Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83 results about "Creep fatigue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Creep And Fatigue are the phenomenon that lead to deformation and eventually failure of Components. Fatigue is a situation in which component is subjected to cyclic loading.Design Stress that is Endurance strength used in fatigue loading is much less than Yield strength and ultimate strength of material .

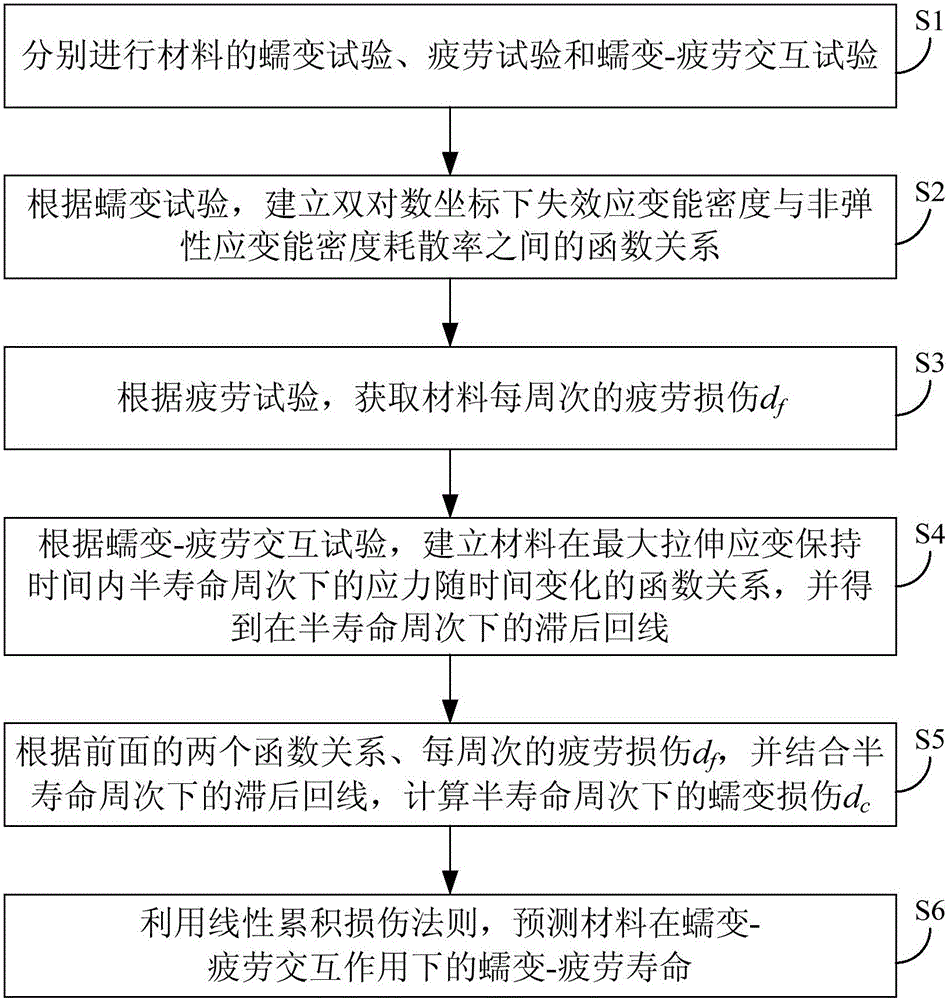

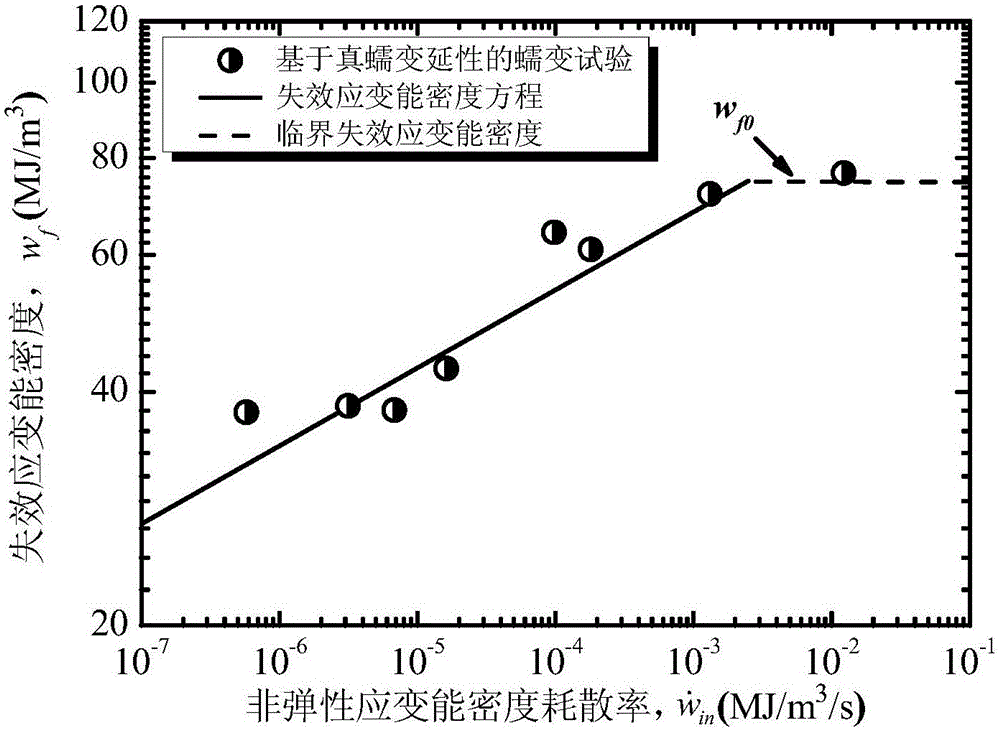

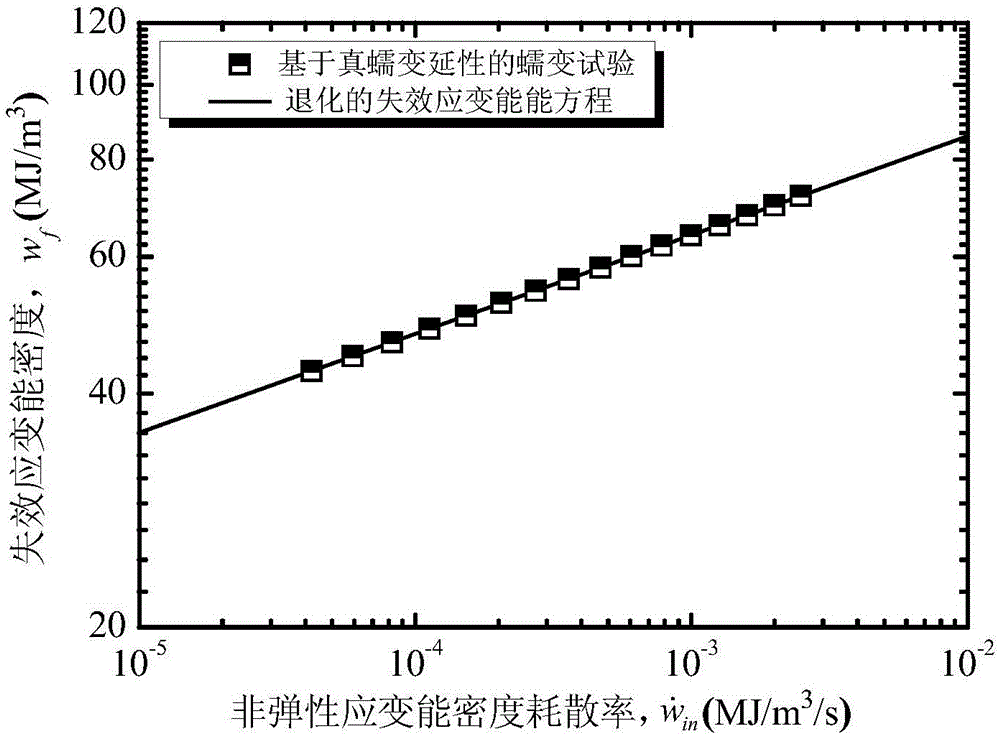

Forecasting method for creep-fatigue life of material

ActiveCN105158084ALife expectancyReal-time Damage DetectionMaterial strength using tensile/compressive forcesFatigue damageHysteresis

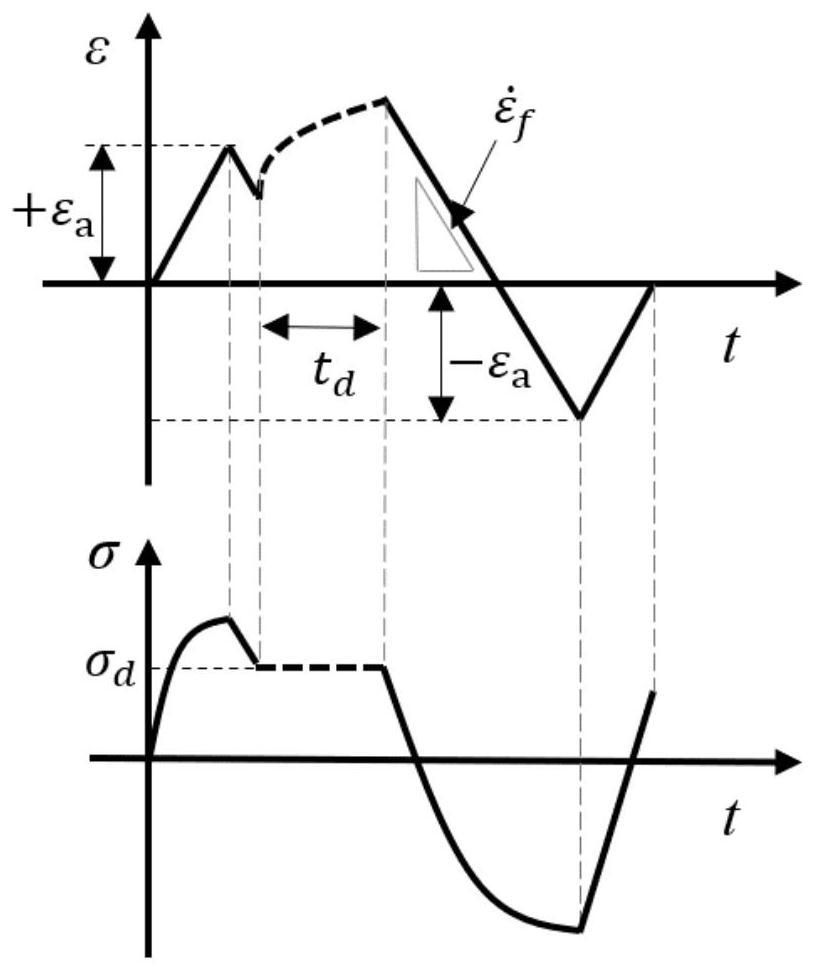

The invention provides a forecasting method for creep-fatigue life of a material. The method comprises the following steps: respectively performing a creep test, a fatigue test and a creep-fatigue interaction test for the material at a same test temperature; establishing a relation between the failure strain energy density wf and a non-elastic strain energy density dissipation rate of the material under a log-log coordinate according to the creep test; acquiring the fatigue damage df of the material per period according to the fatigue test; acquiring a hysteresis loop under a half-life period according to the creep-fatigue interaction test and establishing a function relation of the change of the stress Sigma (t) of the material under the half-life period within the maximum tensile strain maintaining time along with the change of time t; calculating the creep damage dc under the half-life period by combining with the hysteresis loop and based on the relation between wf and the function as shown in the specification and the relation of change of the fatigue damage df and the stress Sigma (t) along with the change of time t; and utilizing a linear accumulating damage rule to forecast the creep-fatigue life of the material under a creep-fatigue interaction. According to the method provided by the invention, the life of the material under the creep-fatigue interaction can be accurately forecasted.

Owner:EAST CHINA UNIV OF SCI & TECH

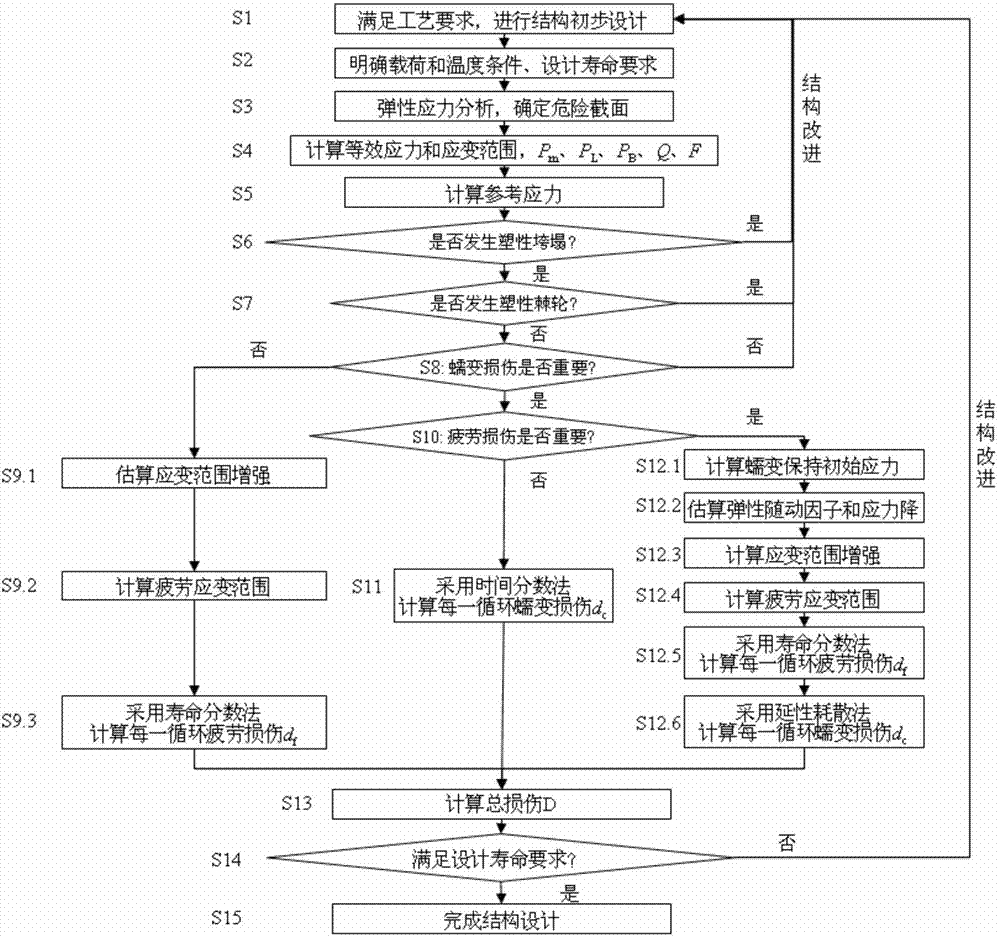

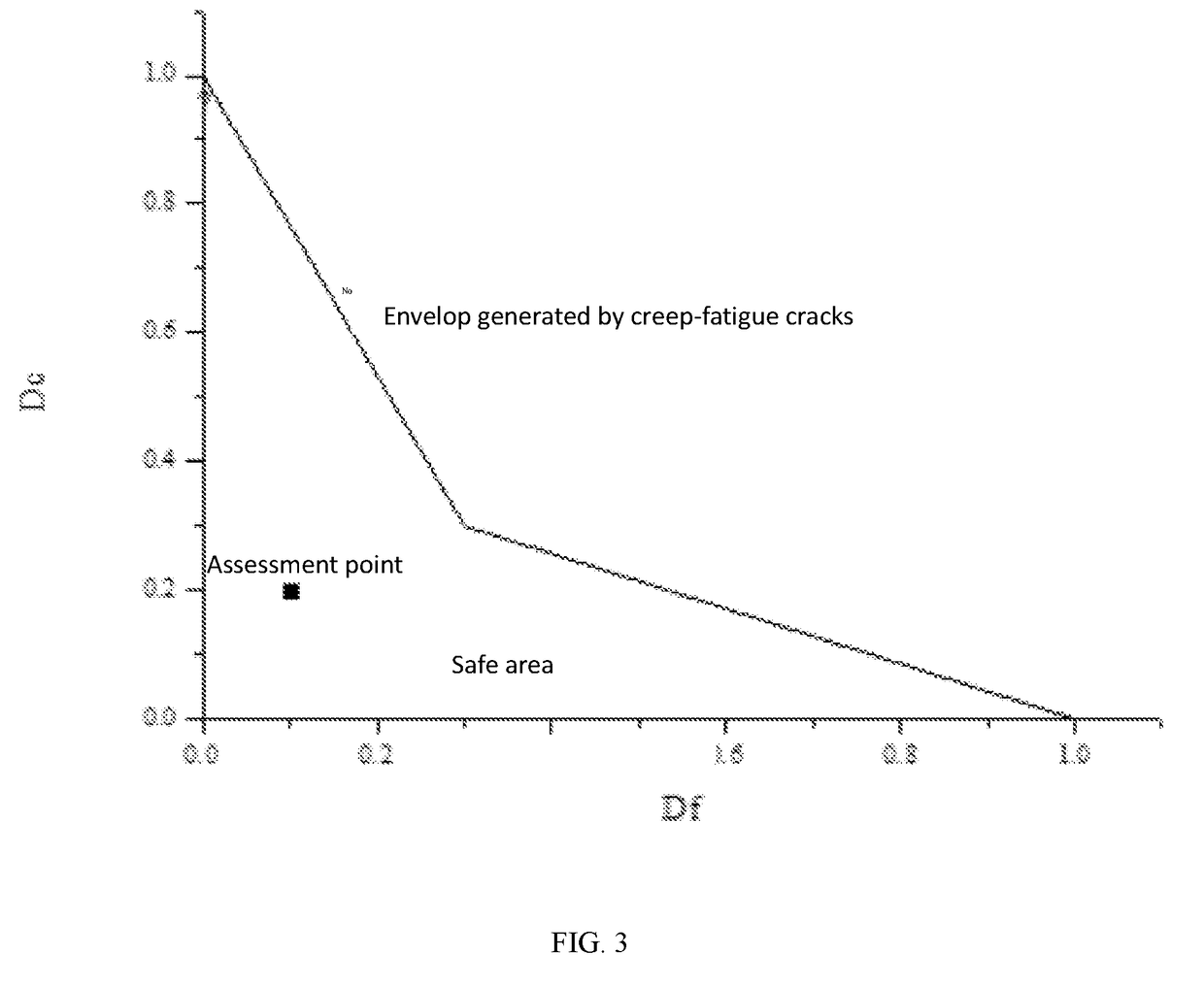

Service life based high-temperature container creep fatigue strength design method

