Low-cycle creep and fatigue life evaluation method under conditions of high temperature and multiaxial spectrum load

A fatigue life and fatigue life prediction technology, applied in the field of fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific embodiments of the present invention will be described with reference to the accompanying drawings and calculation examples.

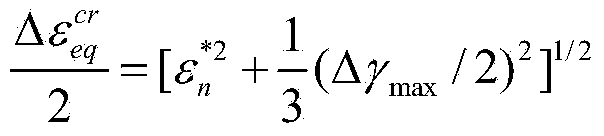

[0047] The damage estimation to be performed in the present invention includes multiaxial fatigue damage estimation and creep damage estimation. According to the damage calculation result, N is the number of load history described by the block load that the part can withstand, which is the predicted fatigue life.

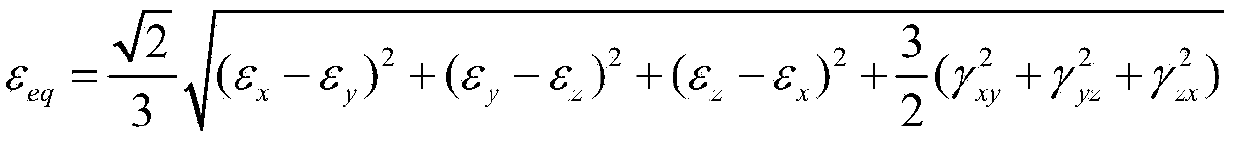

[0048] Step 1): Read the stress-strain history in the load block, and use the Mises criterion to find the equivalent strain ε of each point eq , disconnect the load spectrum from the maximum equivalent strain, and move the load history data before this point to the end of the load history to complete the load arrangement;

[0049] Suppose the fast load history is as follows:

[0050] Table 1 Load History Data

[0051]

[0052] According to the load history, the equivalent strain of each point can be obtained, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com