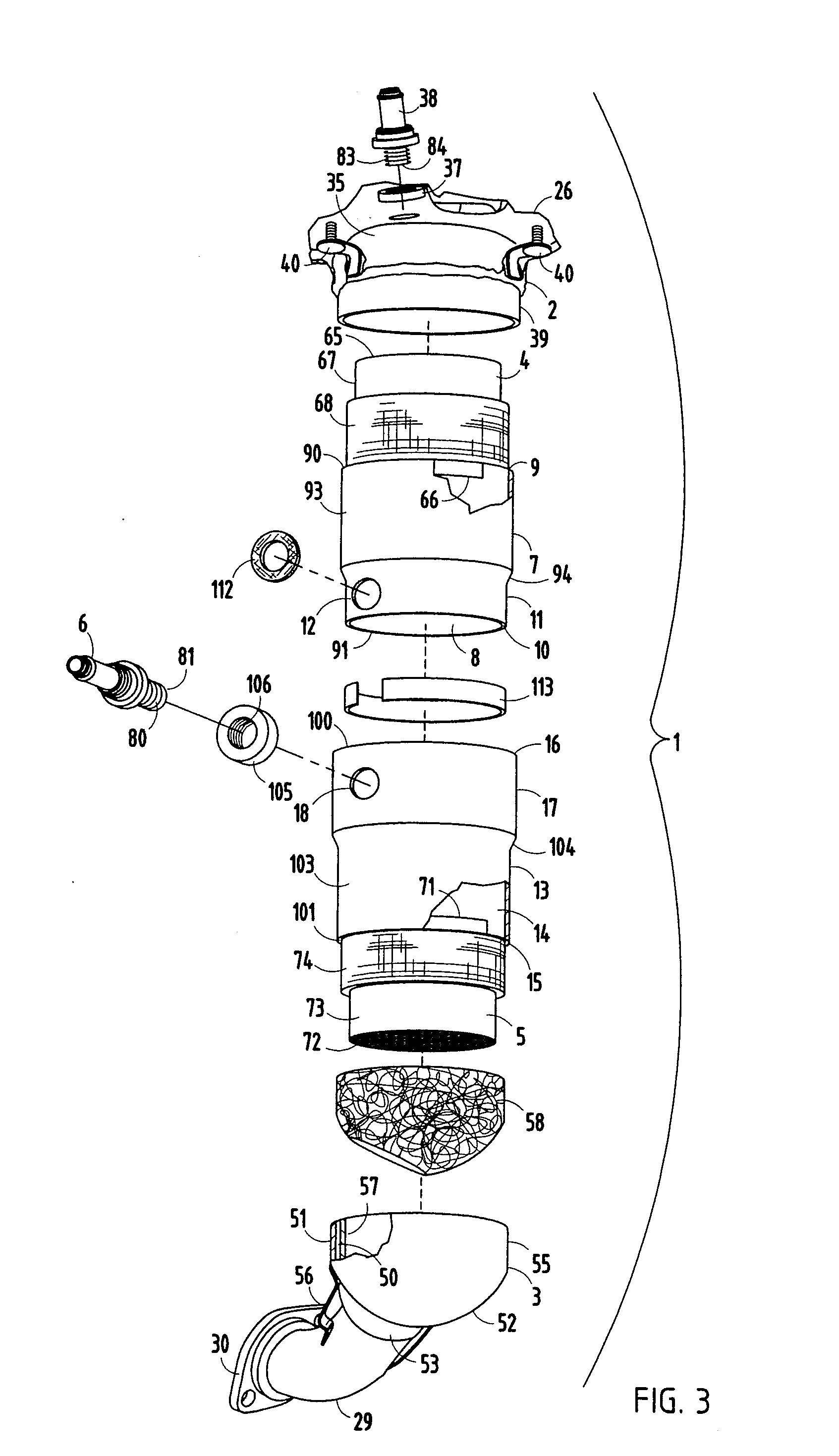

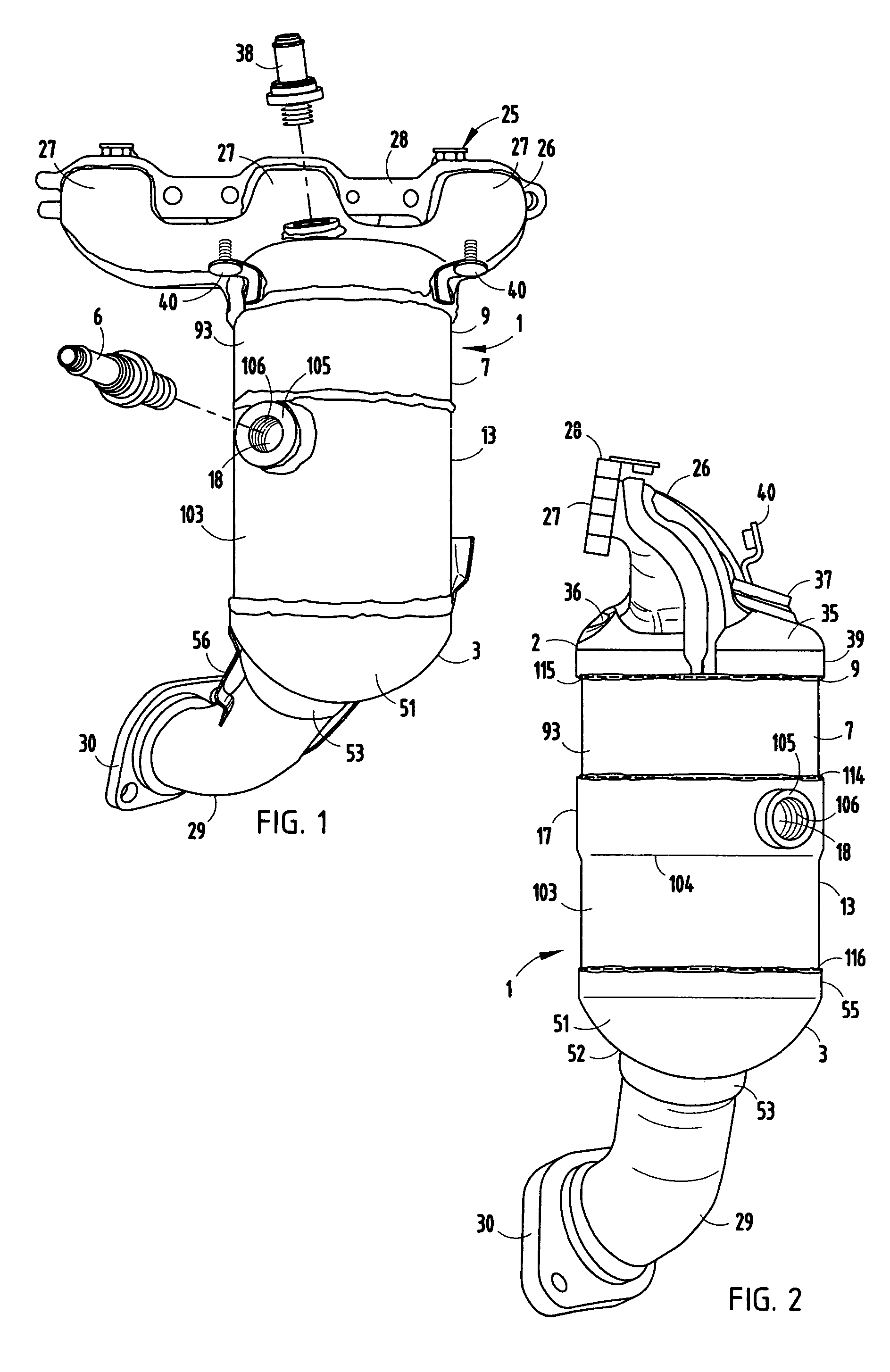

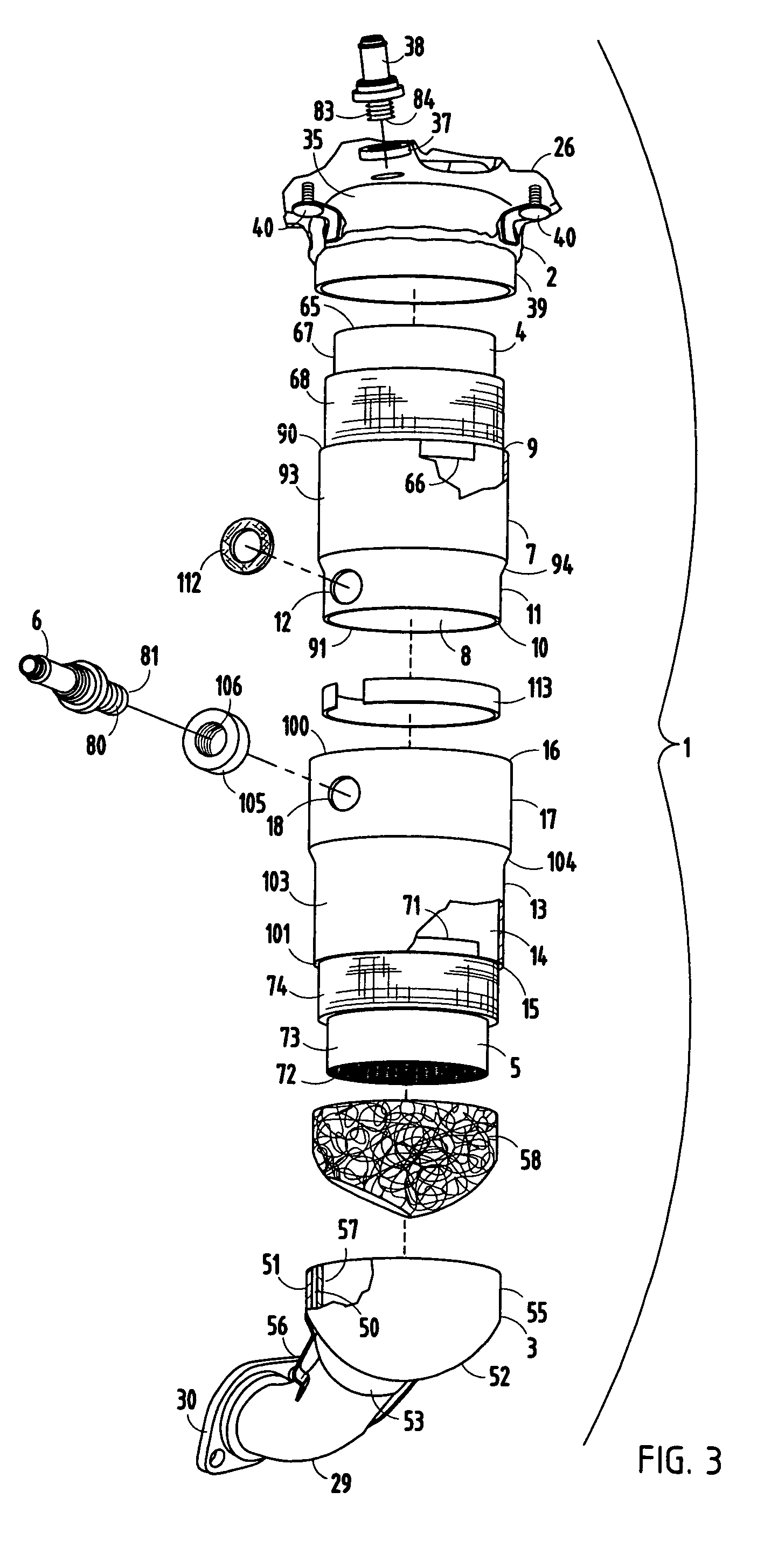

Method for making two-piece catalytic converter with double wall mid-section

ActiveUS20100307001A1Small sizeEfficiently and effectively treats exhaust gasExhaust apparatusSilencing apparatusCombustionDouble wall

An exhaust gas treatment device for internal combustion engines and the like includes inlet and outlet end caps, two catalyst substrates, and a two-piece housing. A first, cylindrically-shaped housing member has a hollow interior in which one of the substrates is retained, a first end sealingly connected with the inlet end cap, and an opposite second end with a radially reduced section. A second cylindrically-shaped housing member has a hollow interior in which the other one of the substrates is retained, a first end sealingly connected with the outlet end cap, and an opposite second end with a radially enlarged section sized to receive therein the second end of the first housing member, whereby the reduced section of the first housing member and the enlarge section of the second housing member are spaced radially apart a predetermined distance to define an annularly-shaped space or gap which thermally insulates the associated portion of the exhaust gas treatment device.

Owner:BENTELER AUTOMOTIVE CORP

Basalt fiber thermal insulation decorative integrated plate and preparation method thereof

ActiveCN110357566AReduce convective heat transferImprove insulation effectCarbon fibersThermal insulation

The invention discloses a basalt fiber thermal insulation decorative integrated plate and a preparation method thereof, belonging to the technical field of building materials. According to the invention, carbon fiber and basalt fiber are taken as framework structural materials, modified SiO2 aerogel is taken as a heat insulation functional material, and inorganic fillers, adhesives and additives are combined to form the basalt fiber heat insulation decorative integrated plate. The basalt fiber thermal insulation decorative integrated plate can be used below 650 DEG C, has a thermal conductivity of about 0.02 W / (mK), is three to five times that of the traditional inorganic thermal insulation material, and can greatly improve the thermal insulation effect and high-temperature resistance.