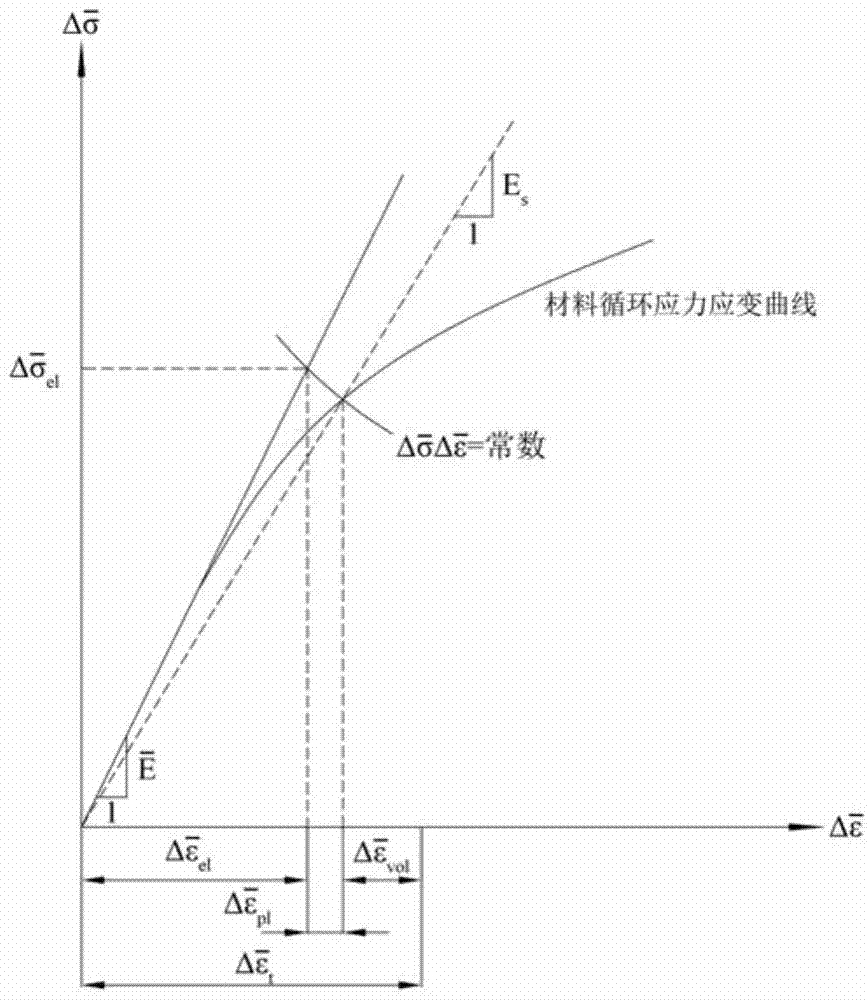

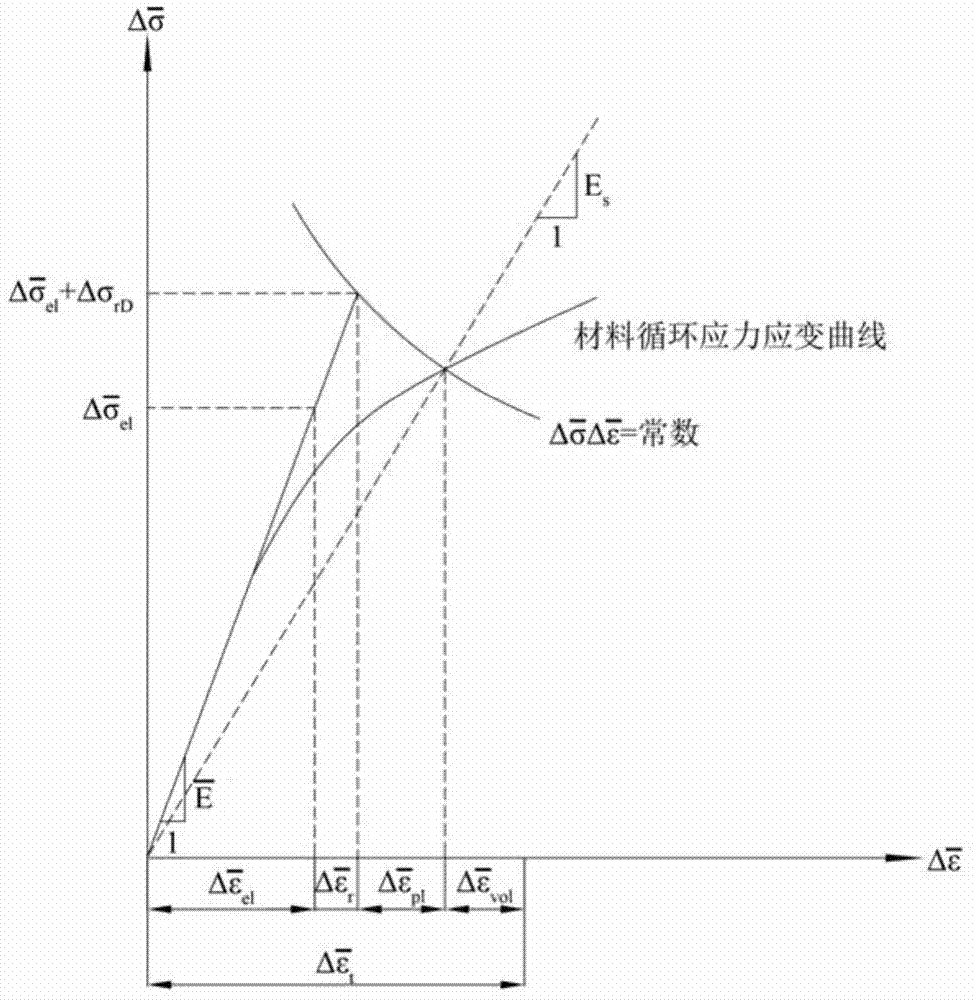

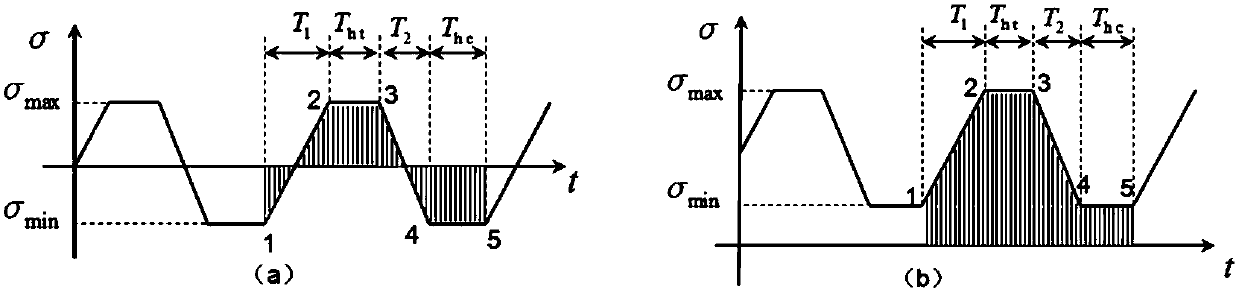

The invention discloses a service life based high-temperature container creep fatigue strength design method. The method comprises the steps of 1, performing structure preliminary design; 2 determining load and temperature conditions and the design service life requirement; 3, determining dangerous sections; 4, calculating the equivalent stress and strain range; 5, calculating reference stress; 6, determining whether plastic collapse occurs; 7 determining whether the plastic ratchet occur; 8, determining whether creep damage is important; 9, estimating fatigue damage of each cycle when the creep damage is not important; 10, determining whether the fatigue damage is important; 11, estimating the creep damage when the fatigue damage is not important; 12, estimating damage of each cycle when the creep damage and the fatigue damage are non-ignorable; 13, estimating creep-fatigue total damage; 14, performing result analysis and structural design improvement; 15, completing structural design. According to the method, the foundation is laid for national establishing of creep and fatigue failure mode based high-temperature pressure container design standards and achieving design and manufacture of high-temperature pressure containers according to the service life.

Owner:HEFEI GENERAL MACHINERY RES INST

A multi-axis creep fatigue prediction method based on ABAQUS

ActiveCN109885874AGain creep damageIntuitiveMaterial strength using tensile/compressive forcesDesign optimisation/simulationFatigue damageElement model

The invention discloses a multi-axis creep fatigue prediction method based on ABAQUS, and the method comprises the steps of S1, building an ABAQUS finite element model, and defining a viscoplastic constitutive equation of a to-be-tested material through a user subprogram UMAT; S2, determining model parameters required by the viscoplastic constitutive equation; S3, establishing a fatigue damage calculation model and a creep damage calculation model of the multi-axis stress-strain state of the to-be-tested material; S4, establishing an ABAQUS finite element model in a multi-axis stress-strain state, and calculating to obtain a stress-strain tensor of each cycle on the basis of the defined viscoplastic constitutive equation and model parameters; and S5, calculating equivalent stress and equivalent plastic strain through a user subprogram USDFLD, and superposing fatigue damage and creep damage of each cycle through a linear cumulative damage criterion on the basis of the fatigue damage calculation model and the creep damage calculation model in combination with the stress strain tensor to obtain the crack initiation life.

Owner:EAST CHINA UNIV OF SCI & TECH

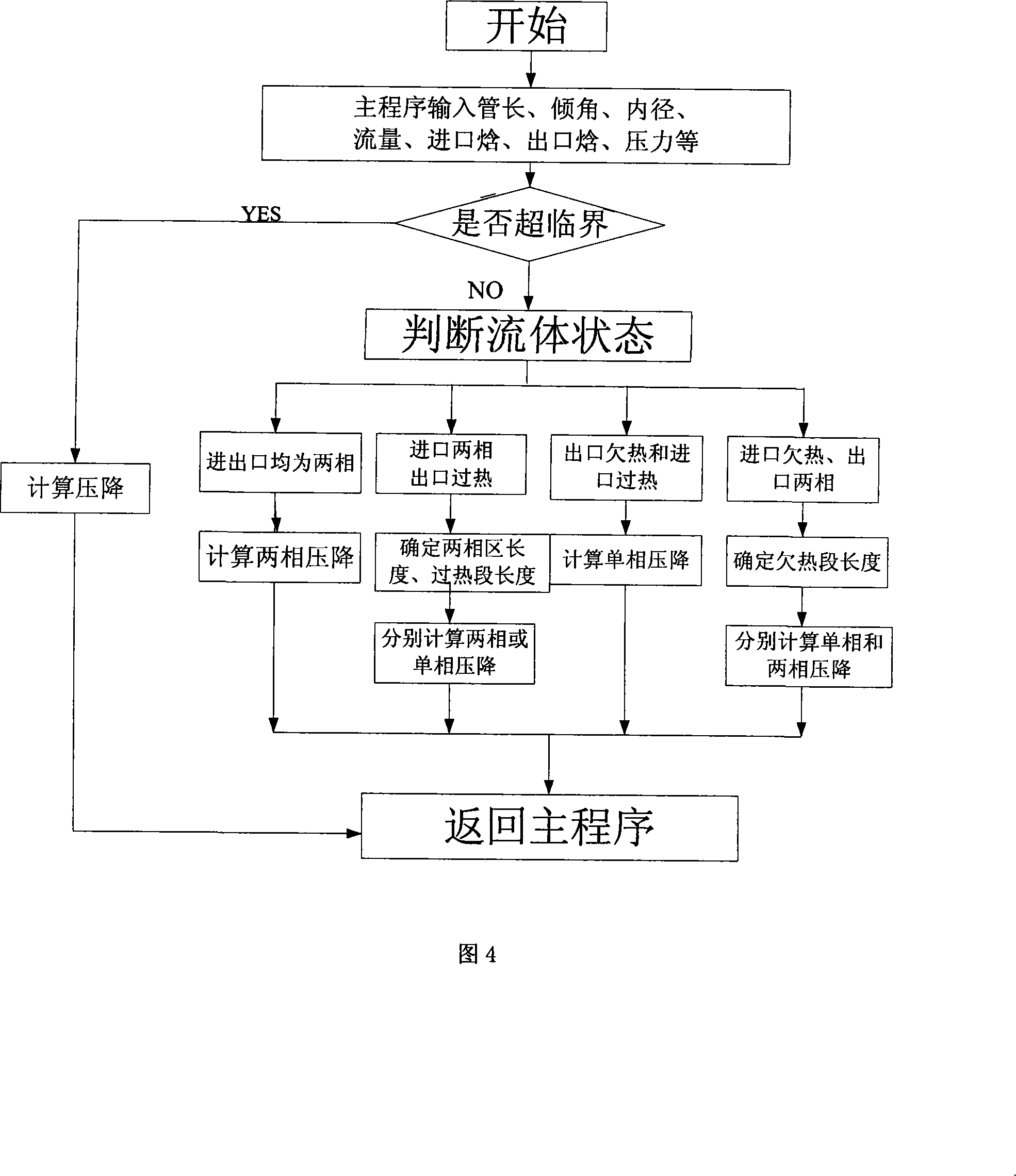

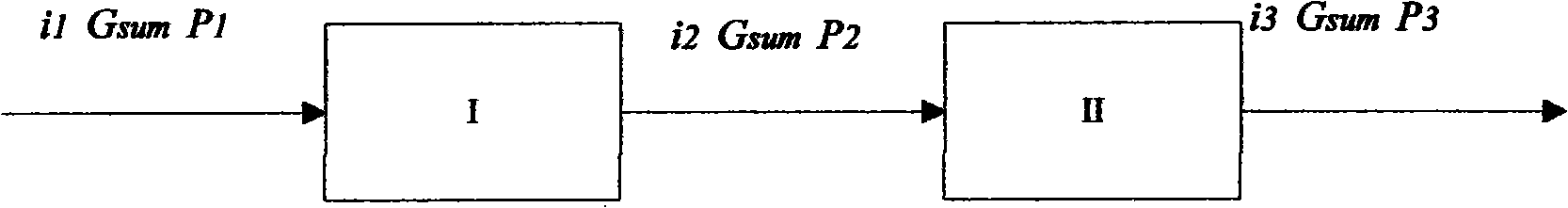

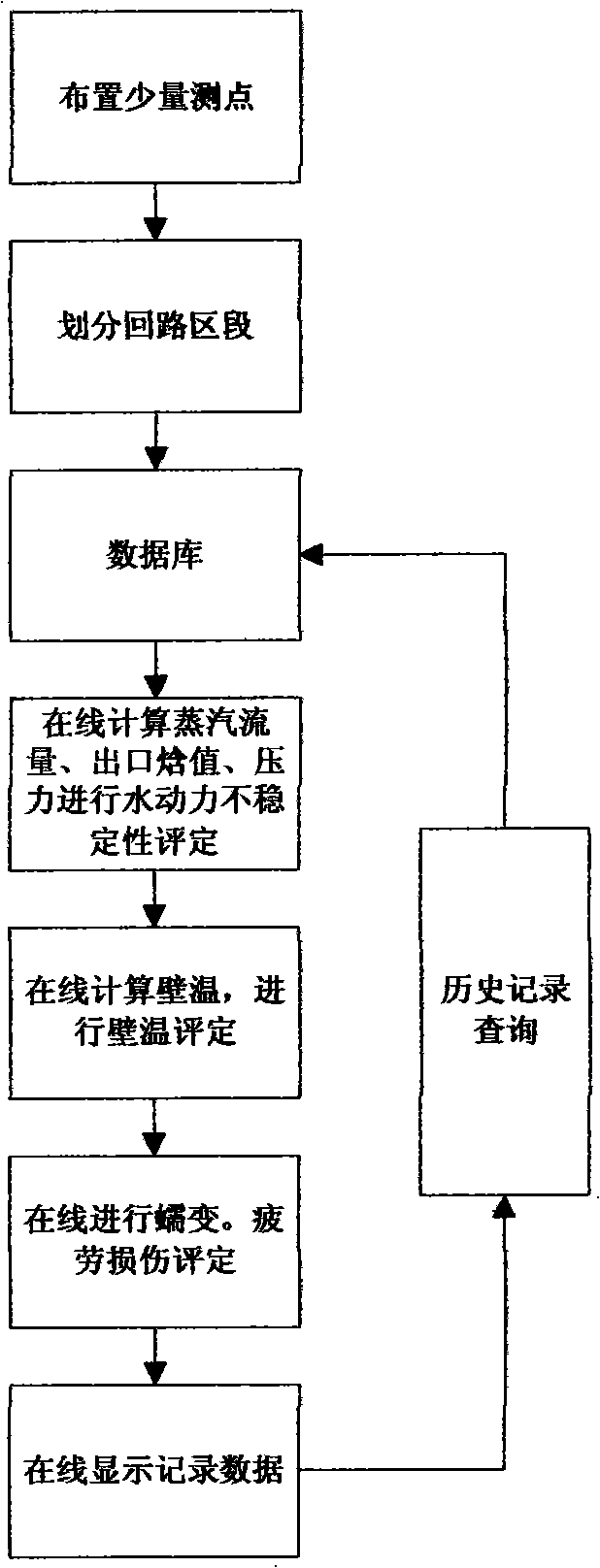

Water-cooled wall on-line safe evaluation method

InactiveCN101216164AHigh precisionReduce occupancySteam boilersSteam boilers componentsInstabilityEngineering

