Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Mean stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

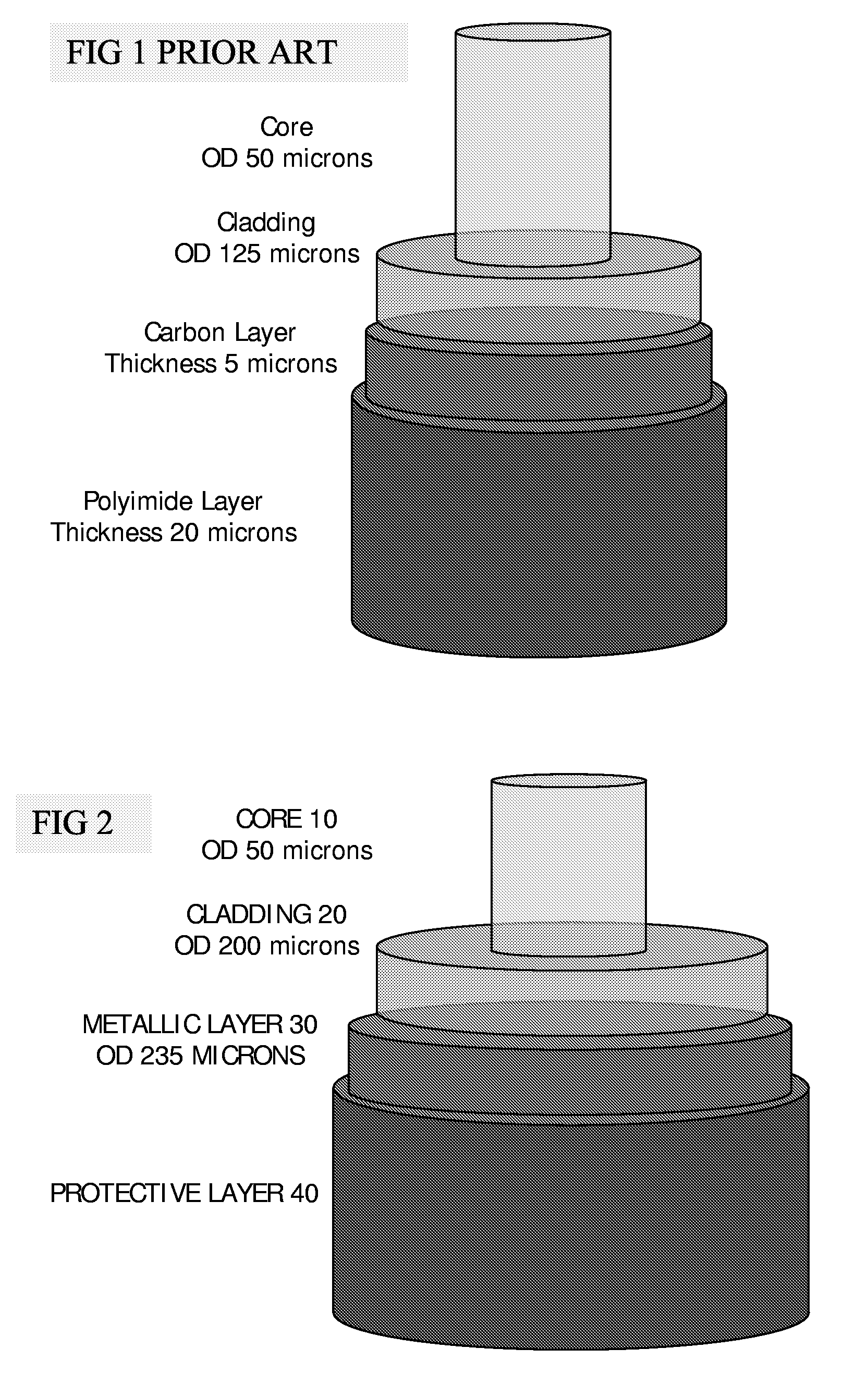

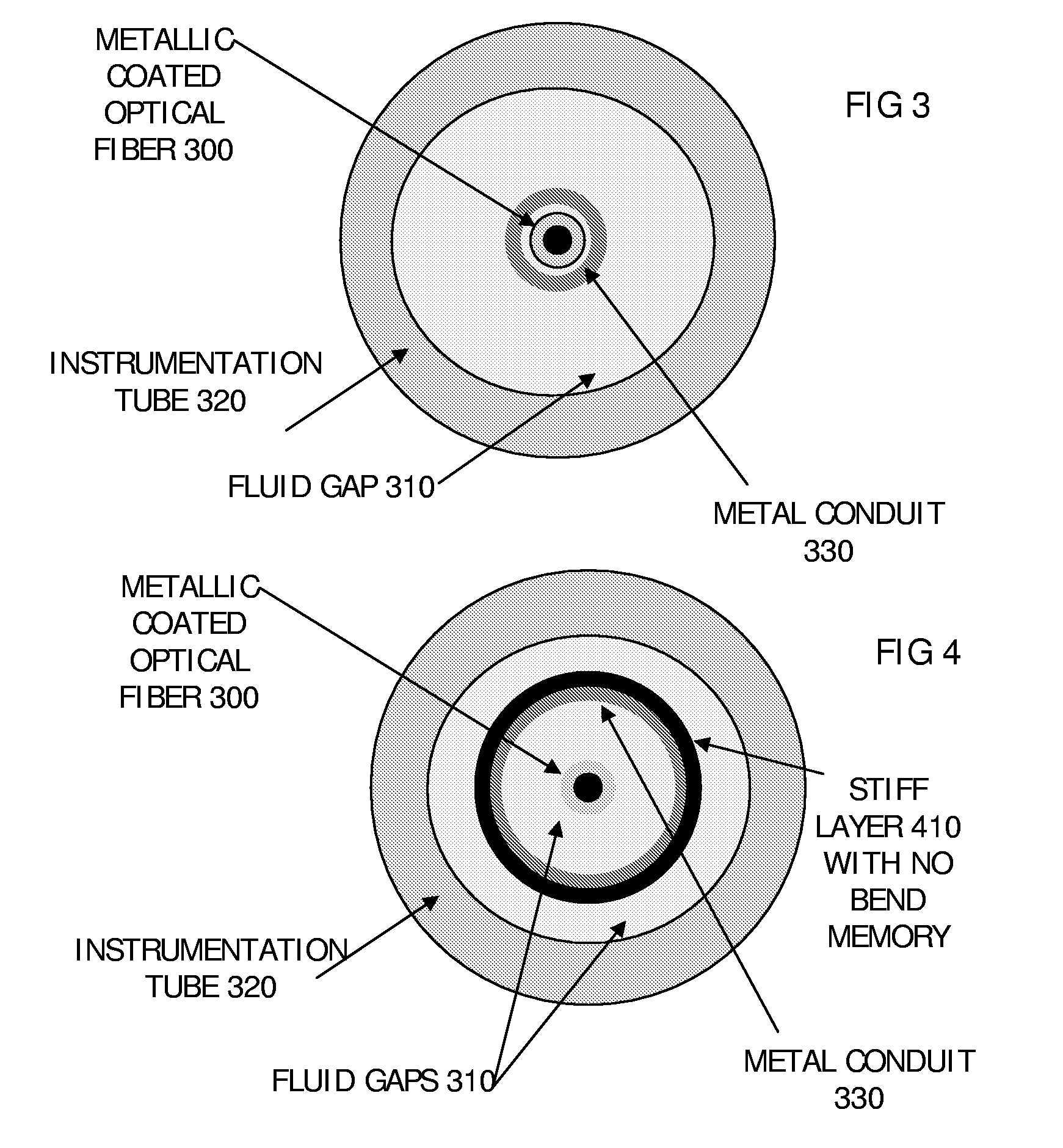

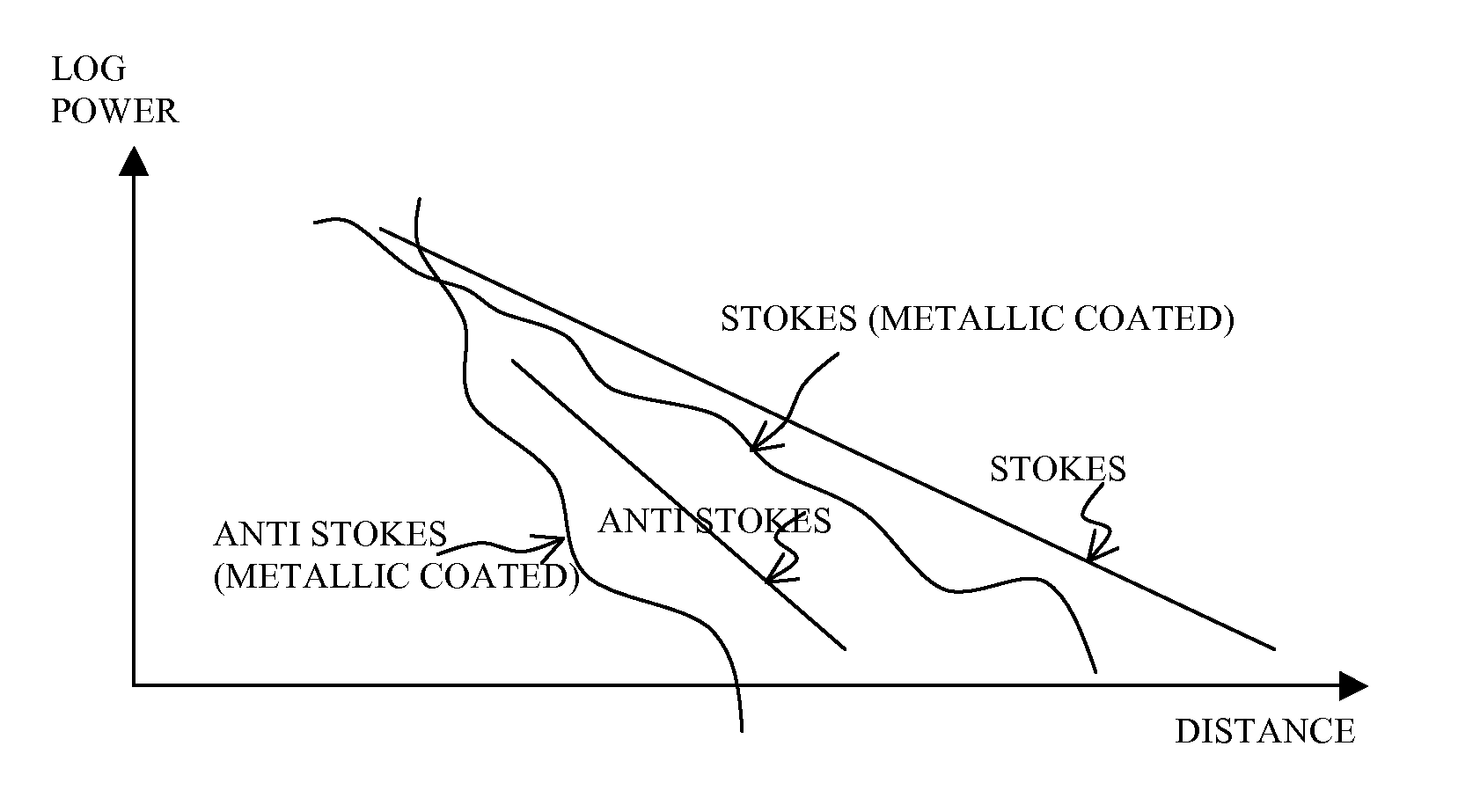

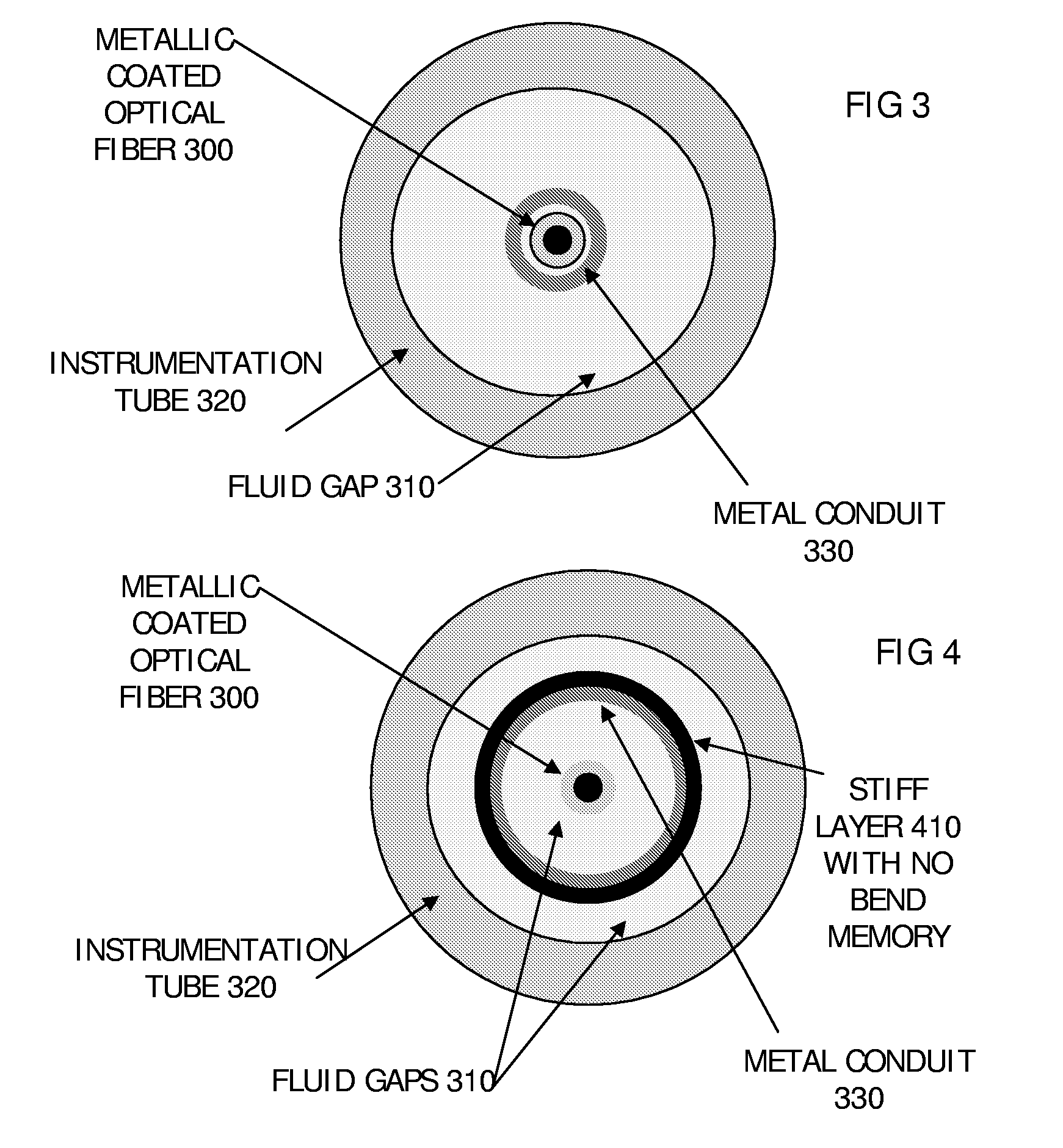

Sensing System Using Optical Fiber Suited to High Temperatures

Remote sensing in an environment having temperatures greater than 300° C., using an optical fiber having a core (10), a cladding (20), and a metallic protective coating (30) on the cladding to protect a surface of the cladding, the cladding having a diameter greater than 150 μm, and a thickness of at least 50 μm. The larger diameter cladding means stress from the metallic protective layer can be reduced, giving lower optical loss and better hydrogen protection. A metal conduit (330) encapsulates the sensing fiber, and a pump evacuates the conduit to reduce hydrogen seepage. Ceramic splice protectors are used. OTDR is used to determine differential loss at different locations along the fiber. A reflective element at the far-end of the fiber eases calibration.

Owner:SENSORNET

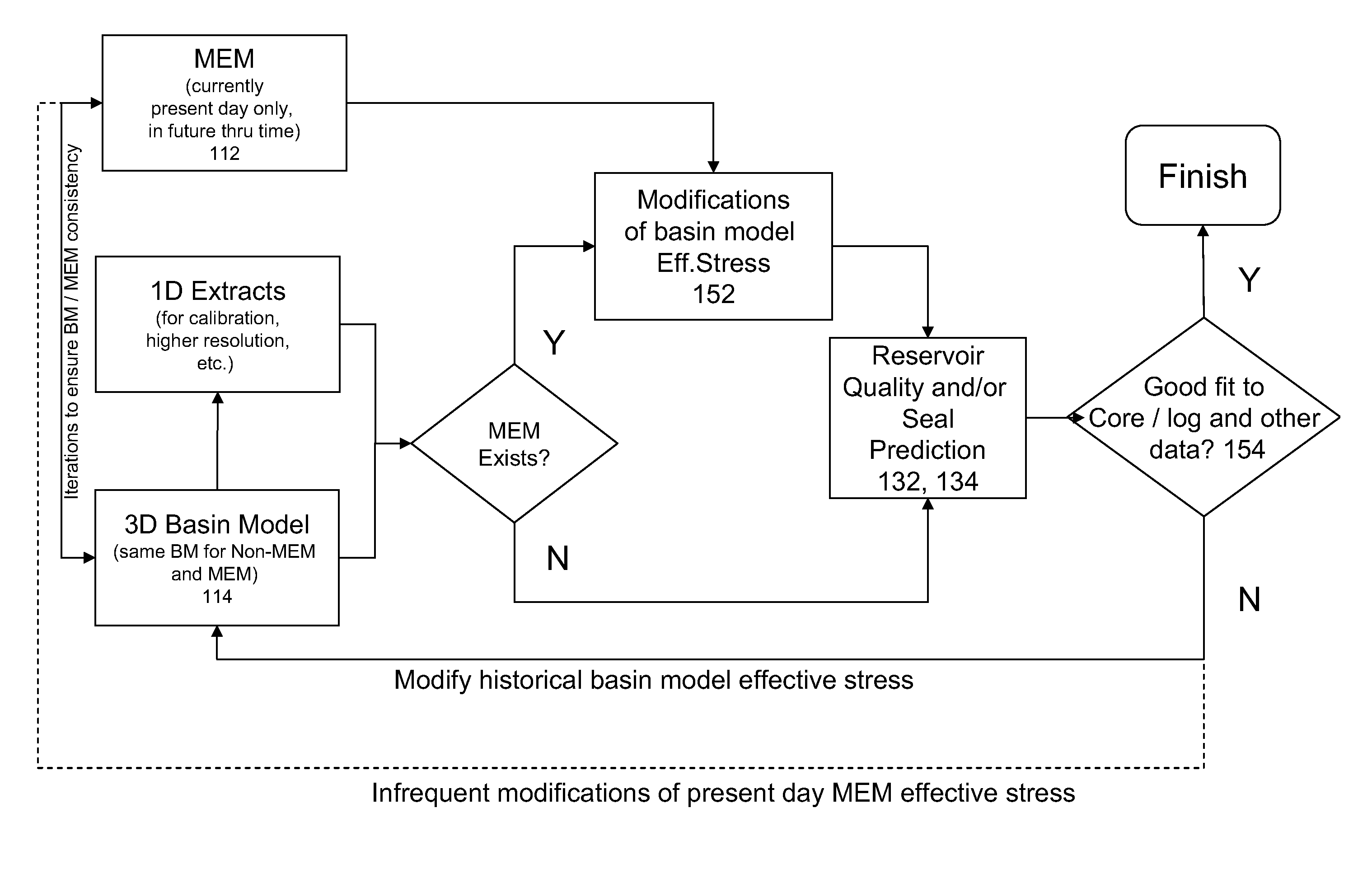

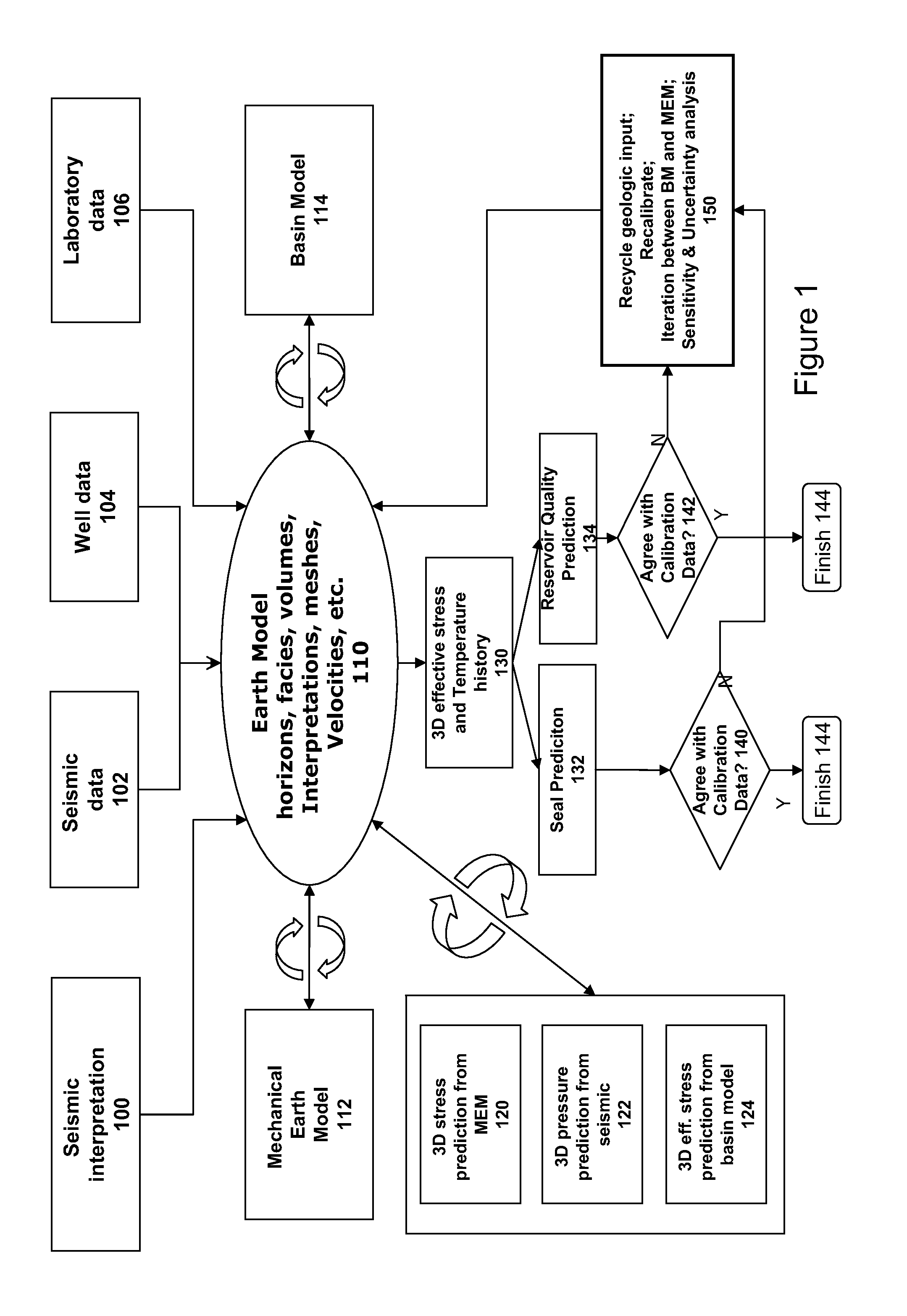

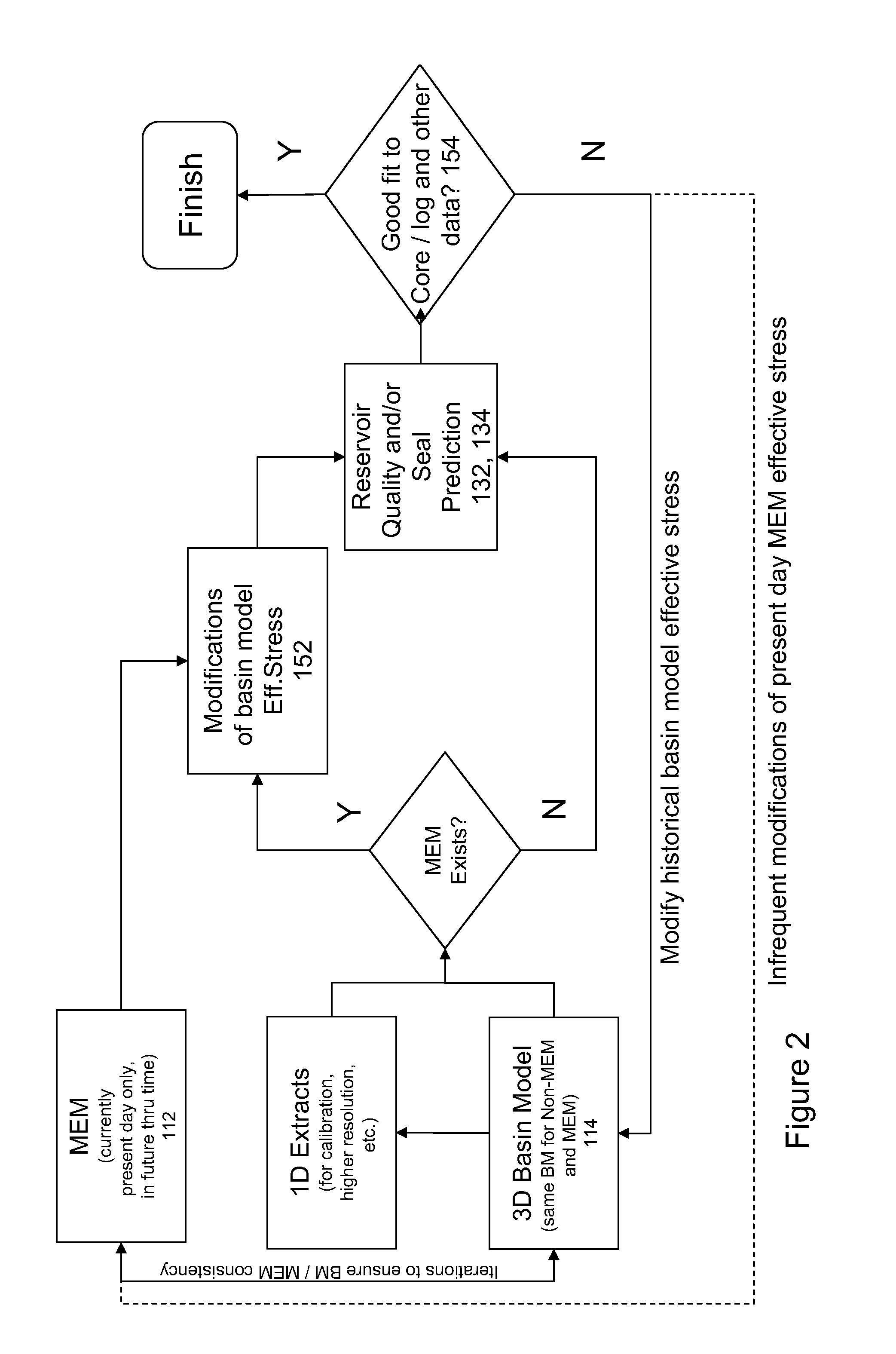

System and method for integrated reservoir and seal quality prediction

A system for and method of integrated reservoir and seal prediction is useful for evaluation of effective mean stresses affecting geologic systems through their history, and subsequently to predict reservoir and seal quality, flow and seal properties and other behaviors. Porosity and permeability as well as seal properties are modeled based on the effective mean stress. Integrated earth models are built using seismic interpretations, wells and other available data. Geo-mechanical earth models are built and stresses are computed. Basin models are built using inputs from seismic interpretation tools, wells, geochemistry, and earth and mechanical earth models. Reservoir quality and seal quality prediction is performed and the building earth models, computing stresses, building basin models and quality prediction are iterated to converge to a solution that honors well, seismic, core, geochemical and any other available calibration data.

Owner:CHEVROU USA INC

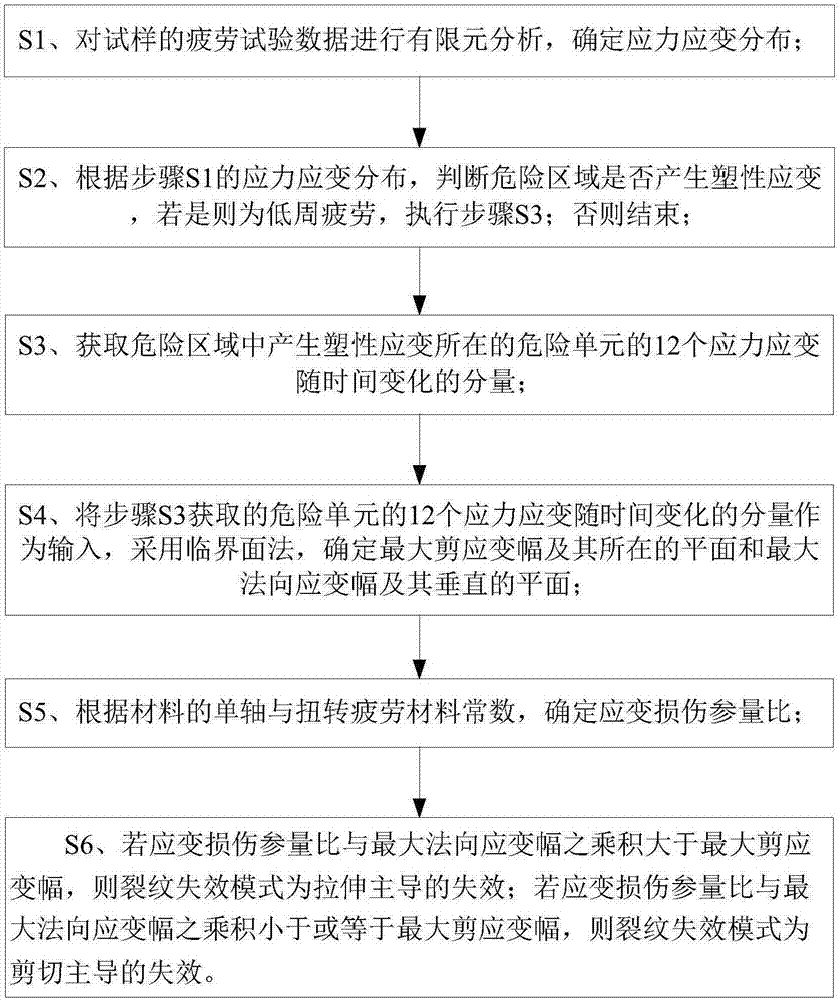

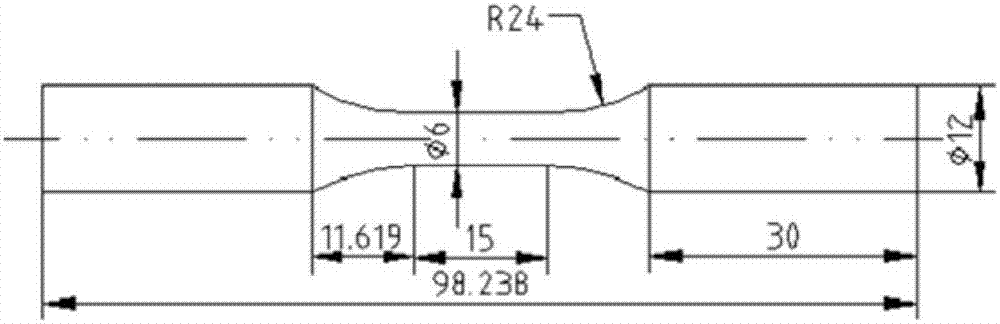

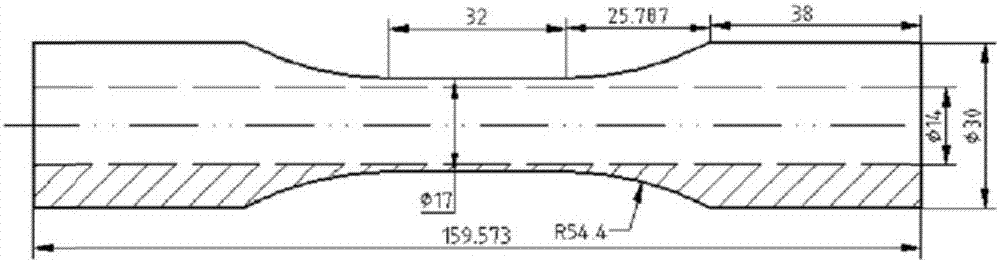

Crack failure mode determination method and fatigue life prediction method based on crack failure mode determination method

ActiveCN107389471AControlling the Problem of Excessive Prediction ErrorsSymmetric fatigue lifeMaterial strength using steady shearing forcesFatigue damageMean stress

The invention discloses a crack failure mode determination method and a fatigue life prediction method based on the crack failure mode determination method and is applied to the field of reliability. A crack failure mode of a part is determined based on contribution made by normal strain and shear strain to fatigue damage, energy and critical plane approach are combined, fatigue life prediction models in two modes such as a stretching dominated failure mode and a shearing dominated failure mode are established, and the problem that the prediction error is too large due to the material dispersion property can be effectively solved, so that the prediction life does not far deviate from experiment life; and moreover, a critical plane stress-strain curve relation and a related material constant are introduced into the model establishing process, the influence on mean stress can be reflected, and the model is capable of predicting the fatigue life under proportional and non-proportional symmetrical or asymmetrical loads.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Sensing system using optical fiber suited to high temperatures

Remote sensing in an environment having temperatures greater than 300° C., using an optical fiber having a core (10), a cladding (20), and a metallic protective coating (30) on the cladding to protect a surface of the cladding, the cladding having a diameter greater than 150 μm, and a thickness of at least 50 μm. The larger diameter cladding means stress from the metallic protective layer can be reduced, giving lower optical loss and better hydrogen protection. A metal conduit (330) encapsulates the sensing fiber, and a pump evacuates the conduit to reduce hydrogen seepage. Ceramic splice protectors are used. OTDR is used to determine differential loss at different locations along the fiber. A reflective element at the far-end of the fiber eases calibration.

