An NTC resistive material and its preparation method

A technology of resistive materials and manufacturing methods, applied in the direction of resistors with negative temperature coefficients, etc., to achieve the effect of less nickel content, which is conducive to mass production and improves stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: by molecular formula Ba 1-x D. x Ti 1-y-z Ni y MZO 3 Dosing was performed where y=0.1, x=z=0. The starting raw material is selected from barium carbonate BaCO 3 , tetra-n-butyl titanate [CH 3 (CH 2 ) 3 O] 4 Ti, basic nickel carbonate CH 2 Ni 2 o 5 . Materials were prepared according to the following experimental process steps:

[0023] ① Press the initial raw material to BaTi 0.9 Ni 0.1 o 3 Molecular formula element ratio, weigh 19.199g of BaCO 3 , 29.760g of [CH 3 (CH 2 ) 3 O] 4 Ti 1.040g CH 2 Ni 2 o 5 ;

[0024] 2. Dissolve the raw materials taken in the previous step in 6mol / L dilute nitric acid respectively;

[0025] ③ Mix the three solutions prepared in the previous step, and use a magnetic stirring heater to stir and mix evenly, and heat and dry;

[0026] ④Calcinate the powder obtained in the previous step at a temperature of 1100°C and keep it warm for 2 hours;

[0027] ⑤ The powder synthesized in the previous step is gran...

Embodiment 2

[0032] Embodiment 2: by molecular formula Ba 1-x D. x Ti 1-y-z Ni y m z o 3 Dosing was performed with y=0.3, x=z=0. The starting raw material is selected from barium carbonate BaCO 3 , tetra-n-butyl titanate [CH 3 (CH 2 ) 3 O] 4 Ti, basic nickel carbonate CH 2 Ni 2 o 5 . Materials were prepared according to the following experimental process steps:

[0033] ① Press the initial raw material to BaTi 0.7 Ni 0.3 o 3 Molecular formula element ratio, weigh 21.117g BaCO 3 , 25.458g[CH 3 (CH 2 ) 3 O] 4 Ti, 3.425g CH 2 Ni 2 o 5 ;

[0034] ② The preparation process is the same as the steps ②~⑧ in Example 1.

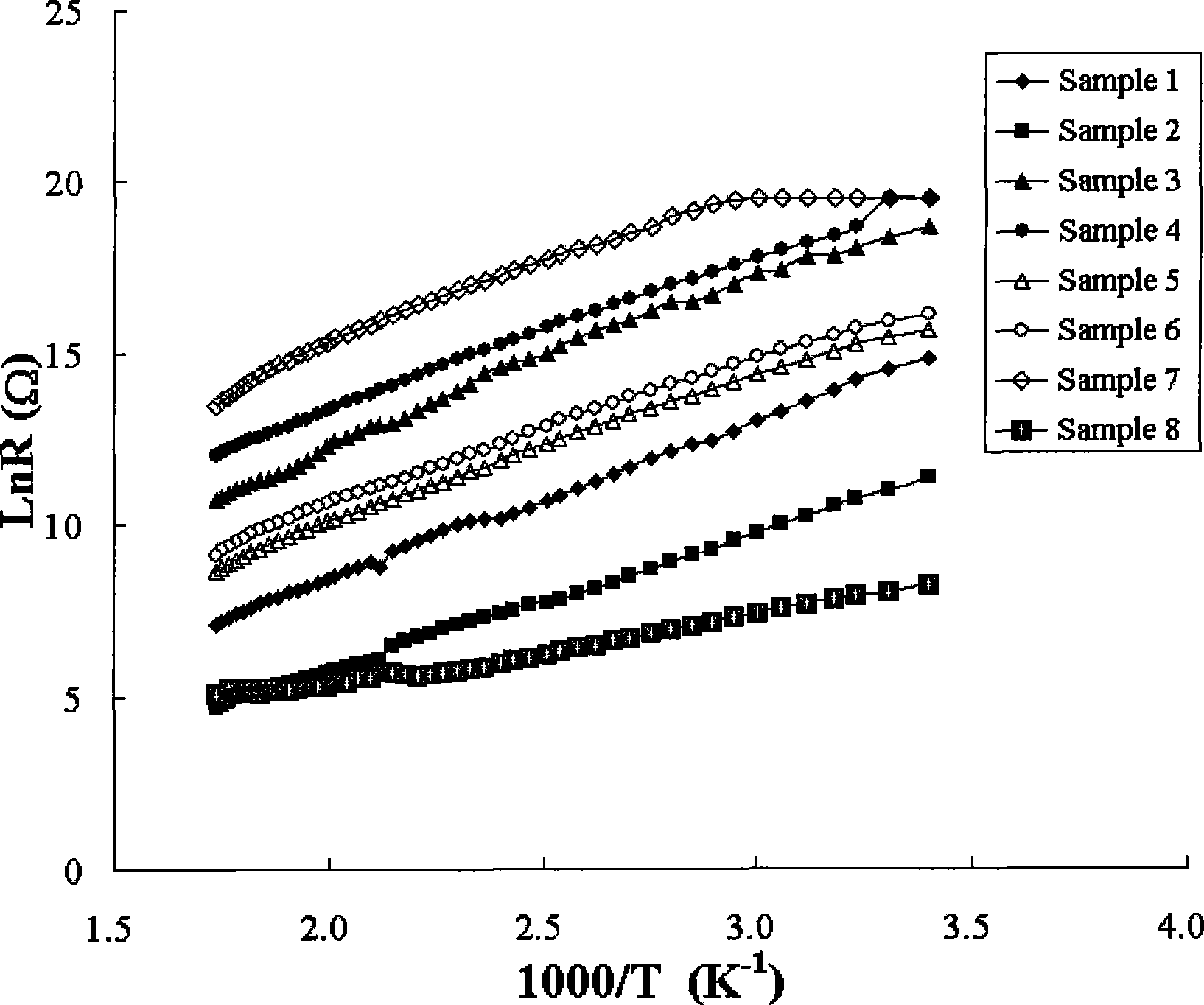

[0035] The properties of the prepared materials are shown in Table 1 and Figure 1.

Embodiment 3

[0036] Embodiment 3: this example presses molecular formula Ba 1-x D. x Ti 1-y-z Ni y m z o 3 Dosing was performed where x=0, y=0.1, z=0.003. The starting raw material is selected from barium carbonate BaCO 3 , tetra-n-butyl titanate [CH 3 (CH 2 ) 3O] 4 Ti, basic nickel carbonate CH 2 Ni 2 o 5 and antimony trioxide Sb 2 o 3 . Materials were prepared according to the following experimental process steps:

[0037] ① Press the initial raw material to BaTi 0.897 Ni 0.1 Sb 0.003 o 3 Molecular formula element ratio, weigh 19.222gBaCO 3 , 29.696g[CH 3 (CH 2 ) 3 O] 4 Ti, 1.392g CH 2 Ni 2 o 5 and 0.043g Sb 2 o 3 ;

[0038] 2. Dissolve the raw materials taken in the previous step in 6mol / L dilute nitric acid respectively;

[0039] ③Mix the four solutions prepared in the previous step, and use a magnetic stirring heater to stir and mix evenly, and heat and dry;

[0040] ④The preparation process is the same as steps ④~⑧ in Example 1.

[0041] The propertie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Room temperature resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com