Owner:中科华坤(北京)科技有限公司

Nano-composite heat insulation plate and preparation method thereof

The invention provides a nano-composite heat insulation plate, which is prepared from the following raw materialsby weight: 30-40 parts of silicon dioxide with a particle size of 20-30nm, 30-40 partsof silicon dioxide with a particle size of 400-600 nm, 5-10 parts of expanded perlite, 5-10 parts of an infrared opacifying agent, 2-5 parts of inorganic refractory fibers, and 5-8 parts of an inorganic adhesive. Compared with the nano-composite heat insulation plate in the prior art, the nano-composite heat insulation plate of the invention has the following characteristics that the nano-composite heat insulation plate has good particle grading by introducing silicon dioxide with a particle size of 400-600nm and expanded perlite so as to achieve the uniform diameter distribution of the internal holes and effectively reduce the convective heat transfer, and the inorganic adhesive is introduced to ensure the normal temperature strength and the after-burning strength of the nano-composite heat insulation plate, so that the product is a pure inorganic product, free of smoke and odor at a high temperature, and low in cost.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Polyurethane foam heat insulation and decoration integrated board and preparation method thereof

ActiveCN110256107AImprove fire performanceStable mechanical propertiesCovering/liningsCeramicwarePolymer scienceFireproofing

The invention discloses a polyurethane foam heat insulation and decoration integrated board and a preparation method thereof, and belongs to the technical field of building materials. The polyurethane foam heat insulation and decoration integrated board is obtained through a reaction among modified basalt fibers, modified SiO2 aerogel and a polyurethane composite. The modified basalt fibers are added to the polyurethane material; excellent fireproofing performance, high-temperature resistance, stable mechanical properties at a high temperature, water resistance, acid resistance and normal-temperature alkaline resistance of the modified basalt fibers are utilized; the modified basalt fibers can serve as reinforcements to improve the toughness and strength of the polyurethane composite board, and can also enable the polyurethane composite board to serve as a heat-insulating building material in severe weather conditions. The modified SiO2 aerogel with excellent heat insulation properties can serve as a filler. The polyurethane foam heat insulation and decoration integrated board has excellent mechanical properties, high-temperature resistance and flame retardancy, and can maintain thermal stability at a high temperature.