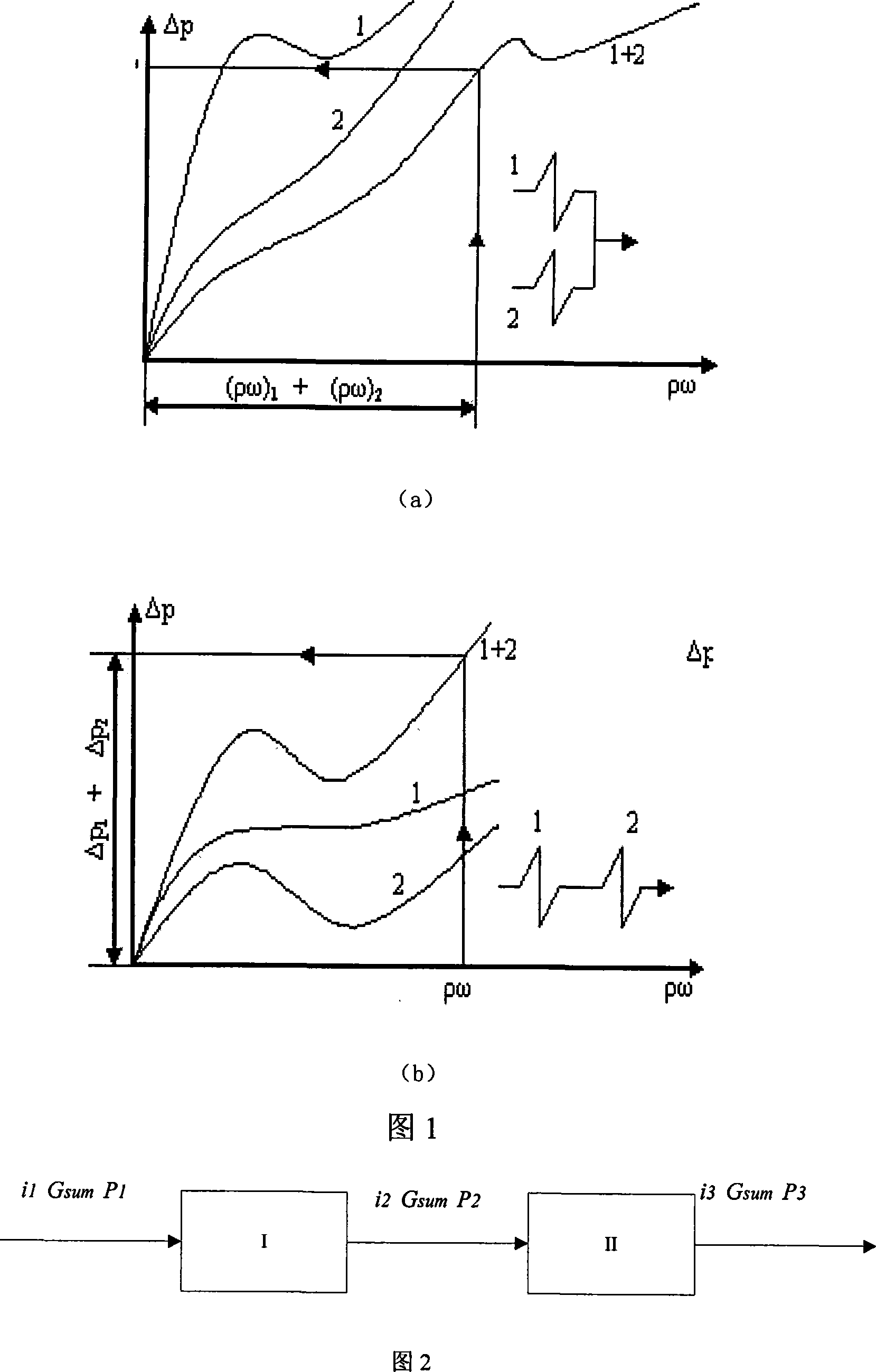

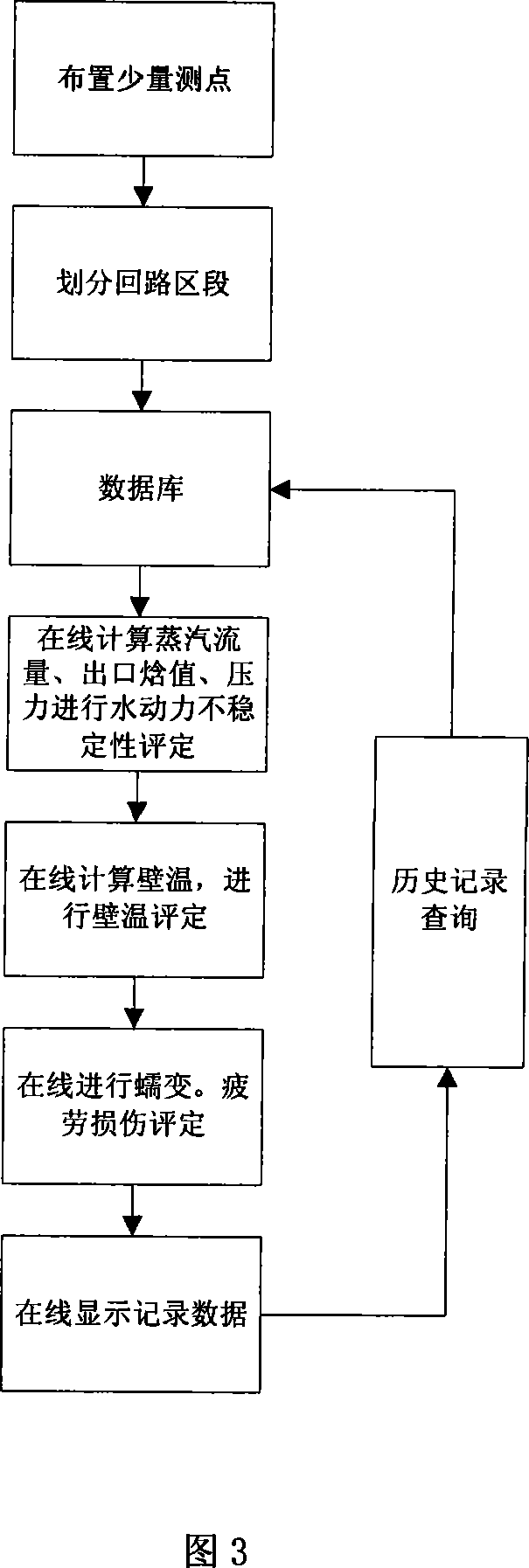

The invention relates to an on-line safety evaluation method for water-cooled walls. The method comprises the following steps: arranging a small amount of test points in the pipeline section with typical flow heat transfer in each radiation zone, combining with the existing test points at the entrance and exit outside the furnace, calculating and checking the characteristic parameters of the inner wall of the water-cooled wall of the station boiler, inputting to a computer for calculation, performing the on-line real-time calculation of the Parameters such as pipeline flow, entrance and exit pressures, enthalpy value, lengthwise furnace inner wall temperature of each pipeline section and stress change value, to judge whether the dangerous factors exist, such as hydrodynamic instability, over-temperature and creep fatigue, displaying the calculation results in real time, recording the data as judgment basis of safe operation of the water-cooled wall. The invention realizes the optimal operation of equipment, manages the repair and maintenance based on the operational state, and ensures the state maintenance and repair of equipment.

Owner:XI AN JIAOTONG UNIV

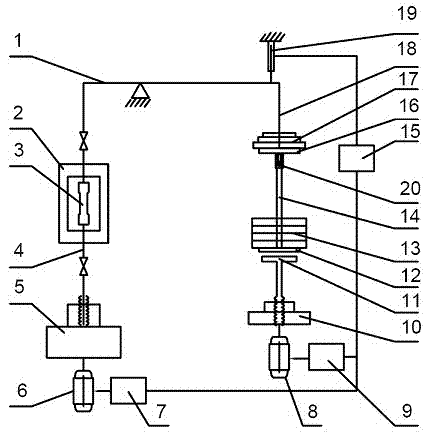

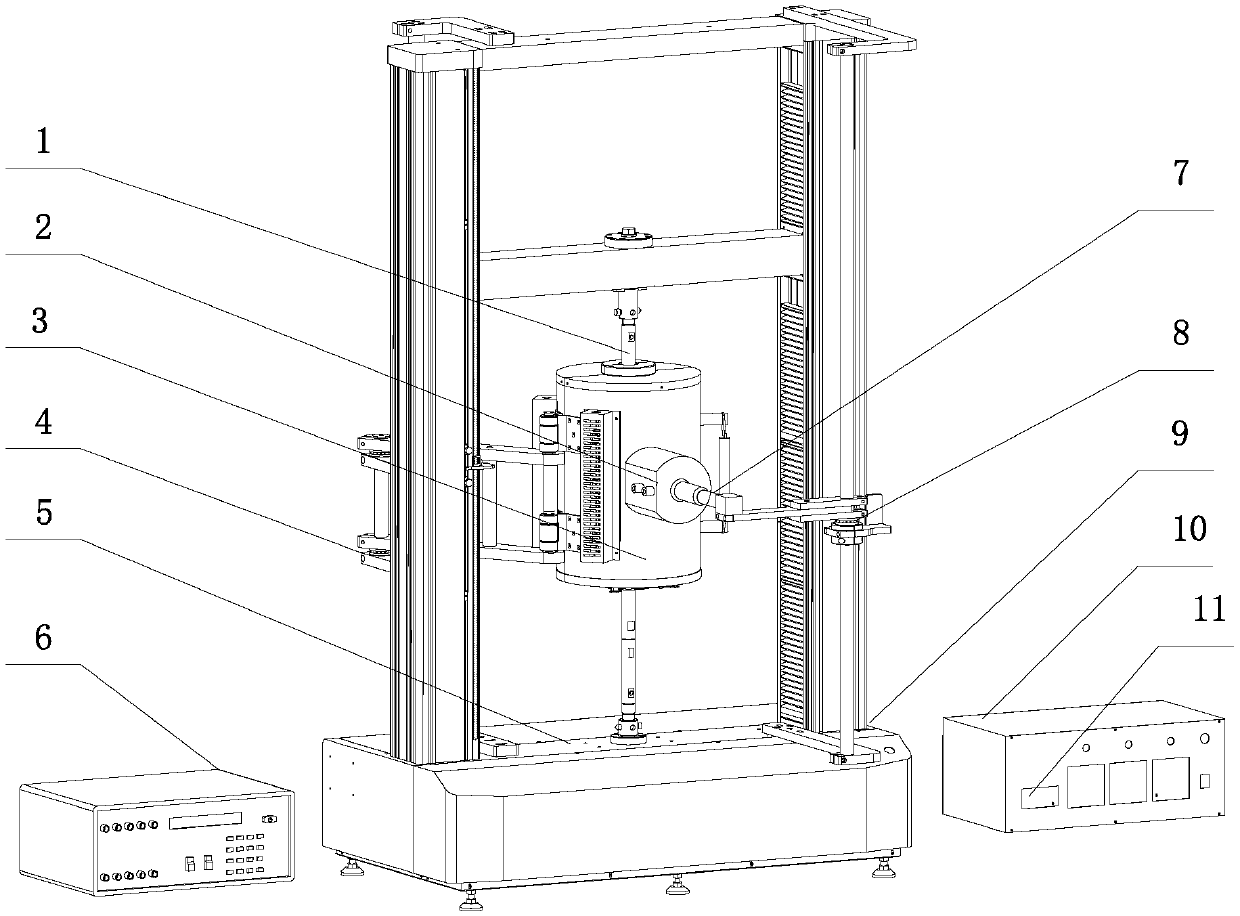

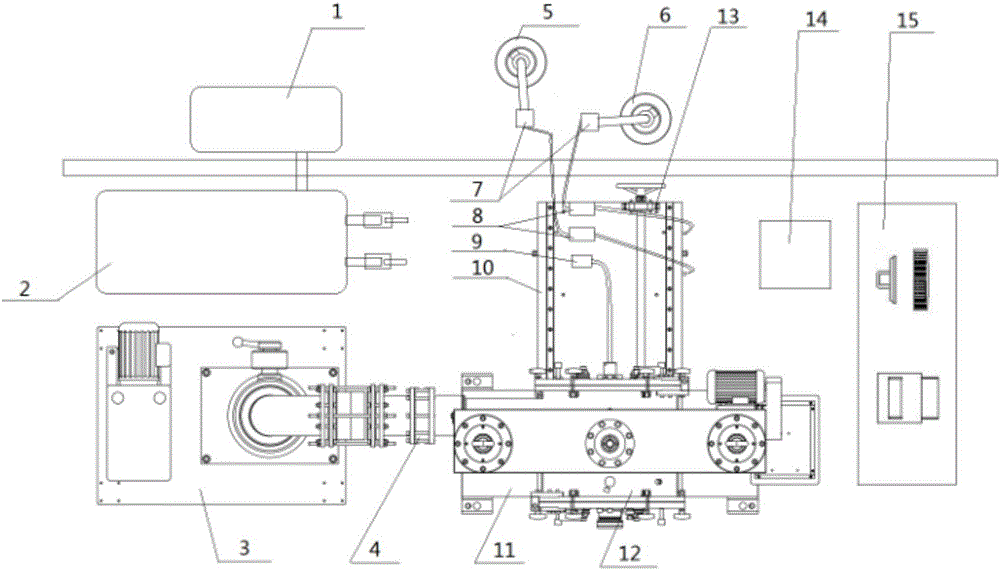

High-temperature creep fatigue test system

InactiveCN105021468AHigh measurement accuracyEasy to operateMaterial strength using tensile/compressive forcesEngineeringFatigue testing

A high-temperature creep fatigue test system, which consists of a fatigue testing machine, specimen holders, a high temperature furnace, a sample, a high temperature extensometer, a cooler and host computer. Upper and lower specimen holders are in threaded connection to ensure the uniform axial loading of the specimen; the specimen holders are connected to the fatigue testing machine; the high-temperature extensometer is connected with the specimen through a jaw; a high temperature furnace mounted on the fatigue testing machine moves to a corresponding position, and wraps the specimen inside; the cooler through inlet and outlet pipes is respectively connected to the upper and lower specimen holders; the fatigue testing machine and the high-temperature extensometer are connected to the host computer; the host computer by reading real-time measurement strain of the high-temperature extensometer controls the fatigue testing machine, so as to conduct strain-controlled high-temperature creep fatigue test. The present invention has the beneficial effects that deformation of the material in high-temperature creep fatigue test can be measured, and has the characteristics of easy operation and high measurement accuracy.