Owner:SENSORNET

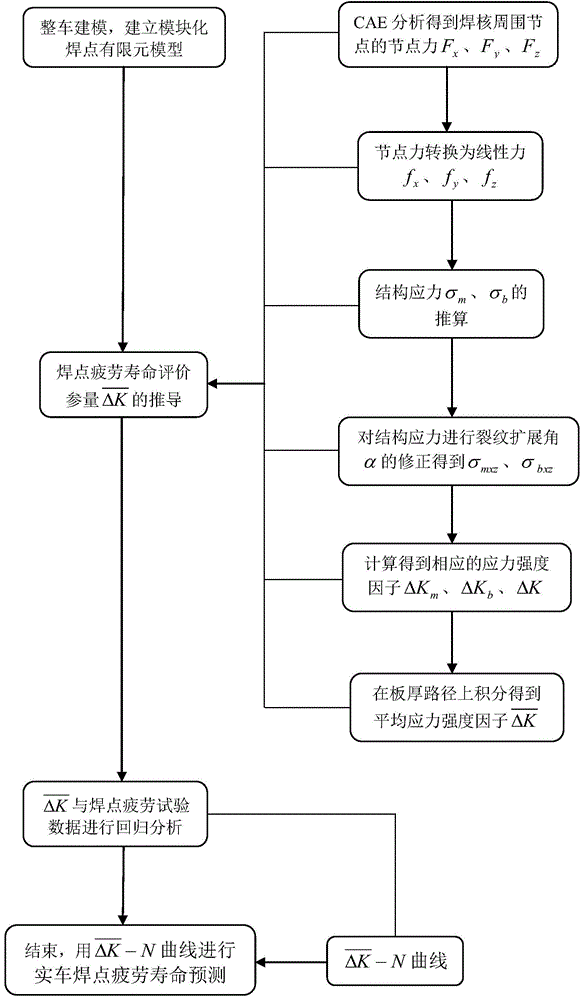

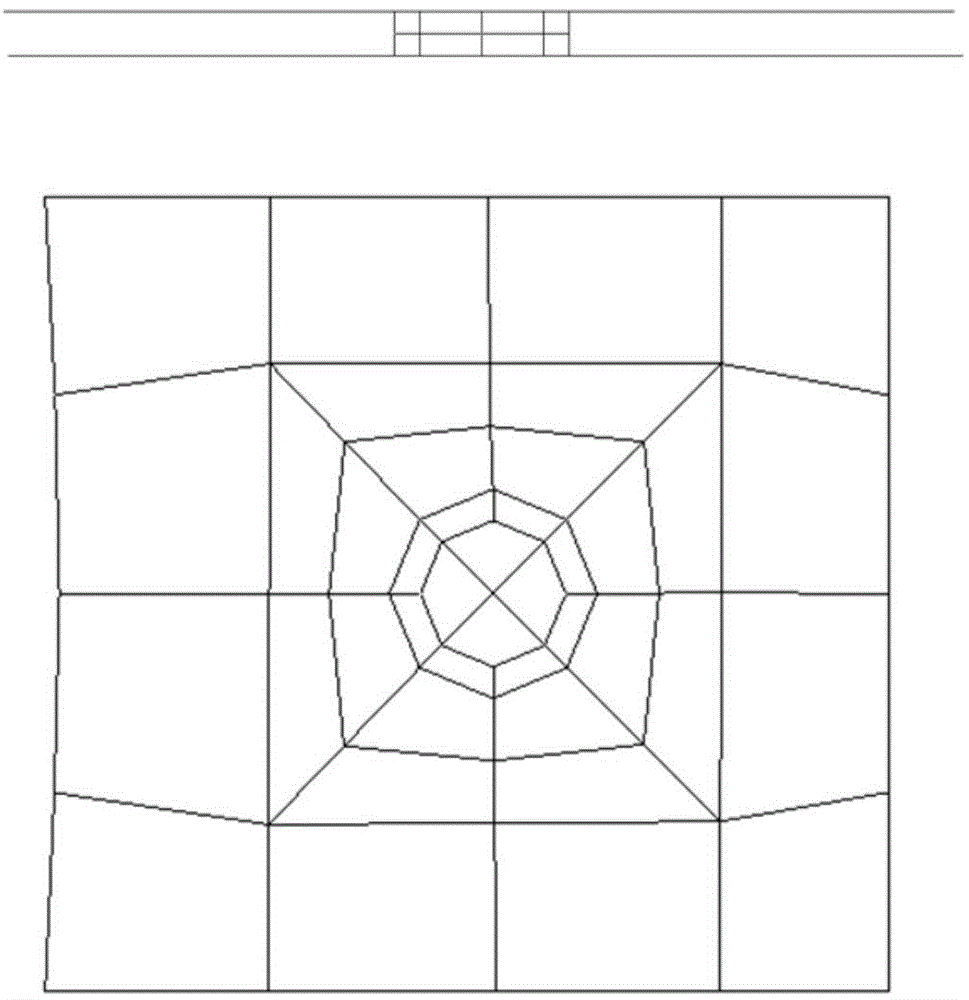

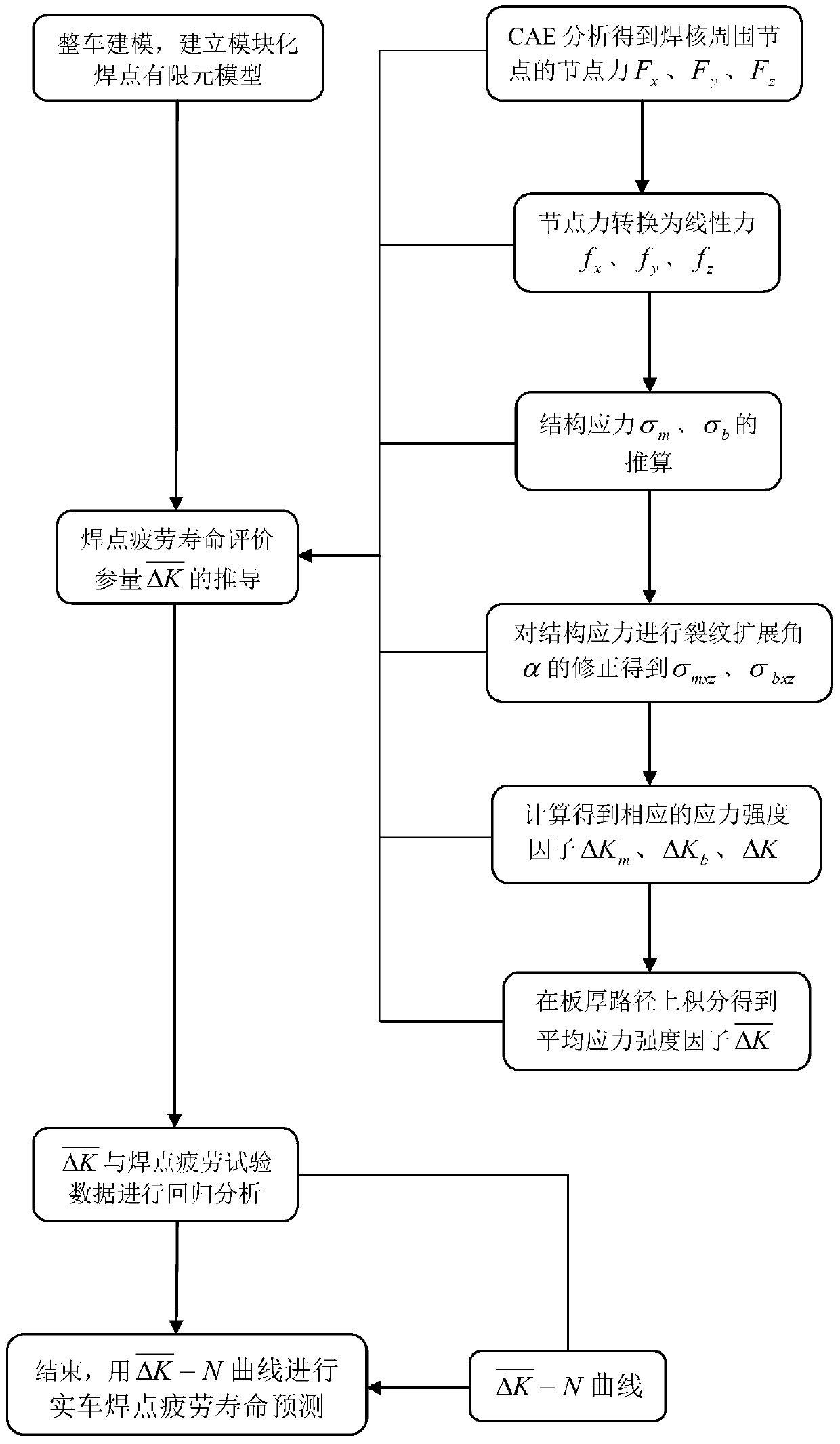

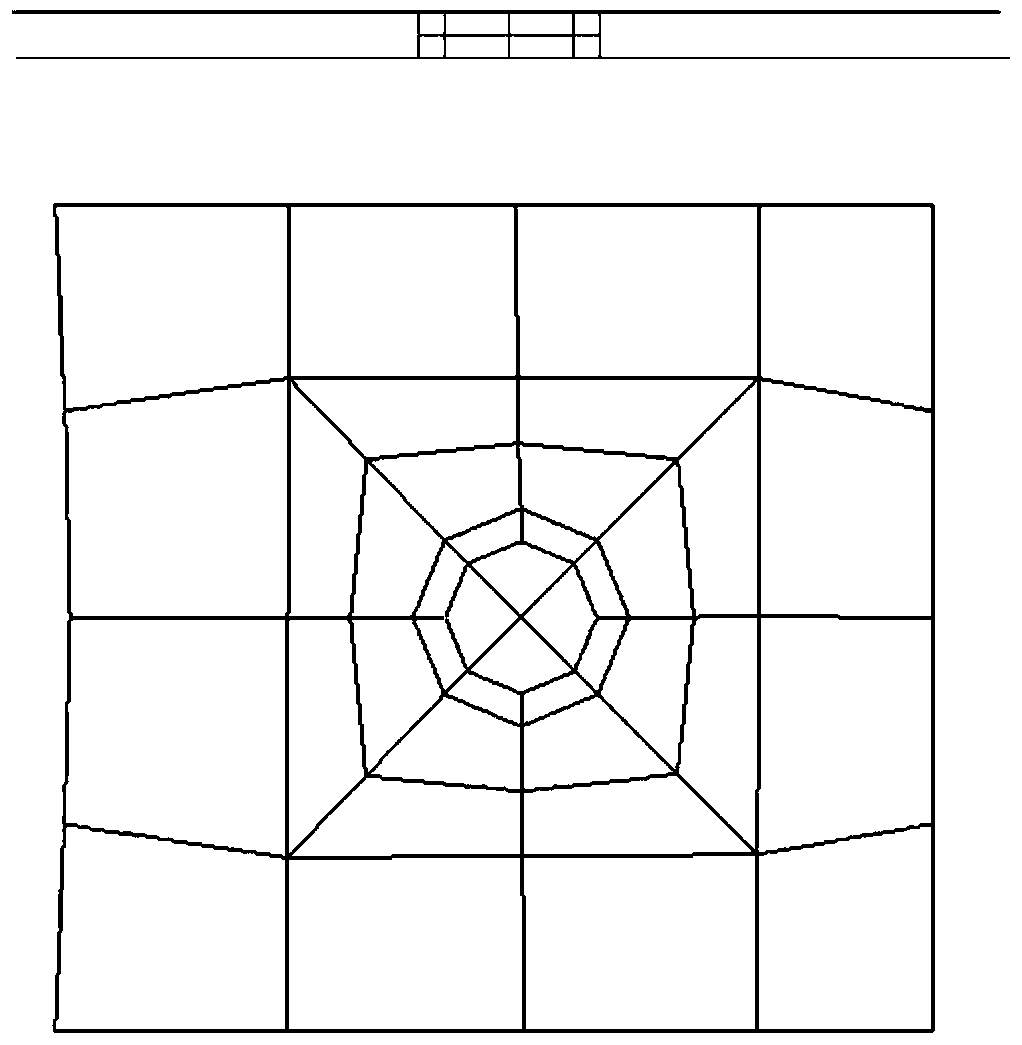

Spot-weld fatigue life predicting method

InactiveCN104573392AImprove efficiencyConform to the physical geometrySpecial data processing applicationsElement modelRegression analysis

The invention relates to a spot-weld fatigue life predicting method. The spot-weld fatigue life predicting method includes steps of 1, modeling a full vehicle and establishing a modularized spot-weld finite element model; 2, deducing spot-weld fatigue life evaluation parameter, mean stress strength factor; 3, subjecting spot-welded joints of different materials to systematic fatigue test, and subjecting the mean stress strength factor and fatigue test data of the spot-welded joints of different materials to regression analysis to obtain a curve of the spot-welded joints of different materials. The spot-weld fatigue life predicting method adopts the modularized spot-weld model to predict the spot-weld fatigue life, in actual application, only nodes of a border unit of the modularized spot-weld model are superposed with nodes of a welding structure unit, and spot-weld modeling efficiency in the full-vehicle modeling is improved.

Owner:HUNAN UNIV

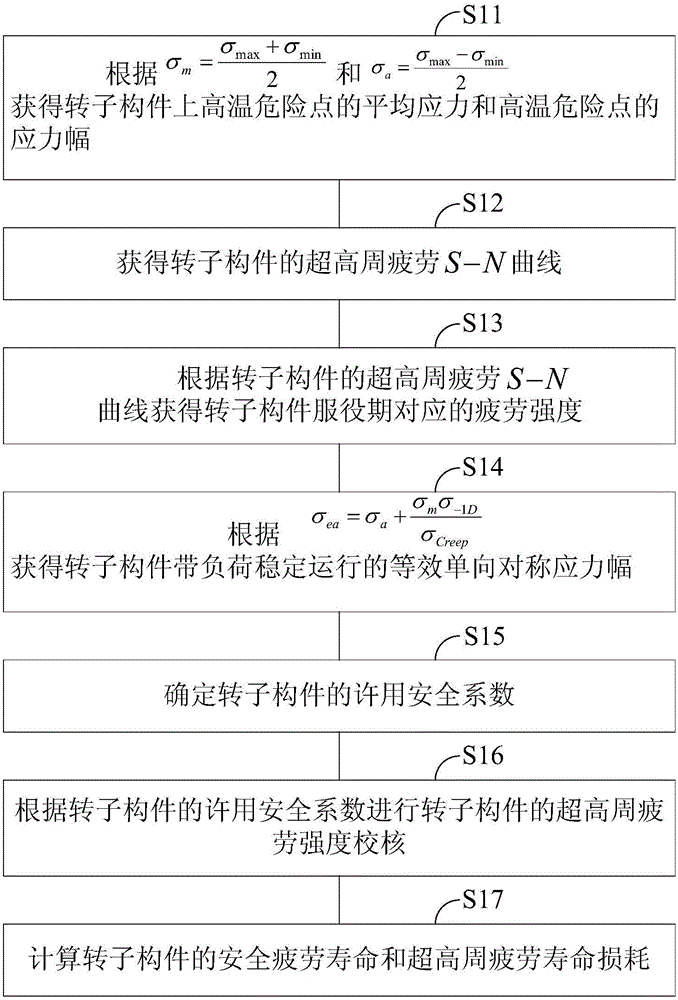

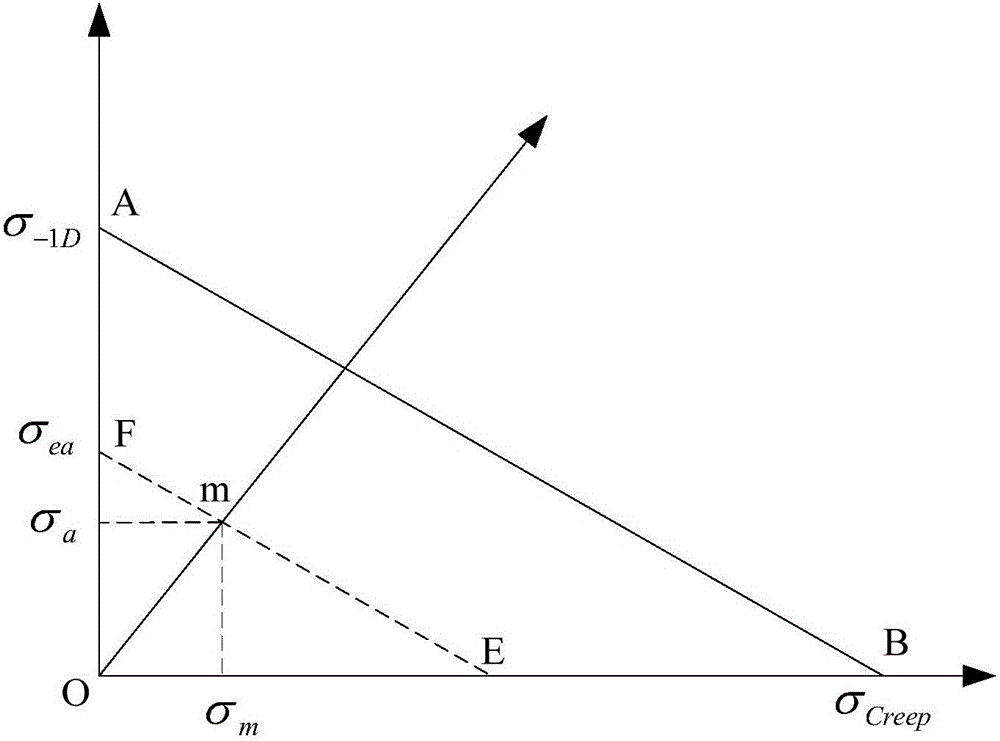

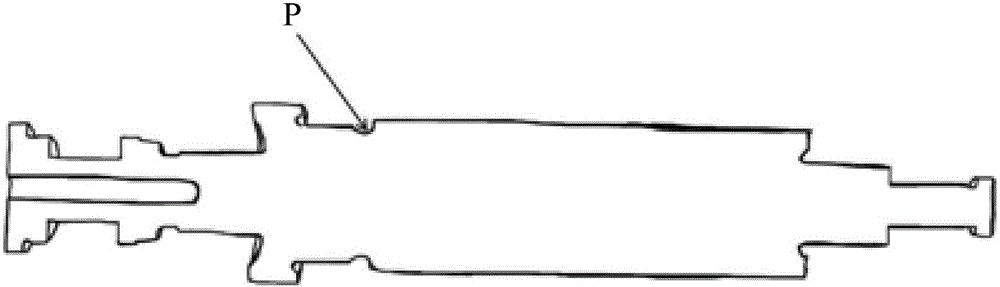

Method for assessing ultra-high cycle fatigue strength and fatigue life of steam turbine rotor

ActiveCN106202630AExact fatigue strengthAccurate Fatigue LifeDesign optimisation/simulationSpecial data processing applicationsEngineeringFatigue life assessment

The invention discloses a method for assessing ultra-high cycle fatigue strength and fatigue life of a steam turbine rotor. The method comprises the following steps of: obtaining mean stress of high-temperature dangerous points and stress amplitude of the high-temperature dangerous points on a rotor component according to sigma<m>=(sigma<max>+sigma<min>) / 2 and sigma=(sigma<max>-sigma<min>) / 2; obtaining an ultra-high cycle fatigue S-N curve of the rotor component; obtaining fatigue strength corresponding to a service period of the rotor component according to the ultra-high cycle fatigue S-N curve of the rotor component; obtaining an equivalent unidirectional symmetric stress amplitude of on-load stable operation of the rotor component according to sigma<ea>=sigma+(sigma<m>*sigma<-1D>) / sigma<Creep>; determining an allowable security coefficient of the rotor component; checking the ultra-high cycle fatigue strength of the rotor component according to the allowable security coefficient of the rotor component; and calculating a security fatigue life and an ultra-high cycle fatigue life loss of the rotor component. The method for assessing the ultra-high cycle fatigue strength and fatigue life of the steam turbine rotor can realize the quantitative calculation and assessment of the high-temperature ultra-high cycle fatigue strength, fatigue life and loss.

Owner:SICHUAN UNIV

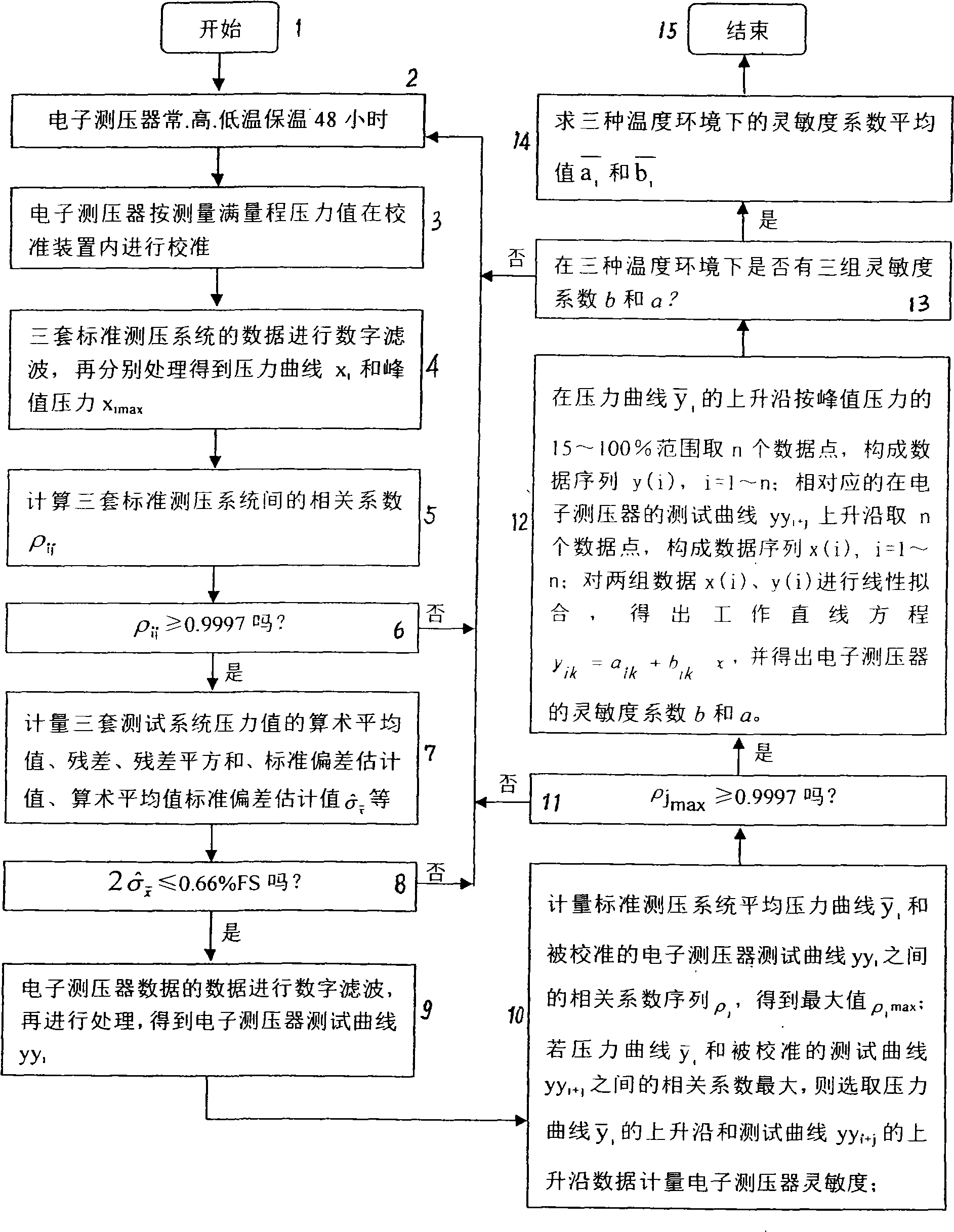

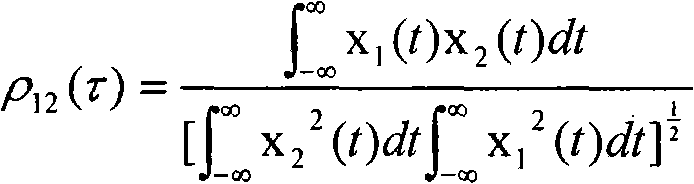

Method for metering sensitivity of electronic pressure detector

InactiveCN101334330AGuaranteed accuracyLow costFluid pressure measurementPressure curveRoom temperature

The invention relates to a method for measuring the sensitivity of an electronic manometer, which belongs to the technical field of electronic measurement. The method comprises the following steps: a pressure value with the measuring pressure of full scale is selected as base measuring pressure; dynamic calibration to the electronic manometer to be calibrated is carried out respectively under normal temperature, high temperature and low temperature environments; under the condition that three sets of standard pressure-measuring systems and the electronic manometer to be calibrated are all effectively calibrated, an average pressure curve measured by the three sets of standard pressure-measuring systems and the rising edge data of the curve measured by the calibrated electronic manometer are utilized to compute to obtain the sensitivity of calibrated electronic manometer. The method of the invention has simple operation, the calibration only needs to be carried out for three times respectively under the normal temperature, the low temperature and the high temperature, the sensitivity coefficient of the electronic manometer under the three temperature environments can be obtained by the calibration of nine times; compared with the existing measuring method, the method of the invention lowers the calibrating period, improves the working efficiency, reduces the testing expenses and the item cost, has precise and reliable result, and is the result of innovative thinking. The method for measuring the sensitivity of the electronic manometer is worthy of being adopted and generalized in the industry.

Owner:ZHONGBEI UNIV

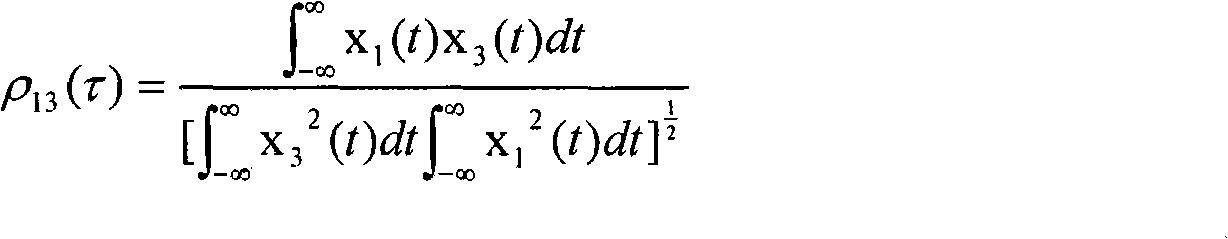

On-line monitoring method for large-scale wind power tower drum structure stress

ActiveCN104122013AEasy to measureEasy and fast measurementAcceleration measurement using interia forcesForce measurement using counterbalancing forcesElectricityStructure health monitoring

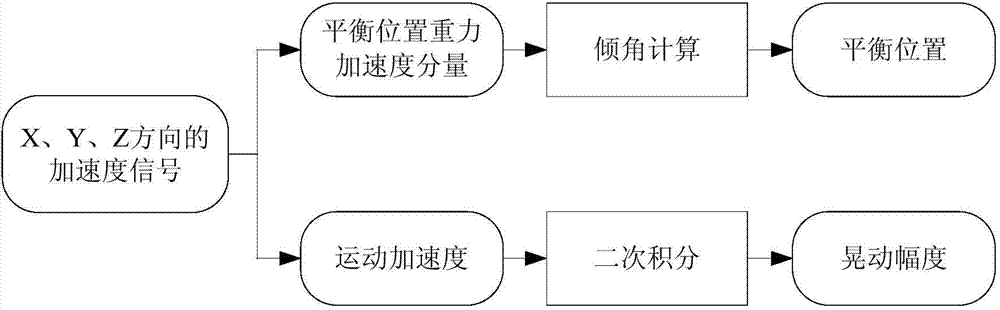

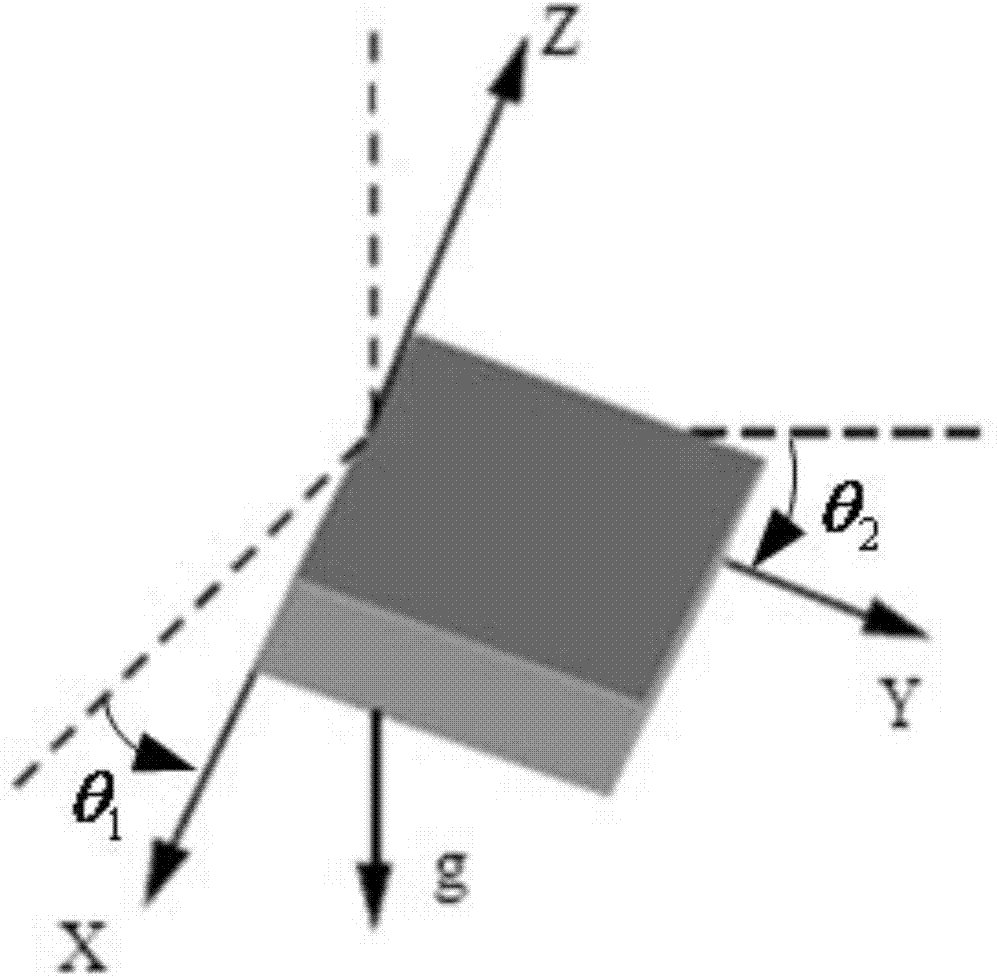

The invention discloses an on-line monitoring method for large-scale wind power tower drum structure stress and belongs to the field of structure health monitoring. Since wind power tower drums are large in size and are located in harsh environment, traditional methods for measuring structure stress with strain gages require more strain gages, and the strain gages are not suitable for use in wind power tower drum structure stress monitoring methods due to the fact that the strain gages cannot be located in harsh environment for a long time. According to the on-line monitoring method for large-scale wind power tower drum structure stress, on the basis of the shaking characteristic of a wind power tower drum, shaking is divided into a shaking balance position and shaking amplitude around the balance position, the shaking balance position and the shaking amplitude correspond to mean stress and stress amplitude in alternating stress respectively, and a relationship between shaking and stress is established, so that structure stress of the wind power tower drum can be reflected by monitoring shaking of the wind power tower drum, and the problem that methods for measuring stress with strain gages are limited by structure sizes and work environment of wind power tower drums is solved. Besides, the on-line monitoring method is convenient, practical, and applicable to on-line stress monitoring of large-scale wind power tower drum structures.