Owner:展宏节能科技有限公司

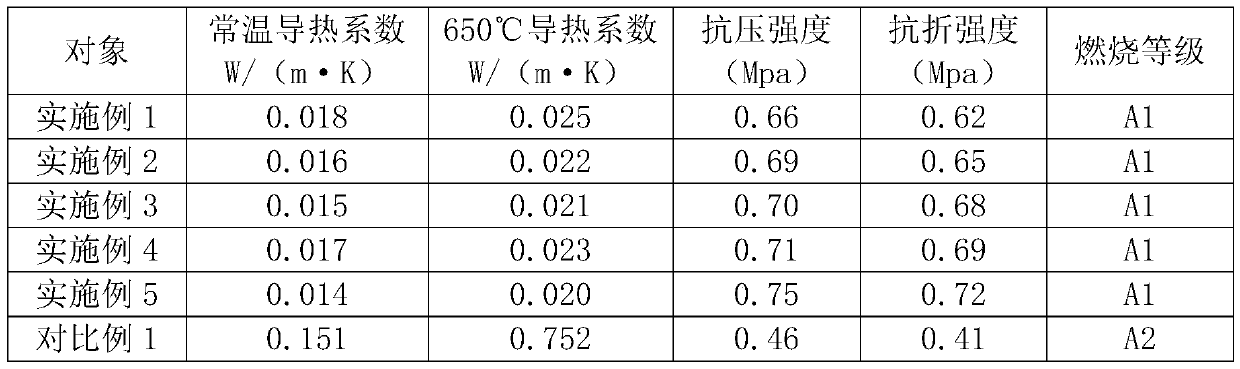

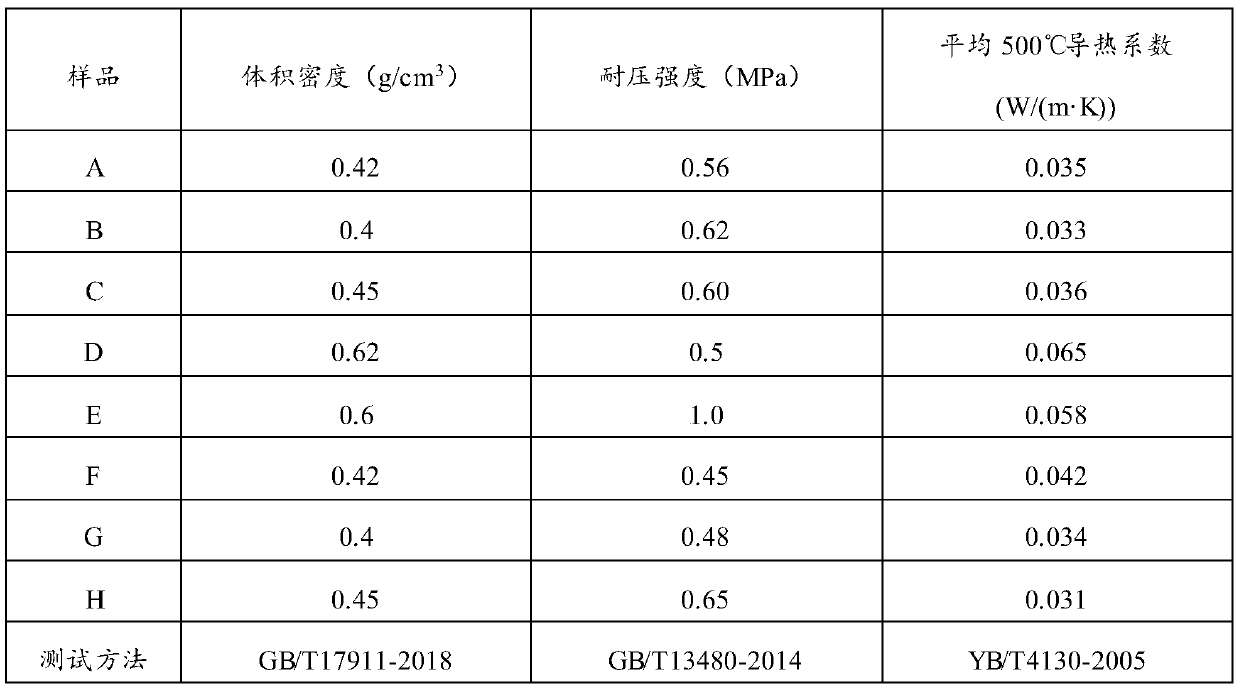

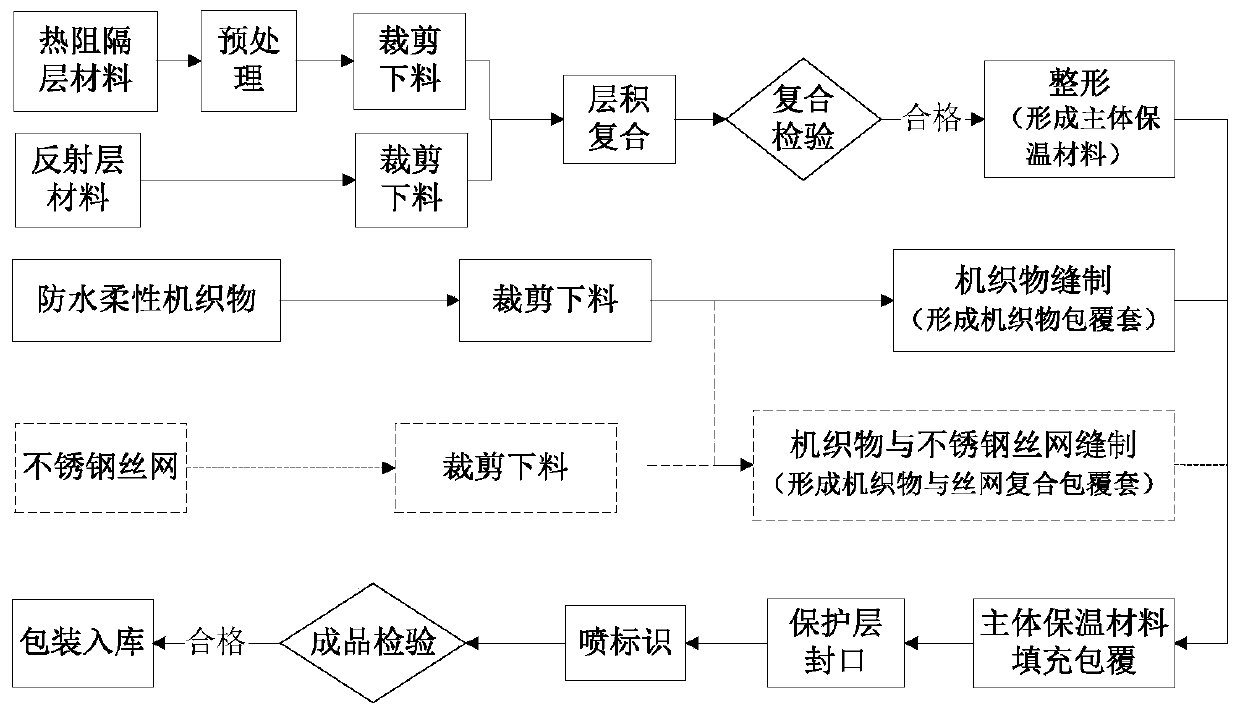

Nuclear-grade modular thermal insulation layer and preparation method thereof

ActiveCN110802885ABreak through the bottleneck problem that is difficult to greatly reduce the high temperature thermal conductivitySolve the weight problemLamination ancillary operationsNuclear energy generationFiberInsulation layer

The invention provides a nuclear-grade modular thermal insulation layer which is composed of a main body thermal insulation material and an outer protective layer material; the main body thermal insulation material is formed by laminating and compounding a thermal barrier layer material and a reflecting layer material; the thermal barrier layer material is an irradiation-resistant ceramic fiber adiabatic composite material which is resistant to irradiation and can bear irradiation of gamma rays with the dosage of 1.0*10<7> Gy or above, the mass moisture absorption rate is not larger than 0.3%,the hydrophobicity is not less than 99.5%, and the heat conductivity coefficient is not larger than 0.016 W*m<-1>*K<-1> at the temperature of 25 DEG C. The problems that a conventional metal thermalinsulation layer is large in weight, special-shaped parts are difficult to process, and a non-metal thermal insulation layer collapses and accumulates and is uneven in volume weight are solved, the equipment or system performance is better guaranteed, and wide market application prospects are achieved. The preparation method is simple and suitable for large-scale production.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Exhaust gas treatment device with insulated housing construction

InactiveUS7765801B2Small sizeEfficiently and effectively treats exhaust gasCombination devicesExhaust apparatusCombustionExhaust fumes

An exhaust gas treatment device for internal combustion engines and the like includes inlet and outlet end caps, two catalyst substrates, and a two-piece housing. A first, cylindrically-shaped housing member has a hollow interior in which one of the substrates is retained, a first end sealingly connected with the inlet end cap, and an opposite second end with a radially reduced section. A second cylindrically-shaped housing member has a hollow interior in which the other one of the substrates is retained, a first end sealingly connected with the outlet end cap, and an opposite second end with a radially enlarged section sized to receive therein the second end of the first housing member, whereby the reduced section of the first housing member and the enlarge section of the second housing member are spaced radially apart a predetermined distance to define an annularly-shaped space or gap which thermally insulates the associated portion of the exhaust gas treatment device.