Owner:BEIHANG UNIV

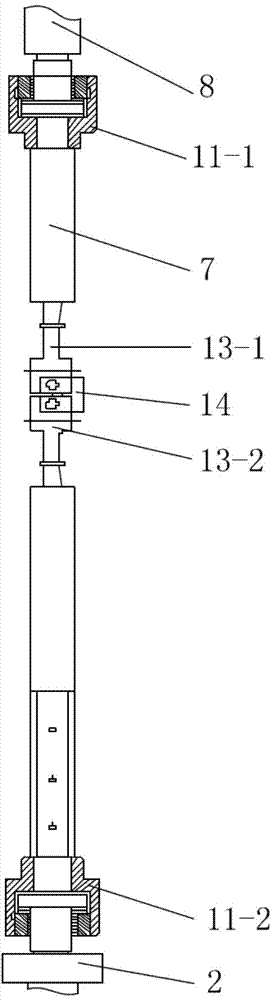

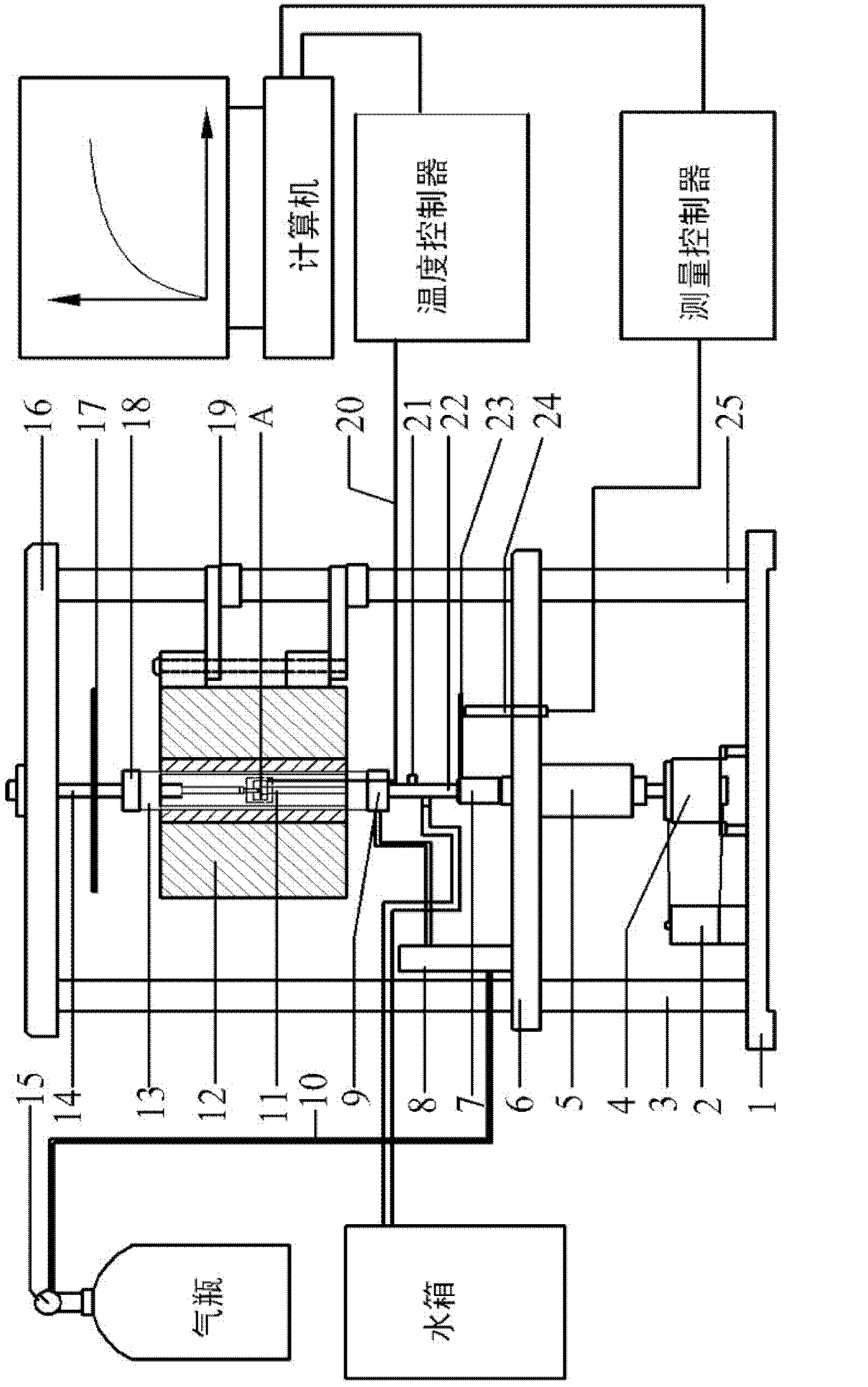

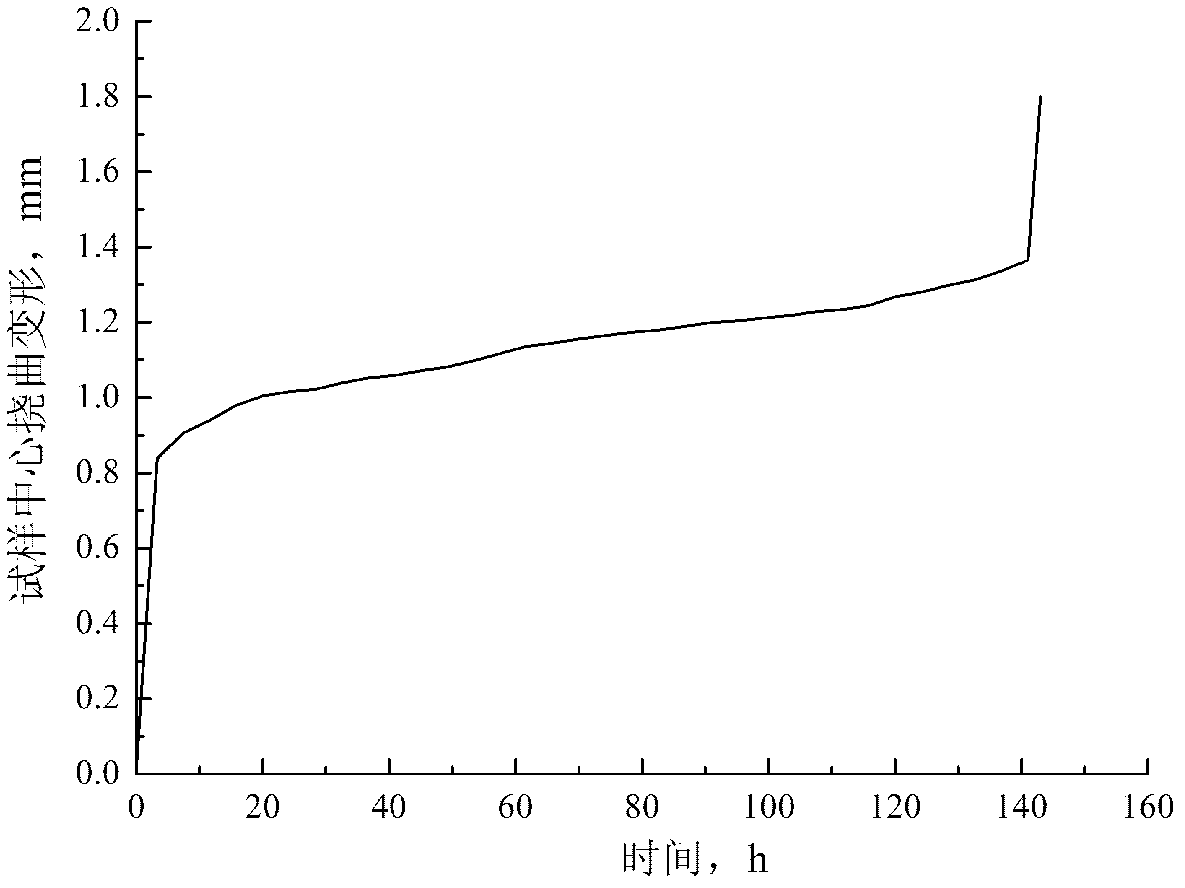

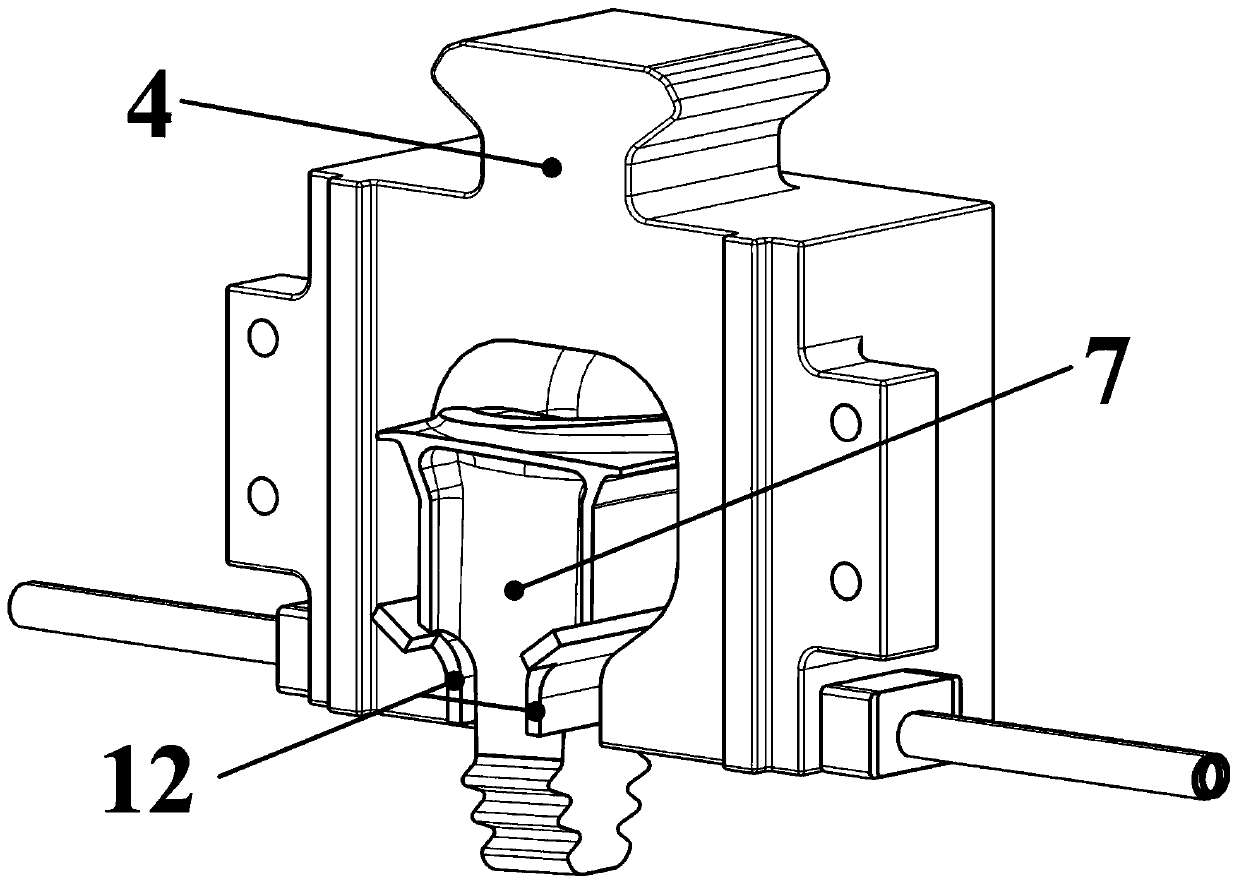

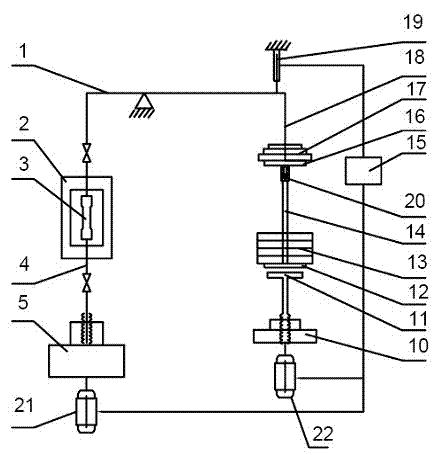

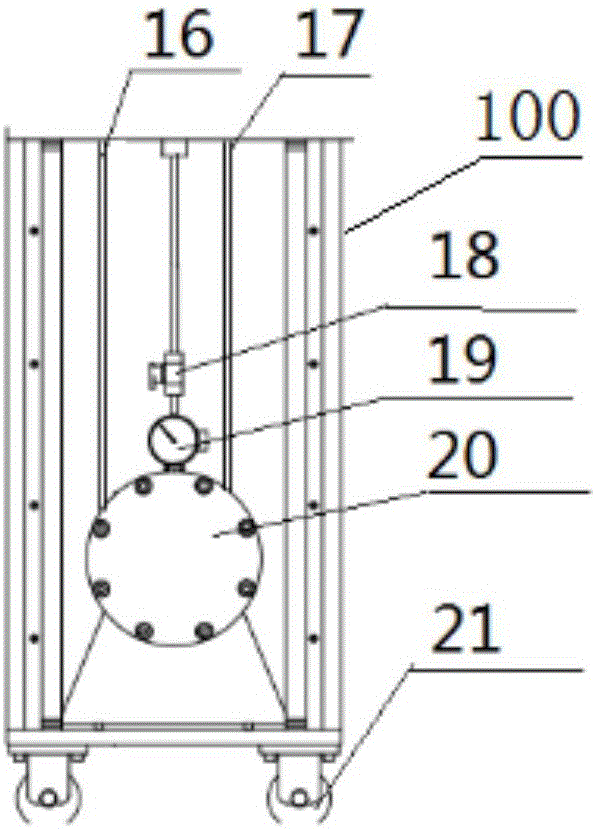

Micro sample creep and creep fatigue test system and test method

InactiveCN103105336AMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesComputer control systemData acquisition

The invention discloses a micro sample creep and creep fatigue test system and a test method. The micro sample creep and creep fatigue test system comprises a host frame, a high-temperature furnace, a servo motor loading system, a distance measuring device, a force measuring device, a cooling system, a clamping mechanism, a quartz tube, an air supply device, a computer control system and a data collection system. The micro sample creep and creep fatigue test system provided by the invention can perform a micro-tensile sample creep test and a micro-bending sample creep test, thereby facilitating test operation by researchers and test popularization.

Owner:EAST CHINA UNIV OF SCI & TECH

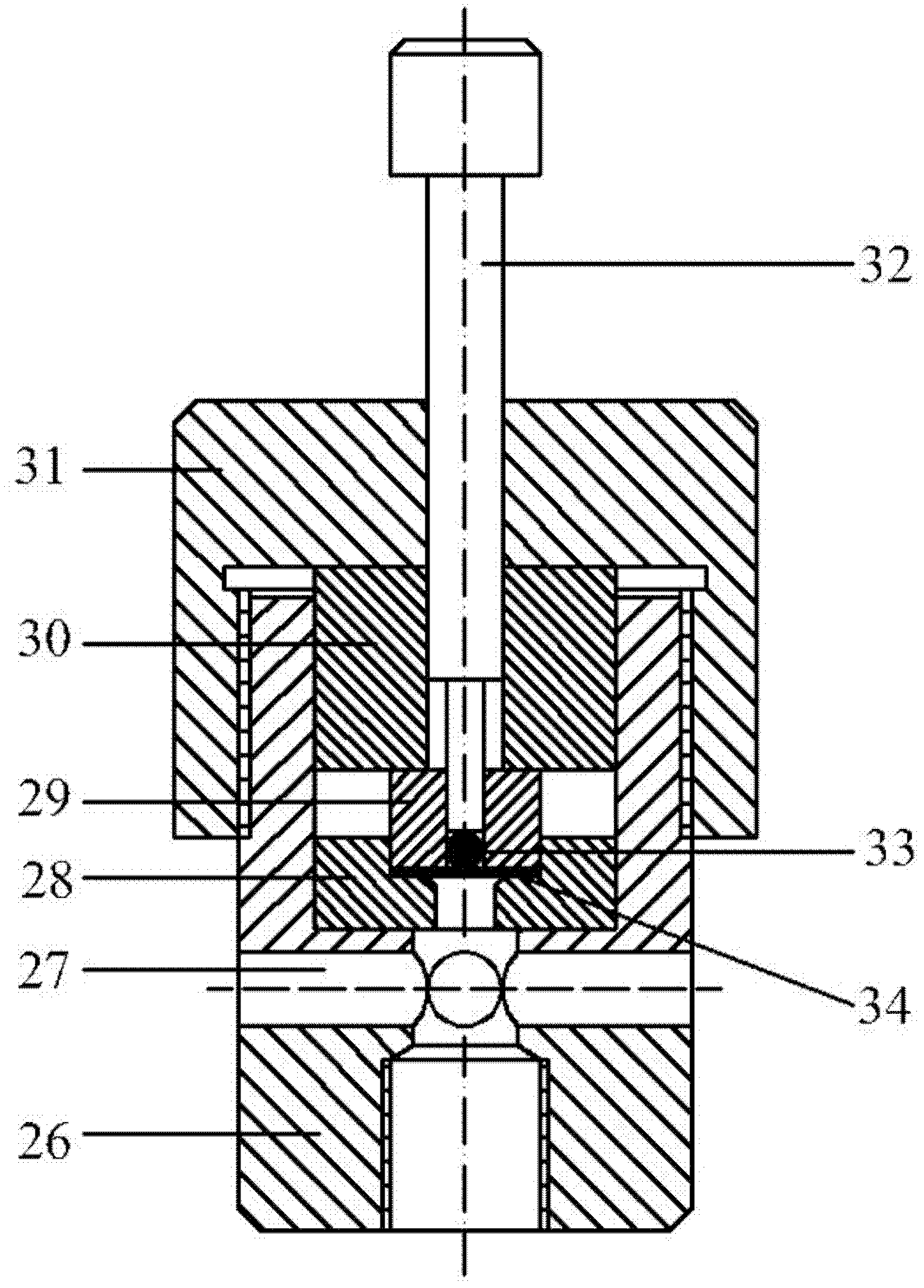

Creep deformation-fatigue crack growth testing device and corresponding testing method

InactiveCN103884603ACompact structureEasy to operateMaterial strength using tensile/compressive forcesCollection systemLength measurement

The invention relates to a creep deformation-fatigue crack growth testing device and a corresponding testing method. The device comprises a loading system, a temperature control system and a measurement and collection system, wherein the measurement and collection system comprises a load linear displacement measurement system and a crack length measurement system; the upper and lower ends of a test sample are fixedly connected with an upper clamp and a lower clamp respectively; a high temperature furnace is connected with the temperature control system and the measurement and collection system; the test sample is loaded by an alternating current servo motor and a controller. The invention further relates to the corresponding testing method. The testing device provided by the invention is compact in structure and convenient to operate; the testing device adopts an insulating chuck and the insulating chuck ensures that constant-current current passing through the test sample is stable; aiming at the test sample of a creep deformation-fatigue crack growth test, the clamps are designed and machined; the temperature in the furnace is high so that a high-temperature clamping type extensometer is used for introducing load linear displacement out of a heating furnace to be measured. The testing method is simple and convenient to operate; the crack length is measured by using an electric potential method and the continuous test can be carried out for long time.