Owner:XI AN JIAOTONG UNIV

Method for auxiliary evaluation of stress states of knee joints

InactiveCN101627900AUnderstand biological relationshipQuick Auxiliary EvaluationDiagnostic recording/measuringSensorsLeft knee jointPhysical medicine and rehabilitation

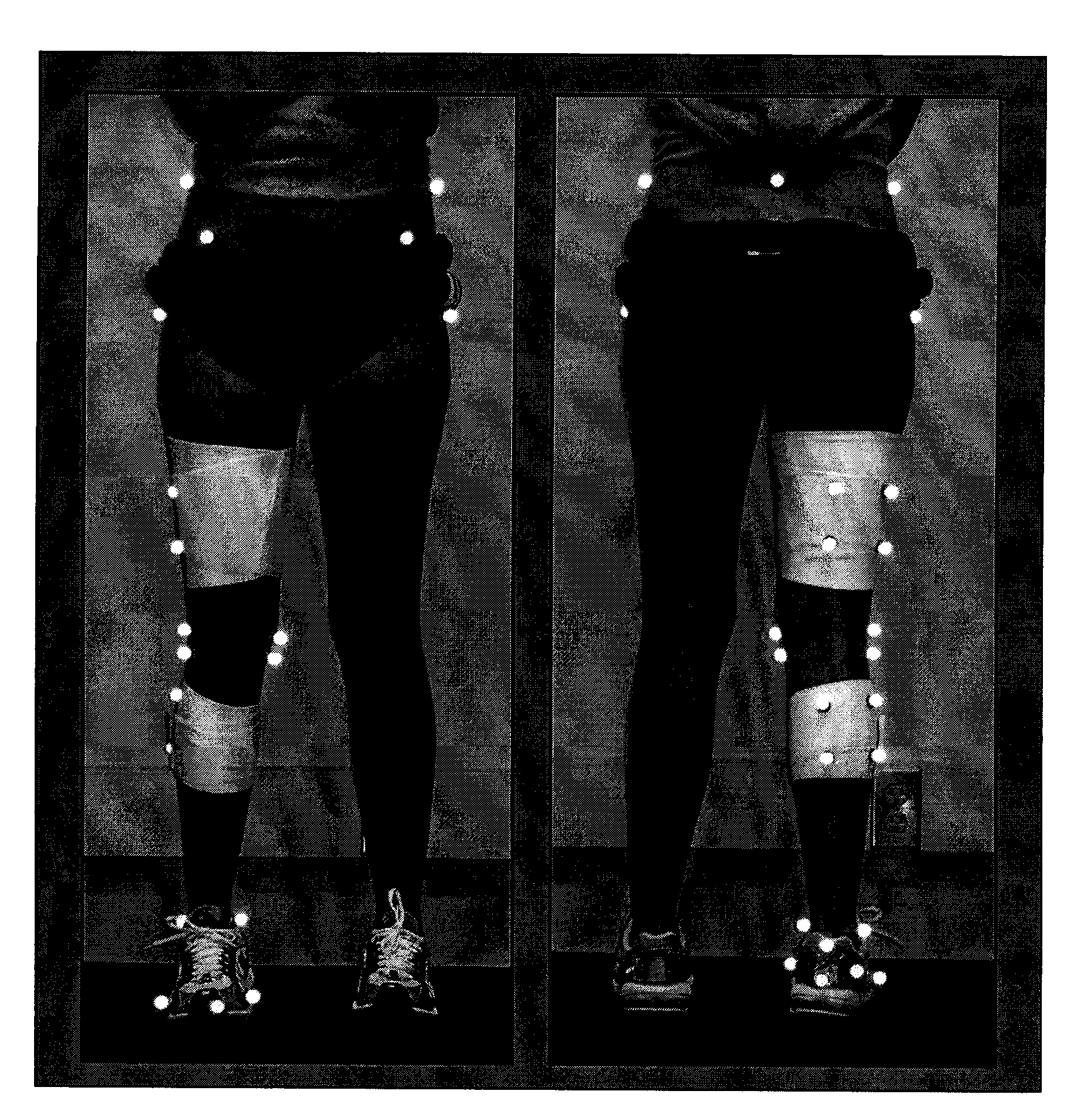

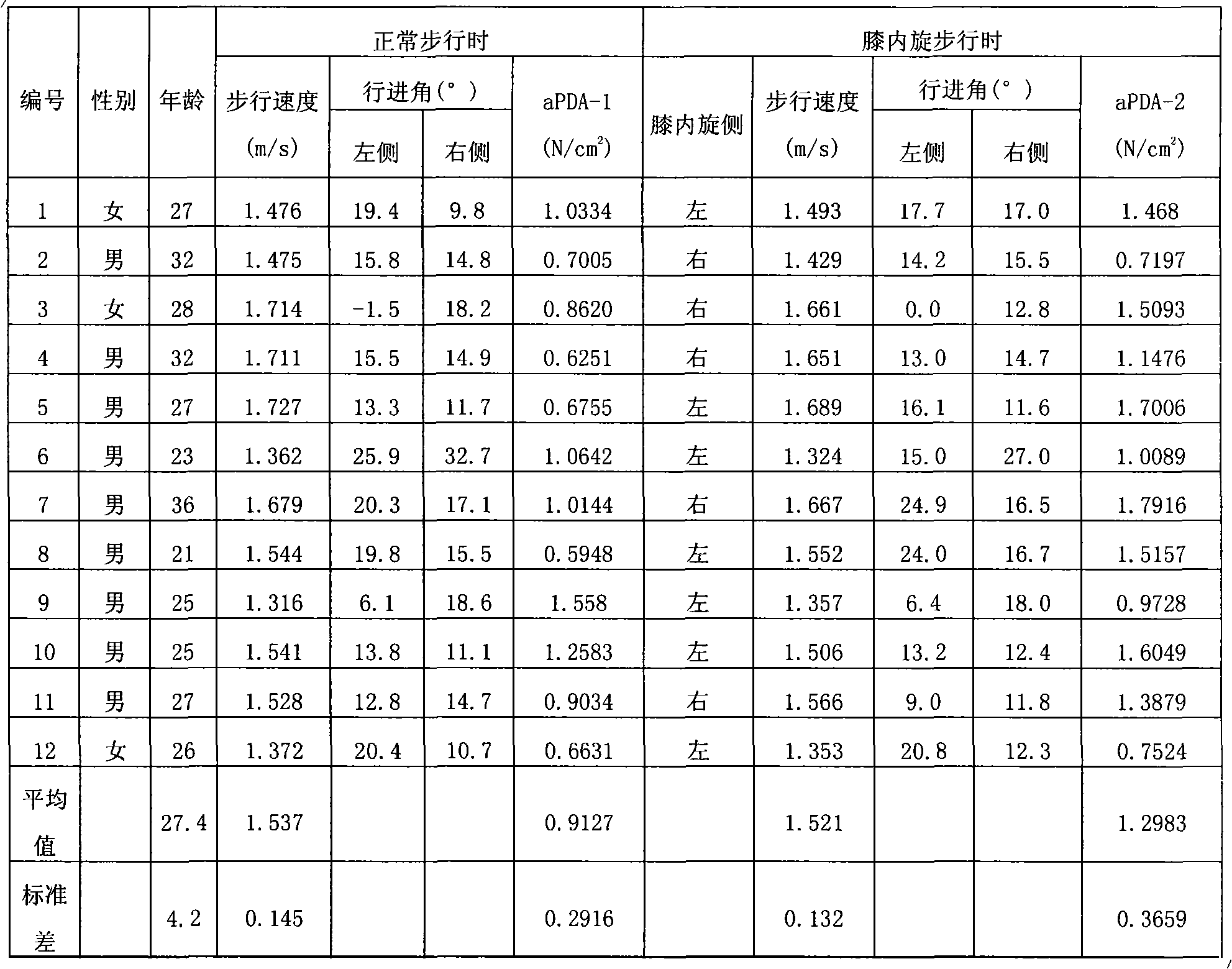

The invention discloses a method for auxiliary evaluation of stress states of knee joints. The method comprises the following steps: obtaining sizes of feet and foot progression angles of the left and the right feet during normal walking of a testee, carrying out standardization on data, then analyzing sole pressure data of the left and the right feet, and obtaining the average pressure difference aPDA-1 of soles of the two feet during the normal walking; obtaining the sizes of the feet and the foot progression angles of the left and the right feet of the testee during unilateral knee rotation walking, carrying out standardization on the data, then analyzing the sole pressure data of the left and the right feet, and obtaining the average pressure difference aPDA-2 of the soles of the two feet during the unilateral knee rotation walking; wherein, the standardization applies MATLAB R2006a software for carrying out treatment, if P is less than 0.05 during the comparison of aPDA-1 with aPDA-2, the situation prompts that the stresses of the left knee joint and the right knee joint of the testee are inconsistent. The application of the method can rapidly and accurately understand the physiological relationship between the feet and the knees under different actions, thereby guiding various types of training or movement.

Owner:PEKING UNIV THIRD HOSPITAL

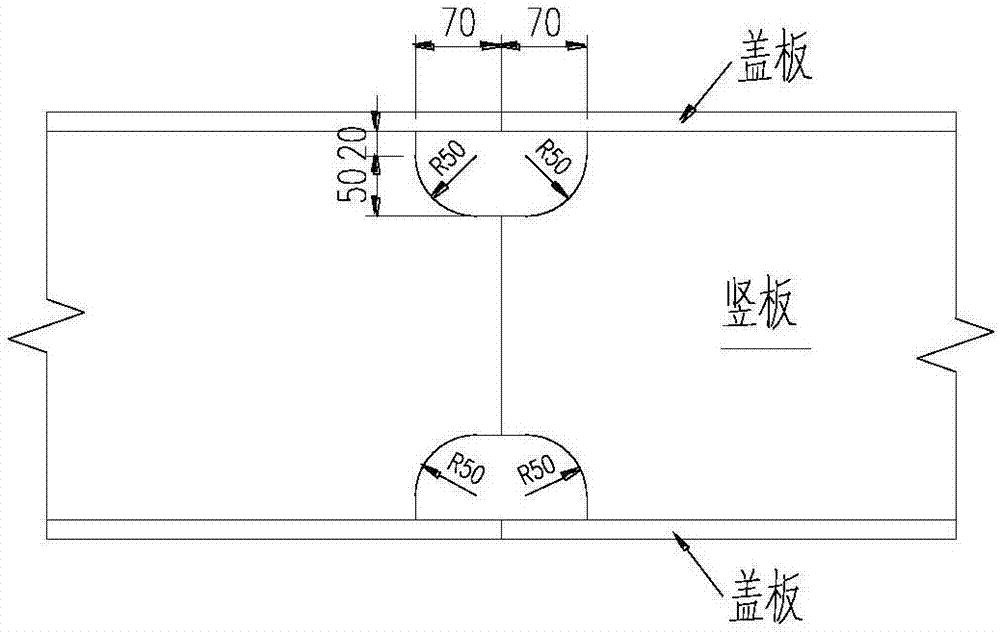

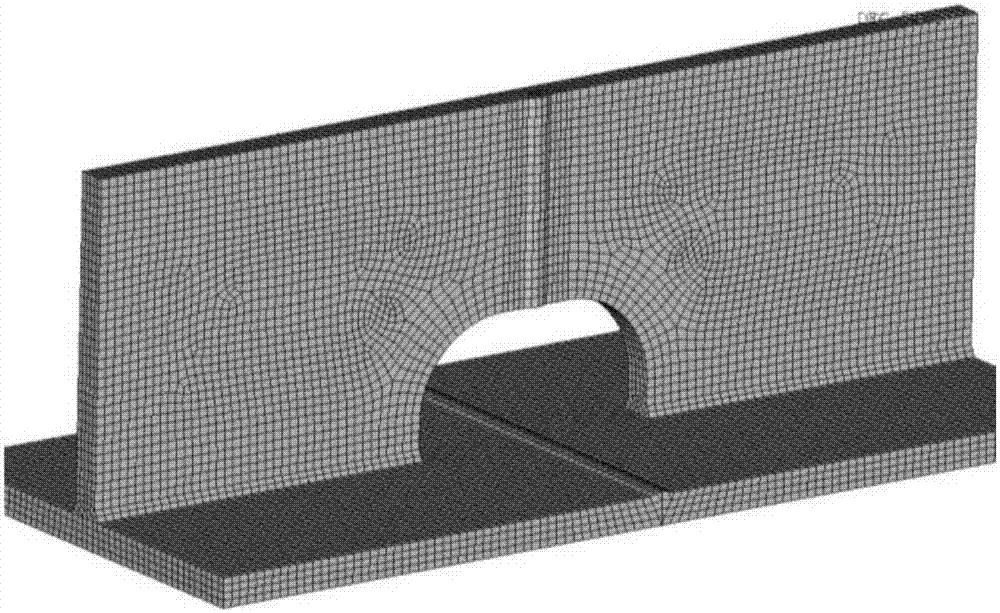

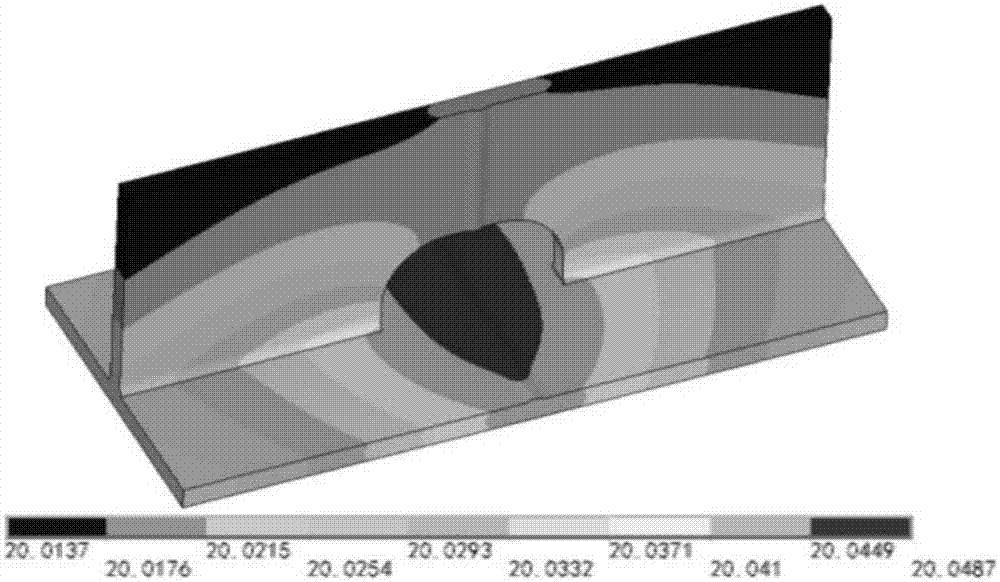

Determination method for steel bridge structure detail S-N curve considering welding residual stress

ActiveCN107103121ASafety by anti-fatigue designAnti-fatigue design is convenient and simpleGeometric CADDesign optimisation/simulationStructural fatigueWelding residual stress

The invention discloses a determination method for a steel bridge structure detail S-N curve considering welding residual stress. The method includes the following steps that the welding residual stress of steel bridge structure details is acquired through a thermal-structural coupling analysis method; the influences of mean stress on structure fatigue strength are considered through a Goodman formula, and a material S-N curve correction formula considering the welding residual stress is derived; the fatigue life of structure detail weld toes under different stress level fatigue loads is calculated according to the material S-N curve considering the welding residual stress, the corresponding relationship between structure detail nominal stress and the fatigue life of the weld toes is established, and the steel bridge structure detail S-N curve considering the welding residual stress is acquired. The influences of welding residual stress specific values on steel bridge structure detail fatigue characteristics are considered, the anti-fatigue design of a steel bridge is safer, and traditional full-size or reduced-scale fatigue model tests consuming a large quantity of manpower, material resources and financial resources are avoided.

Owner:WUHAN UNIV OF TECH

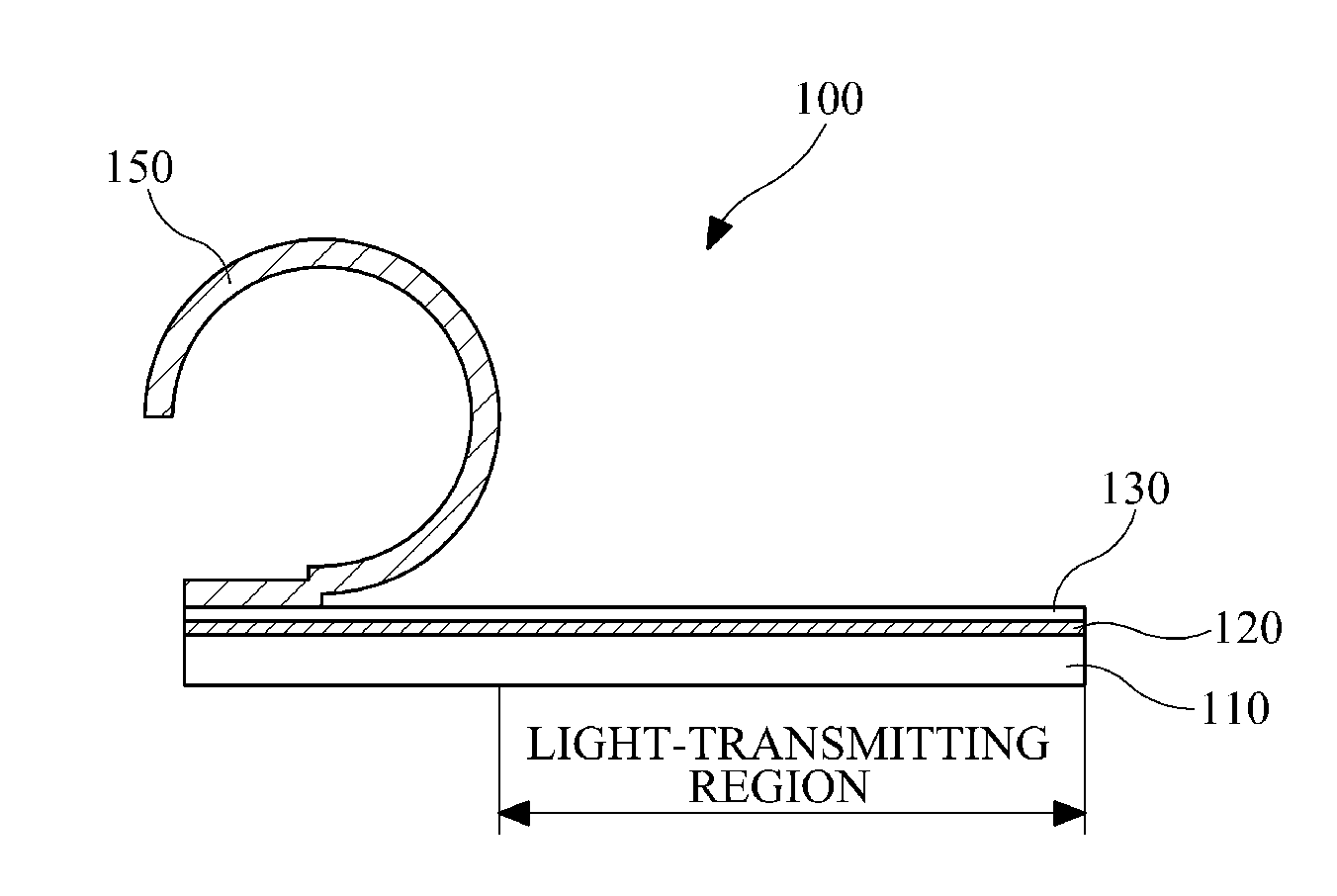

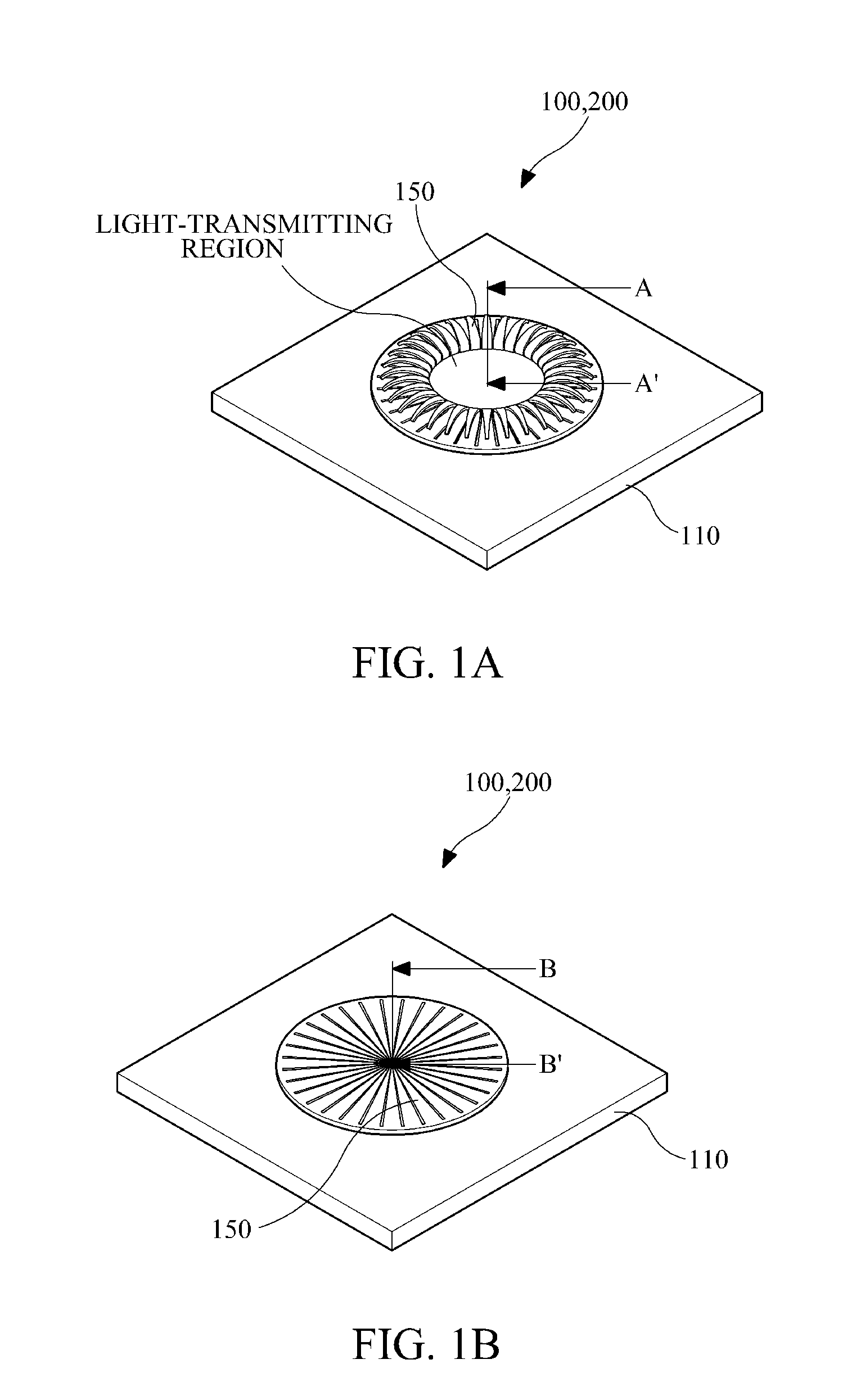

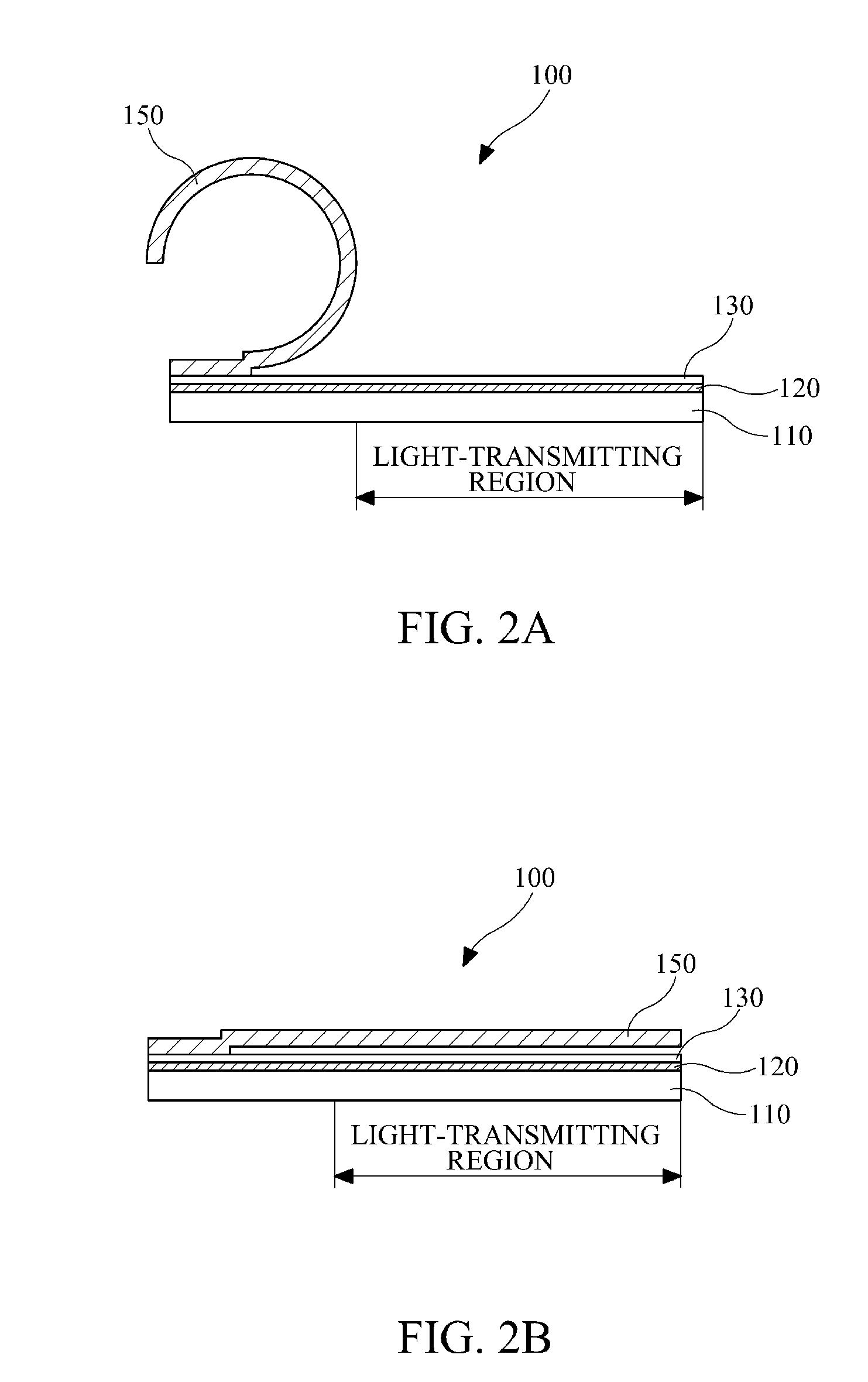

Optical shuttering device and method of manufacturing the same

InactiveUS20110170158A1Quick responseConstant physical and mechanical characteristicsShuttersExposure controlThin layerConductive materials

Provided is an optical shuttering device and a method of manufacturing the same. Device includes a roll-up blade that stays in a rolled-up state while no driving voltage is applied thereto and flattens to shutter a light-transmitting region when a predetermined driving voltage is applied to the roll-up blade. The roll-up blade may be provided as a single roll-up blade or as a plurality of roll-up blades such that the roll-up blade(s) shutters a a portion or the entirety of the light-transmitting region. The roll-up blade may be formed as a thin layer made of a single opaque, conductive material. As a single-layered structure, the roll-up blade may spontaneously roll up due to a stress gradient that is made in a thickness direction of the roll-up blade, and as a multi-layered structure, the roll-up blade may spontaneously roll up due to differences in mean stress of the multi layers.