Owner:BENTELER AUTOMOTIVE CORP

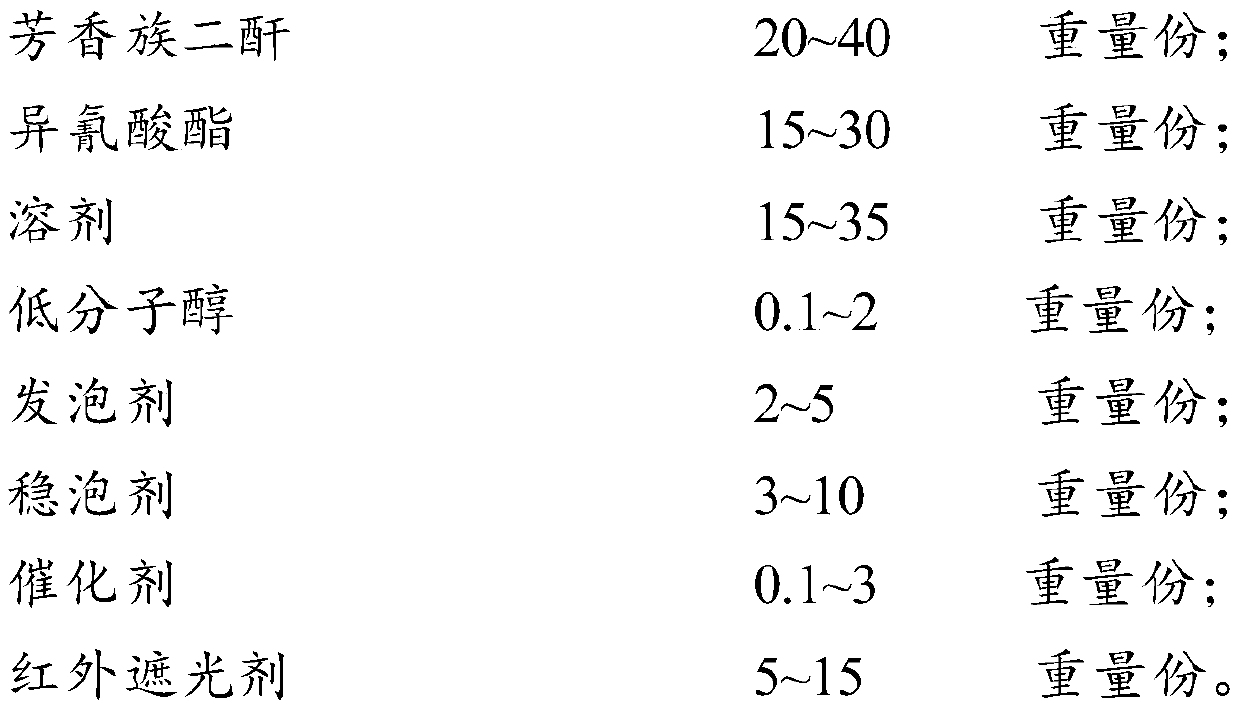

Heat-insulation and heat-preservation polyimide foam material and preparation method thereof

The invention provides a polyimide foam material. The polyimide foam material comprises the following raw materials: 20-40 parts by weight of aromatic dianhydride, 15-30 parts by weight of isocyanate,15-35 parts by weight of a solvent, 0.1-2 parts by weight of low molecular alcohol, 2-5 parts by weight of a foaming agent, 3-10 parts by weight of a foam stabilizer, 0.1-3 parts by weight of a catalyst and 5-15 parts by weight of an infrared opacifying agent. According to the invention, the infrared opacifying agent is added into the polyimide foam material, and the scattering and absorption effects of the infrared opacifying agent are utilized to reduce radiation heat transfer and the heat conductivity coefficient of a material; and by using of the infrared opacifying agent, the heat conductivity coefficient of the polyimide foam material is obviously reduced at a high temperature. The addition ratio of the infrared opacifying agent is regulated and controlled, and the addition ratio ofraw materials is combined, so the polyimide foam material with specific composition and formula is finally obtained. The foam material prepared by using the method provided by the invention has low heat conductivity coefficient, and has excellent heat resistance and mechanical properties at the same time.

Owner:常州福隆科技新材料有限公司

Aerogel modified expanded perlite heat preservation plate and preparing method thereof

ActiveCN107089810AFree from destructionShorten the replacement periodCeramicwareFiberPolymer science

The invention belongs to the technical field of energy-saving and environment-friendly materials, and particularly relates to an aerogel modified expanded perlite heat preservation plate for architecture and industrial energy conservation and heat preservation. The aerogel modified expanded perlite heat preservation plate is prepared from one or two expanded perlite powder, an aerogel intermediate, cement, a mixing material A, water, ceramic fiber cotton and wood fiber cotton. The preparing method comprises the steps of evenly mixing one or two in the expanded perlite powder, the aerogel intermediate, the cement, the ceramic fiber cotton and the wood fiber cotton, adding water to conduct even stirring, adding the mixing material A, after conducting even stirring, adopting a mold to conduct press forming, and conducting airing after conducting drying till full dryness is achieved. According to the aerogel modified expanded perlite heat preservation plate, the thermal conductivity and moisture content of the expanded perlite heat preservation plate product are drastically lowered, and the bending resisting strength and tensile resisting strength are both drastically improved.