Owner:EAST CHINA UNIV OF SCI & TECH

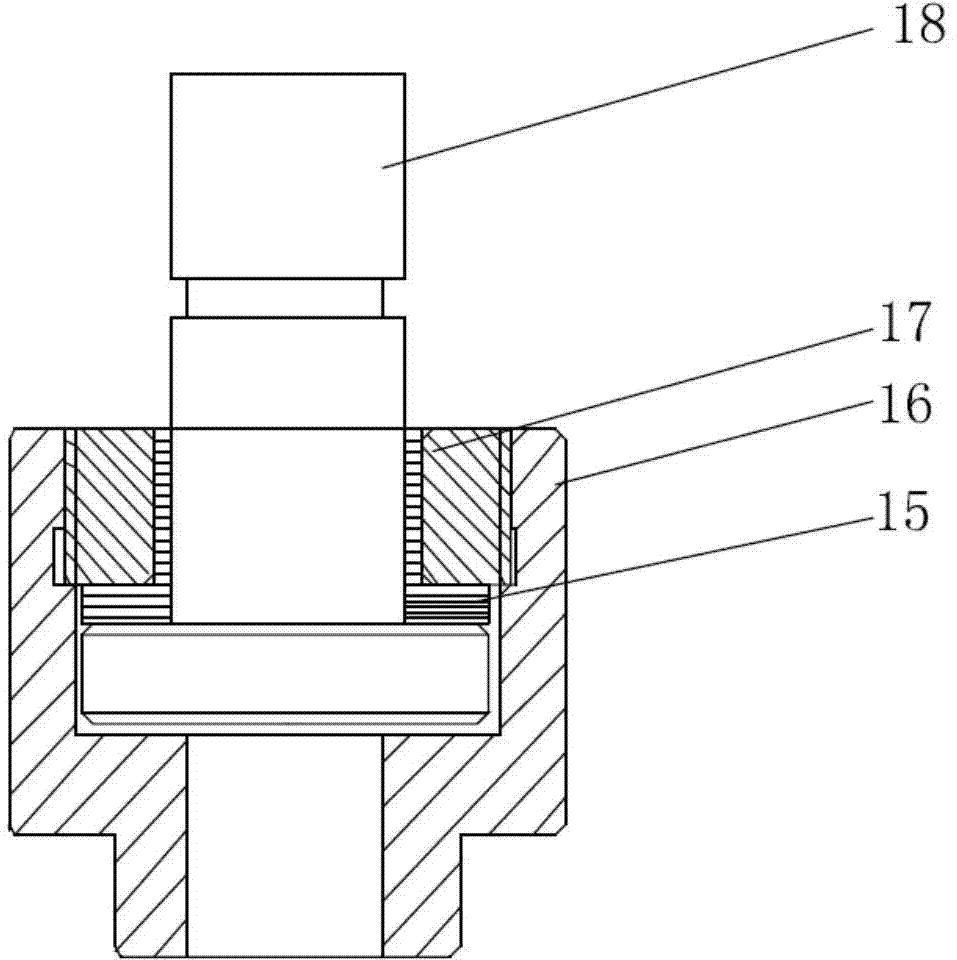

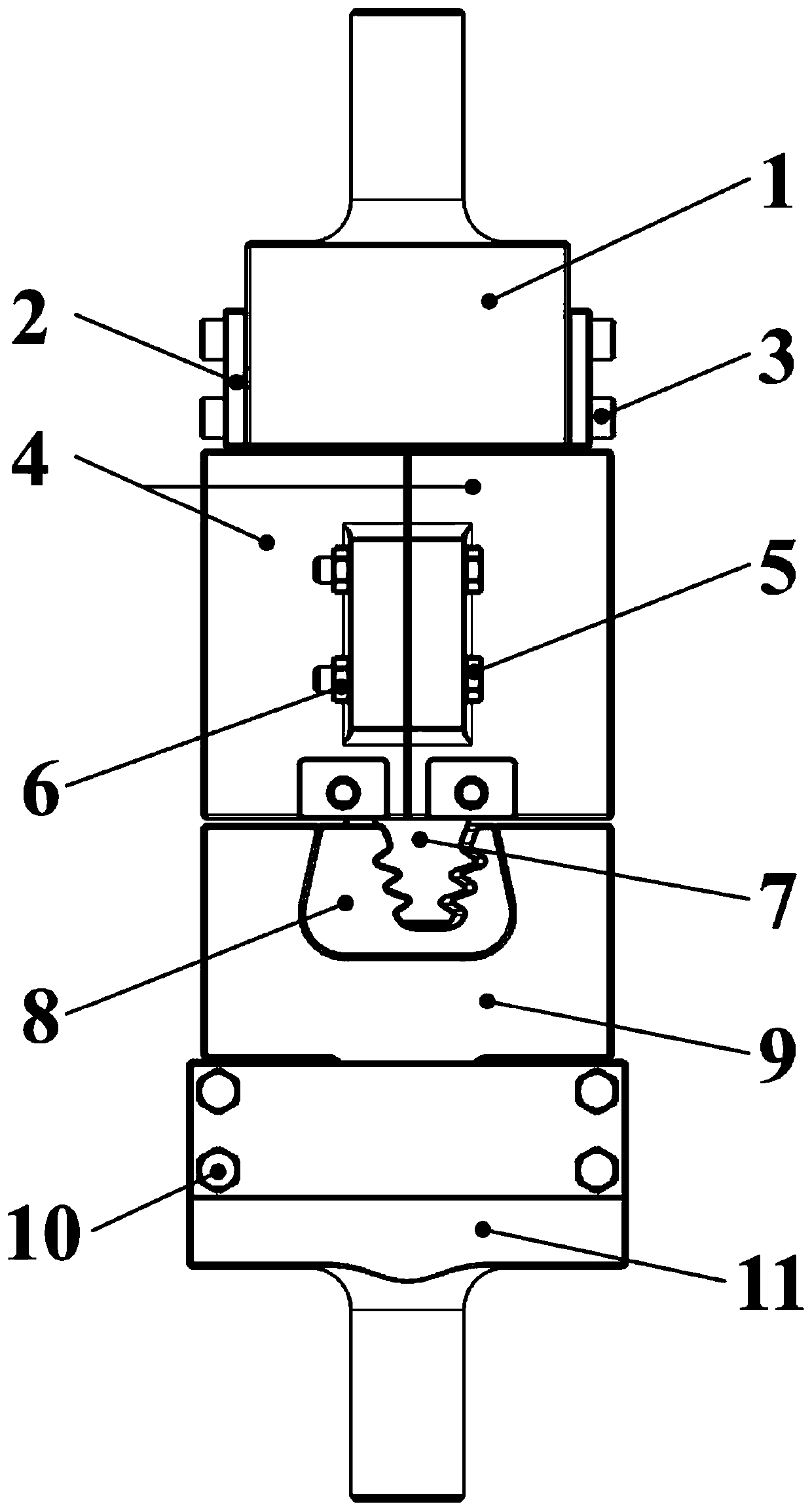

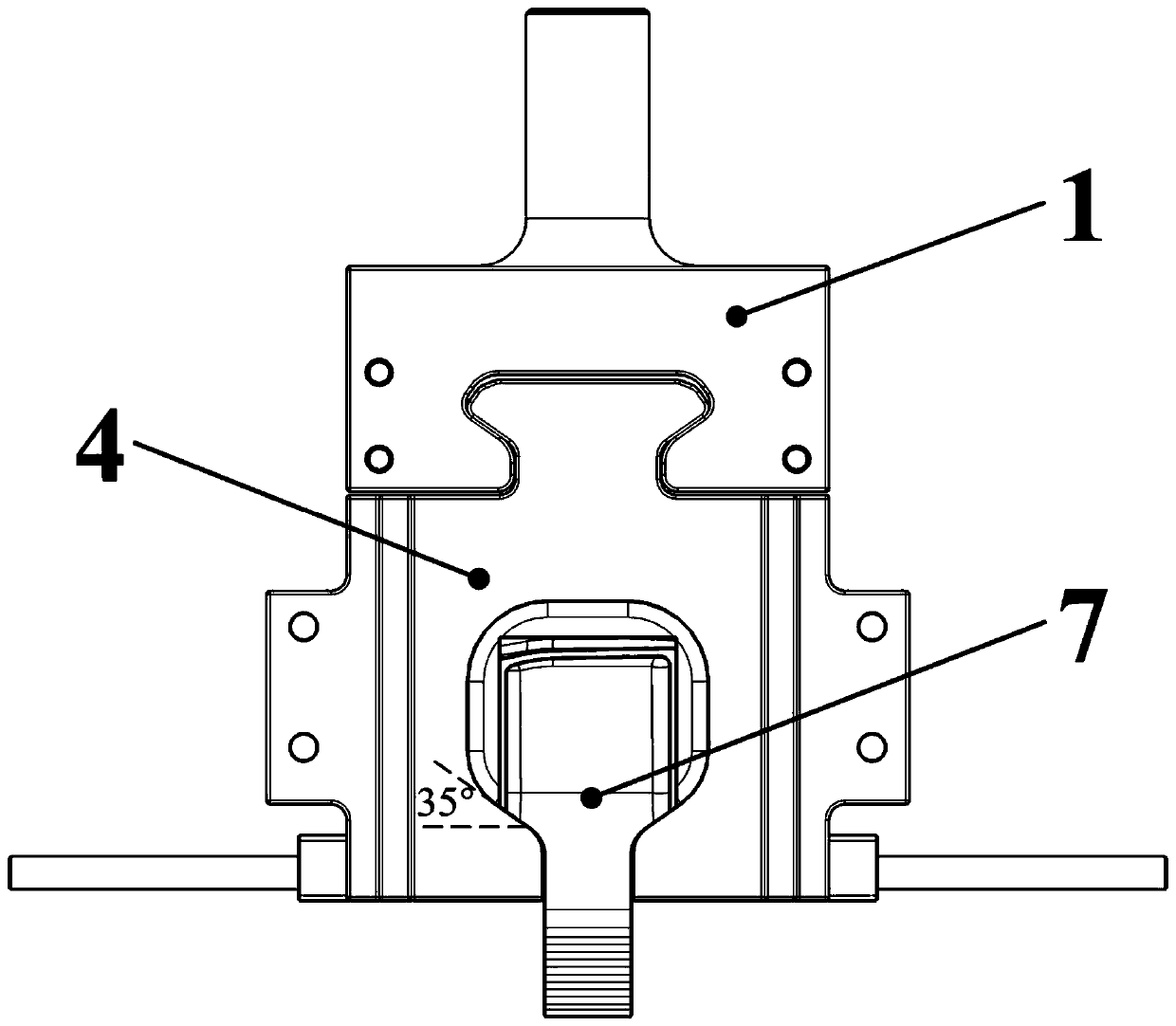

Subminiature minimal invasion high-temperature creep fatigue testing machine and application thereof

ActiveCN102621011AReduce the impactGuaranteed temperatureInvestigating material ductilityEngineeringProtection system

The invention discloses a subminiature minimal invasion high-temperature creep fatigue testing machine and the application thereof. The subminiature minimal invasion high-temperature creep fatigue testing machine mainly includes a driving system, a loading device, a constant temperature atmosphere furnace, a temperature control system, a high temperature gas protection system, a measurement control system and a water cooling system, wherein the loading manner of the machine is top vertical loading; a testing sample is positioned between an upper fixing platform and a lower fixing platform; and when loading is performed, a servo motor controls a lower loading rod to move upwards, a jumper bar is contacted with an upper loading rod, the lower end of the jumper bar is used for testing sample stamping through a pressure head. Aiming at an existing structure and a domain structure at a high temperature, the testing machine provided by the invention can be used for obtaining various high temperature performance of the material and estimating residual service life creep, safety operation state and the like of the high temperature structure, is convenient to operate, is uniform in testing temperature and high in testing precision, can be used for testing various high temperature performances such as high-temperature creep performance, high-temperature relaxation performance, high-temperature creep fatigue performance and high-temperature breaking toughness of the material.