Owner:SAMSUNG ELECTRONICS CO LTD

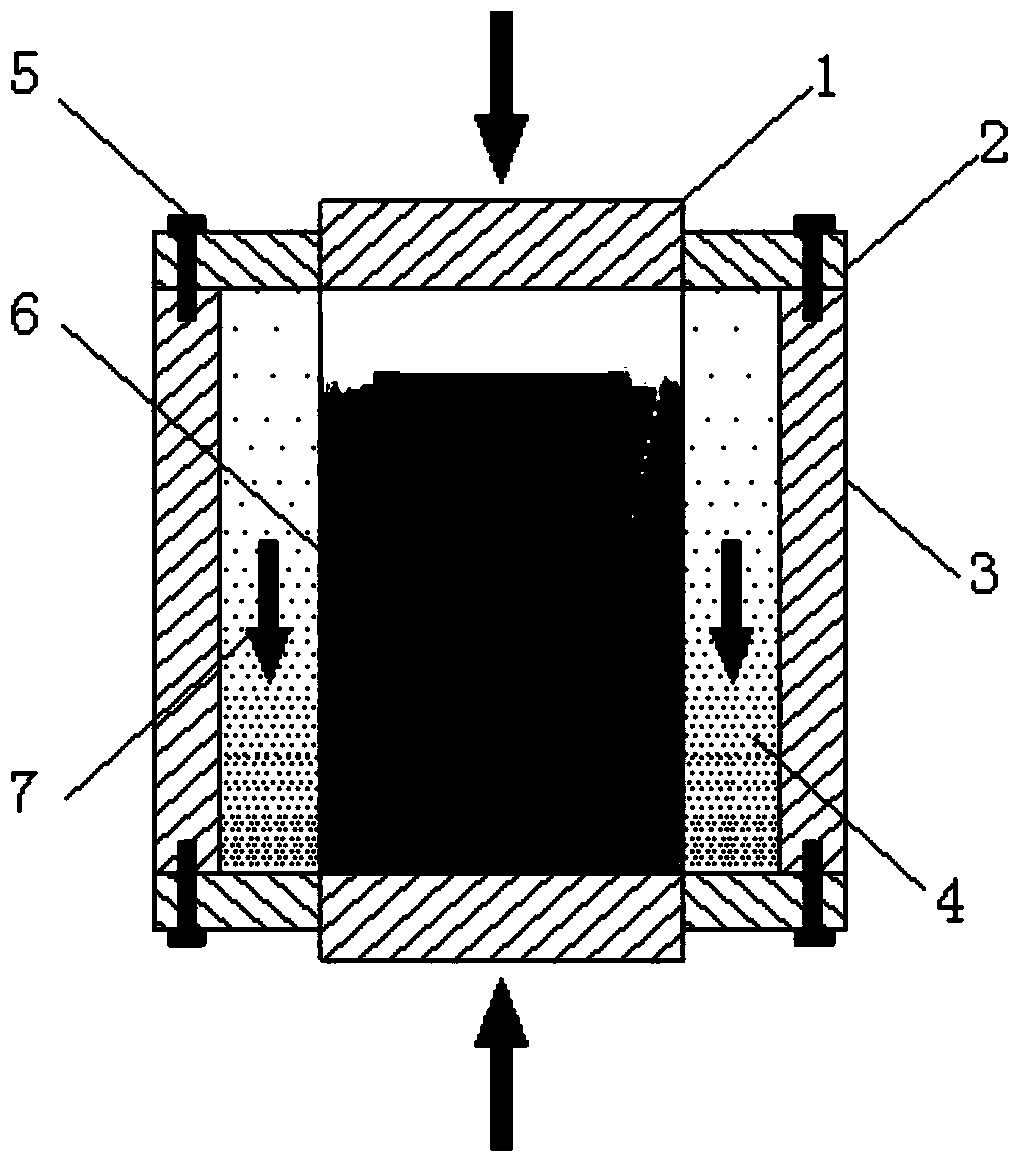

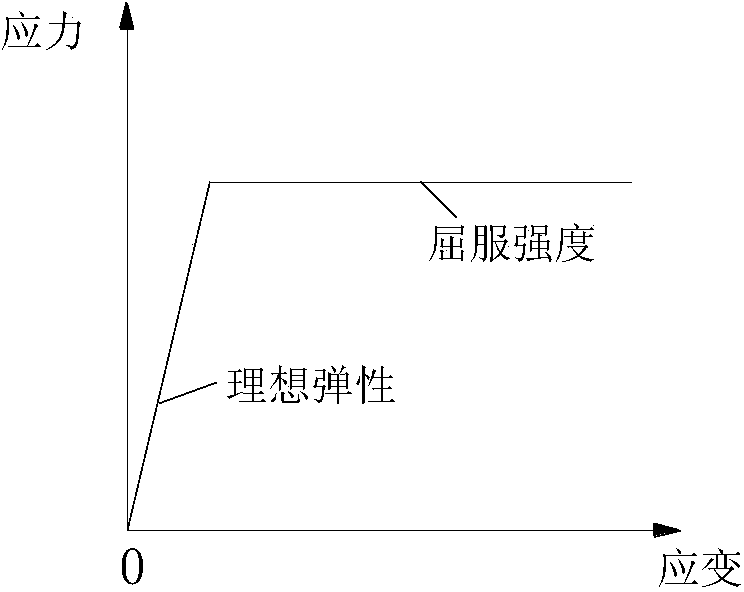

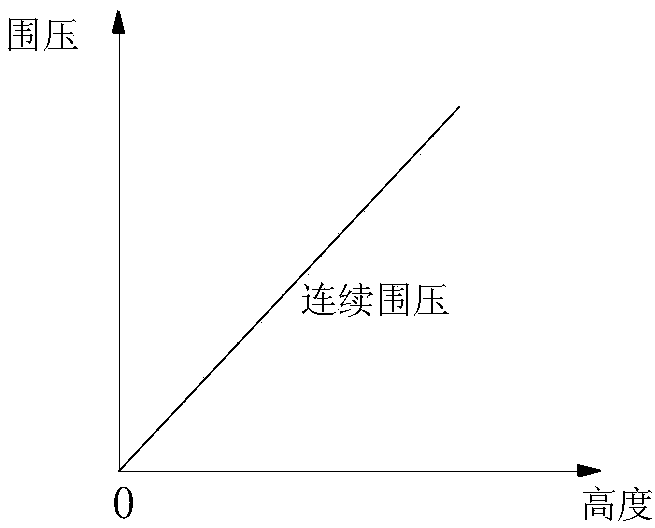

Gradient confining pressure loading method

InactiveCN104215506ASignificant technologySignificant economyPreparing sample for investigationMaterial strength using tensile/compressive forcesVertical gradientPlastic materials

The invention discloses a gradient confining pressure loading method. According to the method, confining pressure loading of a sample is indirectly realized by utilizing pressure of an ideal plastic material layer embedded in a rigid cylinder, the rigid cylinder is completely rigid, and the vertical gradient direction of the ideal plastic material layer is consistent with a heterogeneous vertical gradient direction of the sample; continuous distribution or discontinuous distribution of elasticity modulus of the ideal plastic material layer along the sample height direction is controlled, so that continuous distribution or discontinuous distribution of confining pressure of the sample in the height direction can be realized; and the displacement amount of simultaneously applying pressure in a bidirectional mode in the experimental process is controlled, so that pressure gradient and average pressure stressed by the sample are kept constant. The method is simple, economic and flexible to operate, can simulate non-uniform pressure distribution stressed by rock and soil media in the actual formation indoors and has obvious technical and economic advantages.

Owner:CHINA UNIV OF MINING & TECH

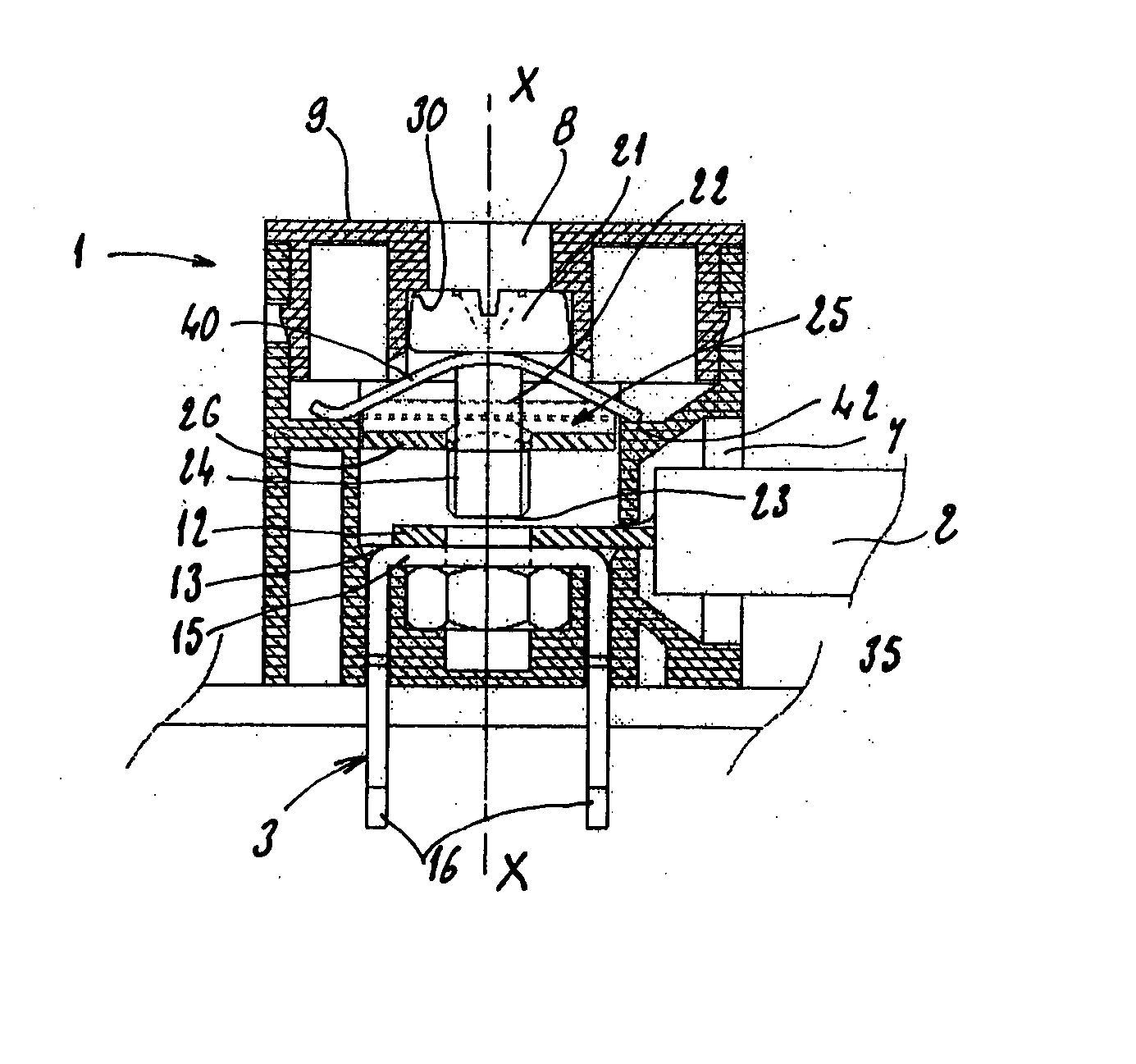

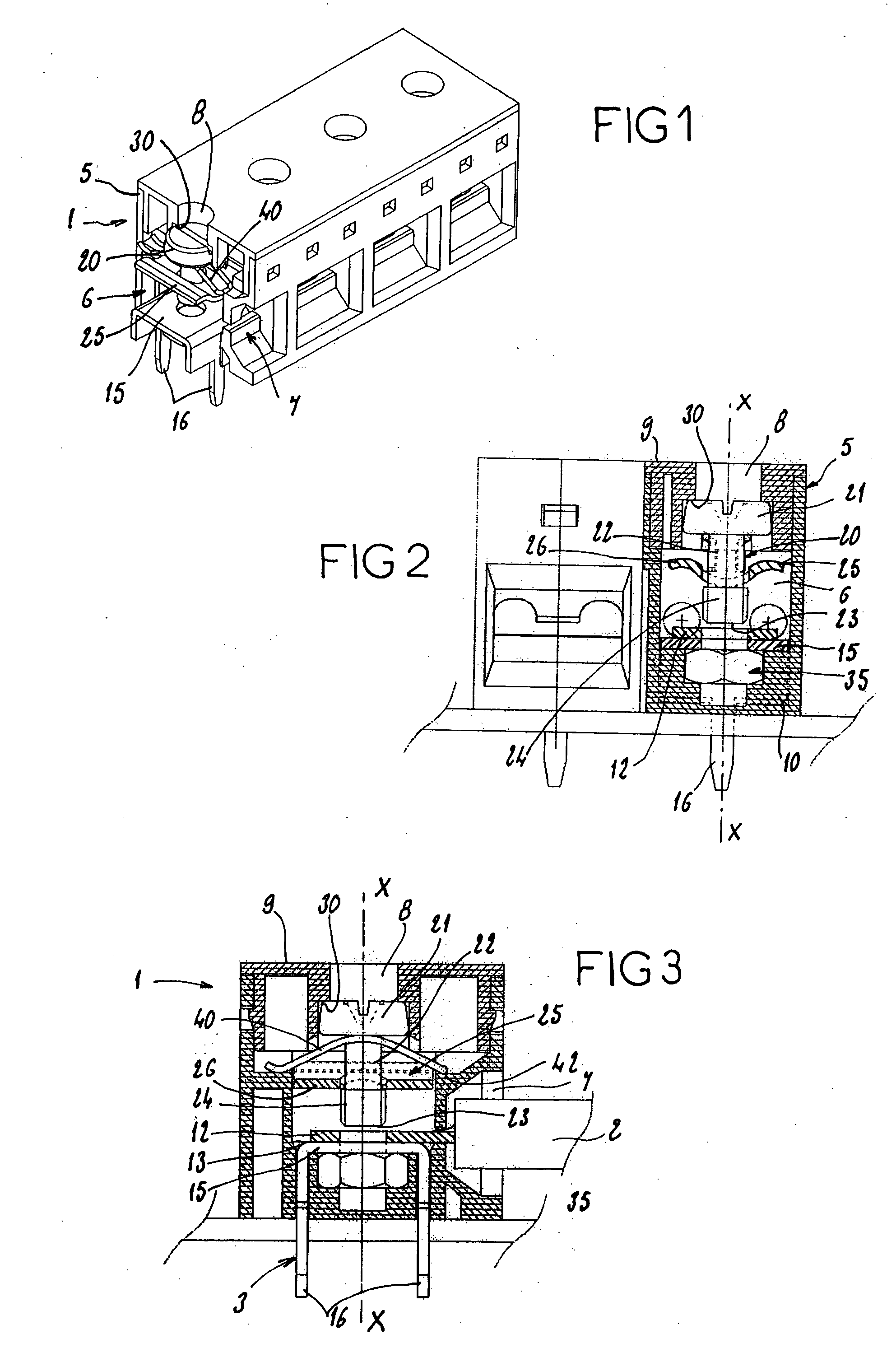

Electrical connection device with protected contact

InactiveUS20050042933A1Simple and effective and inexpensive meanFixed connectionsClamped/spring connectionsElectrical connectionMean stress

Owner:ENTRELEC

Paste pipeline transportation flow measuring method

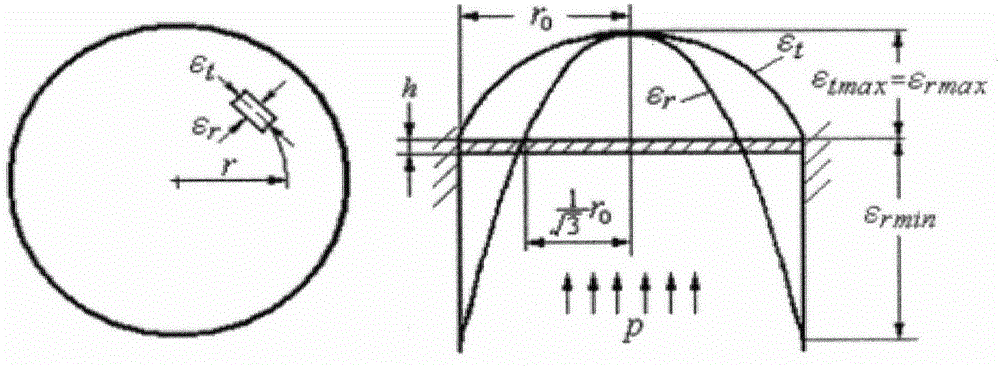

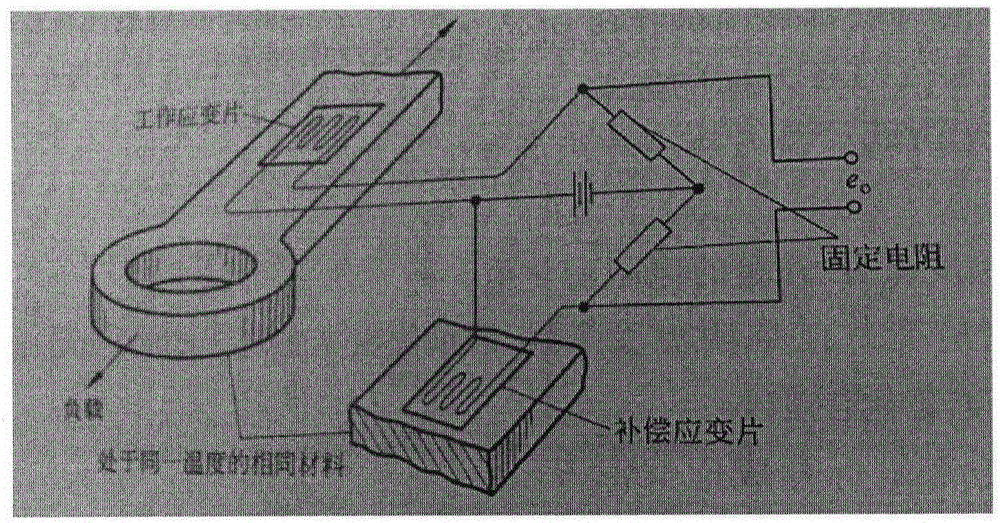

The invention relates to the technical field of measurement of coal mine paste filling pipeline transportation flow. When paste is transported in the pipeline normally, strain gauges are pasted on two specific locations of the paste pipeline which needs to be measured, strain gauges are pasted on the upper part, the lower part, the left part and the right part of each of the two specific locations, when readings are stable, data are read out, the average pressure value of the read data of the four strain gauges of each of the two specific locations is obtained, the calculated two average pressure values serve as the pressure values of pipeline cross sections where the two specific locations are arranged, the difference value, i.e., the pressure drop, of the pressure values of the pipeline cross sections of the two specific locations is calculated, and the flow is calculated through the pressure drop.