Owner:天津朗华科技发展有限公司

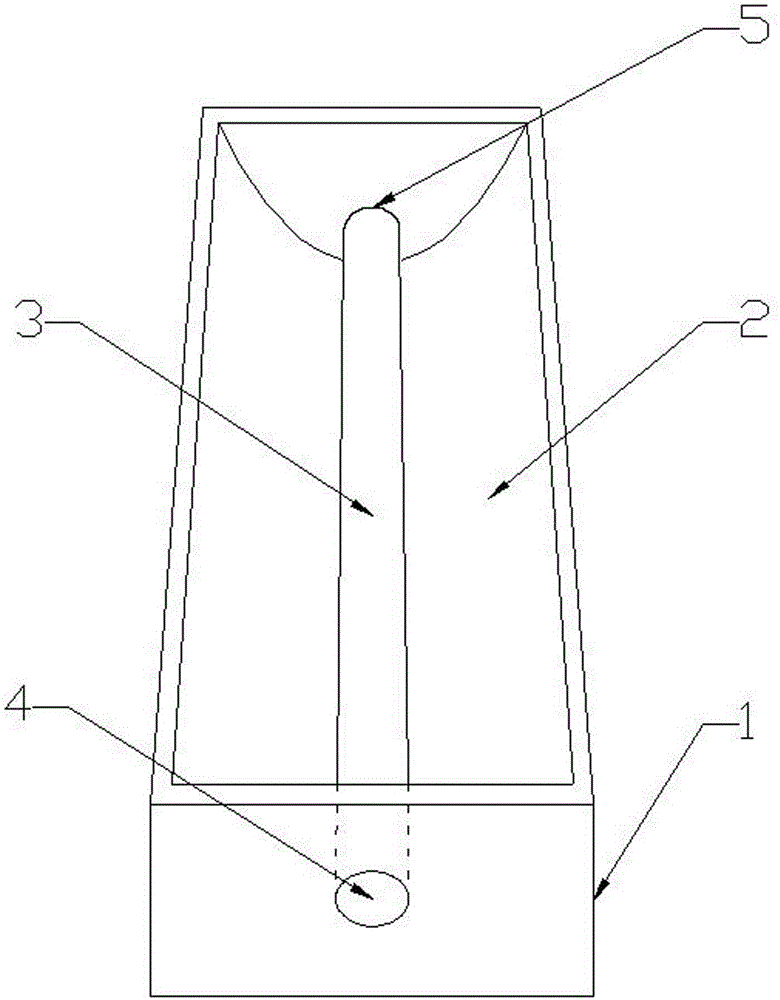

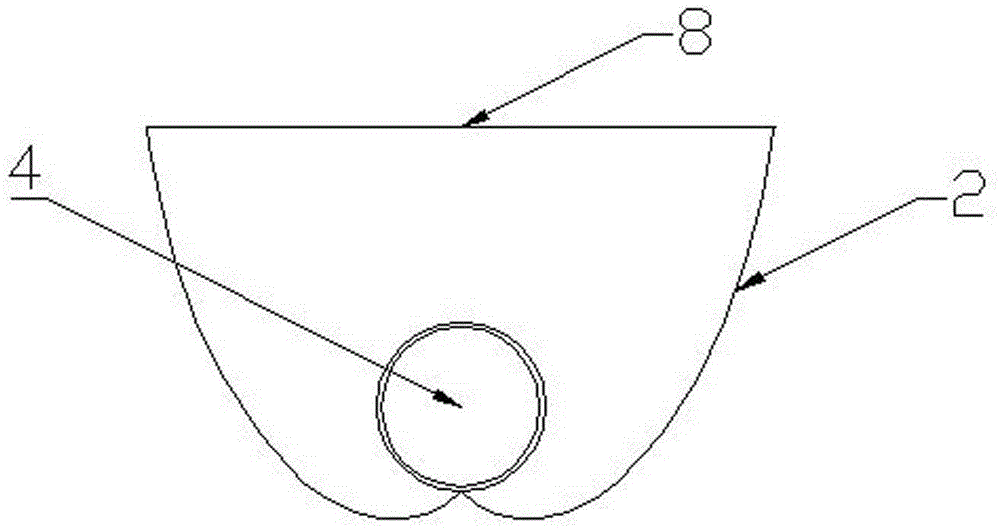

Compound parabolic condensation type heat collection and dissipation device with heat collection function at daytime and radiation refrigeration function at night

InactiveCN105241081AImprove absorption rateReduce radiative heat lossSolar heating energySolar heat devicesEngineeringRefrigeration

The invention belongs to the technical field of energy utilization and particularly relates to a compound parabolic condensation type heat collection and dissipation device with the heat collection function at daytime and the radiation refrigeration function at night. The compound parabolic condensation type heat collection and dissipation device comprises a box body with the top surface opened, a compound parabolic condenser, a glass pipe and a support. The interior of the box body is of a compound parabolic shape. The support is arranged around the box body, the compound parabolic condenser is arranged in the box body, and the glass pipe is arranged in the center of the bottom of the compound parabolic condenser. A water inlet and a water outlet are formed in the two ends of the glass pipe respectively and communicated with the outer surface of the box body. The outer surface of the glass pipe is plated with a solar heat collection and radiation refrigeration composite coating. The compound parabolic condensation type heat collection and dissipation device can collect heat at daytime and carry out radiation refrigeration at night, and therefore the problem that traditional compound parabolic condensation type vacuum pipe heat collectors and radiation refrigeration devices are single in function is effectively solved.

Owner:GUANGDONG FIVESTAR SOLAR ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com