Owner:TIANJIN UNIV

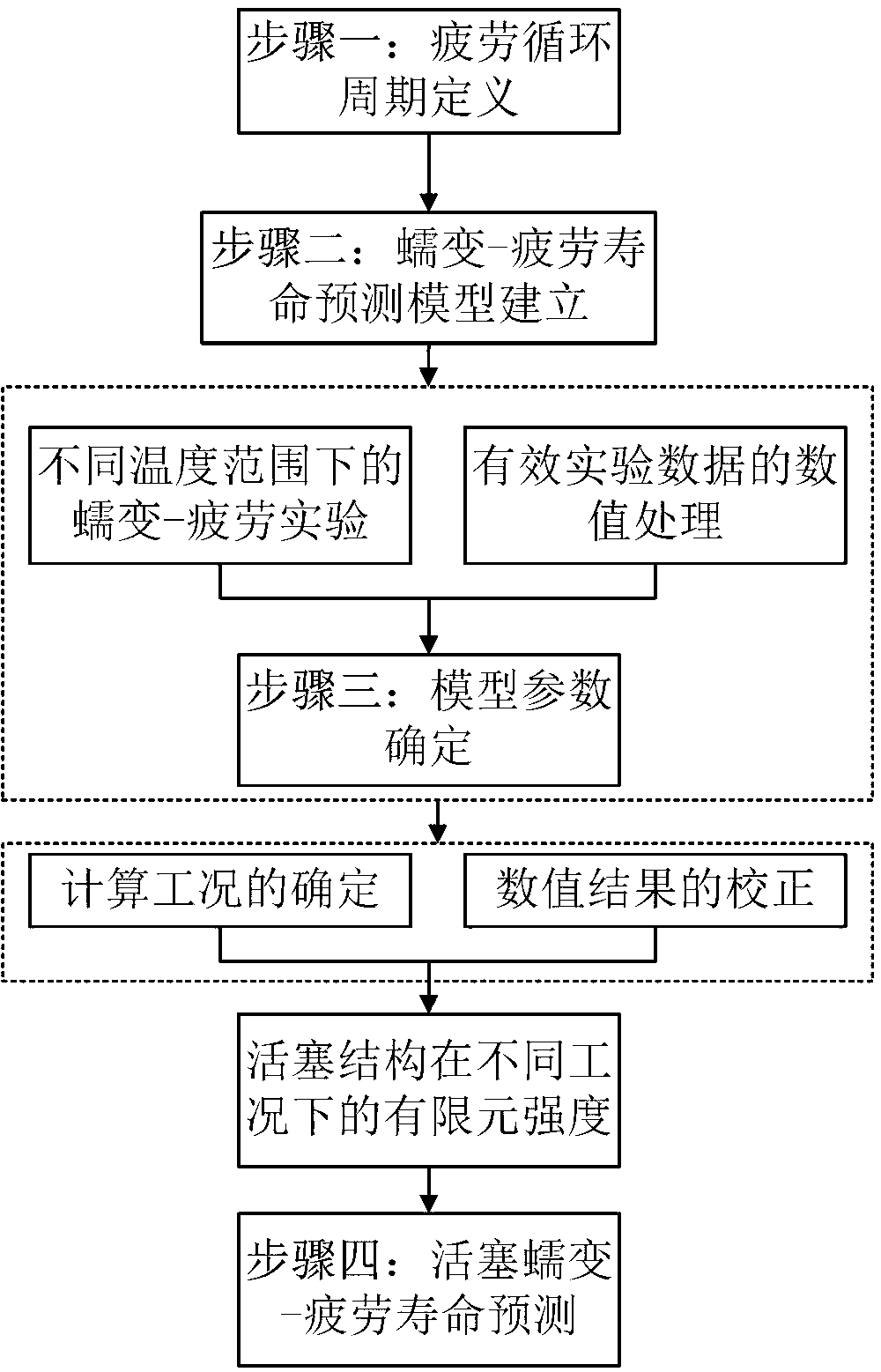

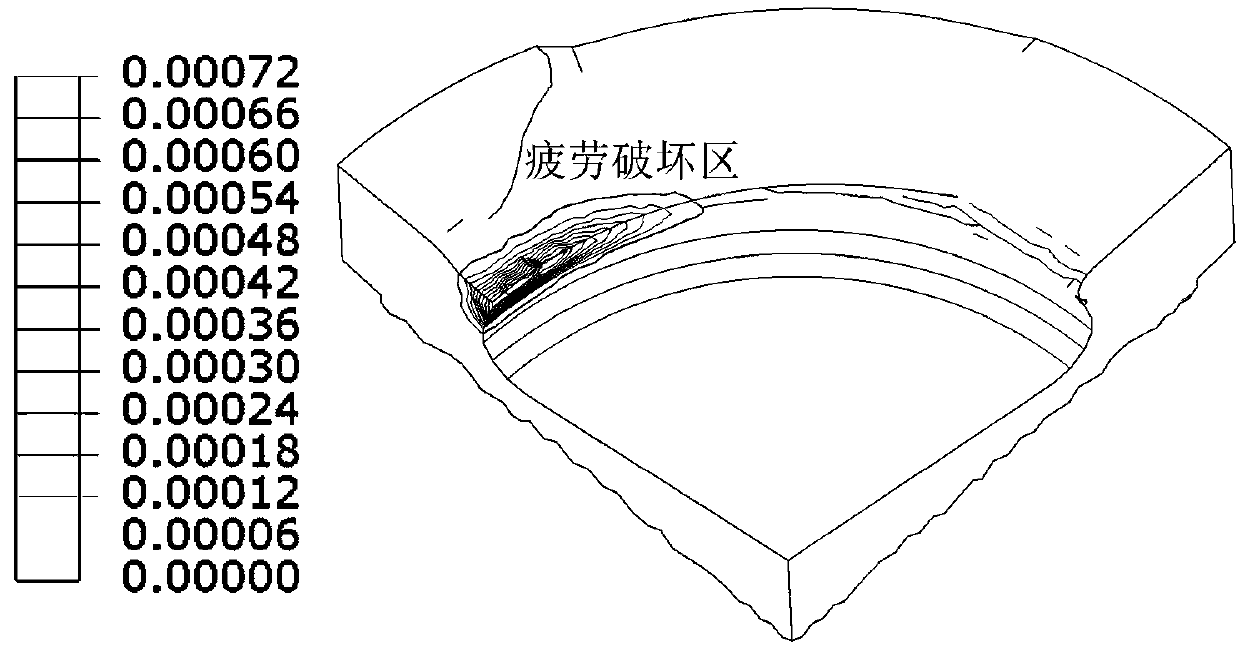

Method for predicting creep-fatigue service life of aluminum alloy piston of high-power diesel engine

InactiveCN103344511ANonlinear Coupling SolutionInvestigating material ductilityMaterial strength using repeated/pulsating forcesFatigue damageNon linear coupling

The invention relates to a method for predicting the creep-fatigue service life of an aluminum alloy piston of a high-power diesel engine, belonging to the field of material science and engineering application technologyies. The influences of large-range and periodic working condition change of the high-power diesel engine on the fatigue service life of the piston structure are taken into account in the method, a new fatigue period is defined to predict the service life of the piston; considering that the engine works under a long-time variable working condition, and the non-linear coupling action between the creep damage and the fatigue damage generated inside a material can be effectively overcome through a creep-fatigue service life prediction model which is built on the basis of damage mechanics.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

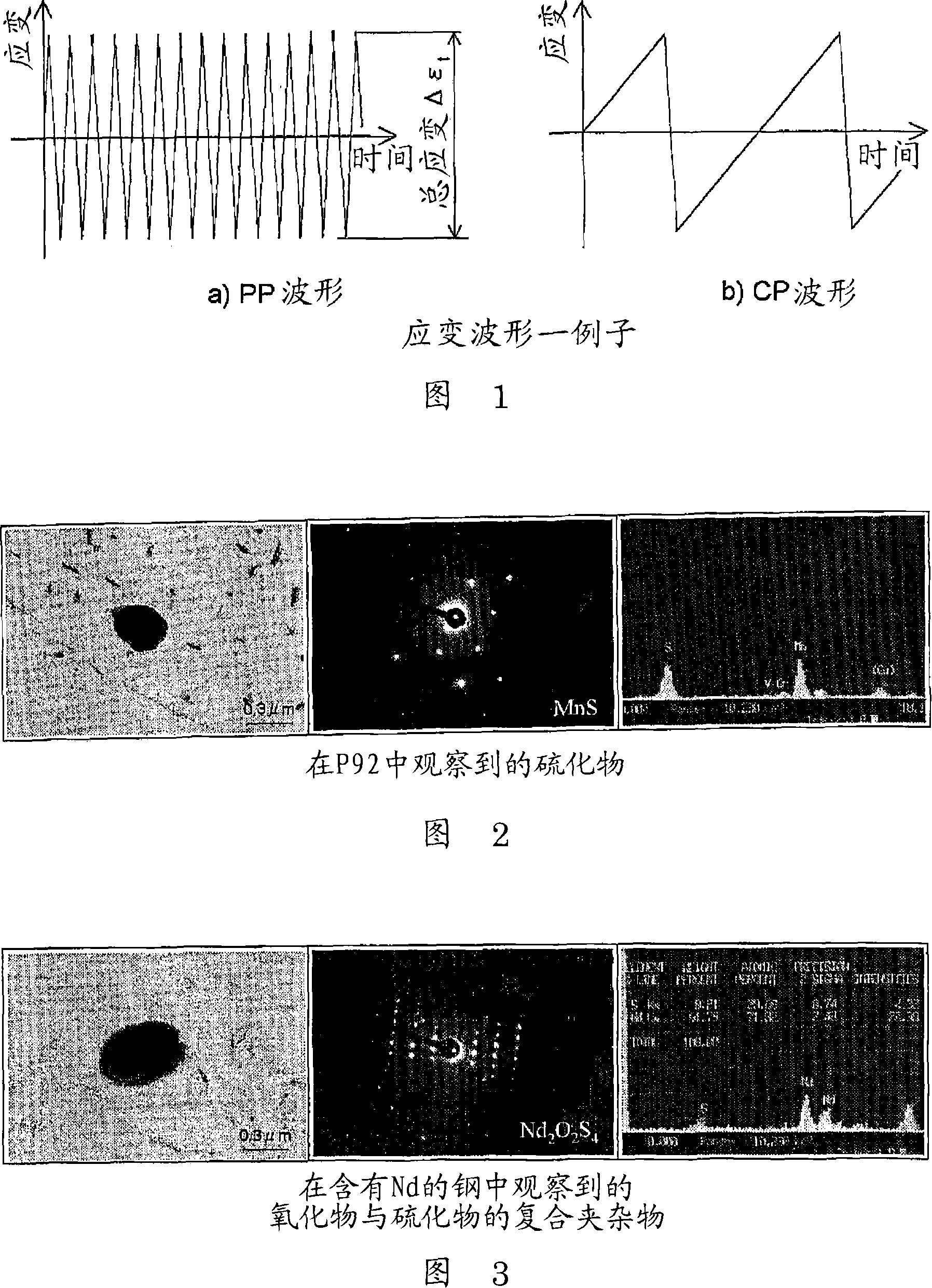

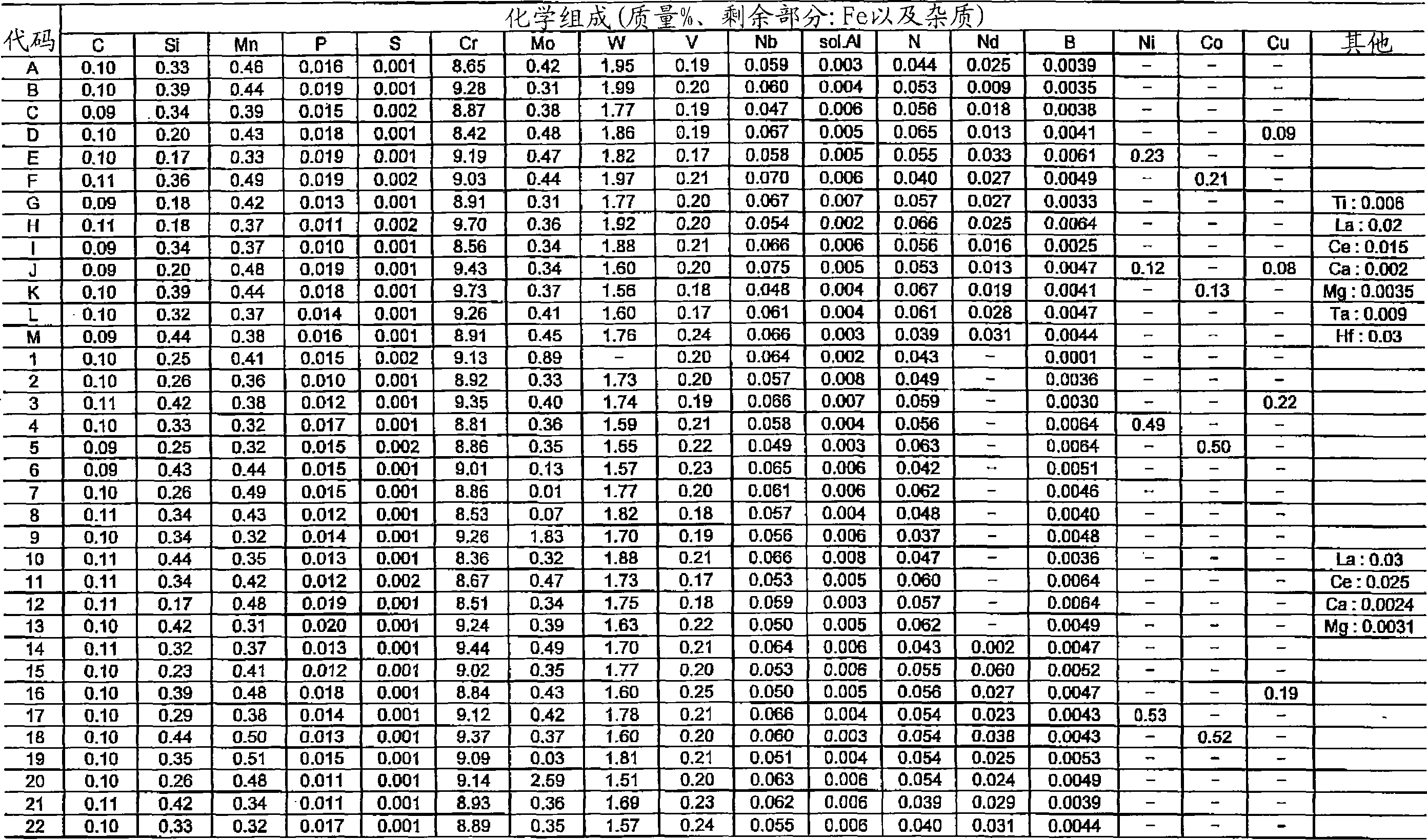

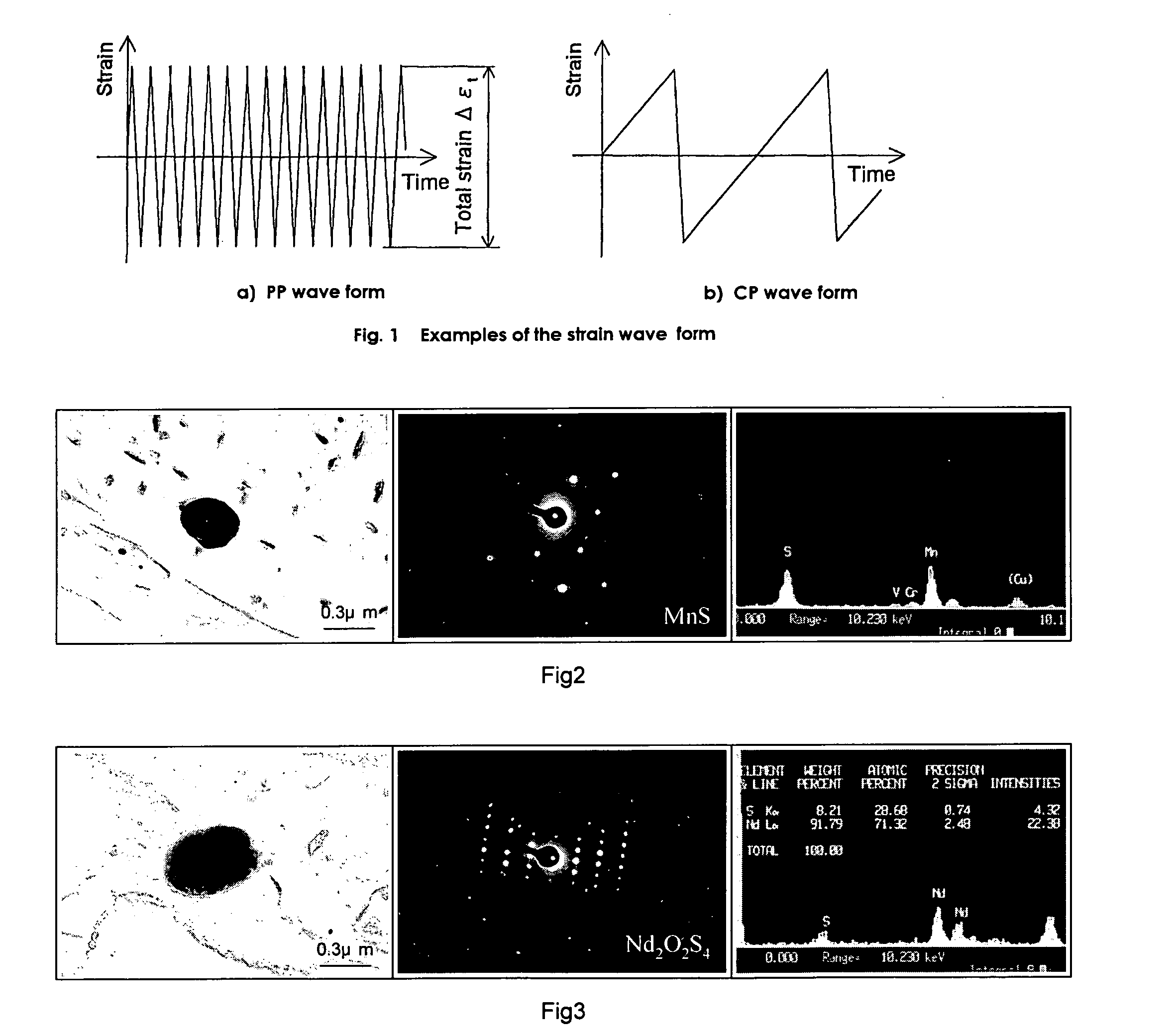

Ferritic heat-resistant steel

Disclosed is a heat-resistant steel which is excellent in high-temperature long-term creep strength and creep-fatigue strength. Specifically disclosed is a heat-resistant steel having a composition consisting of, in mass%, 0.01-0.13% of C, 0.15-0.50% of Si, 0.2-0.5% of Mn, not more than 0.02% of P, not more than 0.005% of S, more than 8.0% but less than 12.0% of Cr, 0.1-1.5% of Mo, 1.0-3.0% of W, 0.1-0.5% of V, 0.02-0.10% of Nb, not more than 0.015% of sol. Al, 0.005-0.070% of N, 0.005-0.050% of Nd, 0.002-0.015% of B, and the balance of Fe and impurities. As some of the impurities, less than 0.3% of Ni, less than 0.3% of Co and less than 0.1% of Cu are contained in the heat-resistant steel. This ferritic heat-resistant steel contains Nd inclusions at a density of not less than 10,000 inclusions / mm<3>. This steel may further contain one or more elements selected from Ta, Hf, Ti, Ca and Mg in addition to the above-described components.

