Spot-weld fatigue life predicting method

A fatigue life prediction and fatigue life technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of low prediction accuracy, low modeling and calculation efficiency, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

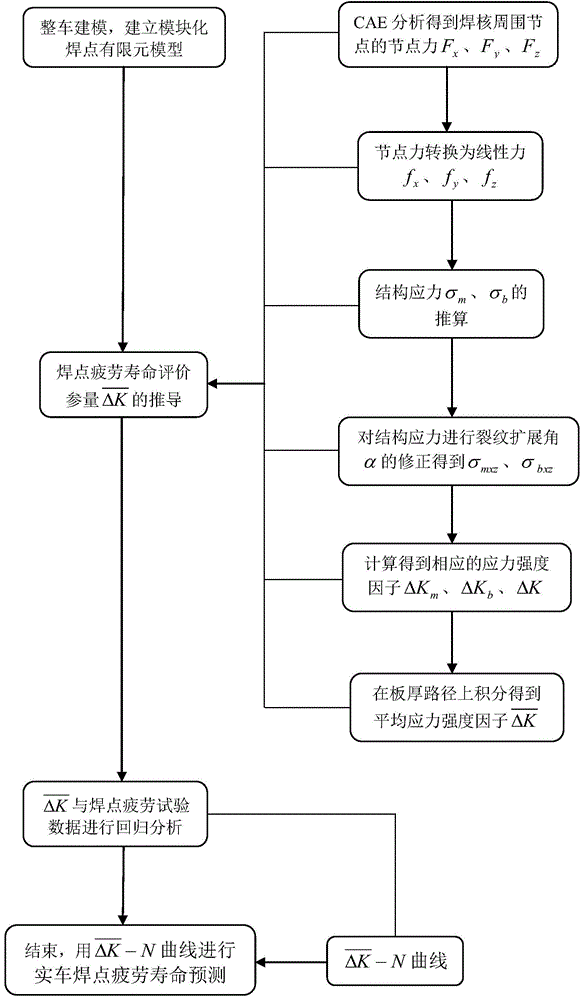

[0042] The following will be combined with Figure 1-9 The technical scheme of the present invention is described in detail

[0043] The invention provides a method for predicting the fatigue life of solder joints, comprising the following steps:

