Method for determining compact rock porosity

A technology of tight rock and porosity, applied in the field of rock porosity determination, can solve the problems of inaccurate measurement results, low measurement accuracy, and difficult to find, and achieve the effect of reducing dead volume, improving measurement accuracy, and rapid measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

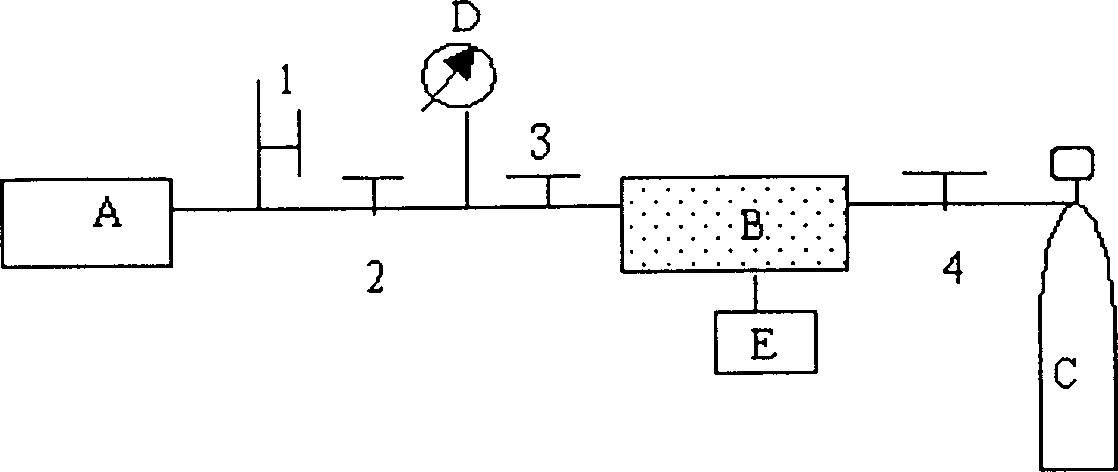

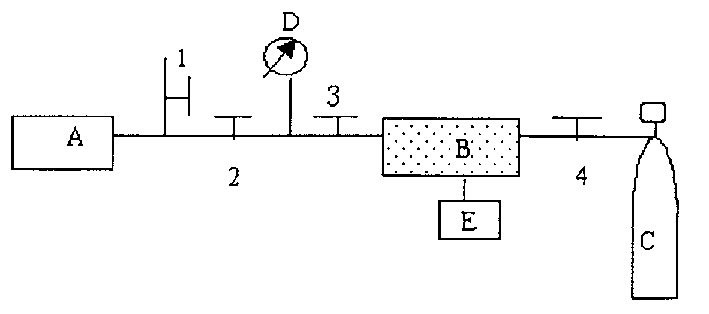

[0039] Such as figure 1 Shown, be the structural representation of embodiment one of the present invention, as can be seen from the figure, A is the standard volume air chamber of known volume (volume 1-8cm 3 ), that is, the low pressure chamber; B is the high pressure chamber, and the rock sample to be tested is placed in the high pressure chamber B, so it can also be called a holder; C is a pressure charging device, which can use a gas source bottle for Pressure chamber B is pressurized; D is a pressure measuring device, and a pressure gauge can be used to measure the air pressure in the high pressure chamber B where the rock samples to be tested are placed under different conditions; E is a confining pressure pump, 1, 2 , 3, 4 are more than one valves arranged on the pipeline, which are used to control the flow direction of the air flow. They are respectively arranged on the pipeline connecting the two adjacent parts of the low pressure chamber A, the pressure measuring de...

Embodiment 2

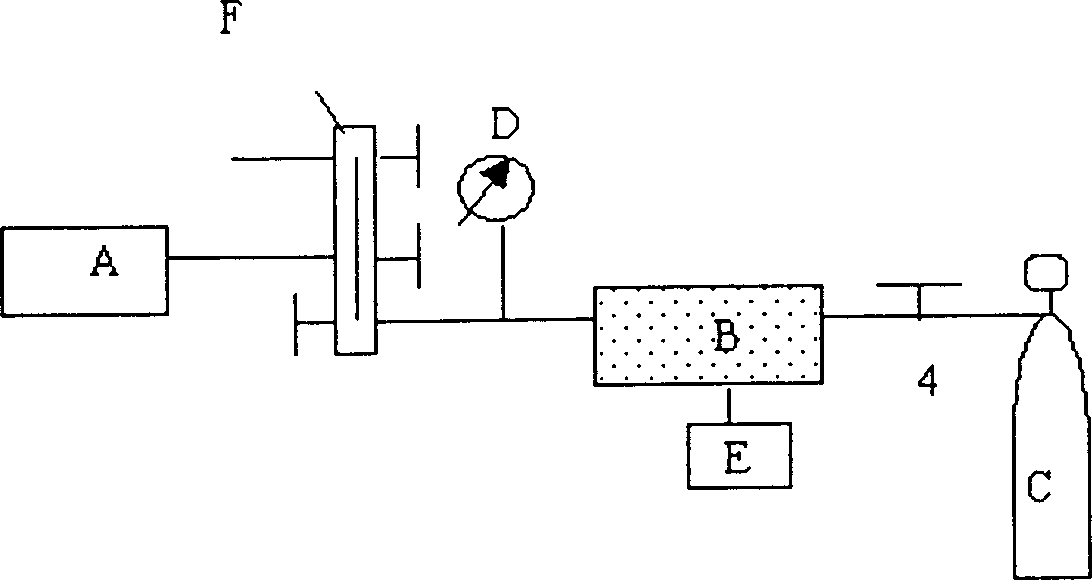

[0059] Such as figure 2 Shown is a schematic structural diagram of Embodiment 2 of the present invention. It can be seen from the figure that the valve F is a multi-way valve combined with the valves 1, 2 and 3 in the first embodiment to realize the multiple functions of the valves 1, 2 and 3 in the first embodiment, and the multi-way valve F and Pressure measuring device (pressure gauge) D connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com