Owner:NIPPON STEEL CORP

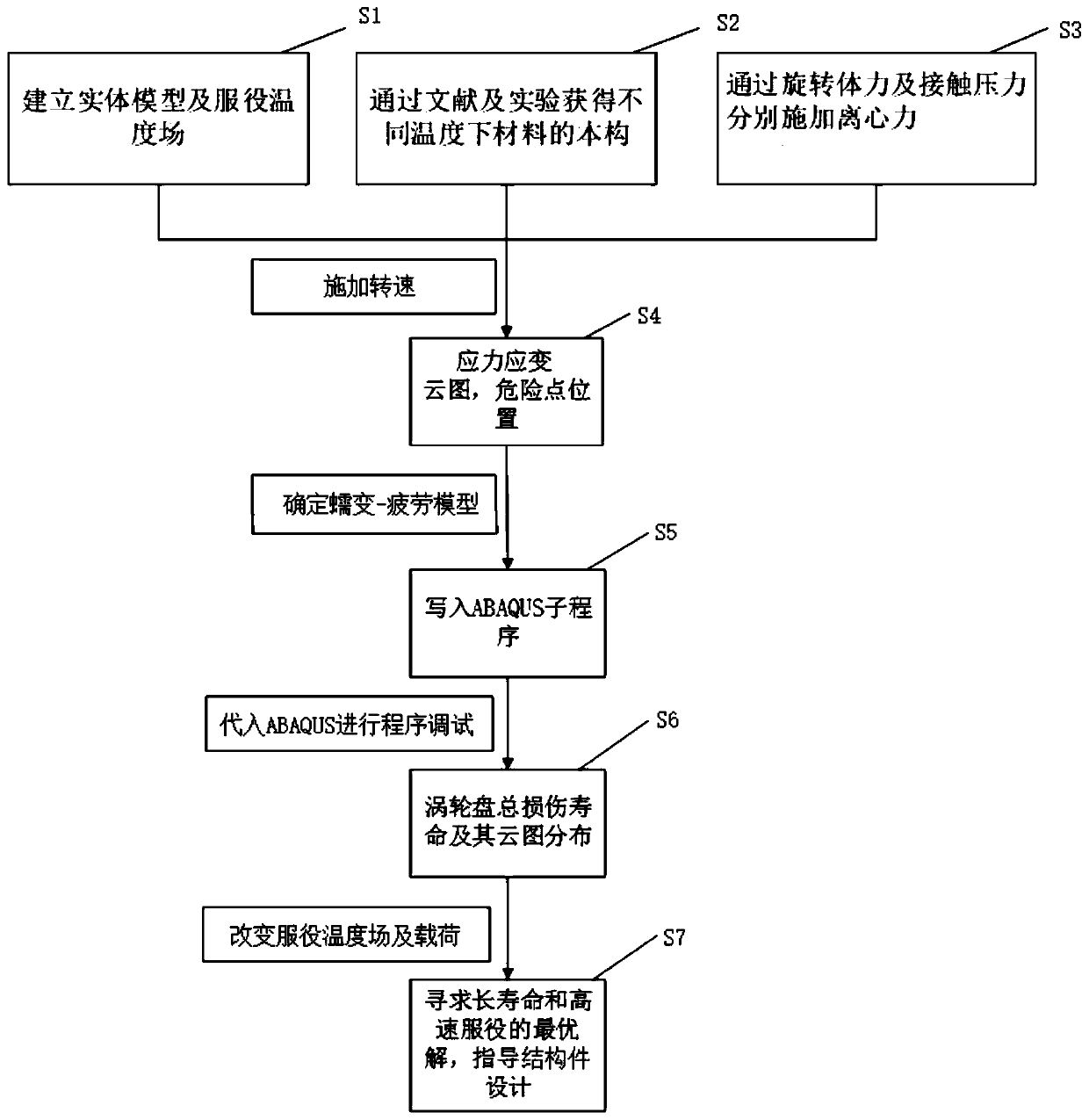

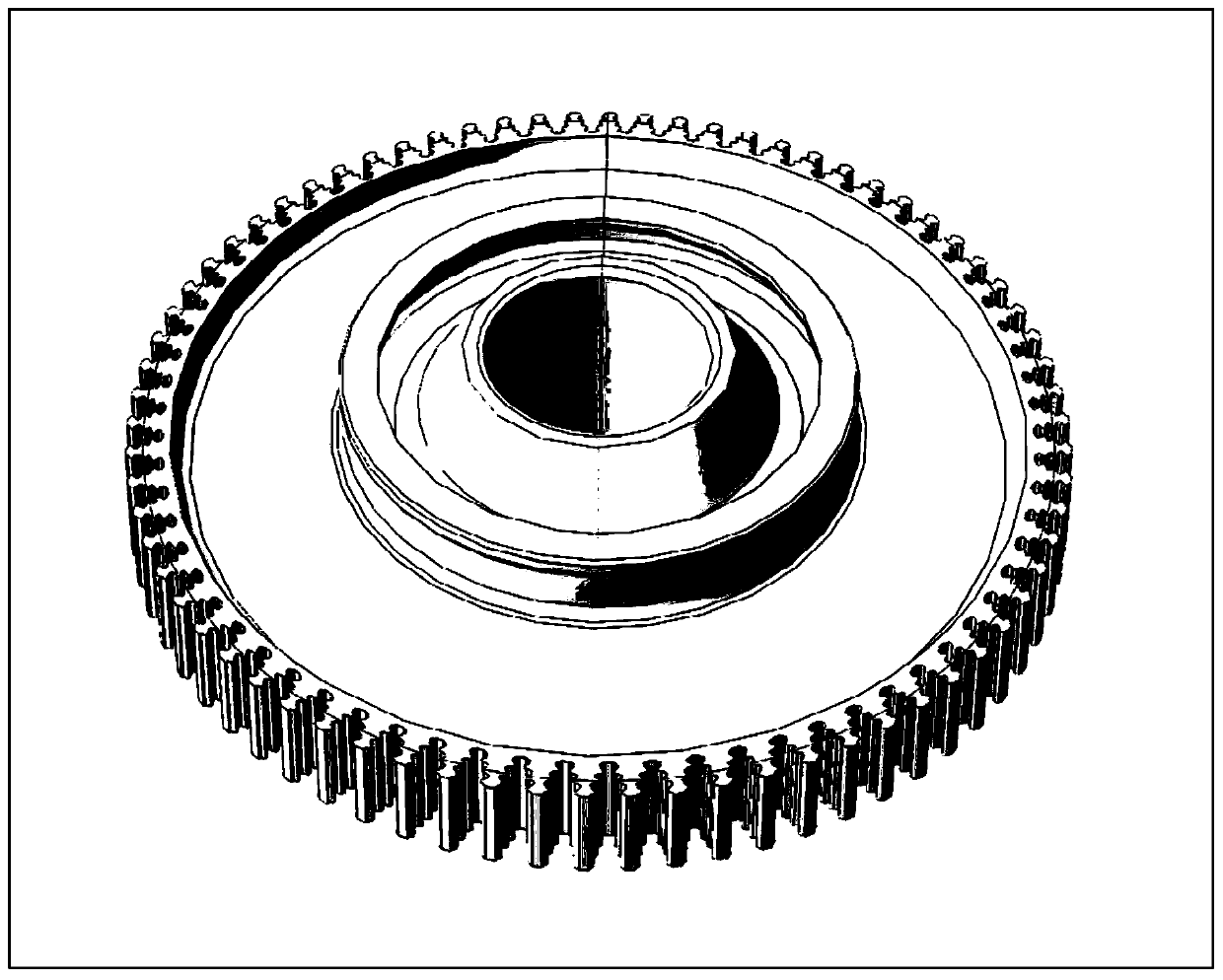

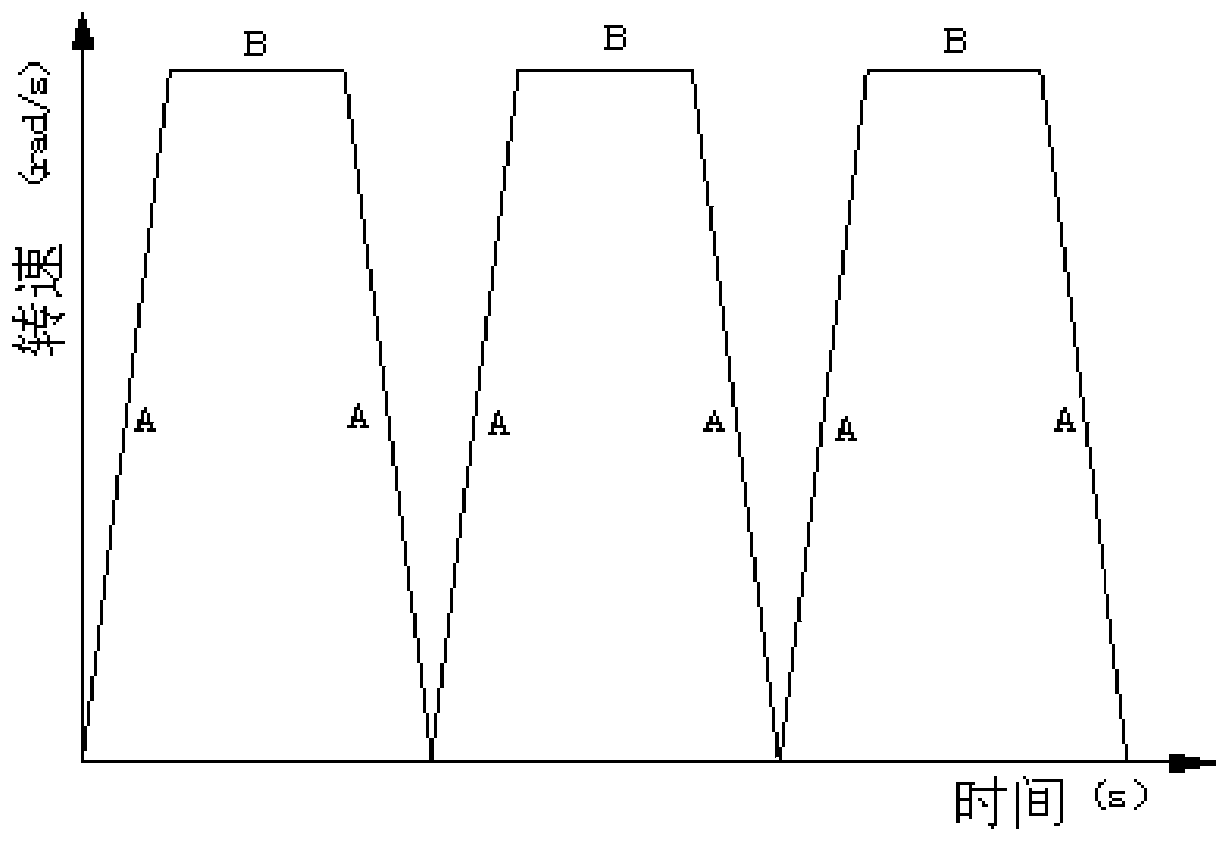

Creep-fatigue life design method for complex geometric structural member

ActiveCN111460583AIntuitiveImprove applicabilityGeometric CADSustainable transportationFatigue damageEngineering

The invention provides a creep-fatigue life design method for a complex geometric structural member. The method comprises the steps: establishing a turbine disc three-dimensional solid model and a temperature field; determining a constitutive model and material parameters of the material of the turbine disc; considering the centrifugal force of the turbine disc, and applying centrifugal loads according to the load condition of the structural member in actual work; respectively selecting a fatigue damage model and a creep damage model, and writing the fatigue damage model and the creep damage model into a subprogram UVARM; substituting the subprograms to obtain a total damage cloud chart, and further obtaining a service life distribution cloud chart of the turbine disc; seeking the optimalsolution of long service life and high load by changing the temperature field and centrifugal load of the turbine disc in the load maintaining stage. According to the service life design method, temperature distribution, fatigue damage and creep damage of the structural member are considered in simulation, the service life of the load structural member under different service temperatures and loadhistories can be predicted, and the method has the advantages of being visual, wide in application range and high in accuracy.

Owner:EAST CHINA UNIV OF SCI & TECH +1

An on-line safety assessment method of water wall

InactiveCN101551650AHigh precisionReduce occupancyProgramme controlComputer controlInstabilityEngineering

The invention relates to an on-line safety assessment method of a water wall, comprising the following steps: firstly arranging a few test points at the pipe section with flow heat transfer representativeness in each radiated area for being combined with the existing inlet and outlet test points outside the furnace, monitoring characteristic parameters in the water wall pipes of the station boiler as calculation and checking point, inputting the characteristic parameters into a computer for processing, and computing the parameters such as the flow rate, the pressure of the inlet and outlet, the enthalpy value, the temperature value of furnace inner wall of each section of pipe along the length, the amplitude value of the variation of stresses and the like of all pipes in the group on line and in real time through a flow heat transfer law so as to judge whether unsafe factors including the instable hydrodynamic force, excess temperature, creep fatigue damage and the like occurs. The computed result is displayed in real time, and the related data is recorded as the basis for judging whether the water wall is in safe operation, thereby realizing optimized running of the equipment, arranging examination and maintenance management according to the state and fully implementing the examination and reparation based on the condition of the equipment.

Owner:SHANXI SHENGSHI HUIHUANG INTELLIGENT TECH

High-temperature large-load test fixture and test method for turbine blade joggle joint structure

ActiveCN110631933ARealize the clamping effectImplement load applicationMachine part testingMaterial strength using repeated/pulsating forcesEngineeringTest fixture

Owner:BEIHANG UNIV

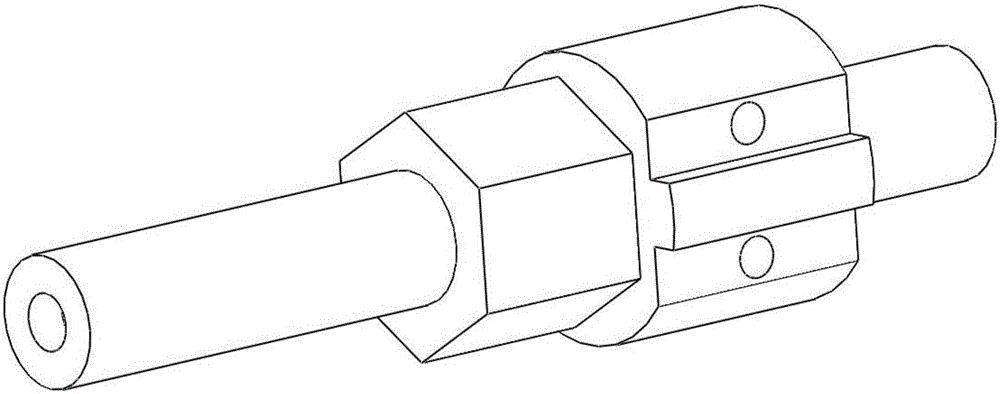

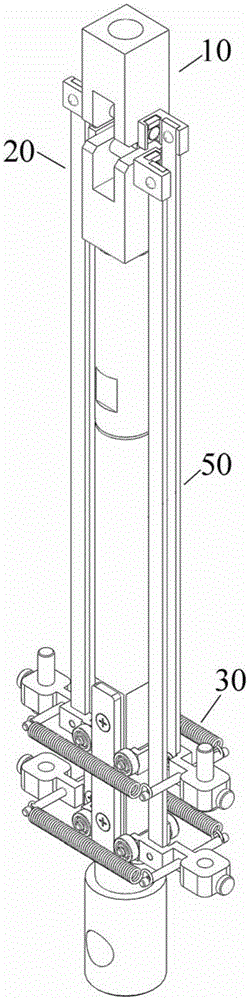

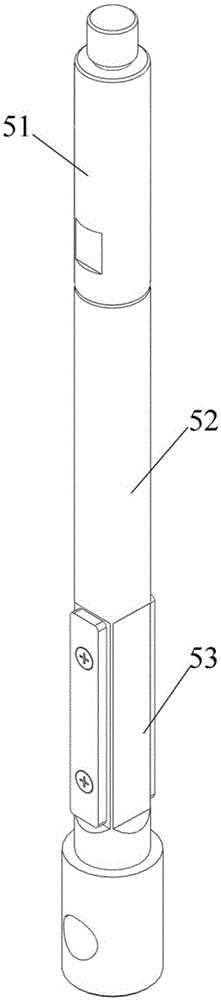

Compact tensile sample creep-fatigue crack propagation testing device

InactiveCN105277445AMaterial strength using tensile/compressive forcesEngineeringLinear displacement

The invention discloses a compact tensile sample creep-fatigue crack propagation testing device. The compact tensile sample creep-fatigue crack propagation testing device comprises a main shaft assembly, an upper chuck assembly and a lower chuck assembly are arranged at one end of the main shaft assembly, and a load linear displacement measurement assembly is arranged at the other end of the main shaft assembly. The upper chuck assembly is in threaded connection with a high-temperature pull rod of a fatigue-creep tester, the main shaft assembly comprises an upper connecting rod and a lower connecting rod, and the upper connecting rod and the lower connecting rod are coaxial. An axial guide rail is arranged at the lower end of the lower pull rod, and the lower chuck assembly is in threaded connection with the upper connecting rod. The load linear displacement measurement assembly comprises two fixing assemblies of the same structure and two measurement assemblies of the same structure, wherein the two fixing assemblies of the same structure and the two measurement assemblies of the same structure are symmetrically arranged on the two sides of the main shaft assembly respectively. Through the device, a compact tensile sample can be fixed, load linear displacement data in creep-fatigue crack propagation can be measured, and the clamp is compact and simple in structure and convenient and flexible to use and is matched with an existing tester well.

