Ceramic fiber board and preparation method thereof

A technology of ceramic fiber board and particle size, which is applied in the field of photothermal power generation, can solve the problems of not being suitable for the solar thermal power generation industry and low solar reflectance of ceramic fiber board, and achieve improved heat insulation effect, reduced convective heat transfer, and simple operation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

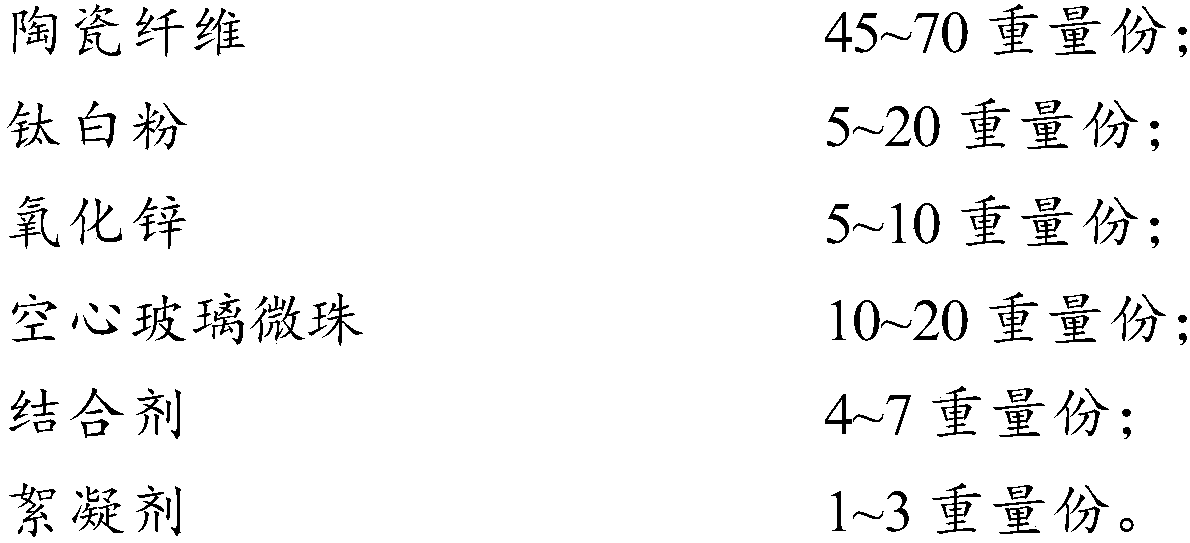

Method used

Image

Examples

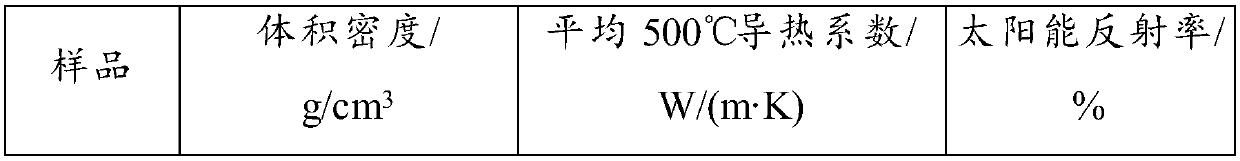

Embodiment 1

[0040] Weigh 45 parts by weight of standard ceramic fiber (fiber diameter 3μm, fiber length 80-100mm, Al 2 o 3 content ≥ 45%), 20 parts by weight of titanium dioxide, 10 parts by weight of zinc oxide, 20 parts by weight of hollow glass microspheres and 4 parts by weight of starch are added to the beating tank filled with water in advance, stirred at high speed, and the stirring speed is 800rpm, stirring 20min; pump the mixed material into the slurry storage tank, turn on the agitator in the slurry storage tank, add 1 part by weight of polyaluminium chloride and anionic amide with a mass ratio of 1:1, and stir until the supernatant appears around the material Liquid, the stirring speed is 200rpm, and the stirring time is 5min; the above-mentioned mixed material is dehydrated and formed by the fourdrinier drawing process, and then dried with hot air at a drying temperature of 120°C to obtain a ceramic fiber board.

Embodiment 2

[0042] Weigh 60 parts by weight of high alumina ceramic fiber (fiber diameter 2μm, fiber length 10-20mm, Al 2 o 3Content ≥ 52%), 13 parts by weight of titanium dioxide, 7 parts by weight of zinc oxide, 13 parts by weight of hollow glass microspheres and 5 parts by weight of polyurethane emulsion are added to the beating tank filled with water in advance, and stirred at a high speed to mix evenly. The stirring speed is 1000rpm. Stir for 25 minutes; pump the mixed material into the slurry storage tank, turn on the agitator in the slurry storage tank, add 2 parts by weight of polyaluminum sulfate and anionic amide with a mass ratio of 1:2, and stir until the supernatant appears around the material Liquid, the stirring speed is 400rpm, and the stirring time is 4min; the above-mentioned mixed material is dehydrated and formed through the fourdrinier drawing process, and then dried with hot air at a drying temperature of 130°C to obtain a ceramic fiber board.

Embodiment 3

[0044] Weigh 70 parts by weight of zirconium-containing ceramic fiber (fiber diameter 5 μm, fiber length 120-150 mm, Al 2 o 3 Content≥36%, ZrO 2 Content ≥ 15%), 5 parts by weight of titanium dioxide, 5 parts by weight of zinc oxide, 10 parts by weight of hollow glass microspheres and 7 parts by weight of cellulose are added to the beating tank filled with water in advance, stirred and mixed at a high speed, the stirring speed is 1200rpm, Stir for 30 minutes; pump the mixed material into the slurry storage tank, turn on the agitator in the slurry storage tank, add 3 parts by weight of polyaluminum chloride and anionic amide with a mass ratio of 1:3, and stir until the upper surface appears around the material. For the clear liquid, the stirring speed is 500rpm, and the stirring time is 3min; the above-mentioned mixed material is dehydrated and formed by a fourdrinier drawing process, and dried with hot air at a drying temperature of 140°C to obtain a ceramic fiber board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com