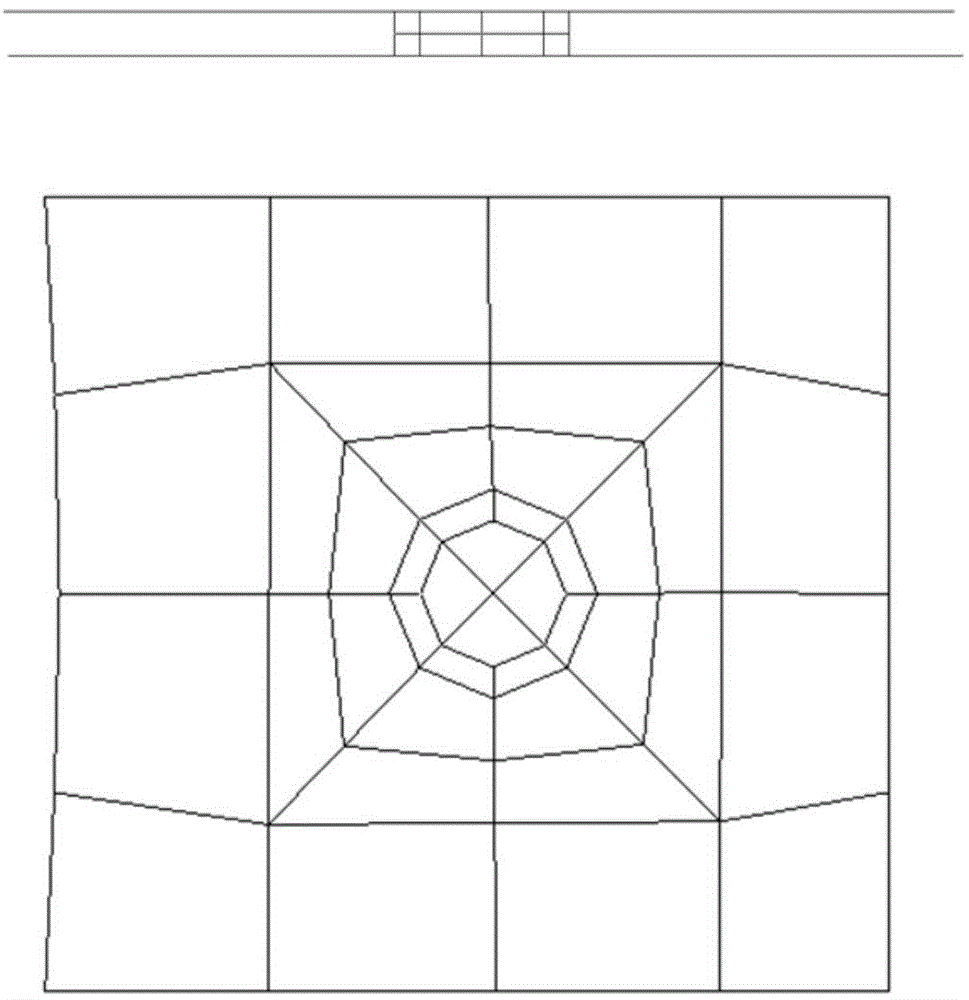

[0044] Step 1. Model the whole vehicle and establish the finite element model of modular solder joints

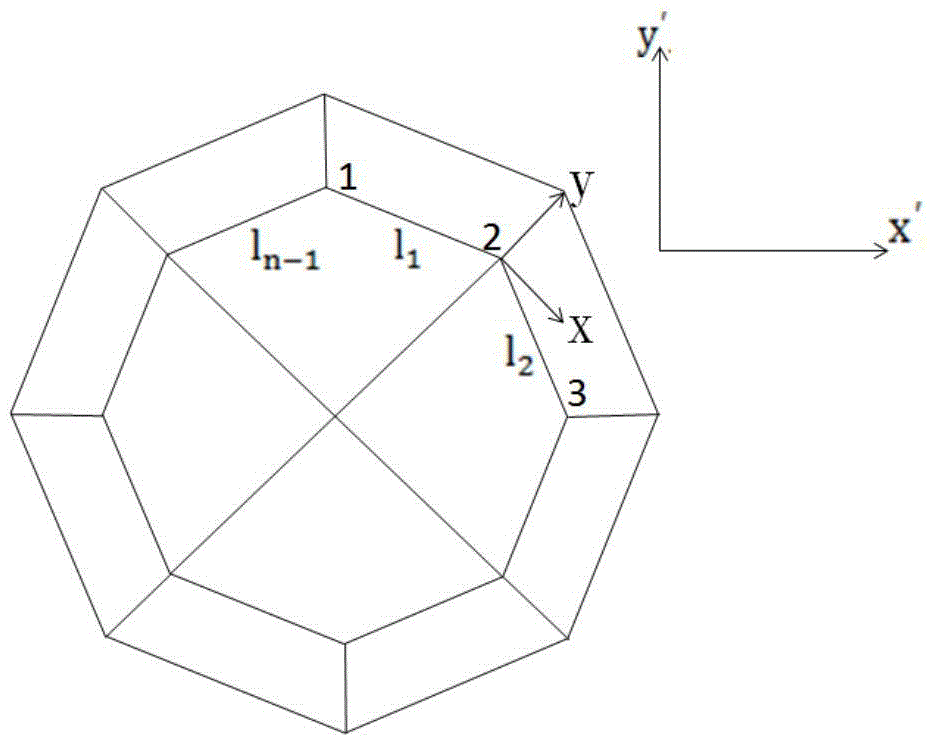

[0045] In vehicle modeling, the established modular solder joint finite element model is as follows: figure 2 As shown, the weld nugget of the solder joint is simulated using two layers of solid elements. In order to solve the problem of matching the finite element model of the solder joint with the structural mesh, each layer is composed of four solid elements to form an equilateral octagon, and the diameter is taken as The actual diameter of the nuclei, the nugget material is assumed to be the same as the parent metal. Then, gradually transition to the basic grid size of 10×10mm through the three-coil shell element.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com