Owner:HEBEI UNIV OF ENG

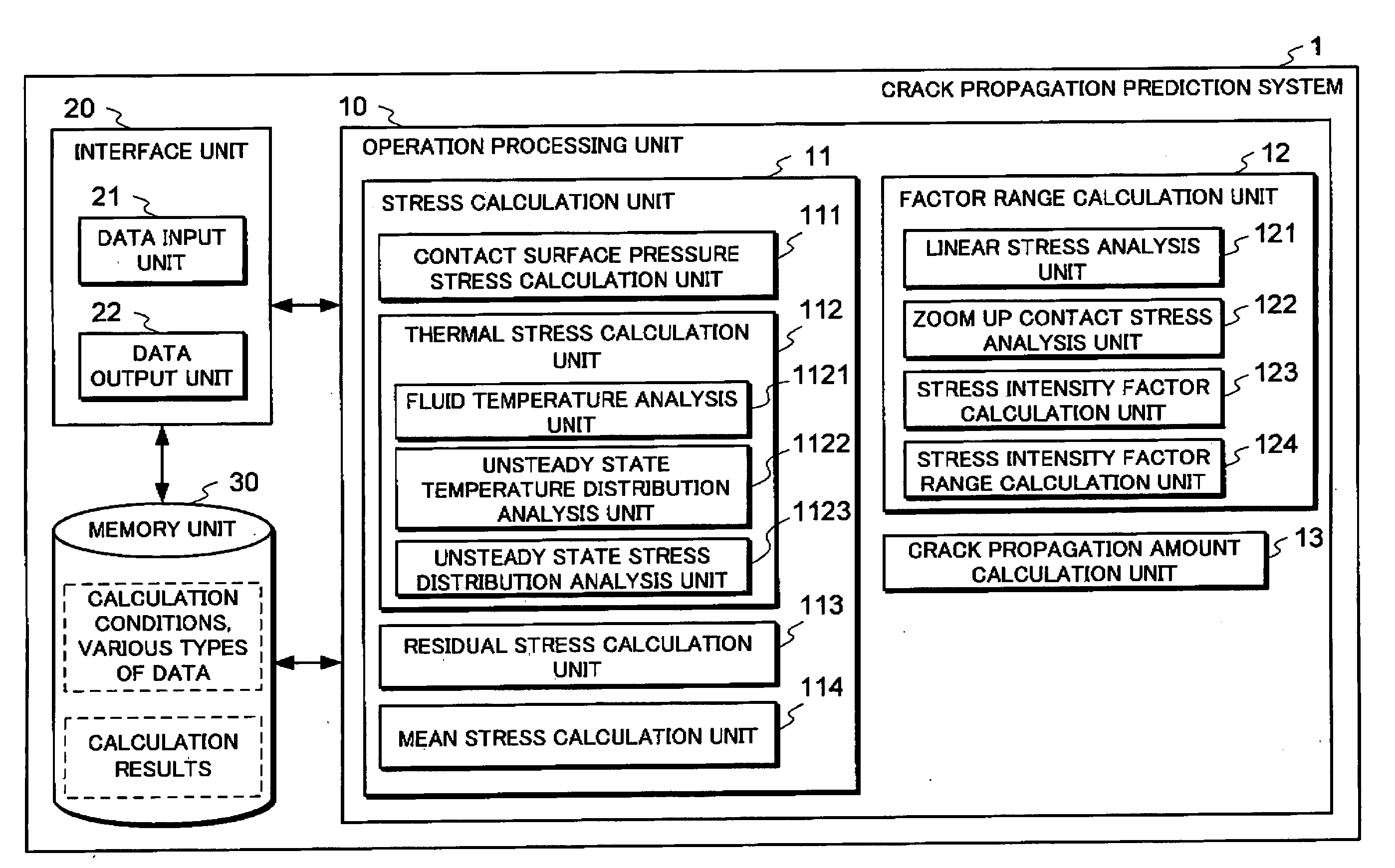

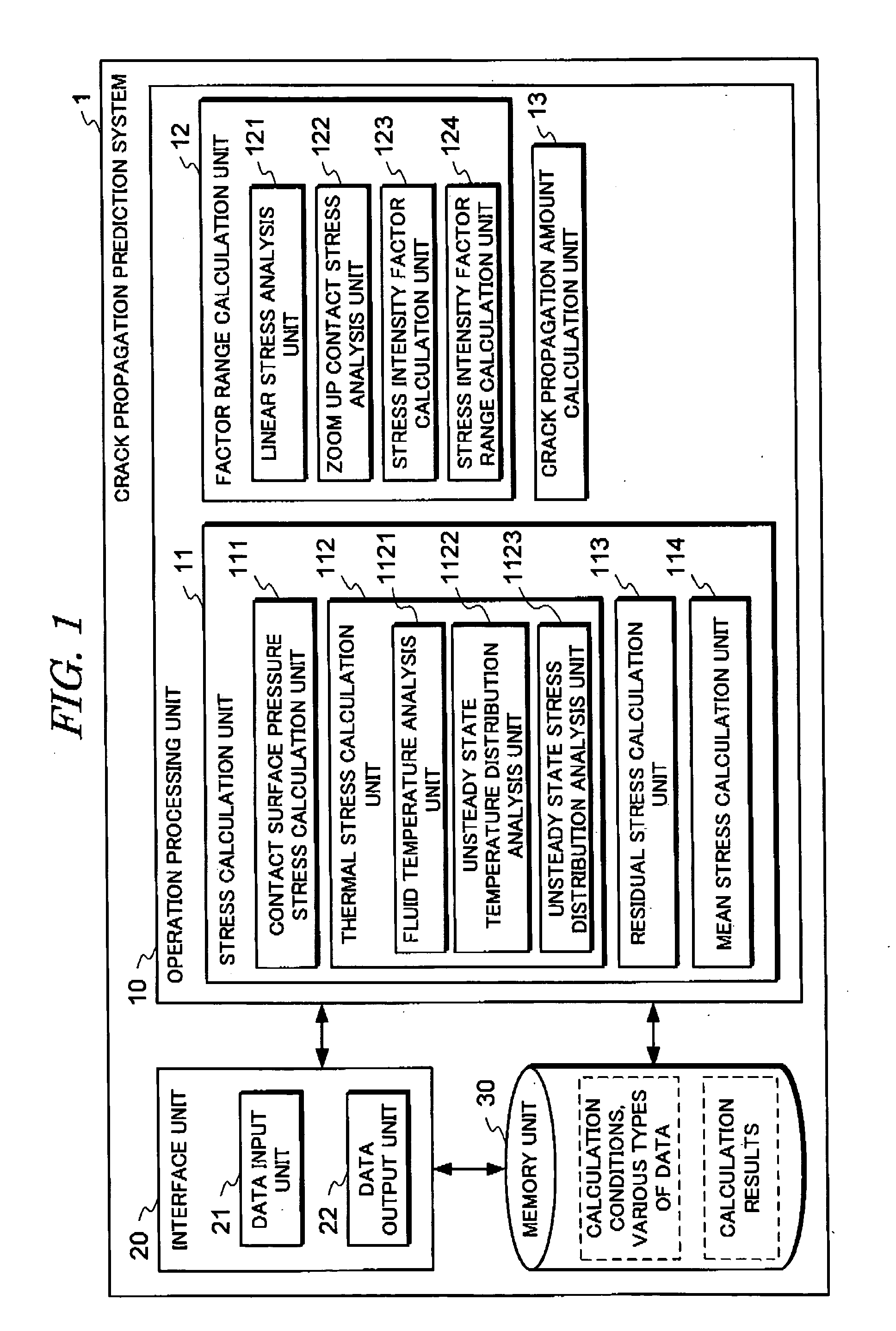

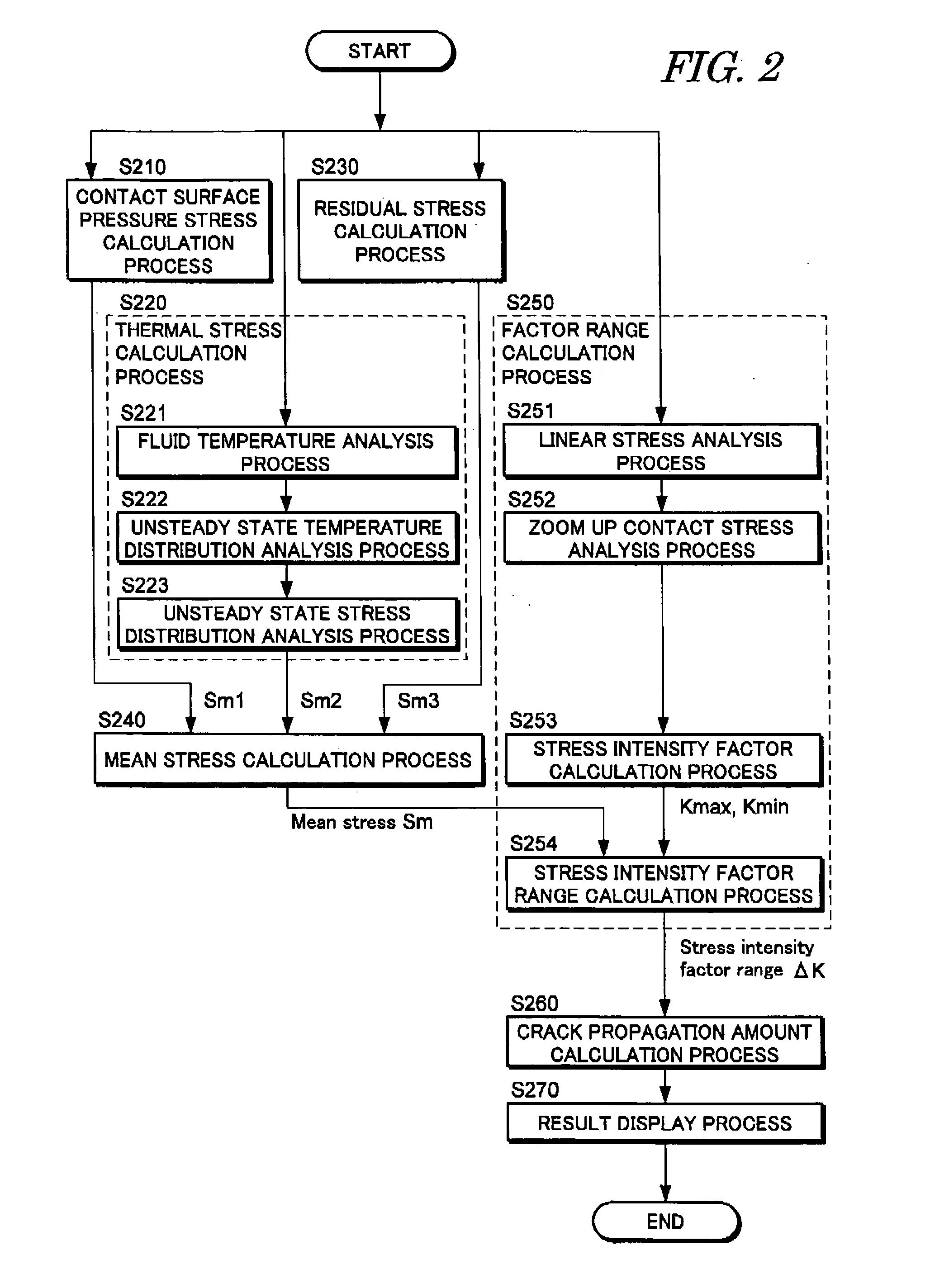

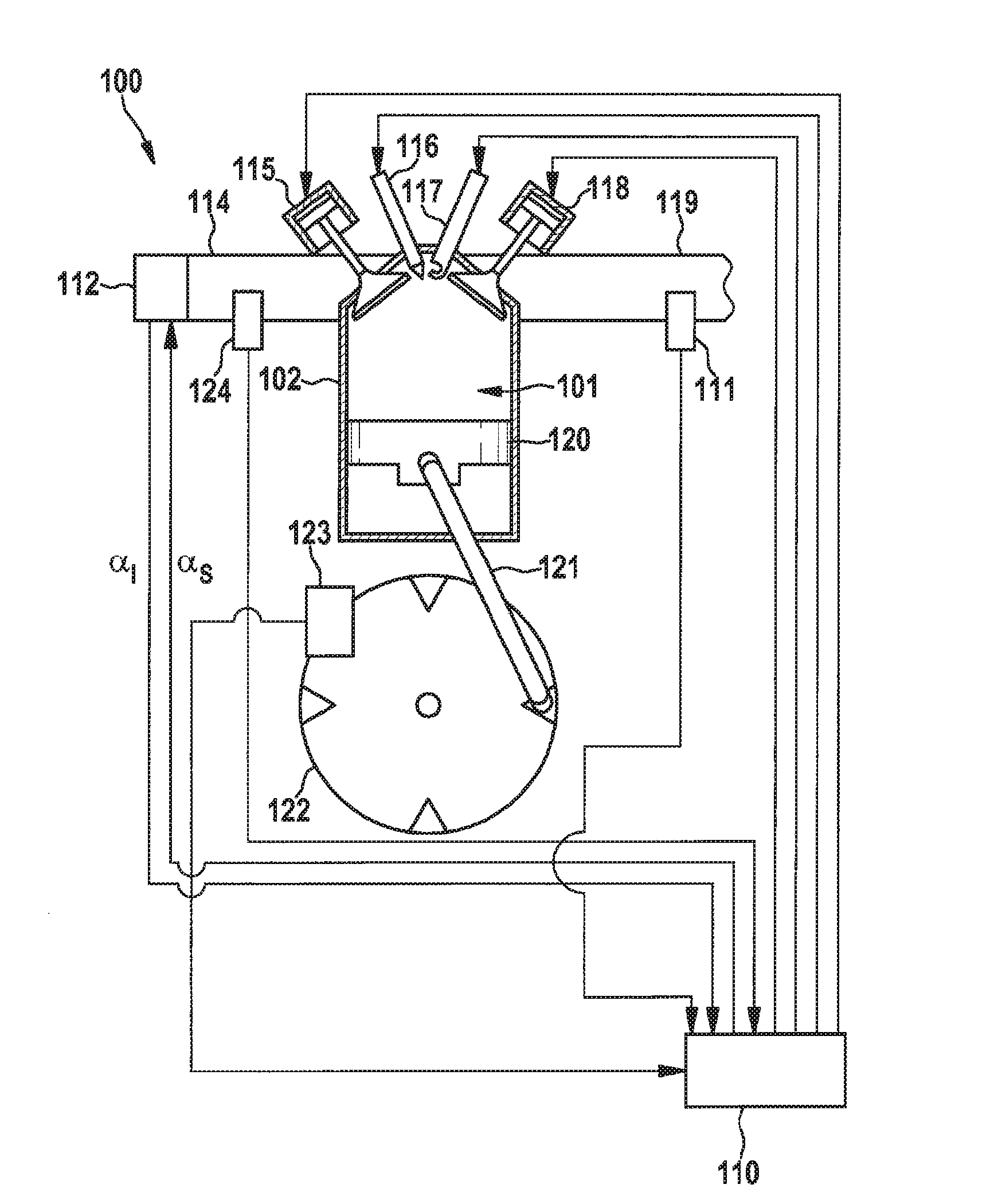

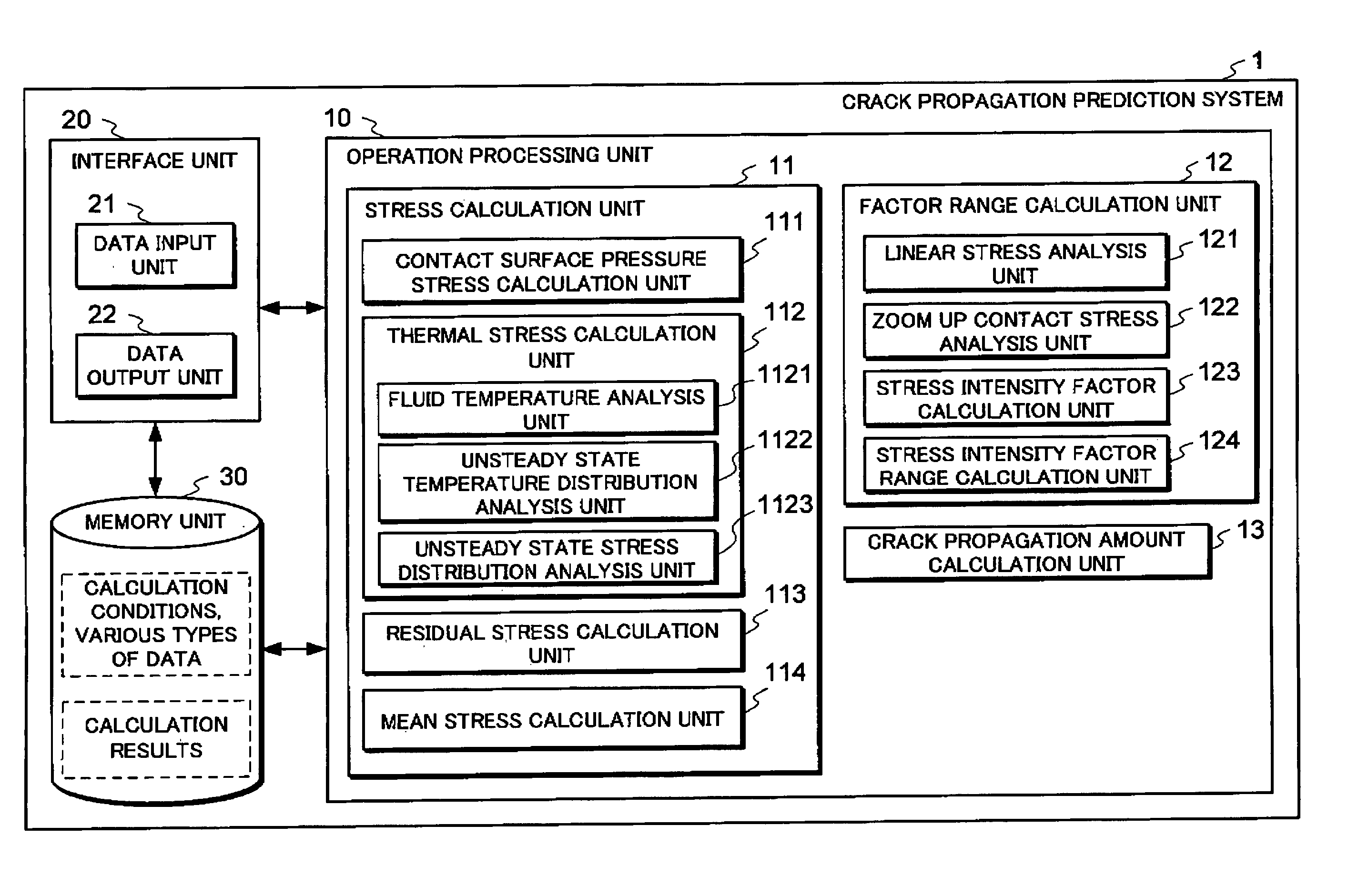

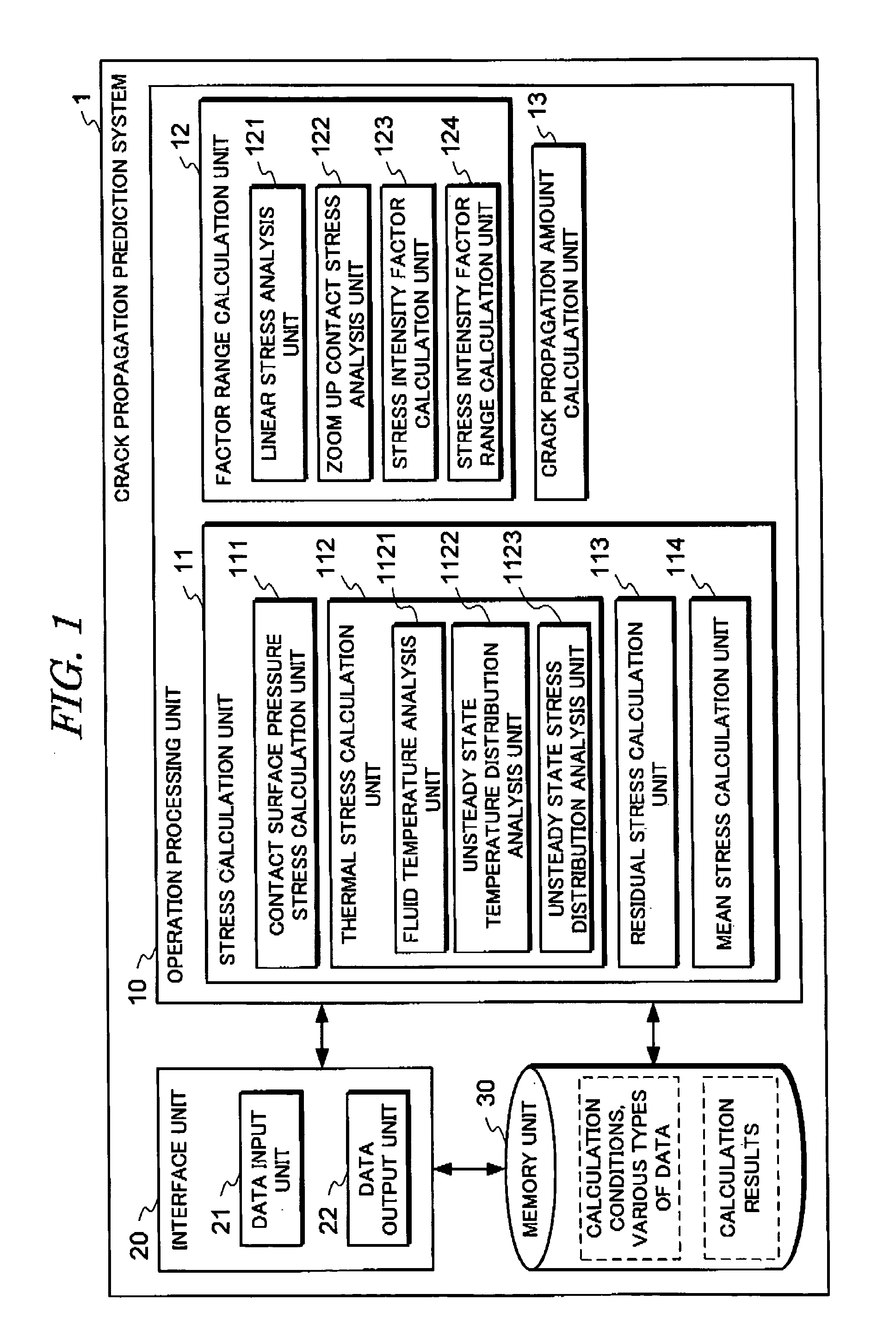

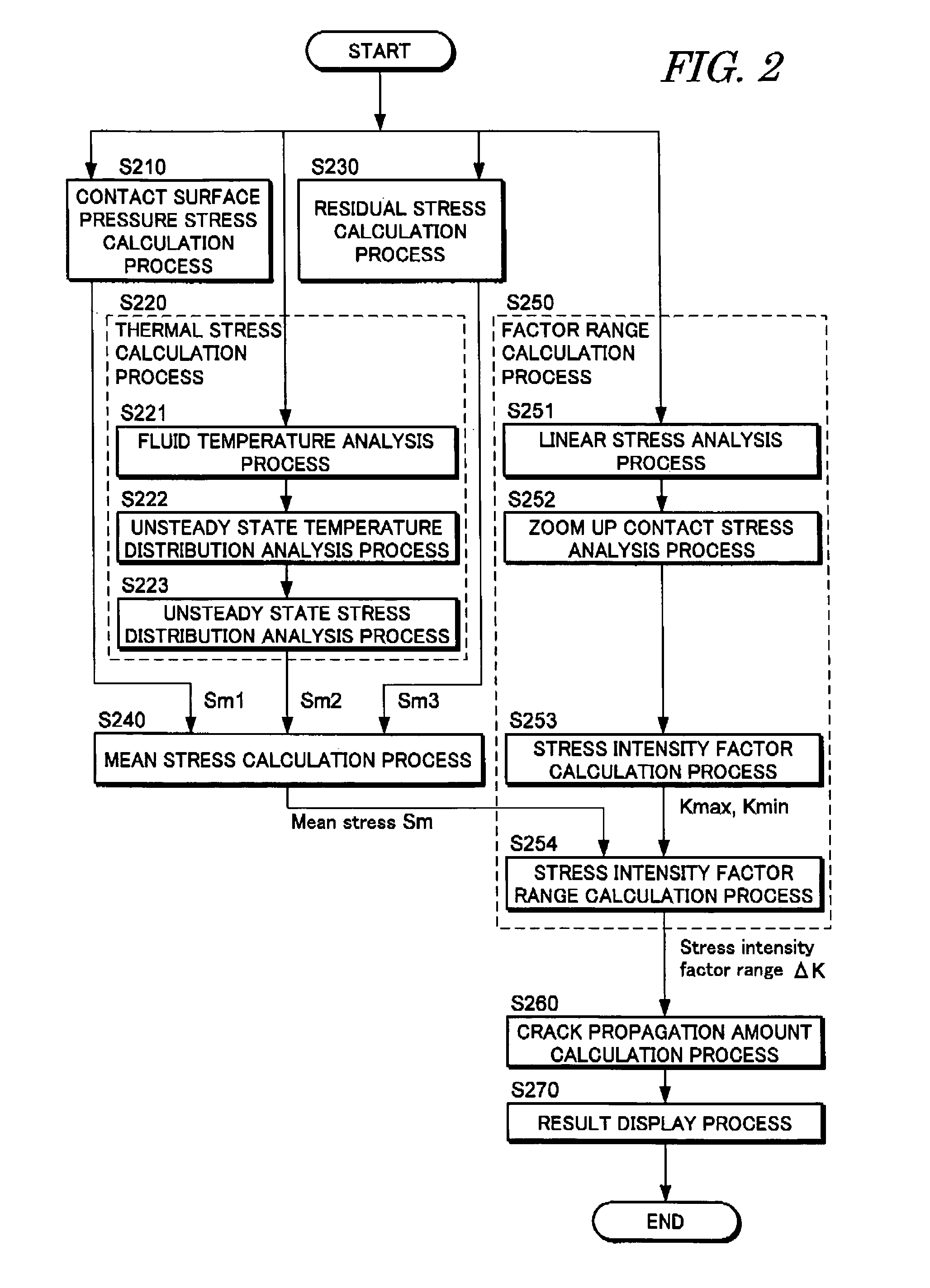

Generator rotor crack propagation prediction system and operation conditions determination support system, method, and program, and operation control system

InactiveUS20070172357A1Resists crack propagationImprove accuracyStructural/machines measurementDigital dataEngineeringOperation mode

An object of the present invention is to control crack propagation, either by predicting shaft dovetail crack propagation with high accuracy, or by determining operation conditions under which the crack does not extend. The crack propagation prediction system includes an operation processing unit, an interface unit, and a memory unit. The operation processing unit includes a stress calculation unit that calculates the mean stress generated in the shaft dovetail, a factor range calculation unit that calculates the stress intensity factor range for the crack in the shaft dovetail, and a crack propagation amount calculation unit that calculates an amount of the shaft dovetail crack propagation for an arbitrary time period, from the obtained mean stress and the stress intensity factor range, an operation pattern, an operation time, and data on the crack. The stress calculation unit includes as individual calculation units that calculate separately different types of mean stress, a contact surface pressure stress calculation unit, a thermal stress calculation unit, and a residual stress calculation unit, as well as a mean stress calculation unit that sums these mean stresses.

Owner:KK TOSHIBA

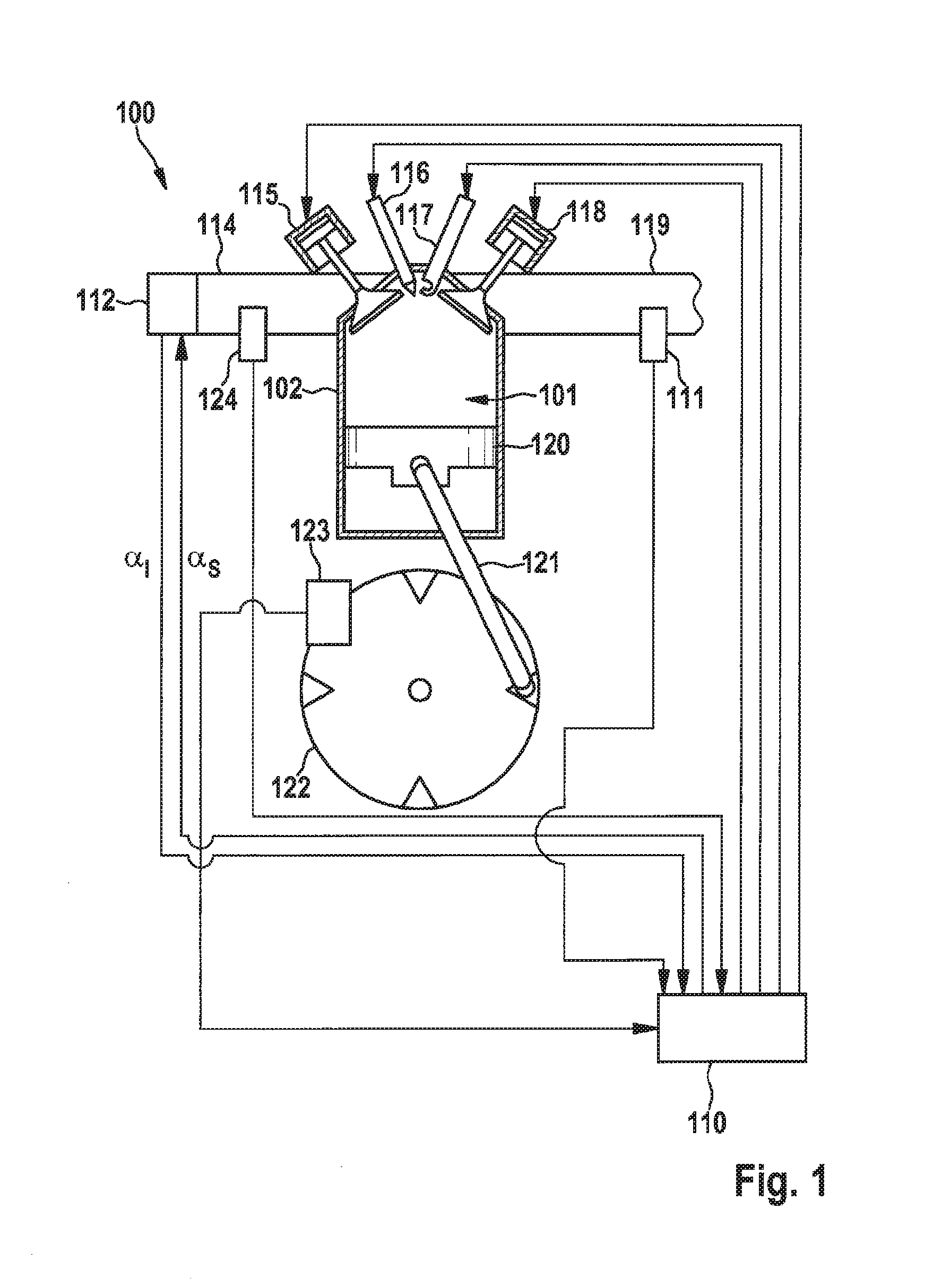

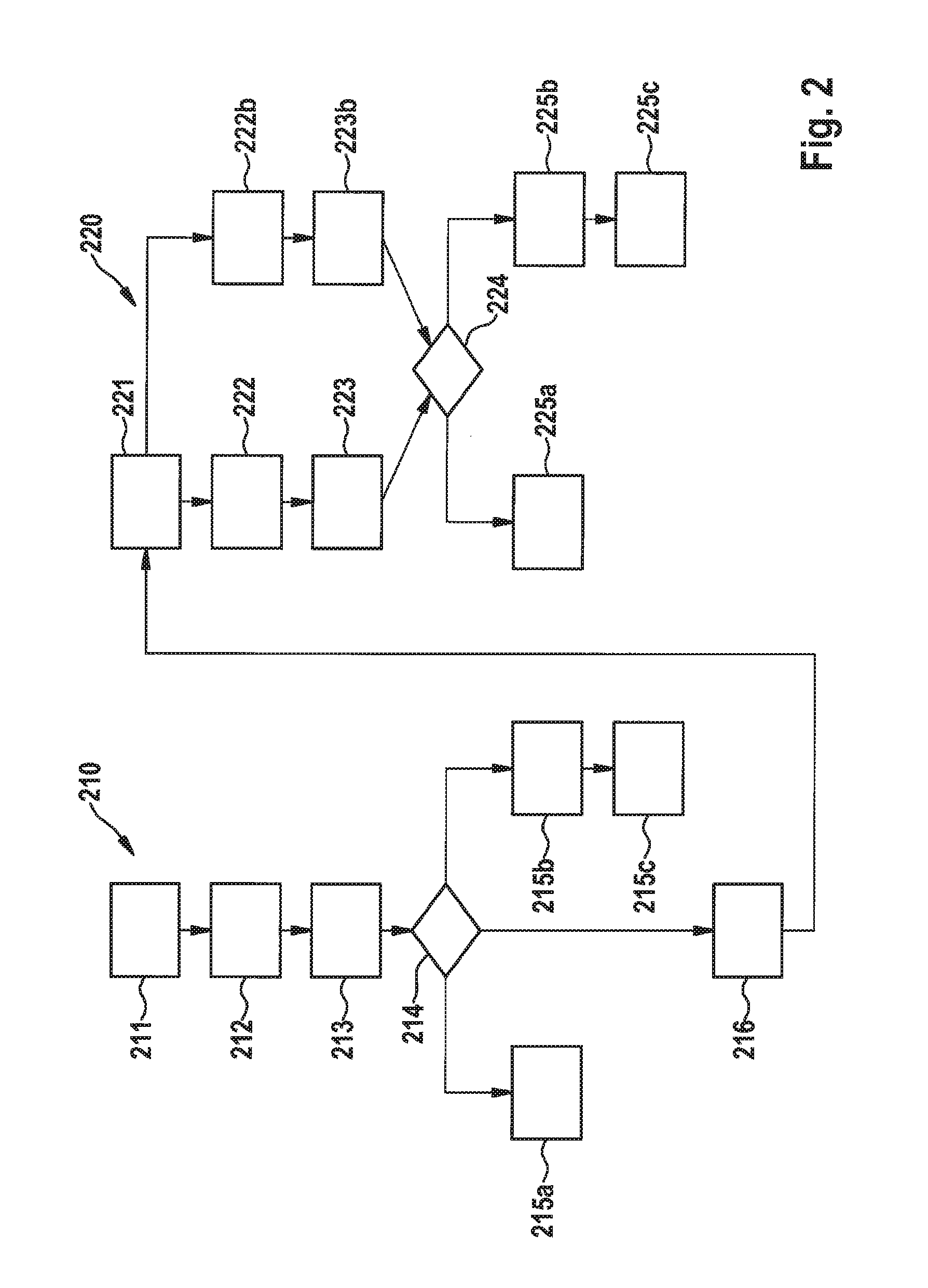

Method for isolating quantity errors of a fuel amount and an air amount delivered to at least cylinder of an internal combusion engine

InactiveUS20160161369A1Reduce environmental impactIncrease fuel consumptionInternal-combustion engine testingElectrical controlInternal combustion engineMean stress

A method for determining quantitative errors in a fuel quantity and air quantity delivered to at least one cylinder of an internal combustion engine, in which in a first phase a cylinder equalization of the internal combustion engine is accomplished, and an error in the fuel quantity delivered to the at least one cylinder is determined therefrom. In a second phase the internal combustion engine is operated with a stoichiometric ratio of air quantity and fuel quantity, a feature of the at least one cylinder correlating with an indicated mean pressure is sensed, and an error in the air quantity delivered to the at least one cylinder is determined from the feature correlating with the indicated mean pressure.

Owner:ROBERT BOSCH GMBH

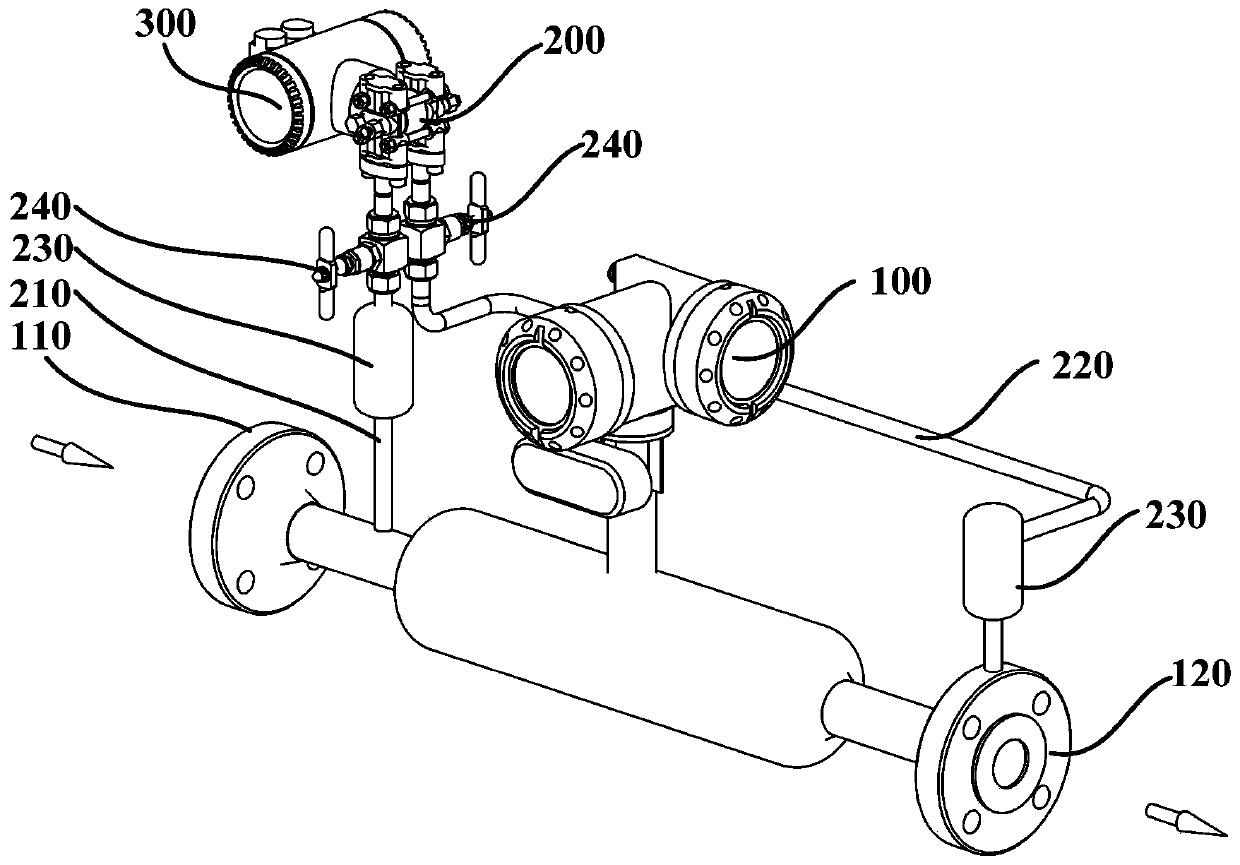

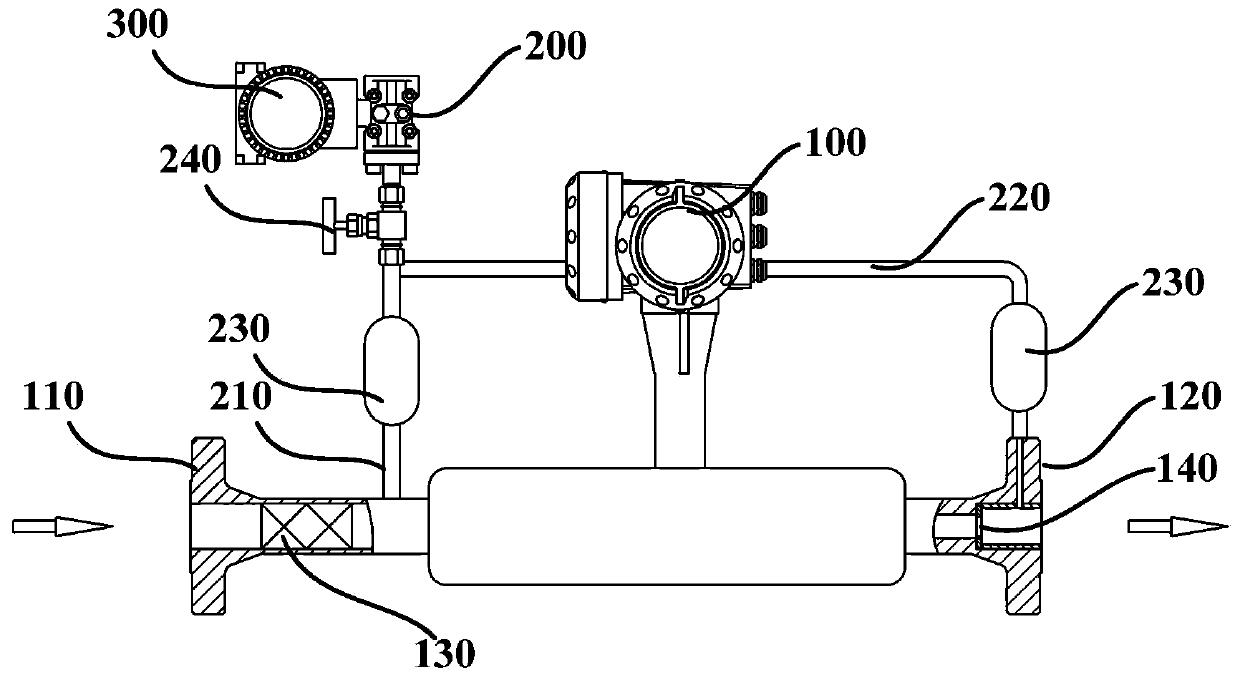

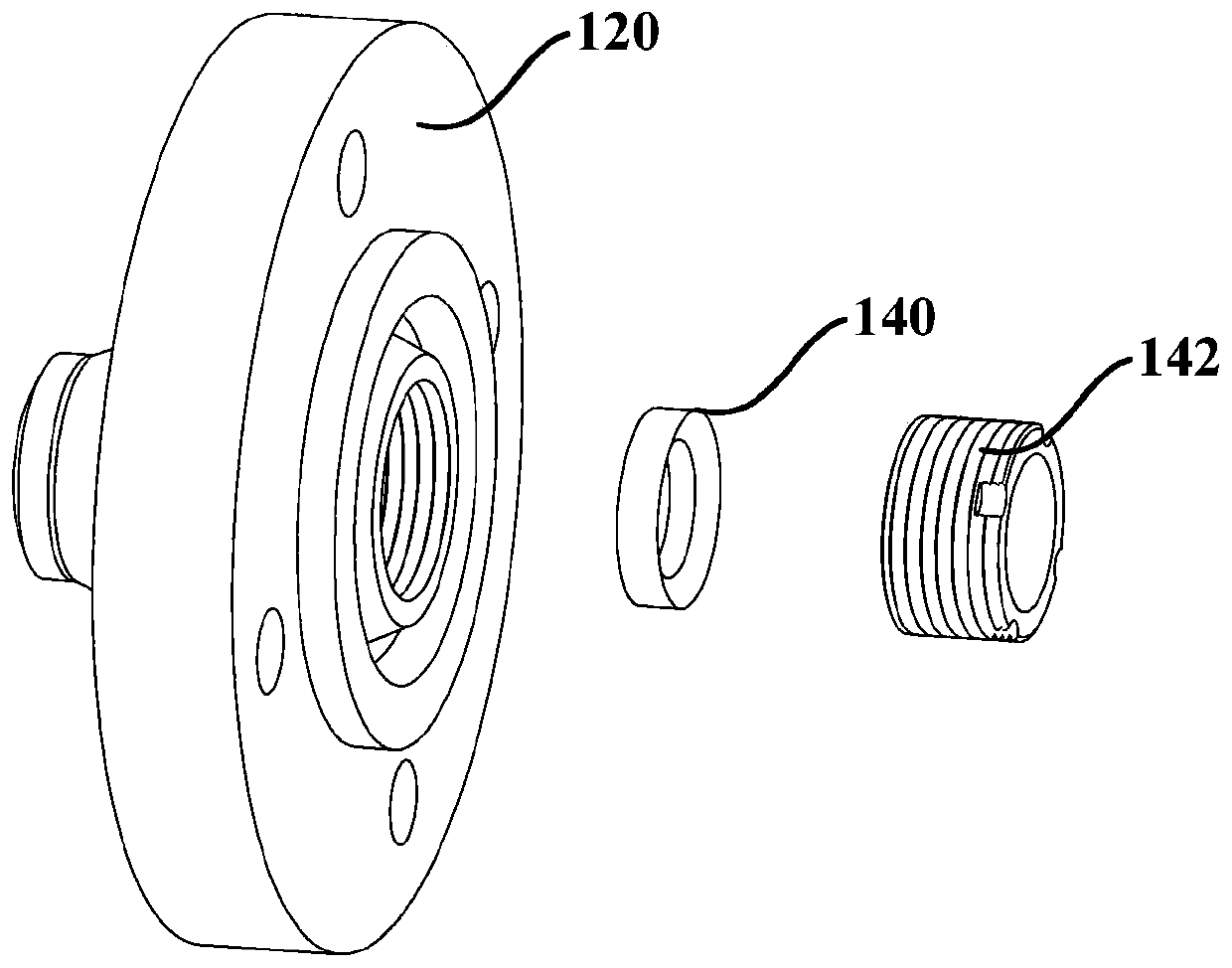

Gas-liquid two-phase mass flowmeter

PendingCN109738034AImprove adaptabilityGuarantee working reliabilityVolume flow measuring devicesIndirect mass flowmetersGas phaseDifferential pressure

The invention provides a gas-liquid two-phase mass flowmeter. The gas-liquid two-phase mass flowmeter comprises a mass flowmeter, a differential pressure composite sensor and a flow computer, whereinthe mass flowmeter is used for measuring a mass flow, a temperature and a mixing density of a tested gas-liquid two-phase fluid; a differential pressure positive pressure pipe and a differential pressure negative pressure pipe of the differential pressure composite sensor are respectively connected with a pipeline, flowing to downstream and a pipeline, flowing to upstream, of the mass flowmeter; the differential pressure composite sensor is used for measuring average pressure and differential pressure of the tested gas-liquid two-phase fluid before and after flowing through the mass flowmeter;and the flow computer is connected with each of the mass flowmeter and the pressure differential composite sensor, and is used for calculating a gas-liquid two-phase flow of the tested gas-liquid two-phase fluid by combining a database in the mass flowmeter according to measurement parameters of the mass flowmeter and the differential pressure composite sensor, external input liquid-phase densityand gas-phase density. The gas-liquid two-phase mass flowmeter can be applied to condensate natural gas wells, aqueous shale gas wells, oil wells and other fields of multi-phase flow measurement, andthe measurement range and adaptability of the gas-liquid two-phase mass flowmeter are improved.

