Compressor, motor and stator mechanism thereof

A stator and rotor technology, applied in the field of compression equipment, can solve problems such as easy increase of iron loss, achieve the effect of avoiding deterioration of iron loss, simple and reasonable structural design, and guaranteed performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose of the present invention, technical solutions and advantages clearer, the following examples are combined with Attached picture , the compressor, motor and stator mechanism of the present invention will be further described in detail. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

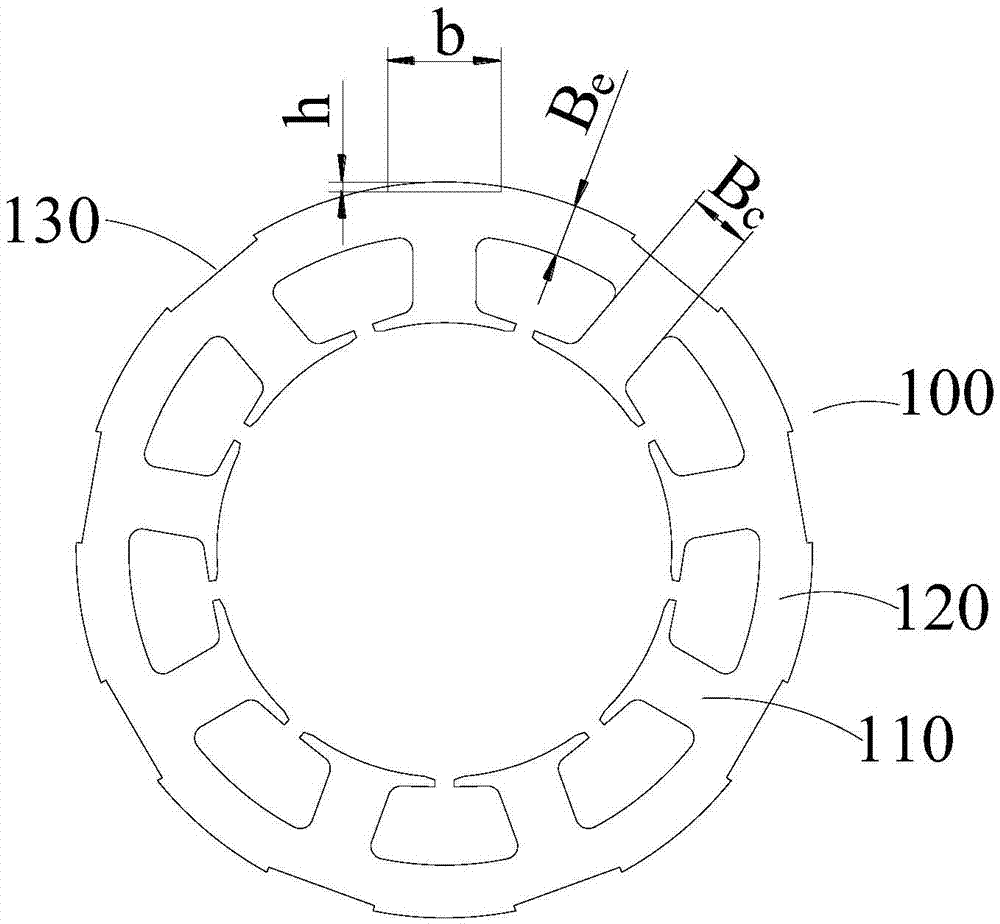

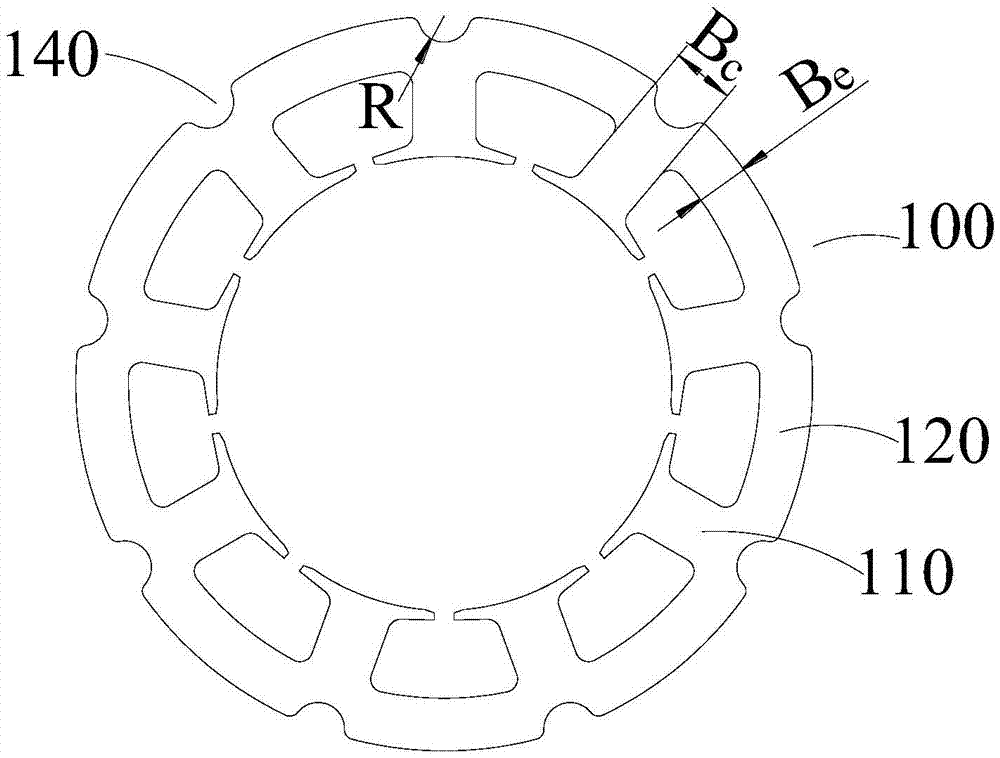

[0031] see picture , the present invention provides a stator mechanism 100 including a plurality of teeth 110 and a plurality of yokes 120 .

[0032] In the present invention, both the teeth 110 and the yoke 120 are punched from silicon steel sheets, the number of teeth 110 is equal to the number of yokes 120, and a plurality of teeth 110 and a plurality of yokes 120 are staggered and connected to form ring structure. That is, one tooth portion 110 is located between two adjacent yoke portions 120, and one yoke portion 120 is located between two adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com