Paste pipeline transportation flow measuring method

A technology for flow measurement and pipeline transportation, which is applied in the field of measurement of coal mine paste filling pipeline transportation flow, and can solve problems such as difficult operation, unsuitable for industrial applications, and restrictions on the application of radioactive particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] With the massive mining of coal mines by humans, most of the ground below the surface is hollow, and the paste filling process has emerged. As for the measurement of the flow rate of the coal mine paste filling pipeline, the accuracy of the measurement results is related to the normal operation of the filling, and plays an important role in ensuring the normal operation of the paste filling.

[0051] With the development of modern science and technology, the requirements of enterprises for the degree of automatic control of the production system are constantly increasing. best operating plan.

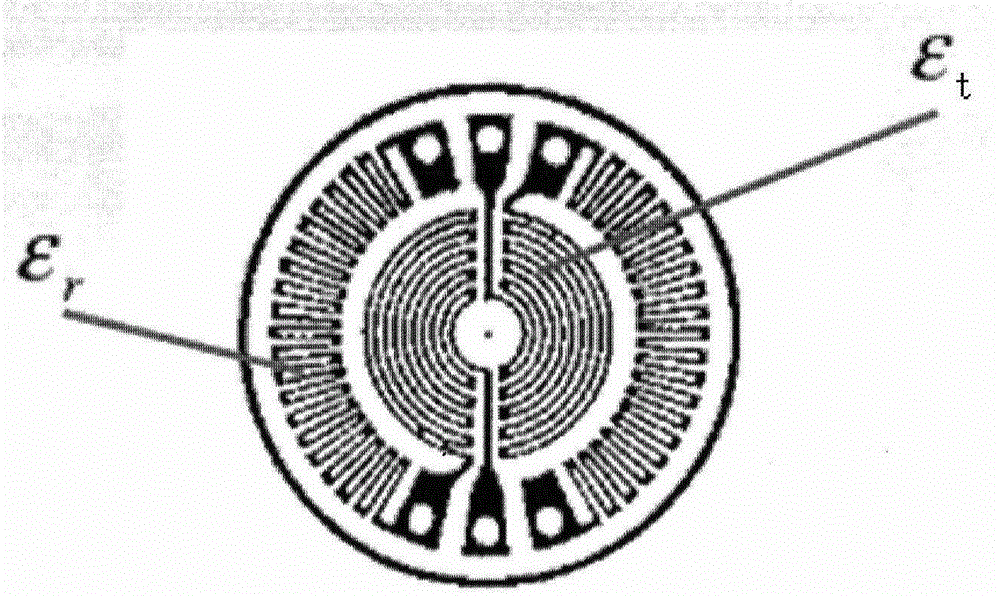

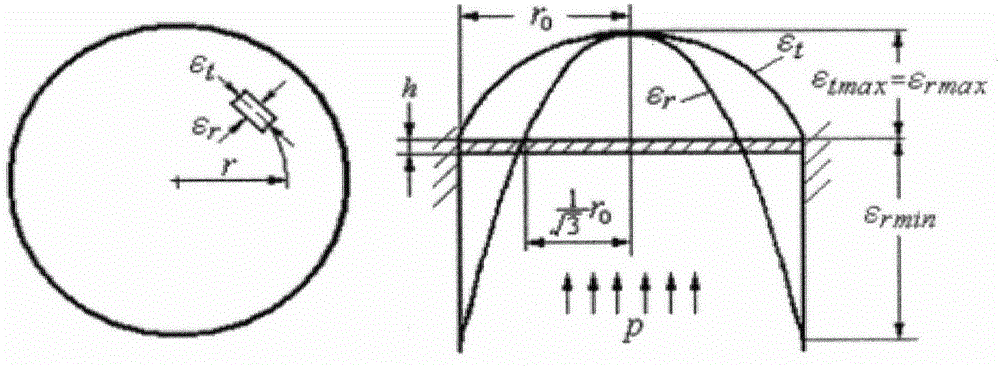

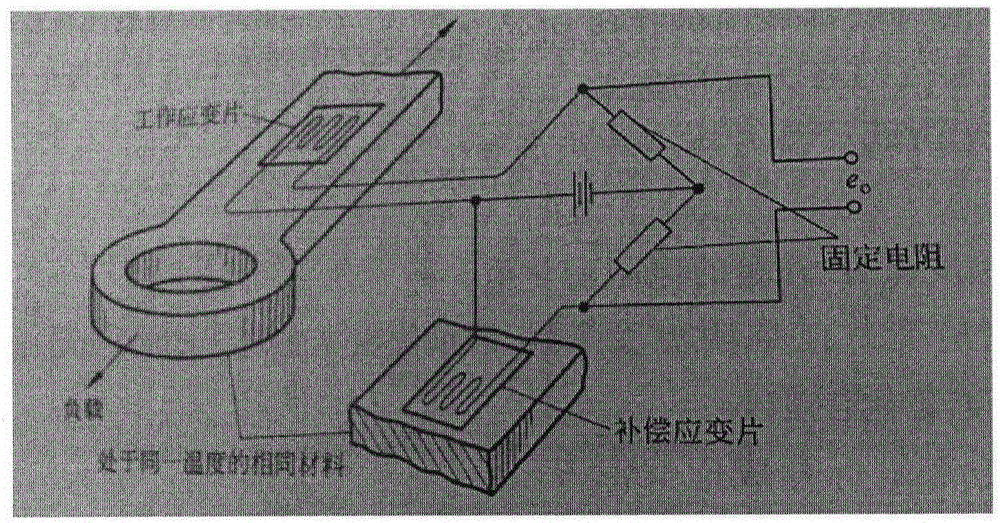

[0052] Since it is necessary to detect the pressure difference between the two cross-sections of the pipeline, it is necessary to paste the strain gauges on the two positions of the measuring pipeline, and respectively paste them in the four directions of the upper, lower, left, and right sides of the two positions, and the obtained data are averaged as The pressure value for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com