Owner:XINJIANG ZHONGYUAN TIANNENG OIL & GAS TECH CO LTD

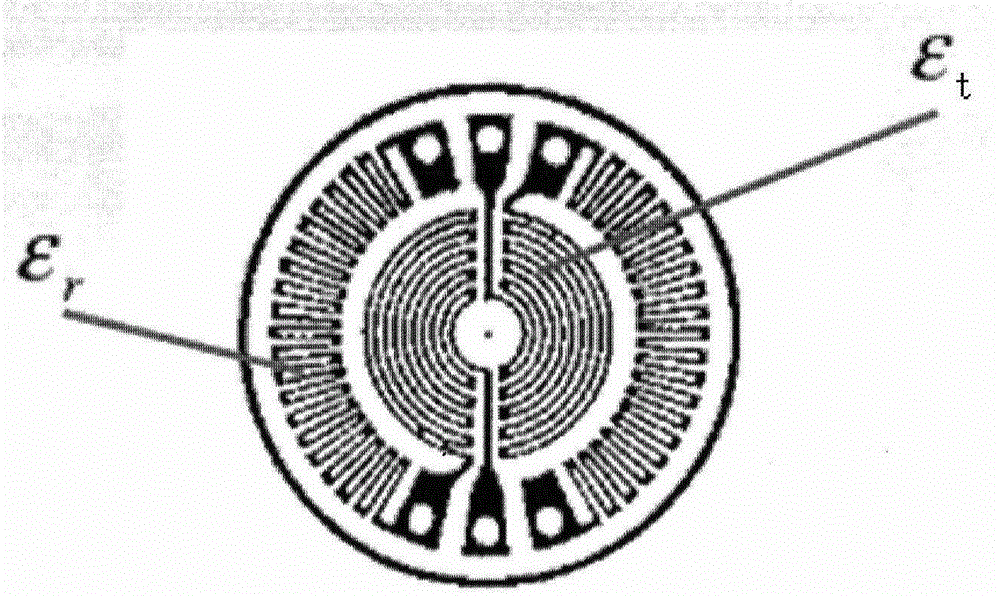

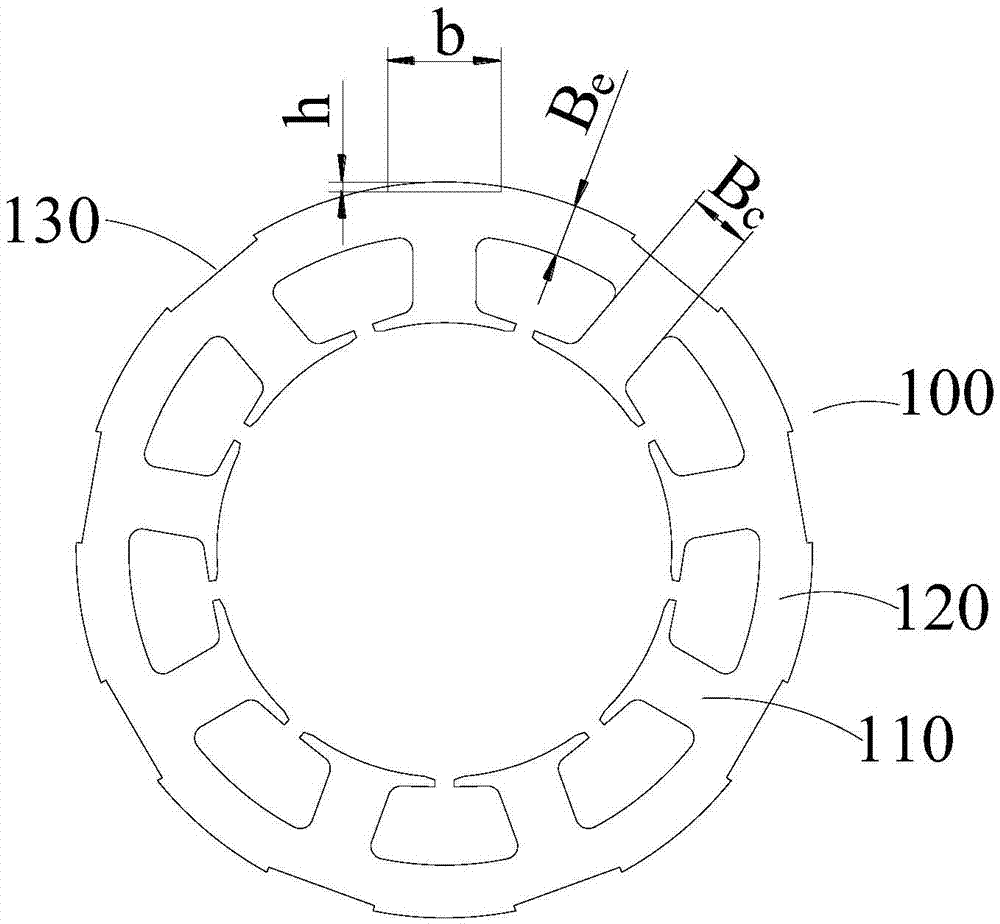

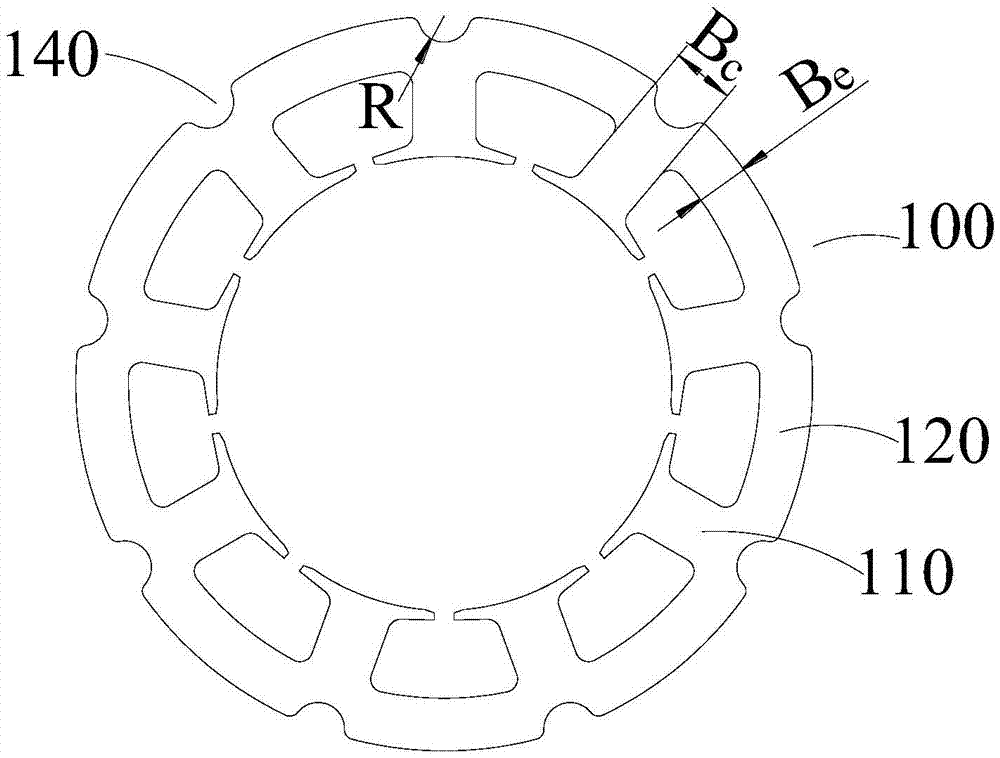

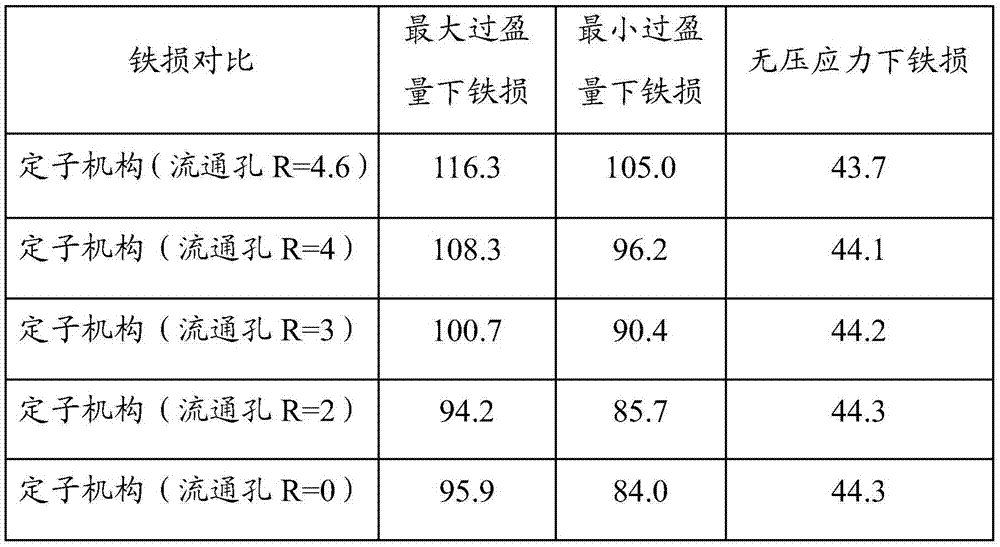

Compressor, motor and stator mechanism thereof

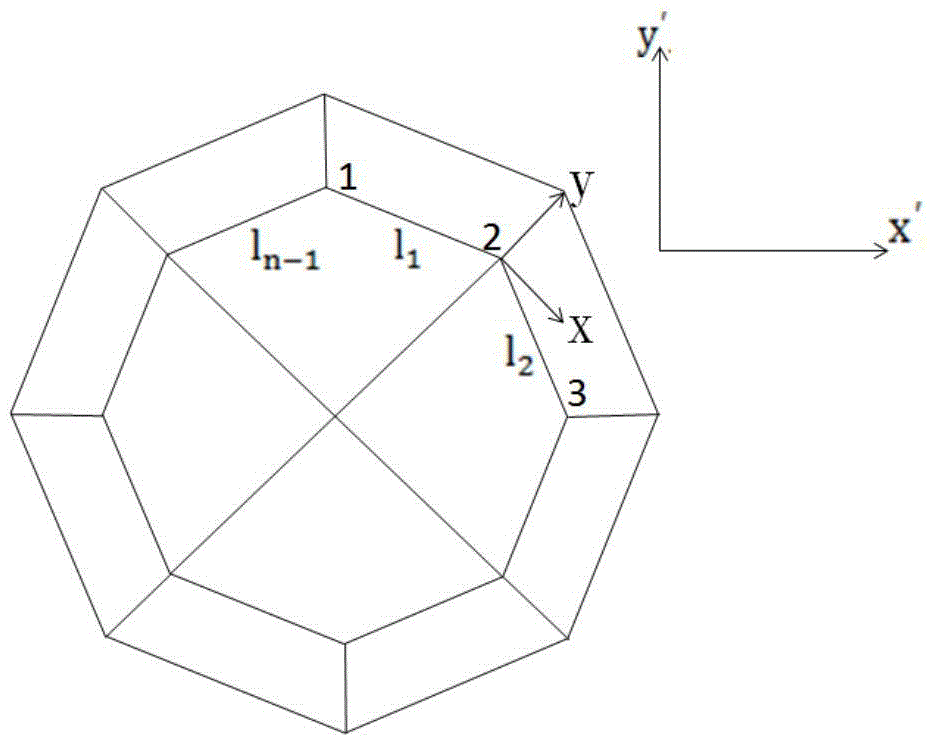

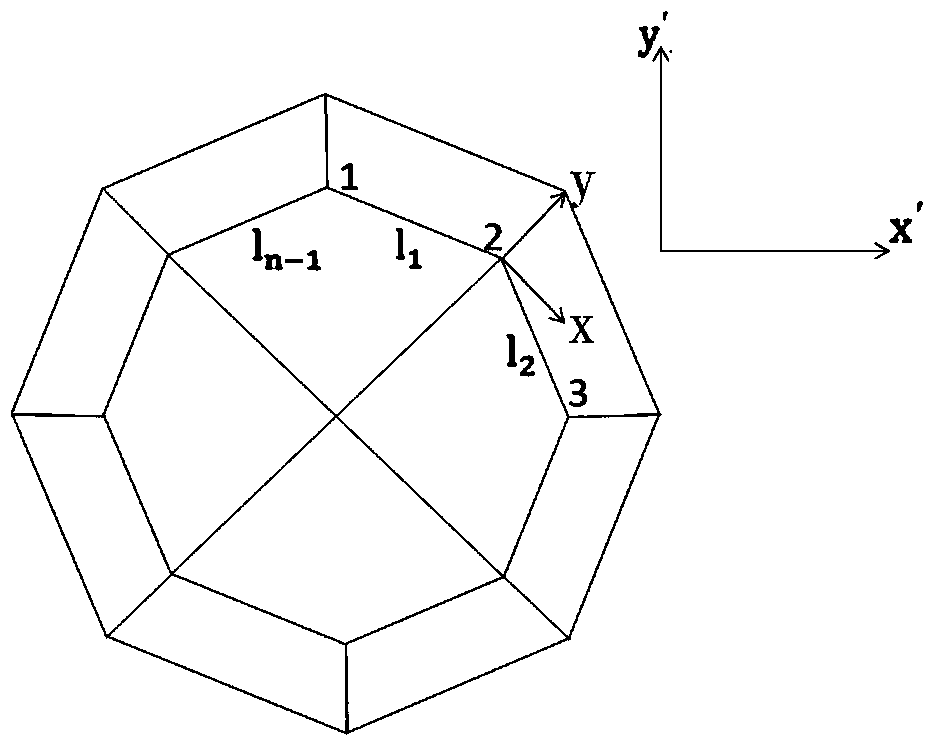

PendingCN106936229ASimple structural designReduce iron lossMagnetic circuit stationary partsStress distributionElectric machine

The invention provides a compressor, a motor and a stator mechanism thereof. The compressor, the motor and the stator mechanism thereof comprise multiple teeth and multiple yokes. The width of each tooth is Bc. The multiple teeth and the multiple yokes are arranged in a staggered manner and connected to form a ring structure. The width of each yoke is Be. The relationship between the width Bc of each tooth and the width Be of each yoke is as follows: 2*Bc / 3<=Be<=Bc. The width of the yokes of the stator mechanisms is increased according to the stress distribution under shrinkage fit between the stator mechanism and a shell. Thus, the mean stress under shrinkage fit between the stator mechanism and the shell and the flux density amplitude of the yokes of the stator mechanism are reduced while the width of the yokes is increased. The iron loss of the motor is reduced under both effects. Deterioration of iron loss caused by compressive stress under shrinkage fit is avoided. The performance of the compressor is ensured.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

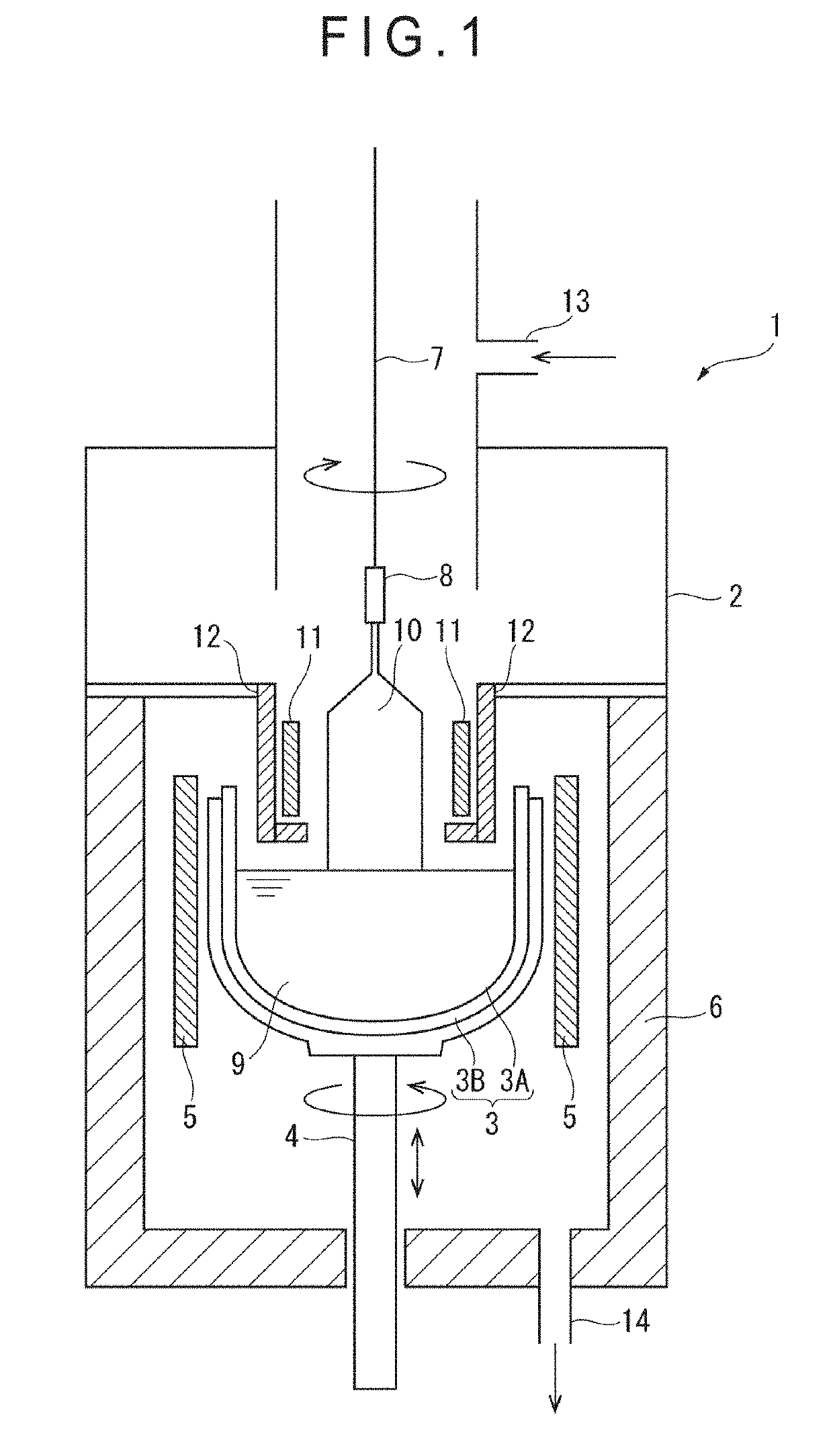

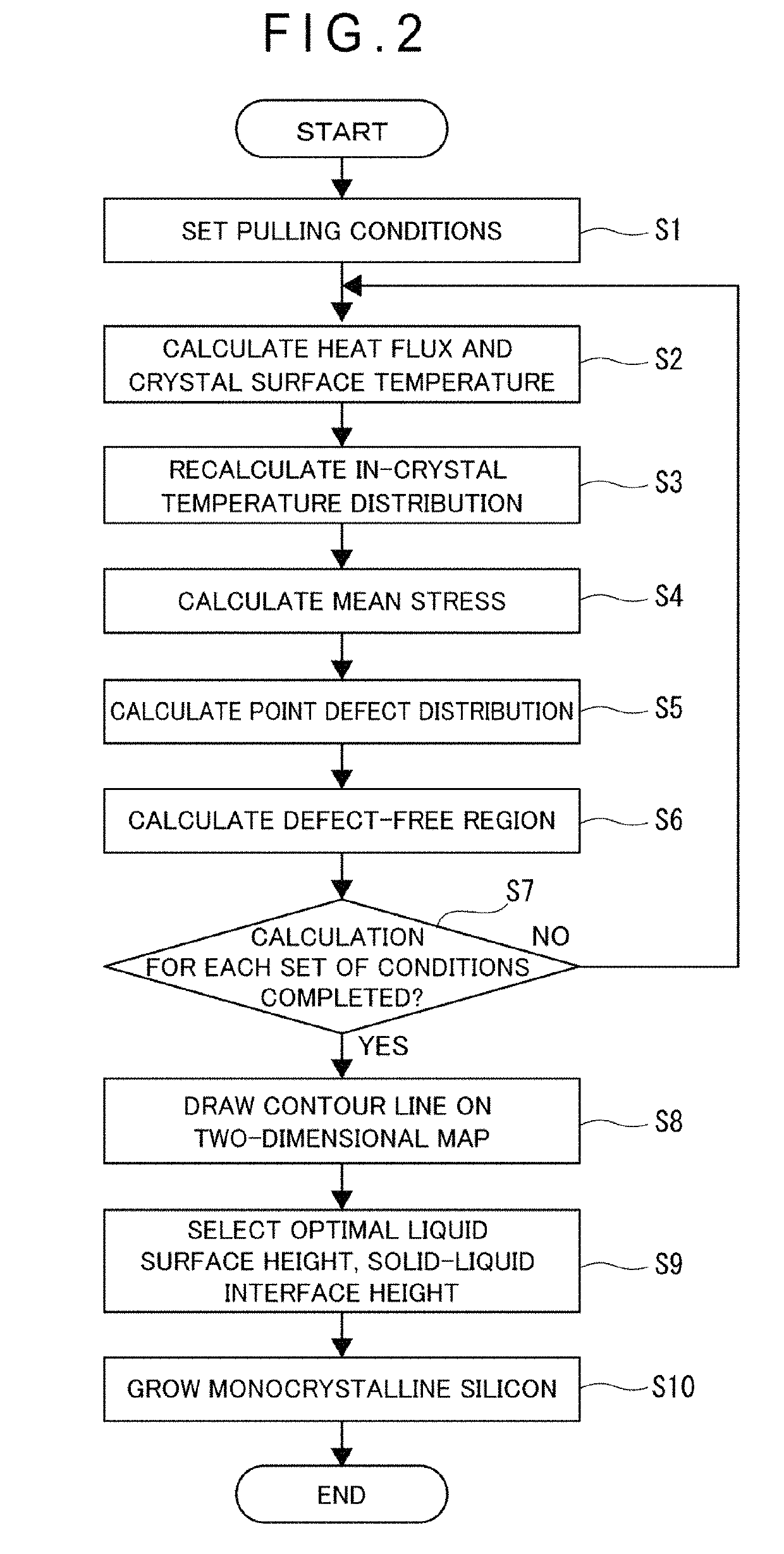

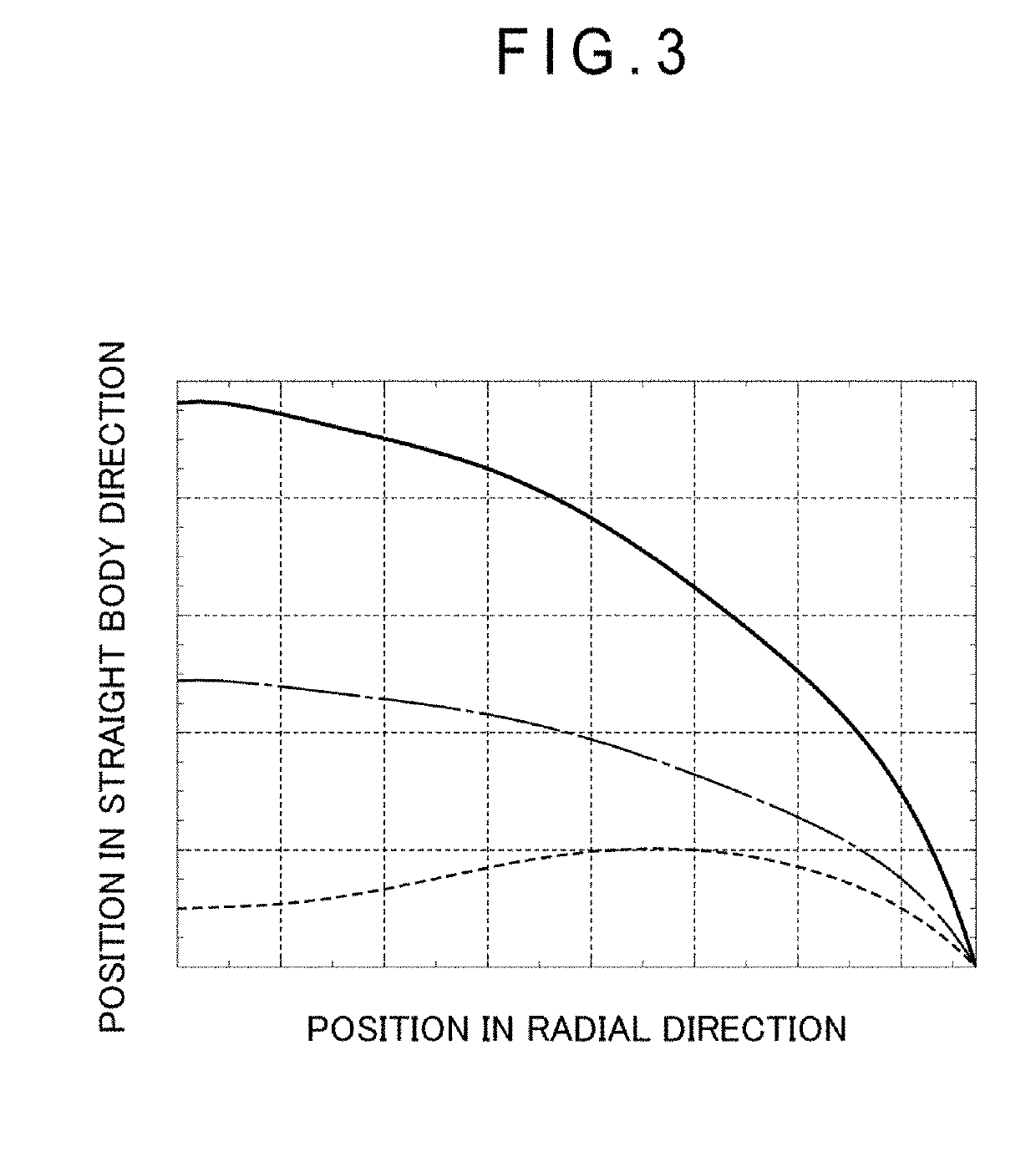

Silicon single crystal pulling condition calculation program, silicon single crystal hot zone improvement method, and silicon single crystal growing method

ActiveUS20190330760A1Large regionOptimizationPolycrystalline material growthBy pulling from meltHeat fluxHot zone

A pulling condition calculation program enables a computer to perform the steps of: setting a plurality of sets of pulling conditions based on solid-liquid interface height and distance between a surface of a silicon melt and a heat shield plate; performing, for each set of the pulling conditions, the steps of: calculating a heat flux (q) (W / m2) and a crystal surface temperature (T); defining a reference temperature (Tref) given by an equation (1) below and a geometry of the solid-liquid interface as boundary conditions,recalculating an in-crystal temperature distribution; calculating a mean stress in the monocrystalline silicon; calculating a defect distribution in a pulling direction based on the mean stress and the in-crystal temperature distribution; determining a defect-free region in the pulling direction; and drawing a contour line showing a dimension of the defect-free region on a two-dimensional map defined by the distance and the solid-liquid interface height.Tref=T4-qɛσ4(1)

Owner:SUMCO CORP

Predicting crack propagation in the shaft dovetail of a generator rotor

InactiveUS7711664B2Operation efficiency can be improvedImprove equipment reliabilityPlug gaugesEngine fuctionsStress intensity factorOperation mode

An object of the present invention is to control crack propagation, either by predicting shaft dovetail crack propagation with high accuracy, or by determining operation conditions under which the crack does not extend. The crack propagation prediction system includes an operation processing unit, an interface unit, and a memory unit. The operation processing unit includes a stress calculation unit that calculates the mean stress generated in the shaft dovetail, a factor range calculation unit that calculates the stress intensity factor range for the crack in the shaft dovetail, and a crack propagation amount calculation unit that calculates an amount of the shaft dovetail crack propagation for an arbitrary time period, from the obtained mean stress and the stress intensity factor range, an operation pattern, an operation time, and data on the crack. The stress calculation unit includes as individual calculation units that calculate separately different types of mean stress, a contact surface pressure stress calculation unit, a thermal stress calculation unit, and a residual stress calculation unit, as well as a mean stress calculation unit that sums these mean stresses.

Owner:KK TOSHIBA

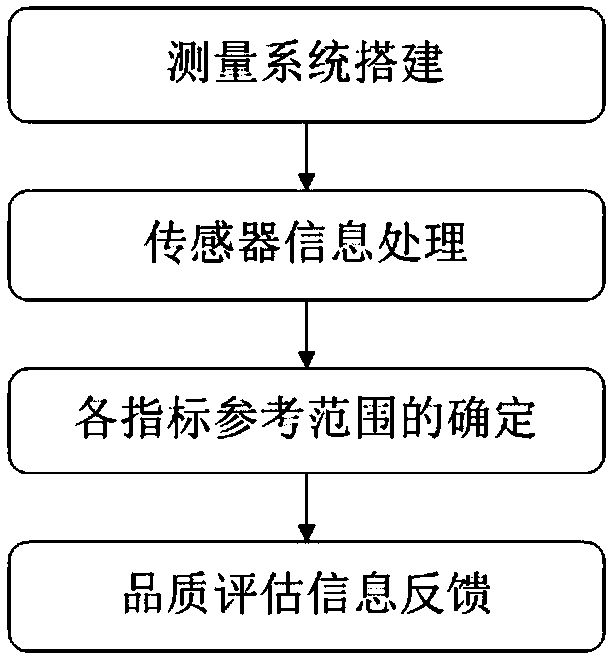

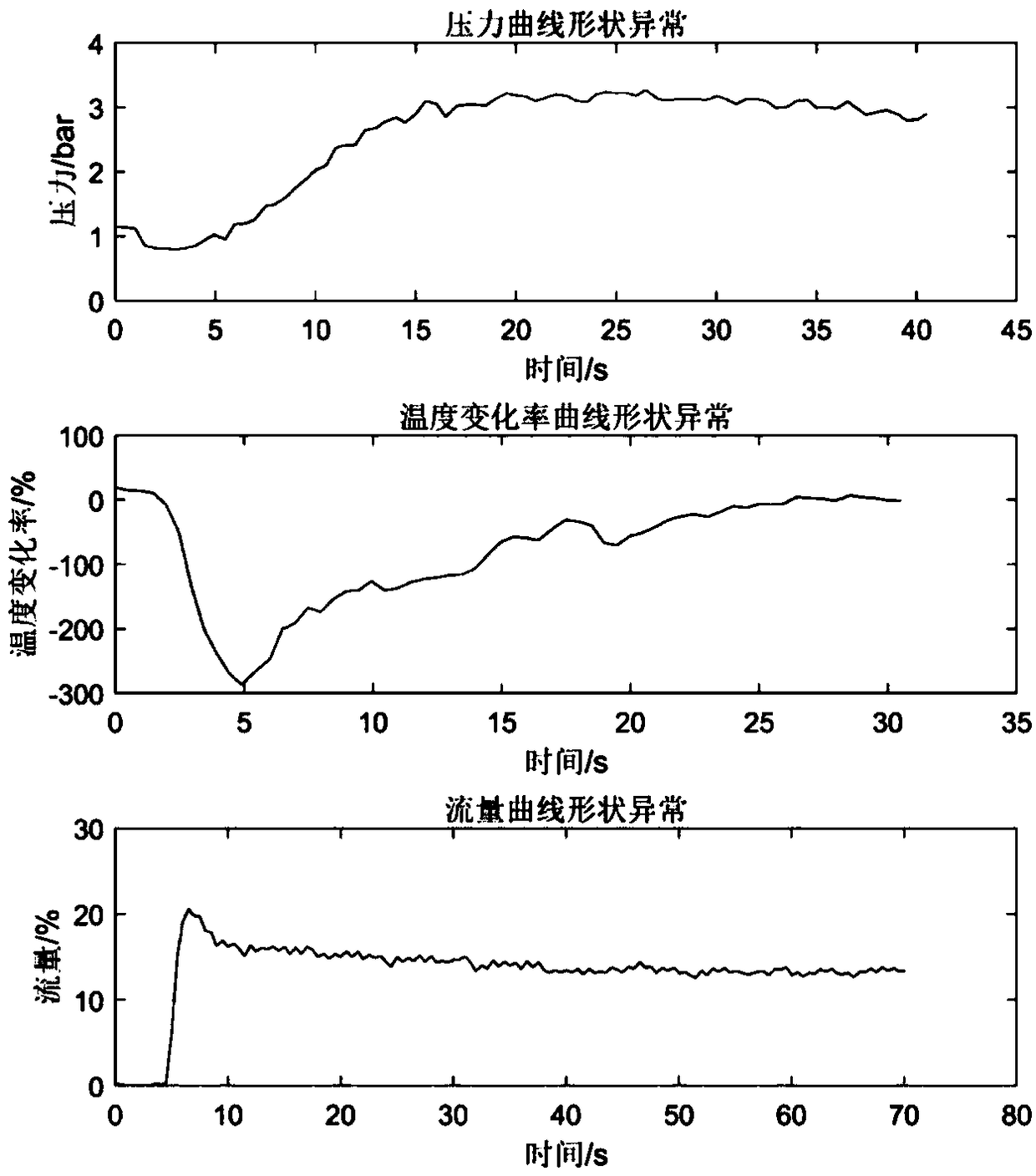

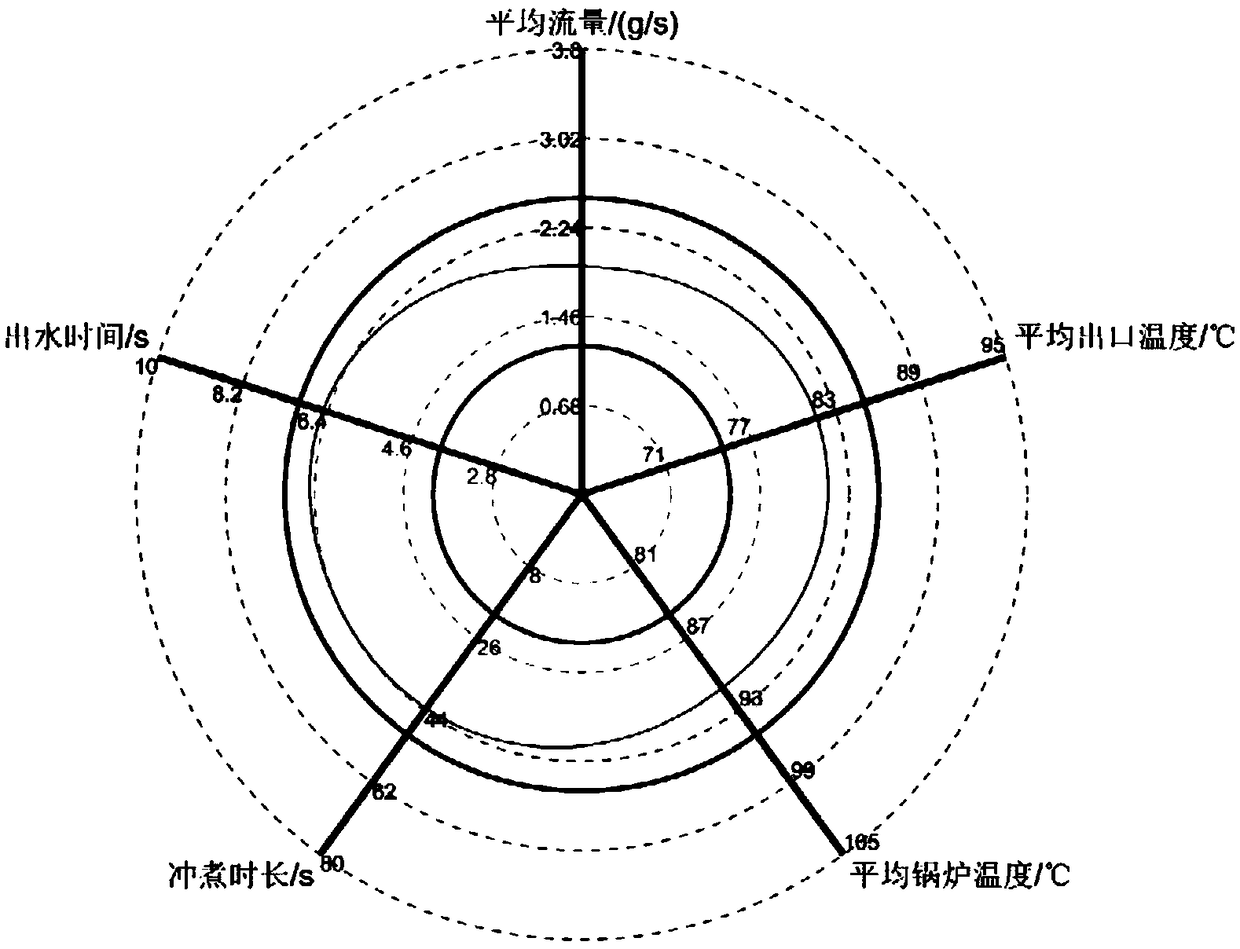

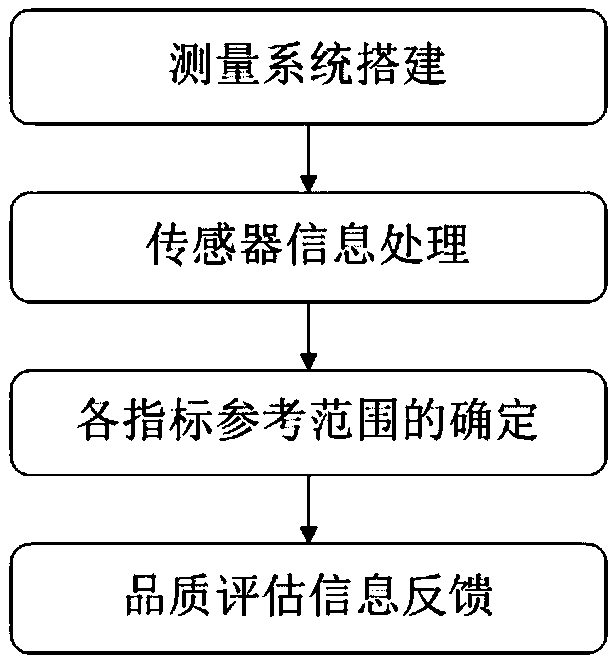

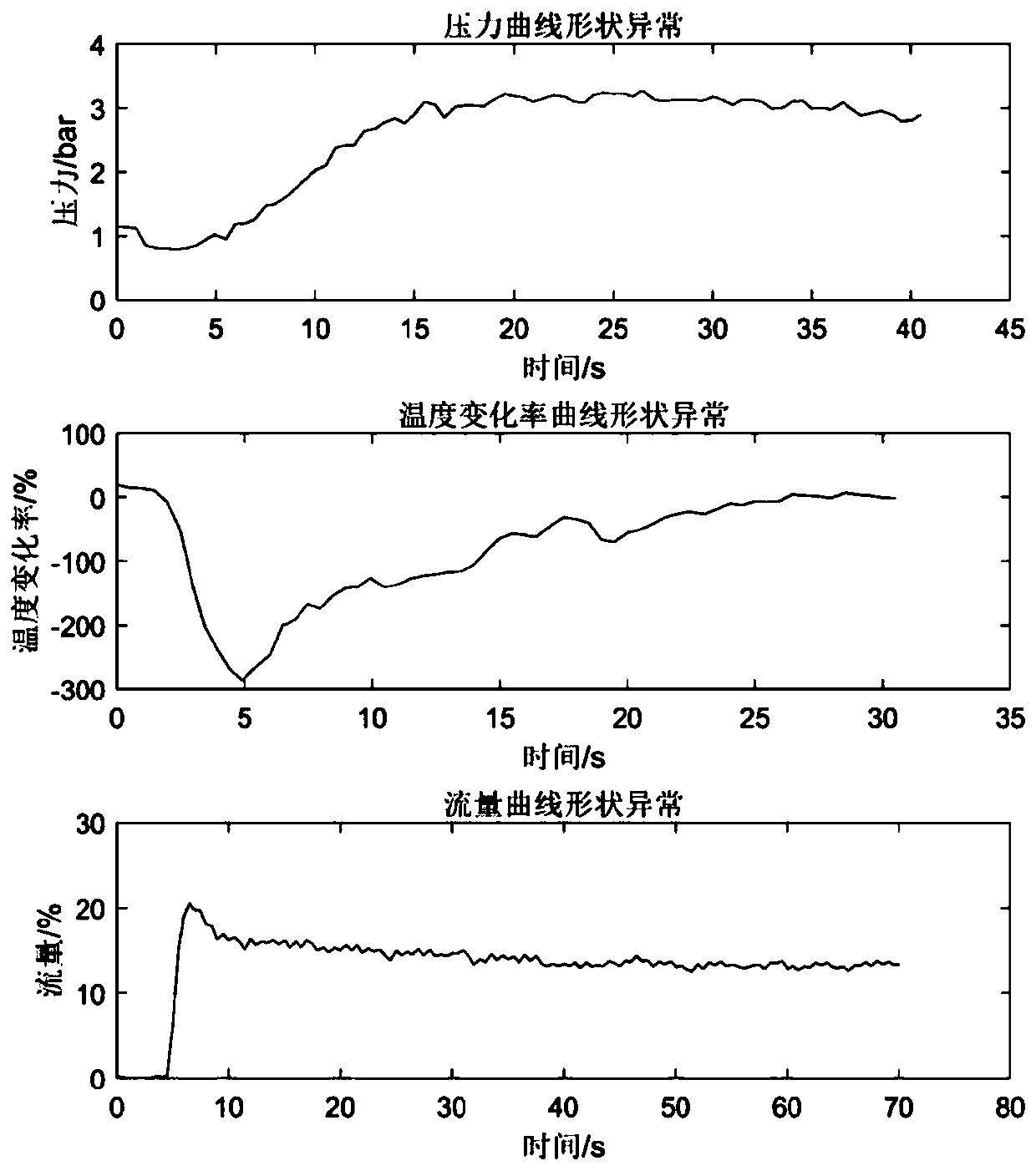

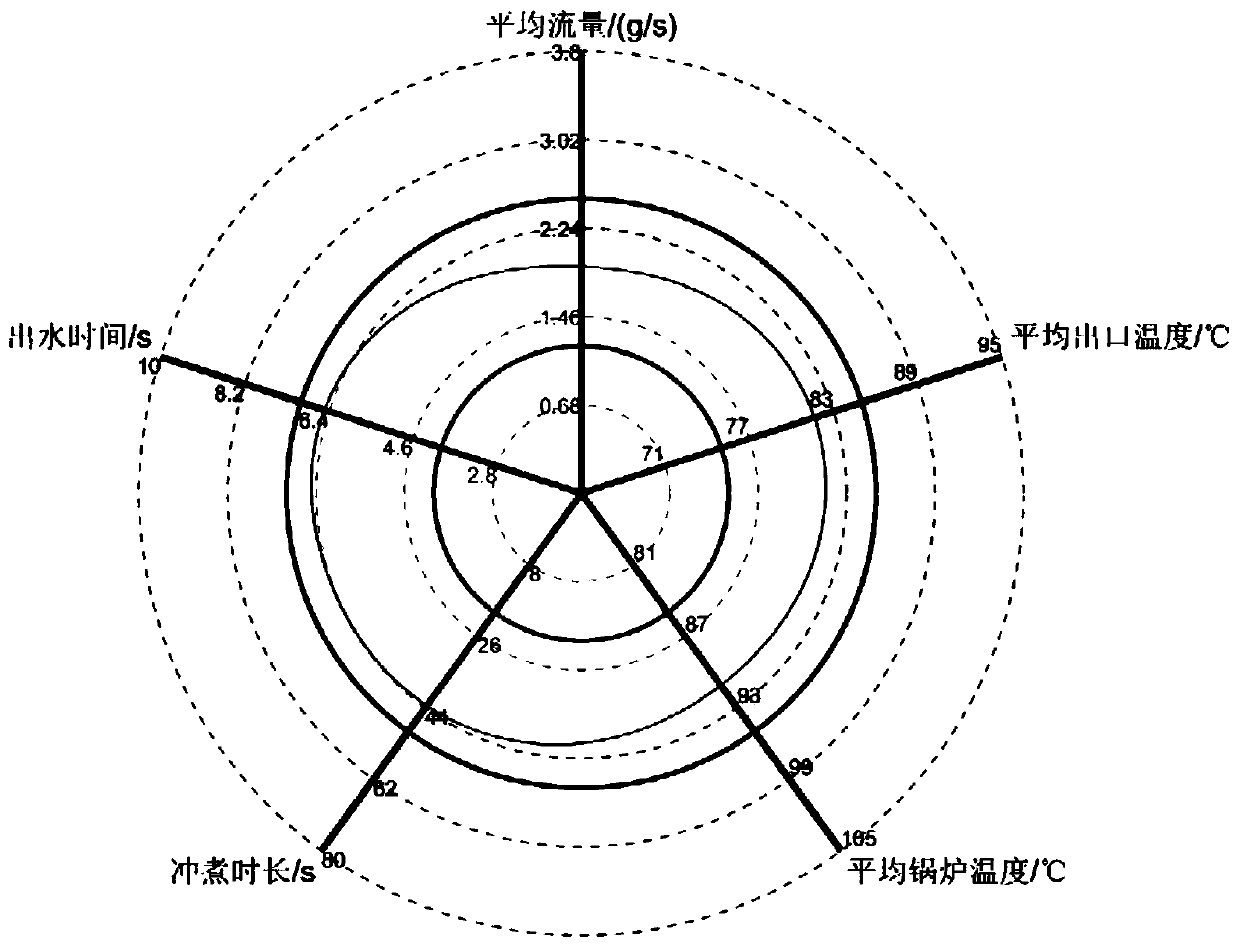

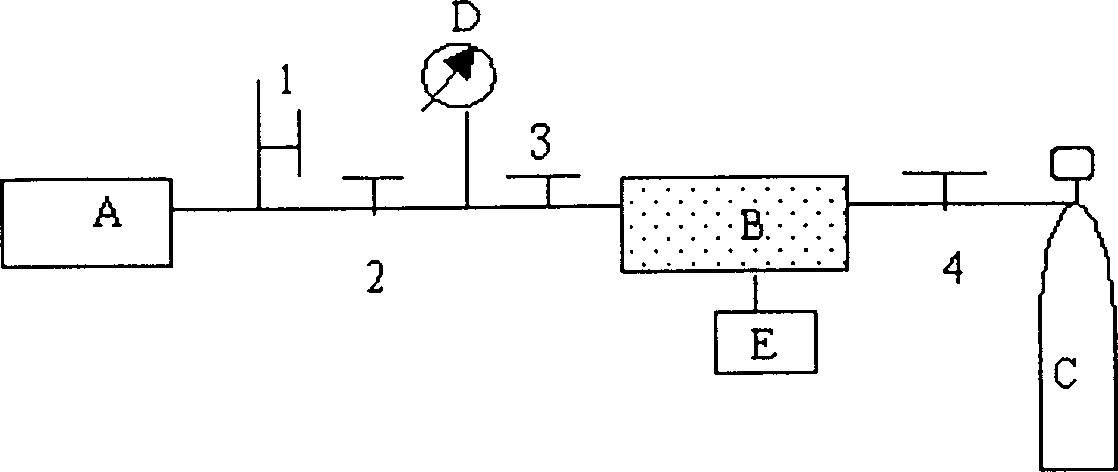

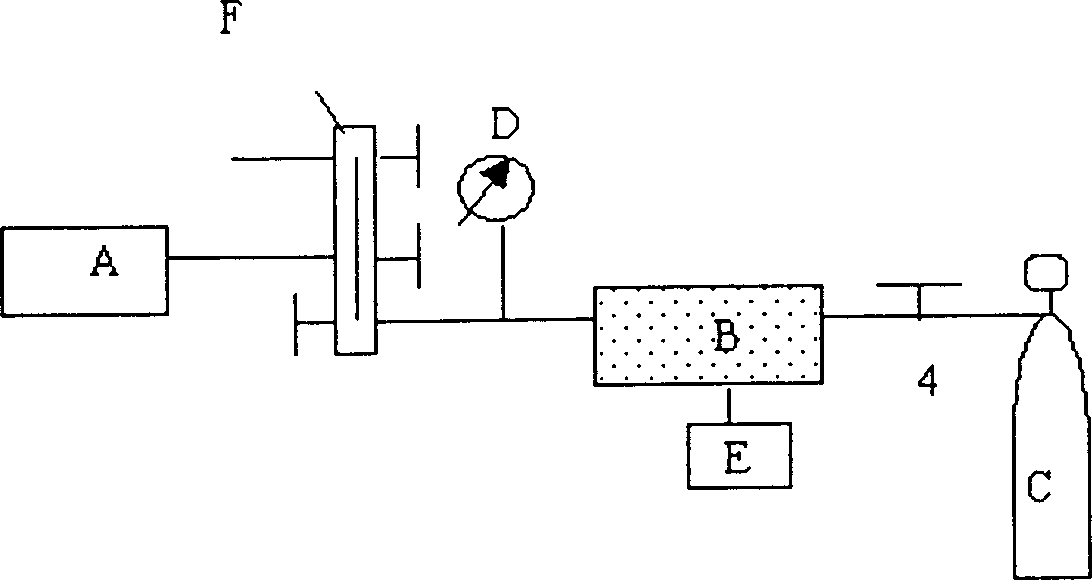

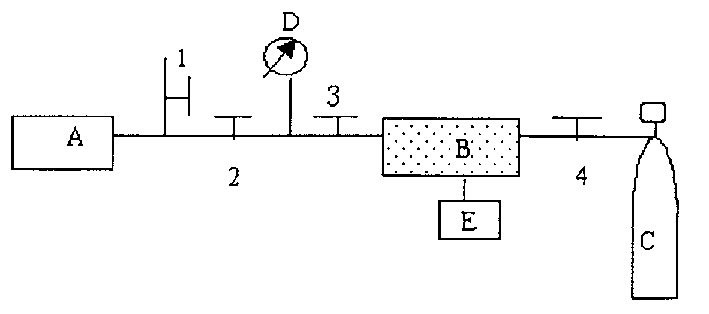

Soft-measurement method of quality of espresso coffee

The invention discloses a soft-measurement method of quality of espresso coffee. A sensing information measurement system is built on a coffee machine. The sensing information measurement system includes a weighing module, a thermal resistor, a thermocouple, a pressure gauge and a vision sensor. The thermal resistor is used to measure temperature of an outer wall of a boiler. The thermocouple is used to measure temperature of coffee liquid of an outlet of the coffee machine. The pressure gauge measures pressure of the outlet of the pump. The visual sensor is used to obtain color information ofthe coffee liquid of the outlet. Sensor information is processed, and indexes of average boiler temperature, average outlet temperature, time in which the outlet temperature reaches a stable state, water discharging time, brewing-boiling duration, average pressure, an average flow rate, time in which a flow rate reaches a stable state, coffee outlet color changes and the like are calculated. Upper / lower-limit reference ranges of the indexes are determined through historical statistics of the coffee sensor information and a coffee extraction process mechanism. A priori statistical knowledge iscombined for soft measurements on the quality of the espresso coffee, and arbitrariness and empirical dependence of human tasting are eliminated.

Owner:ZHEJIANG UNIV

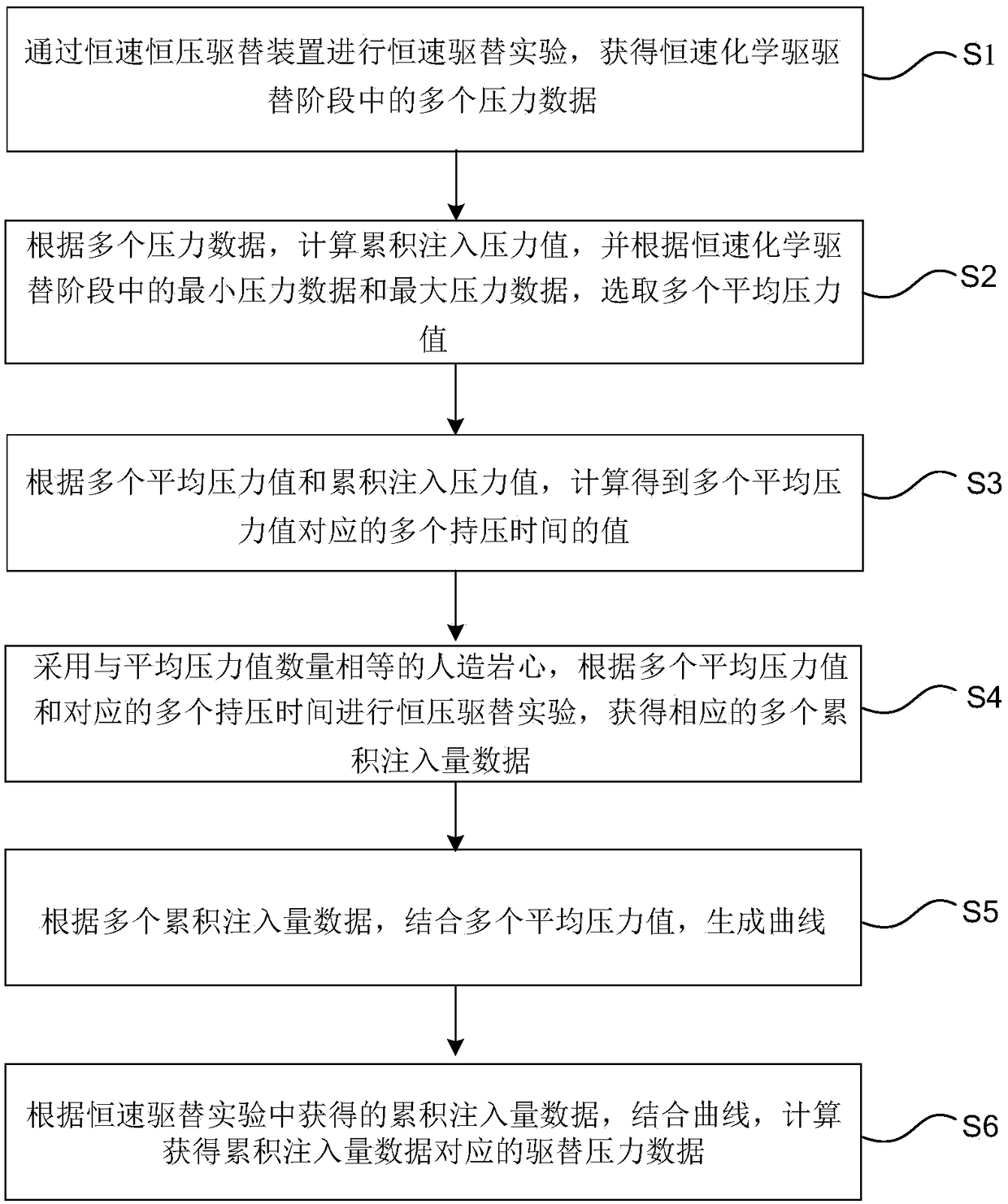

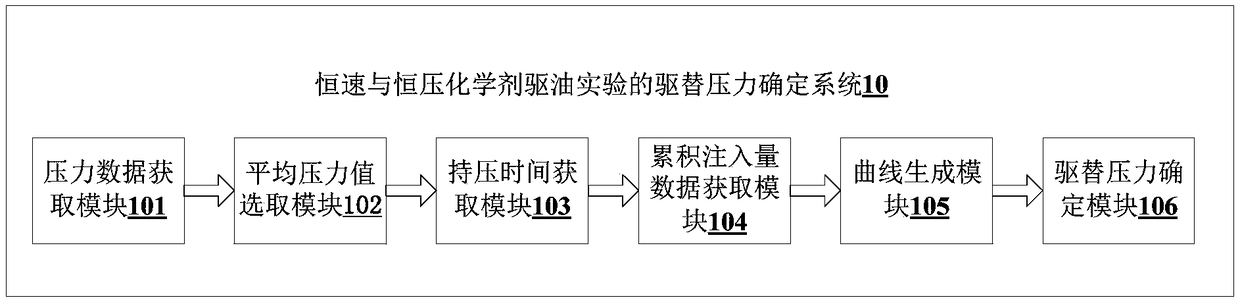

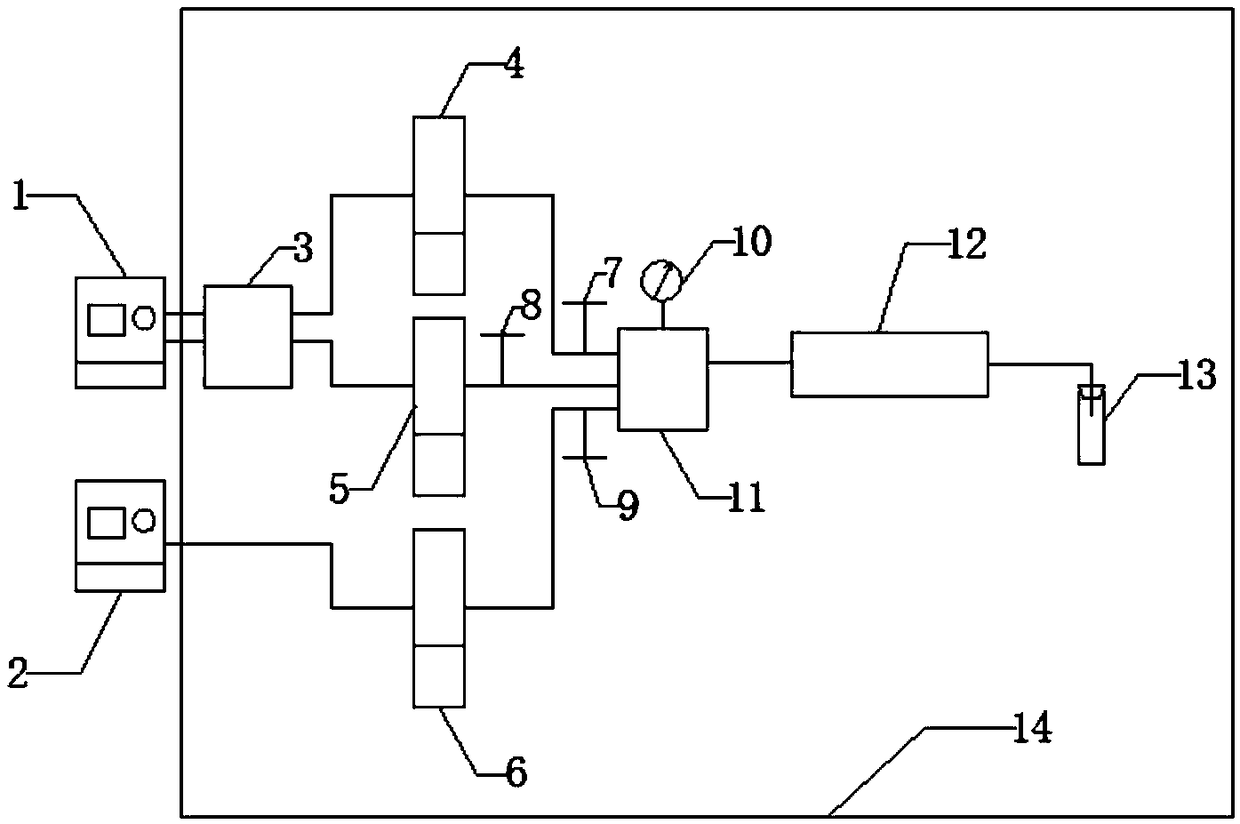

Displacement pressure determination method and system for constant speed and constant pressure chemical flooding oil displacement experiments

The invention provides a displacement pressure determination method and system for constant speed and constant pressure chemical flooding oil displacement experiments, wherein the method comprises the steps: obtaining a plurality of pressure data in a constant speed chemical flooding displacement stage, calculating a cumulative injection pressure value, selecting a plurality of average pressure values according to minimum pressure data and maximum pressure data, calculating to obtain a plurality of pressure holding times corresponding to the plurality of average pressure values, then carrying out a constant pressure displacement experiment, to obtain a plurality of corresponding cumulative injection amount data, combining with the plurality of average pressure values, and generating a curve; and according to the cumulative injection amount data obtained in a constant speed displacement experiment, combining with the curve, and calculating to obtain displacement pressure data. According to the displacement pressure determination method and system for the constant speed and constant pressure chemical flooding oil displacement experiments, through the constant speed and constant pressure experiments, the displacement pressure suitable for the constant pressure displacement experiment is obtained. Under the condition of a certain cumulative injection amount, the results of the constant speed and constant pressure experiments can be compared and transformed effectively, so as to play a guiding role in mine field practice.

Owner:NORTHEAST GASOLINEEUM UNIV

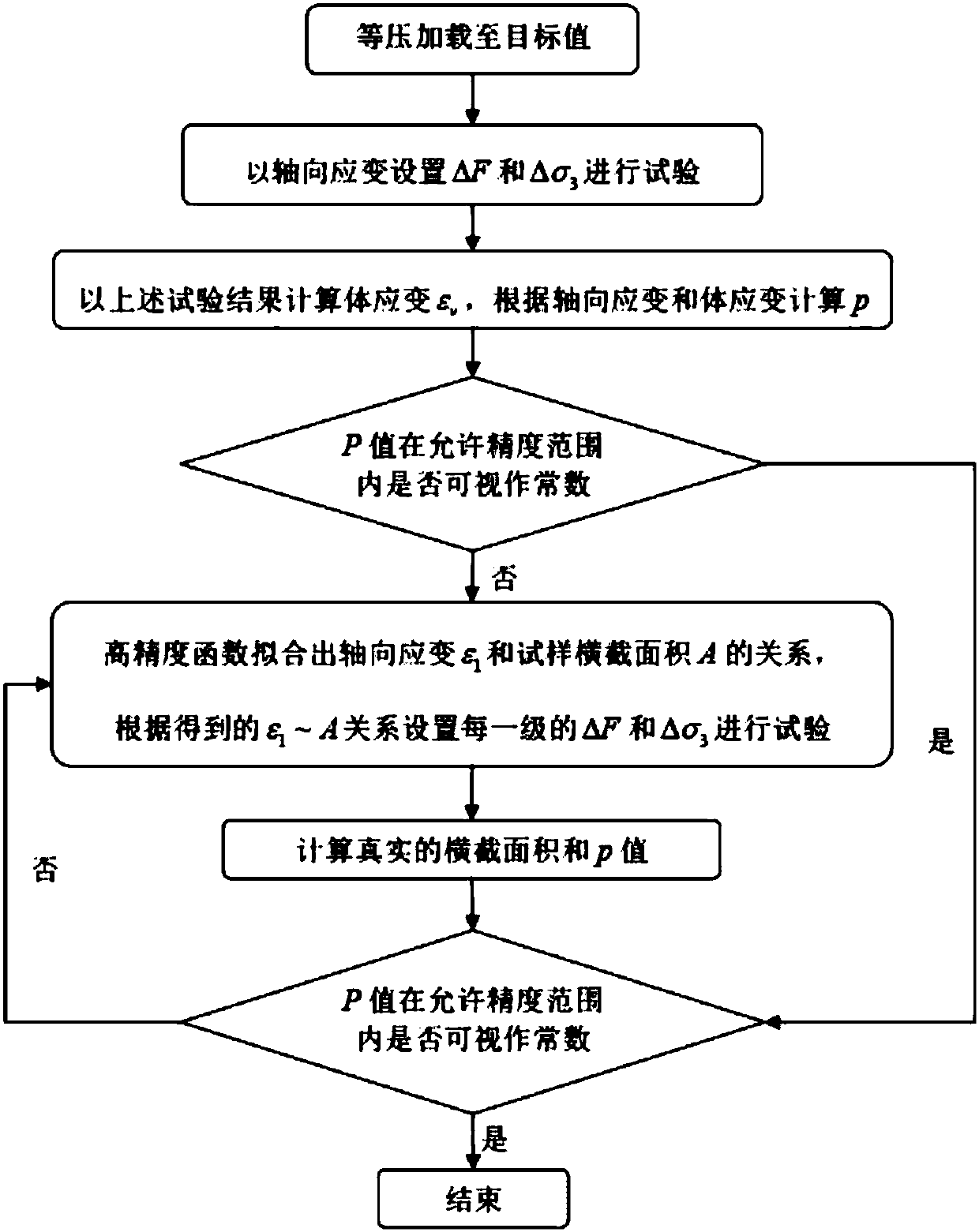

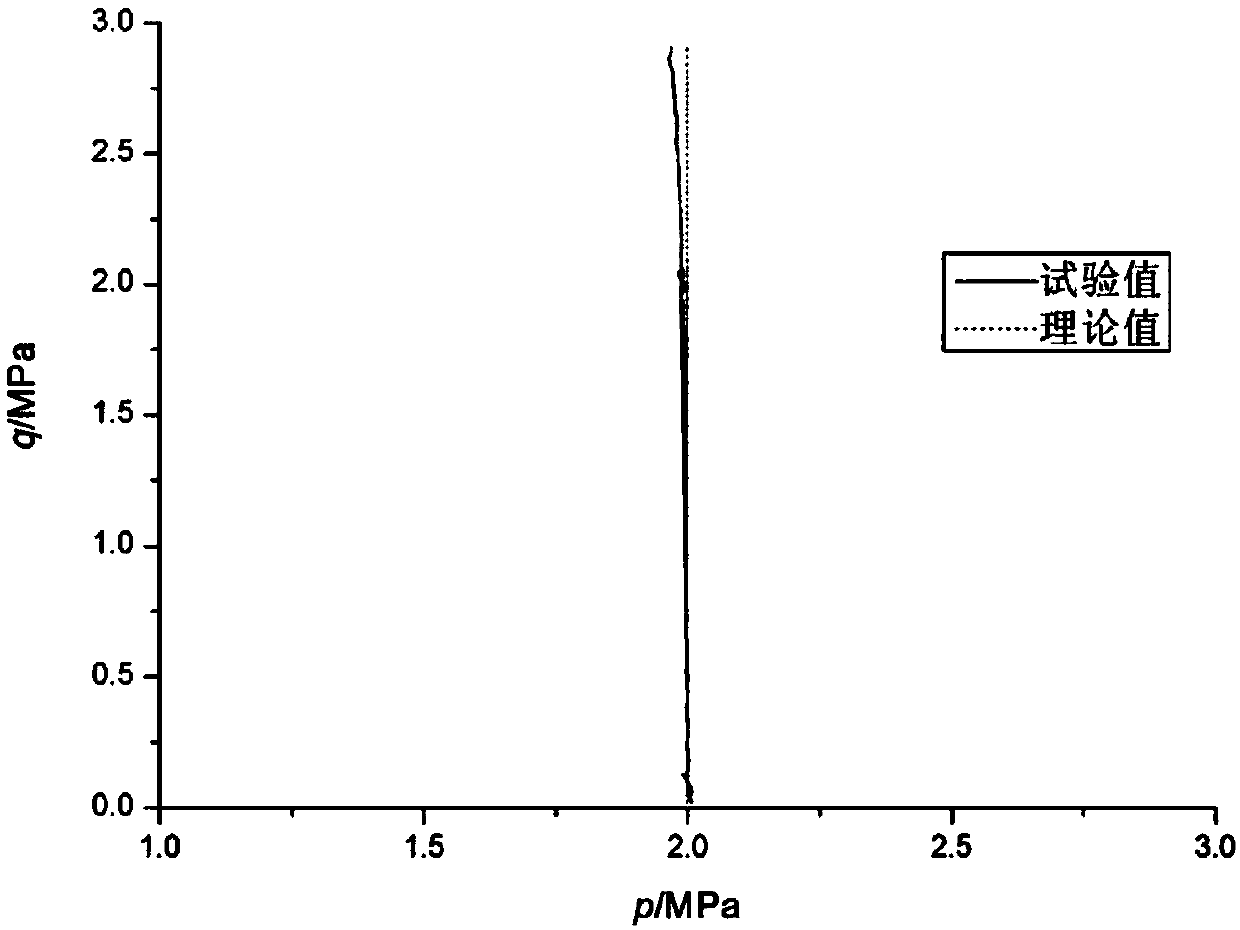

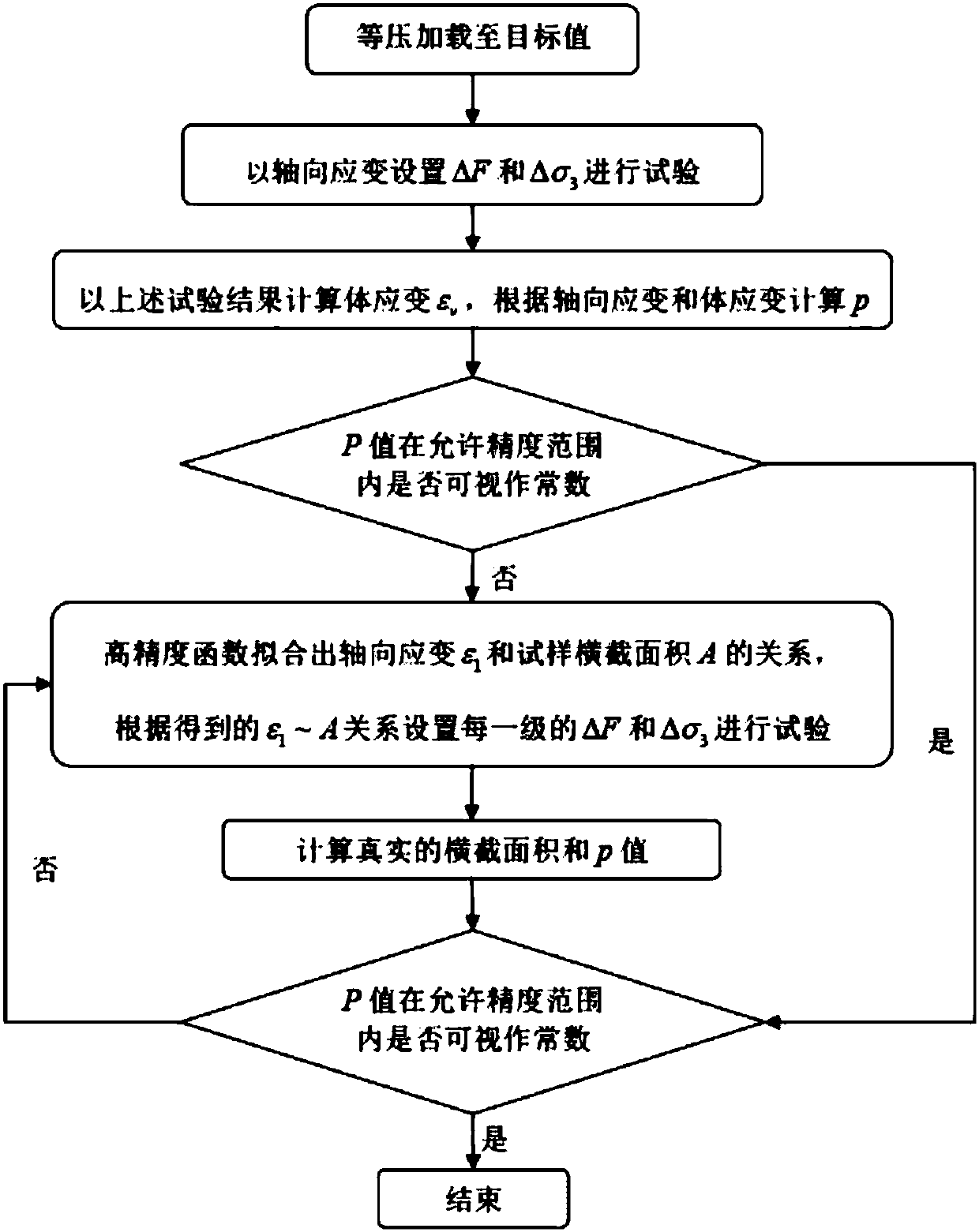

High-precision frozen soil p-equaling-constant test method

InactiveCN109959563AHigh precisionTo fill the vacancy that has not yet been carried outMaterial strength using tensile/compressive forcesAxial forceMean stress

The invention discloses a high-precision frozen soil p-equaling-constant test method, which comprises the following steps: a) putting a frozen soil sample into a low-temperature tri-axial apparatus pressure chamber, and realizing consolidation under a given confining pressure; b) calculating correction area based on axial strain to set each stage of axial force, realizing approximate p-equaling-constant test, calculating volumetric strain after finishing loading, calculating correction area based on the axial strain and the volumetric strain and obtaining an actual mean stress p; c) checking whether the p obtained in the step b) is a constant within a permissible range of accuracy, if so, ending the test, or otherwise, carrying out fitting to obtain a relation between the axial strain epsilon1 and the sample cross-sectional area A through a high-precision function; and d) according to the epsilon1-A relation obtained in the step c), setting each stage of axial force and confining pressure and carrying out p-equaling-constant test, after finishing the test, calculating true cross-sectional area and p, and if the p can be regarded as a constant within the permissible range of accuracy, judging that the test is the p-equaling-constant test, or otherwise, carrying out p-equaling-constant test again according to a new epsilon1-A relation, and repeating iteratively until the obtainedp can be regarded as a constant.

Owner:国网内蒙古东部电力有限公司经济技术研究院 +3

A Method for Predicting the Fatigue Life of Solder Joints

InactiveCN104573392BImprove efficiencyConform to the physical geometrySpecial data processing applicationsElement modelRegression analysis

The invention relates to a spot-weld fatigue life predicting method. The spot-weld fatigue life predicting method includes steps of 1, modeling a full vehicle and establishing a modularized spot-weld finite element model; 2, deducing spot-weld fatigue life evaluation parameter, mean stress strength factor; 3, subjecting spot-welded joints of different materials to systematic fatigue test, and subjecting the mean stress strength factor and fatigue test data of the spot-welded joints of different materials to regression analysis to obtain a curve of the spot-welded joints of different materials. The spot-weld fatigue life predicting method adopts the modularized spot-weld model to predict the spot-weld fatigue life, in actual application, only nodes of a border unit of the modularized spot-weld model are superposed with nodes of a welding structure unit, and spot-weld modeling efficiency in the full-vehicle modeling is improved.

Owner:HUNAN UNIV

Method and system for determining displacement pressure in constant-rate and constant-pressure chemical flooding experiments

The present invention provides a displacement pressure determination method and system for constant-rate and constant-pressure chemical flooding experiments. The method is: obtain multiple pressure data in the constant-rate chemical flooding stage, calculate the cumulative injection pressure value, and According to the minimum pressure data and maximum pressure data, select multiple average pressure values, and calculate multiple pressure holding times corresponding to multiple average pressure values, and then conduct constant pressure displacement experiments to obtain corresponding multiple cumulative injection data. Combine multiple average pressure values to generate a curve; according to the cumulative injection data obtained in the constant-rate displacement experiment, combine the curves to calculate the displacement pressure data. The method and system for determining the displacement pressure of the constant speed and constant pressure chemical flooding experiment of the present invention can obtain the displacement pressure suitable for the constant pressure displacement experiment through the constant speed and constant pressure experiment. Under the condition of a certain cumulative injection volume, the results of constant velocity and constant pressure experiments can be effectively compared and transformed, and then play a guiding role in mine practice.

Owner:NORTHEAST GASOLINEEUM UNIV

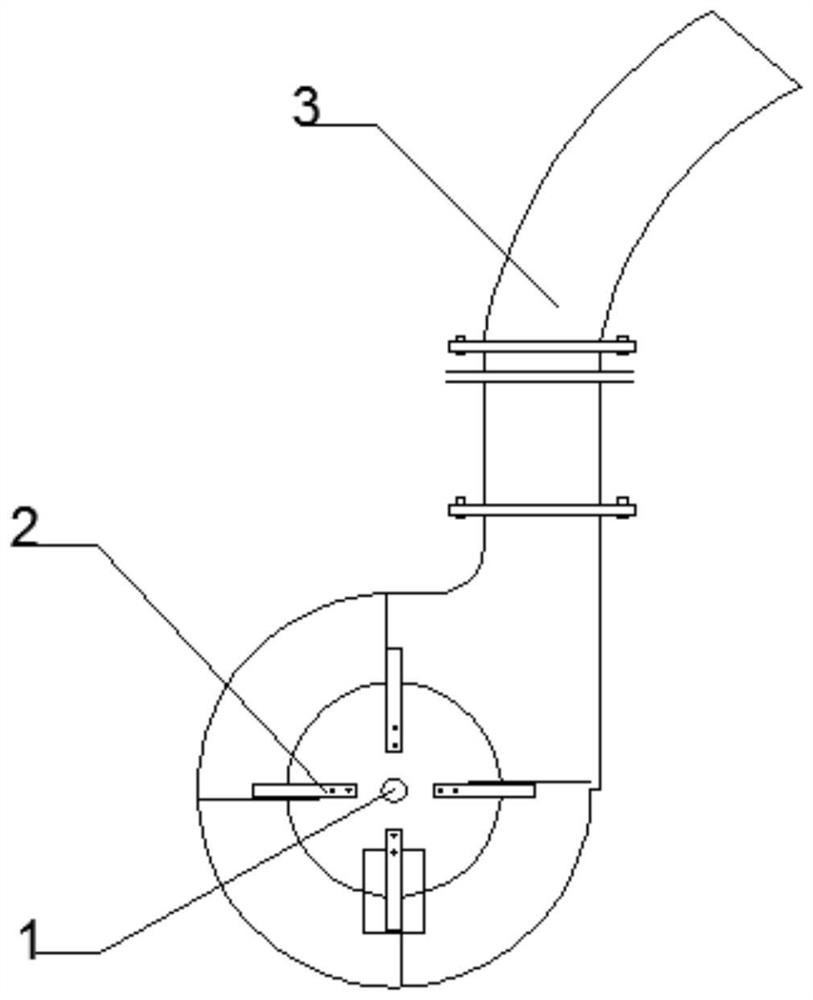

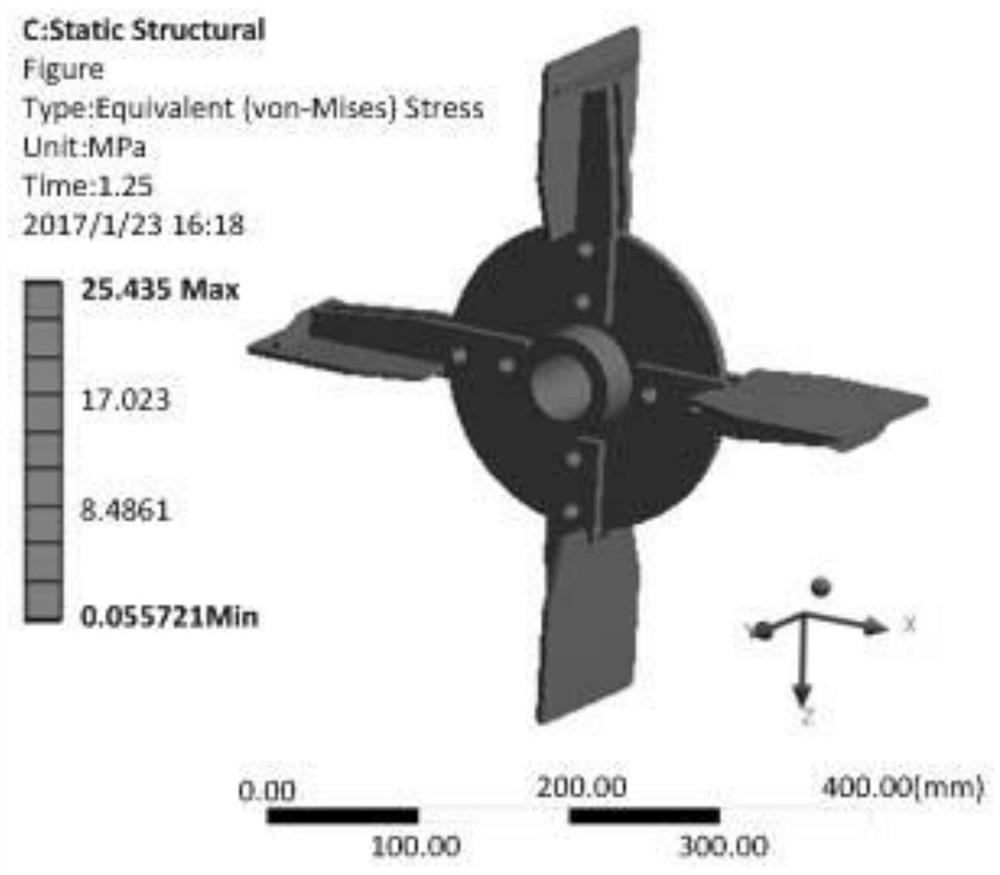

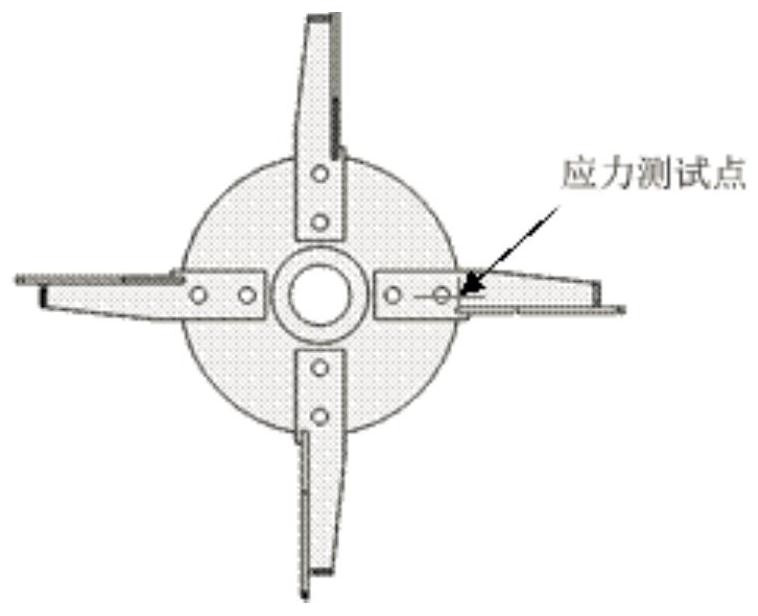

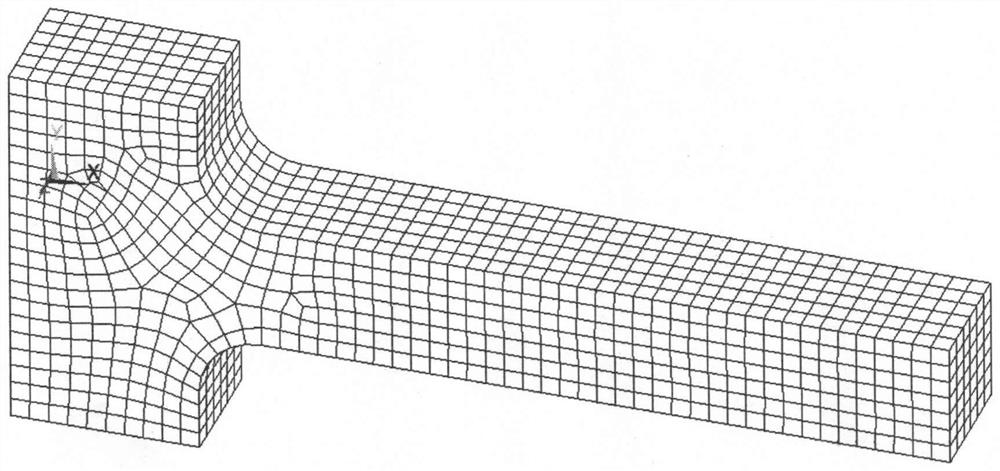

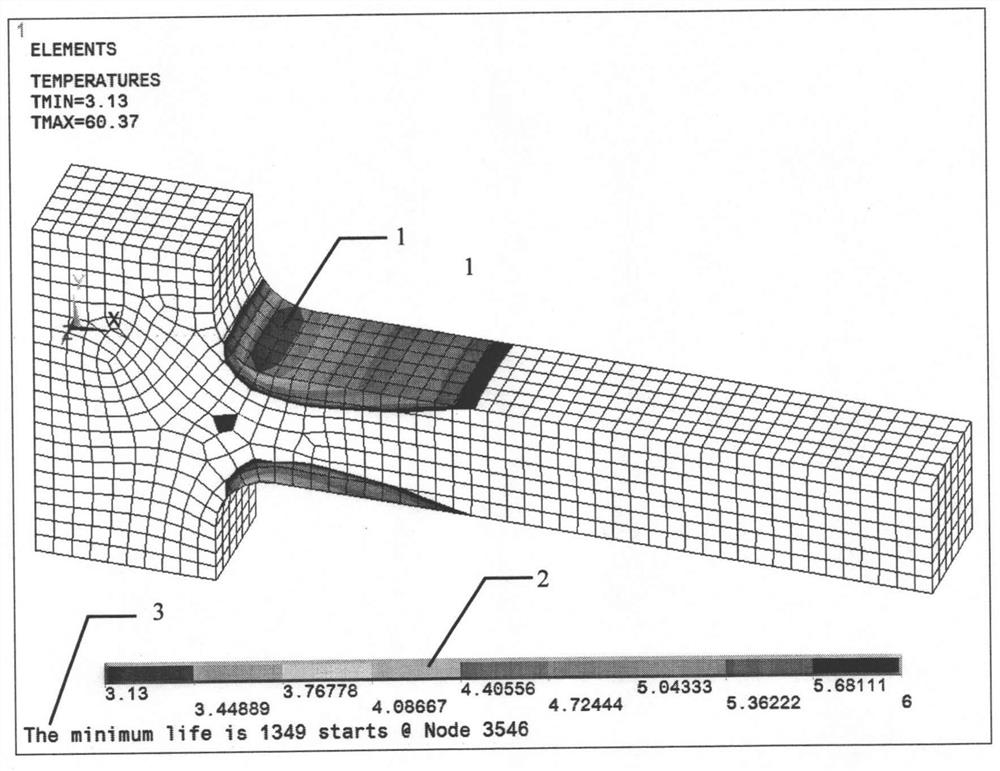

A Method for Predicting the Fatigue Life of Straw Throwing Impeller

ActiveCN108829917BReasonable designHigh precisionGeometric CADDesign optimisation/simulationFluid solid couplingMean stress

Owner:INNER MONGOLIA UNIV OF TECH

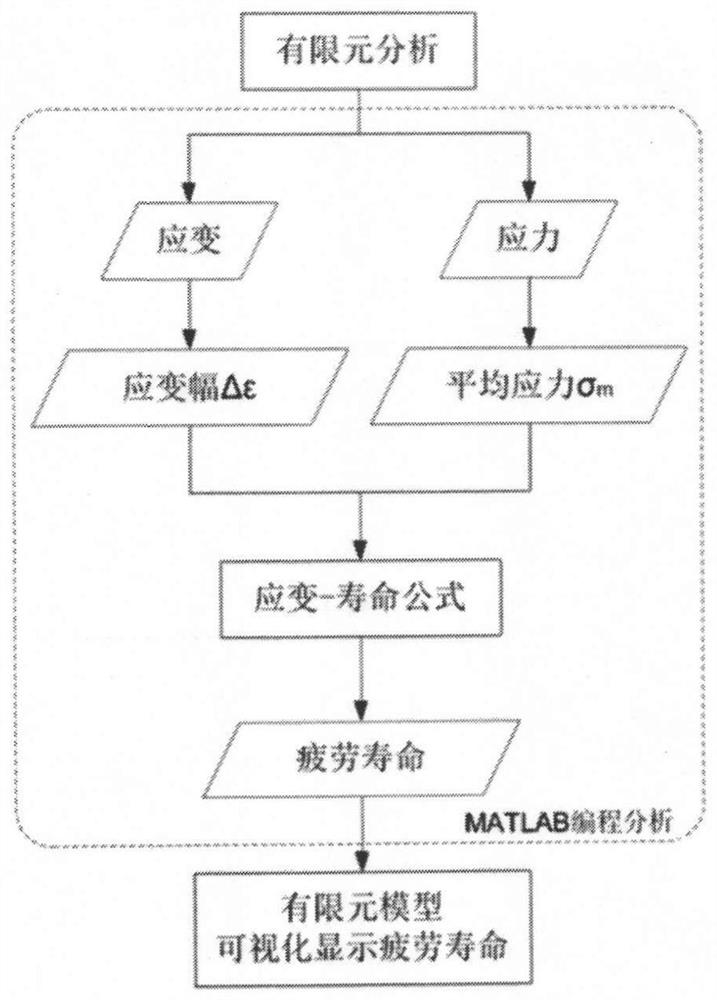

A low-cycle fatigue life analysis method for generator structures

ActiveCN108228979BAccurate calculationEasy to operateDesign optimisation/simulationSpecial data processing applicationsPrincipal stressClassical mechanics

The invention provides a low-cycle fatigue life analysis method for a generator structure, which is characterized by comprising: Step 1: input the cyclic stress-strain curve of the material into a finite element numerical simulation model of the generator structure, and derive the generator Strain components at rated conditions, strain components at rest conditions, equivalent stresses at rated conditions, equivalent stresses at rest conditions, first principal stress and third principal stress at all nodes of the structure; steps 2: Calculate the strain amplitude and mean stress; Step 3: Calculate the low-cycle fatigue life N of the generator structure at any node. The invention provides a low-cycle fatigue life analysis method for generator structures, which is suitable for various generator structures, has accurate calculation, simple operation, and can realize the standardization of calculation methods and processes.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

A Soft Measurement Method for Espresso Quality

The invention discloses a soft-measurement method of quality of espresso coffee. A sensing information measurement system is built on a coffee machine. The sensing information measurement system includes a weighing module, a thermal resistor, a thermocouple, a pressure gauge and a vision sensor. The thermal resistor is used to measure temperature of an outer wall of a boiler. The thermocouple is used to measure temperature of coffee liquid of an outlet of the coffee machine. The pressure gauge measures pressure of the outlet of the pump. The visual sensor is used to obtain color information ofthe coffee liquid of the outlet. Sensor information is processed, and indexes of average boiler temperature, average outlet temperature, time in which the outlet temperature reaches a stable state, water discharging time, brewing-boiling duration, average pressure, an average flow rate, time in which a flow rate reaches a stable state, coffee outlet color changes and the like are calculated. Upper / lower-limit reference ranges of the indexes are determined through historical statistics of the coffee sensor information and a coffee extraction process mechanism. A priori statistical knowledge iscombined for soft measurements on the quality of the espresso coffee, and arbitrariness and empirical dependence of human tasting are eliminated.

Owner:ZHEJIANG UNIV

Method for determining compact rock porosity

InactiveCN1226608CSmall dead volumeHigh measurement accuracyPermeability/surface area analysisPorosityMeasurement device

The invention discloses a method for measuring thickening rock hole gap rate. It at least includes: puts the sample into the measuring instrument, presses with confining pressure pump; presses the high pressure room; measures the pressure value of high pressure room; measures the pressure value of low pressure room; connects the low pressure room and the high pressure room, and measures the even pressure value; calculates the hole gap volume of the sample, measures and calculates the vision volume of the sample, gets the rock sample hole gap rate.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

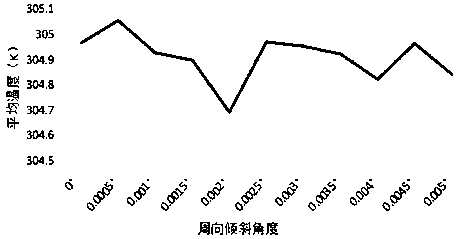

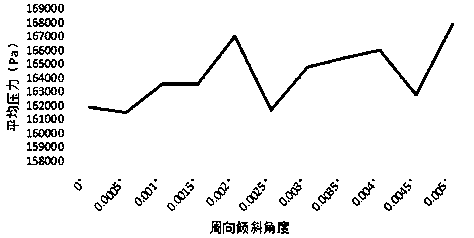

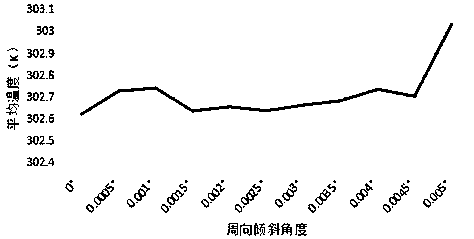

Optimal circumferential inclination angle determination method influencing lubricating performance of static and dynamic pressure oil pad

InactiveCN110046449AGood circumferential inclinationImprove the lubrication effectGeometric CADDesign optimisation/simulationPressure curveTemperature curve

The invention relates to a research on the influence of the circumferential inclination angle of a new static pressure mixing hydrostatic support structure on the lubricating performance under different loads, so as to better realize the dynamic and static pressure mixing lubrication, to achieve the effect of preventing friction failure and ensuring the high speed and heavy static pressure, and high-precision stable operation of high-speed heavy-load hydrostatic bearing is ensured. The methjod comprises: comprehensively considering and analyzing influence of a temperature field, a pressure field and a flow field to obtain the optimal circumferential inclination angle of the oil pad under different extreme working conditions when the lubricating performance is optimal; Under the extreme working conditions of no load and 12t load, through oil film pressure fields with different circumferential inclination angles of the static and dynamic pressure oil pad, temperature fields and flow fields, generating an average temperature curve and an average pressure curve for comparative analysis; obtaining circumferential inclination angle to be 0.002 degrees when the extreme working conditionis no-load, and when the extreme working condition is 12t, and the circumferential inclination angle is 0.0025 degrees, the average temperature of the system being the lowest, the average pressure being the highest, the number of times of shearing oil particles in a flow field being the lowest, and the comprehensive lubricating performance being the best; and finally, analyzing the circumferentialinclination angle under other extreme working conditions when the lubricating property is optimal through the method.

Owner:HARBIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com