Owner:TIANJIN UNIV

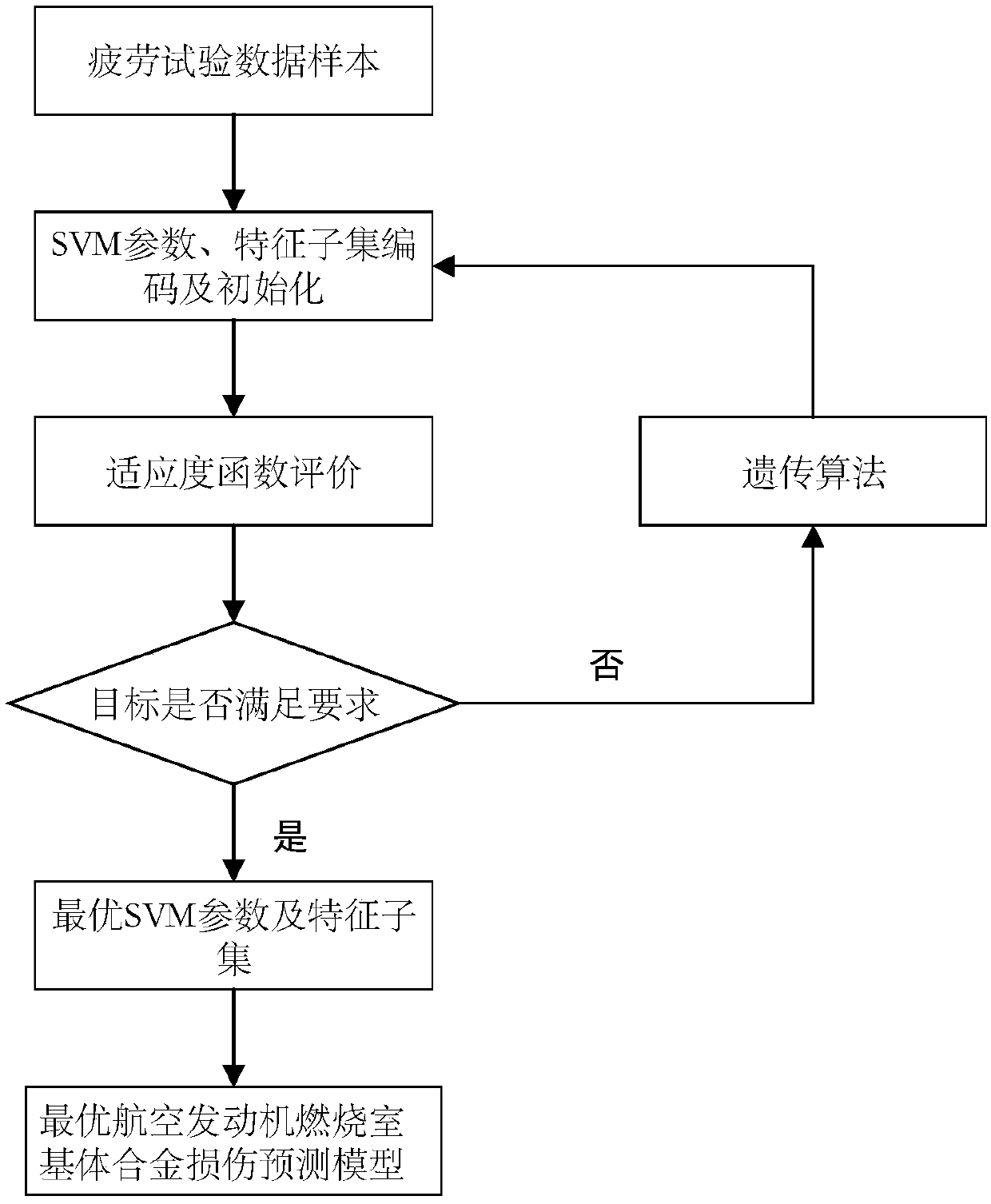

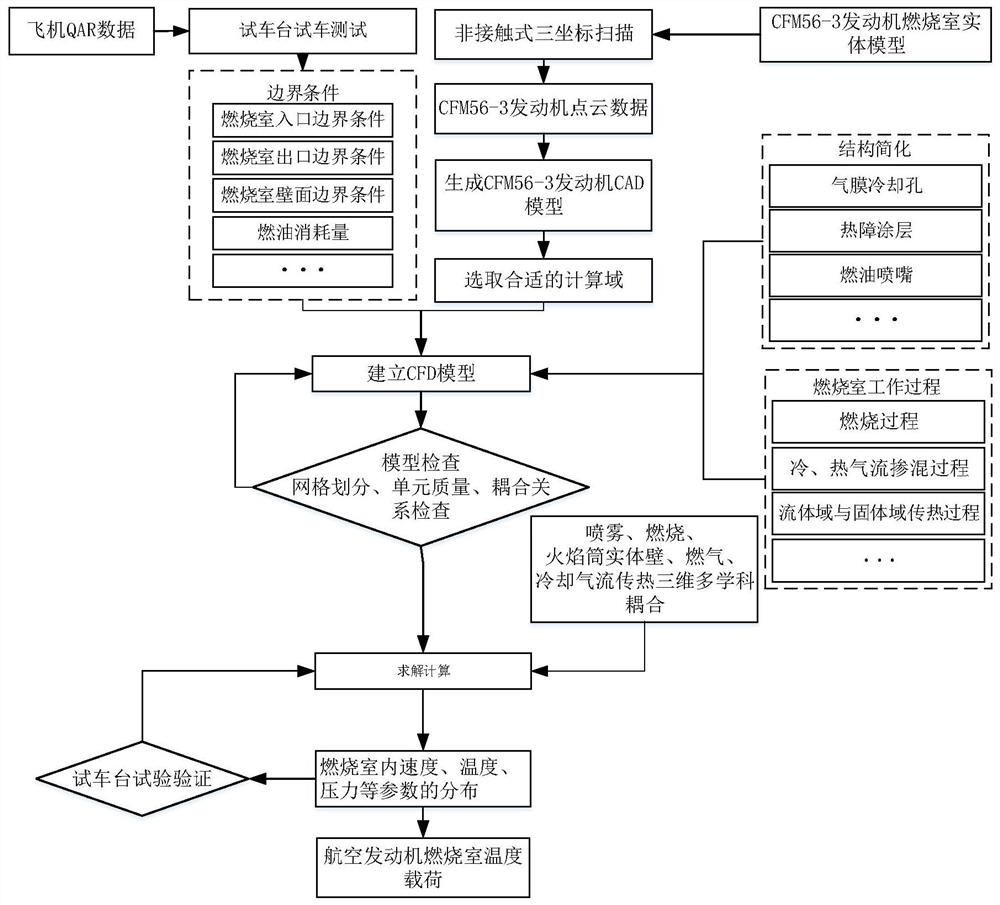

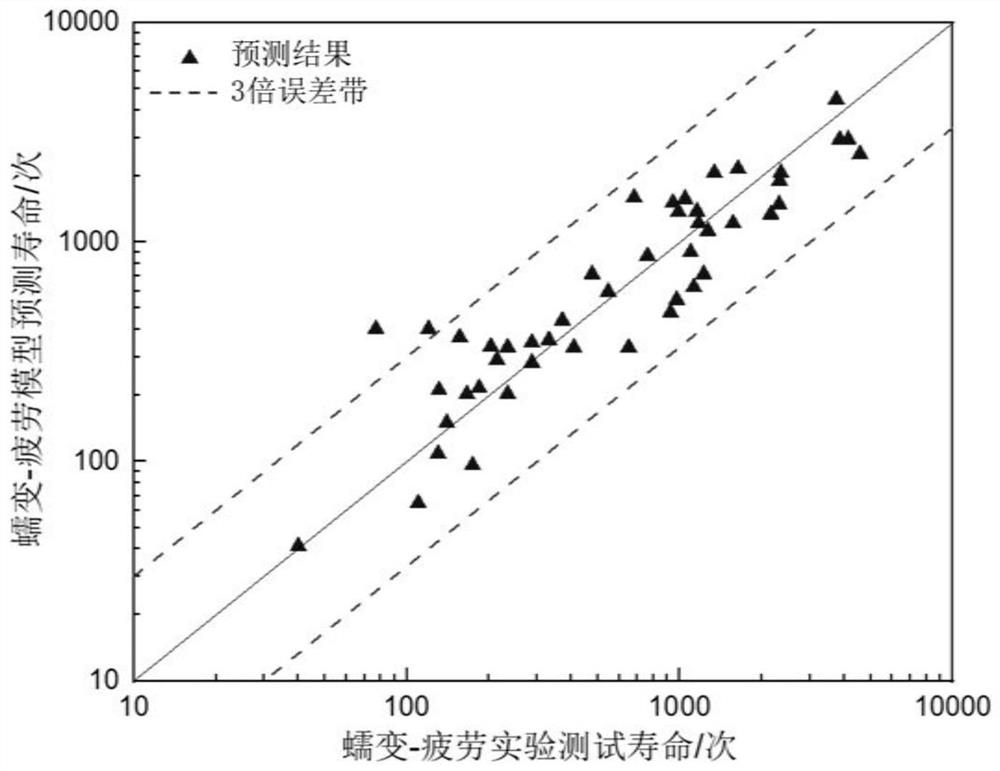

Aeroengine combustion chamber service life prediction method

ActiveCN107895088AReduce the number of experimentsGeometric CADSpecial data processing applicationsAviationSupport vector machine

The invention relates to an aeroengine combustion chamber service life prediction method. The method comprises following steps: aeroengine combustion chamber CFD analysis; aeroengine combustion chamber elastoplastic static analysis; aeroengine combustion chamber load spectrum compilation; aeroengine combustion chamber base alloy fatigue test piece design: designing hastelloy alloy creep-fatigue experimental standard pieces; aeroengine combustion chamber base alloy fatigue test load design; aeroengine combustion chamber base alloy test; using a combination of support vector machine (SVM) and genetic algorithm (GA), a model of alloy damage prediction for aeroengine combustor is established; aeroengine combustion chamber service life prediction is achieved.

Owner:TIANJIN UNIV

Ferritic heat resistant steel

Heat-resistant steel excellent in high-temperature long-term creep strength and creep-fatigue strength is provided. This heat-resistant steel comprises C: 0.01 to 0.13%, Si: 0.15 to 0.50%, Mn: 0.2 to 0.5%, P: not higher than 0.02%, S; not higher than 0.005%, Cr: exceeding 8.0% but lower than 12.0%, Mo: 0.1 to 1.5%, W: 1.0 to 3.0%, V: 0.1 to 0.5%, Nb: 0.02 to 0.10%, sol. Al: not higher than 0.015%, N: 0.005 to 0.070%, Nd: 0.005 to 0.050% and B: 0.002 to 0.015%, with the balance Fe and impurities; the content of Ni is lower than 0.3%, the content of Co is lower than 0.3% and the content of Cu is lower than 0.1% among the impurities; the steel contains Nd inclusions at a Nd inclusion density of not lower than 10000 inclusions / mm3. This steel may contain, in addition to the above-specified components, one or more elements of Ta, Hf, Ti, Ca and Mg.

Owner:SUMITOMO METAL IND LTD

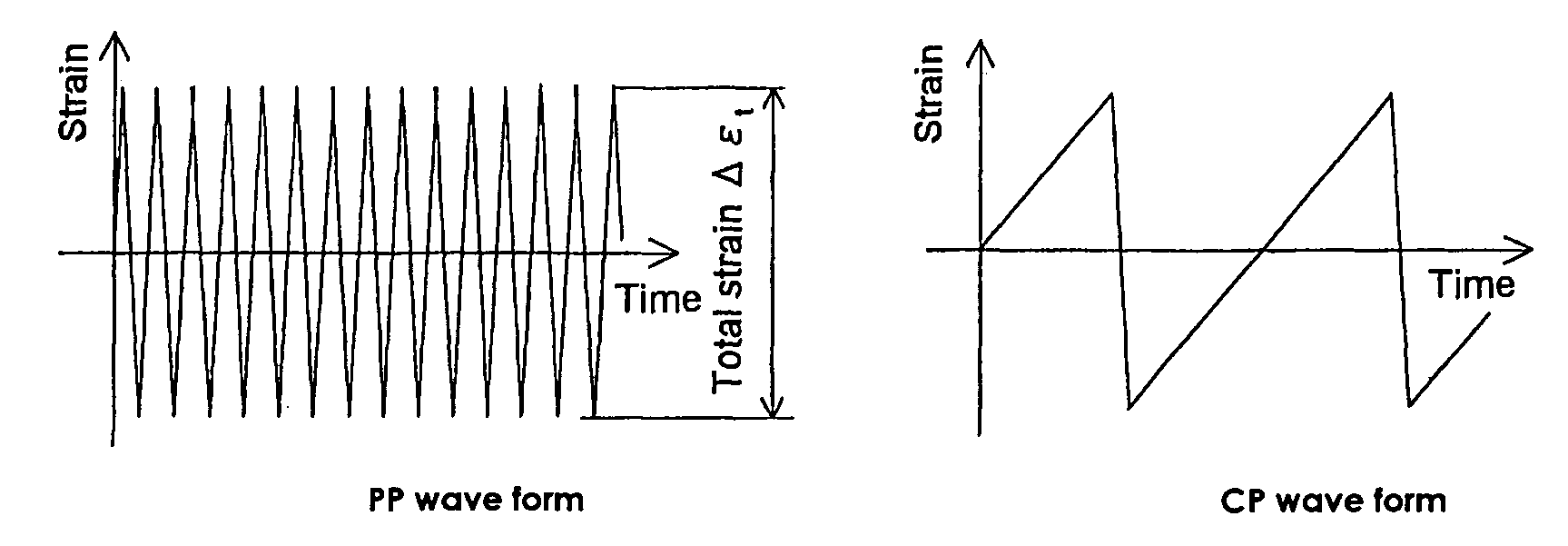

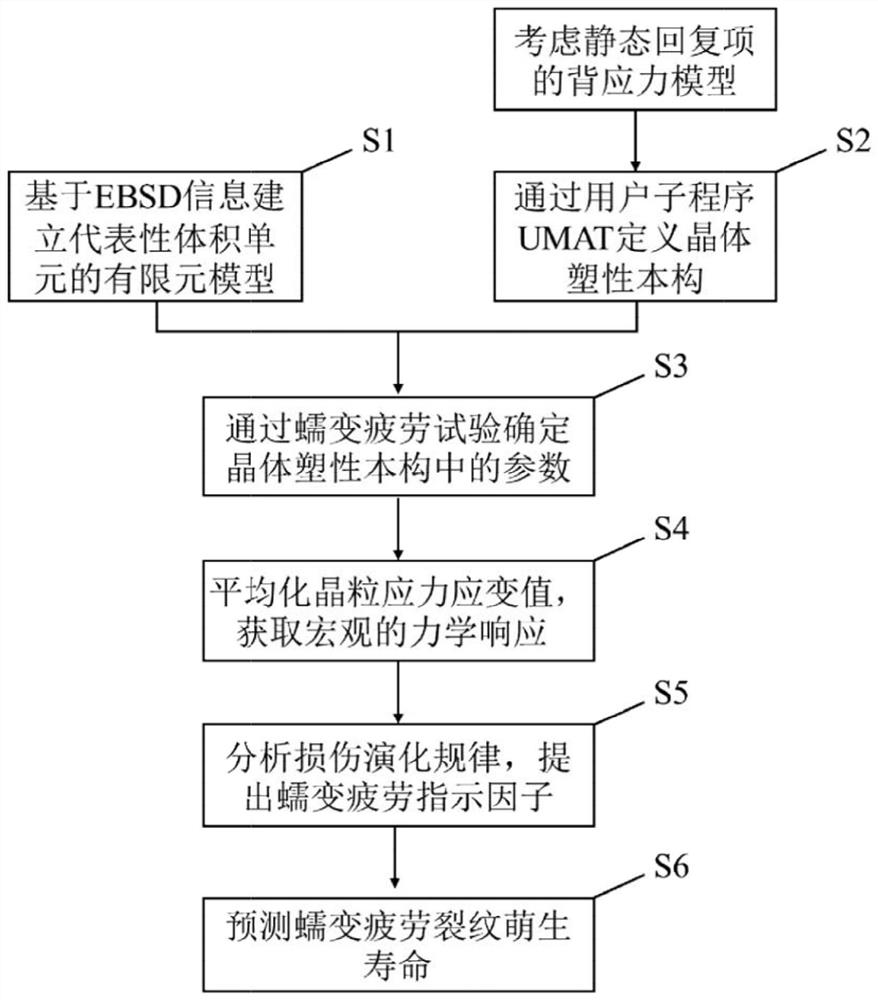

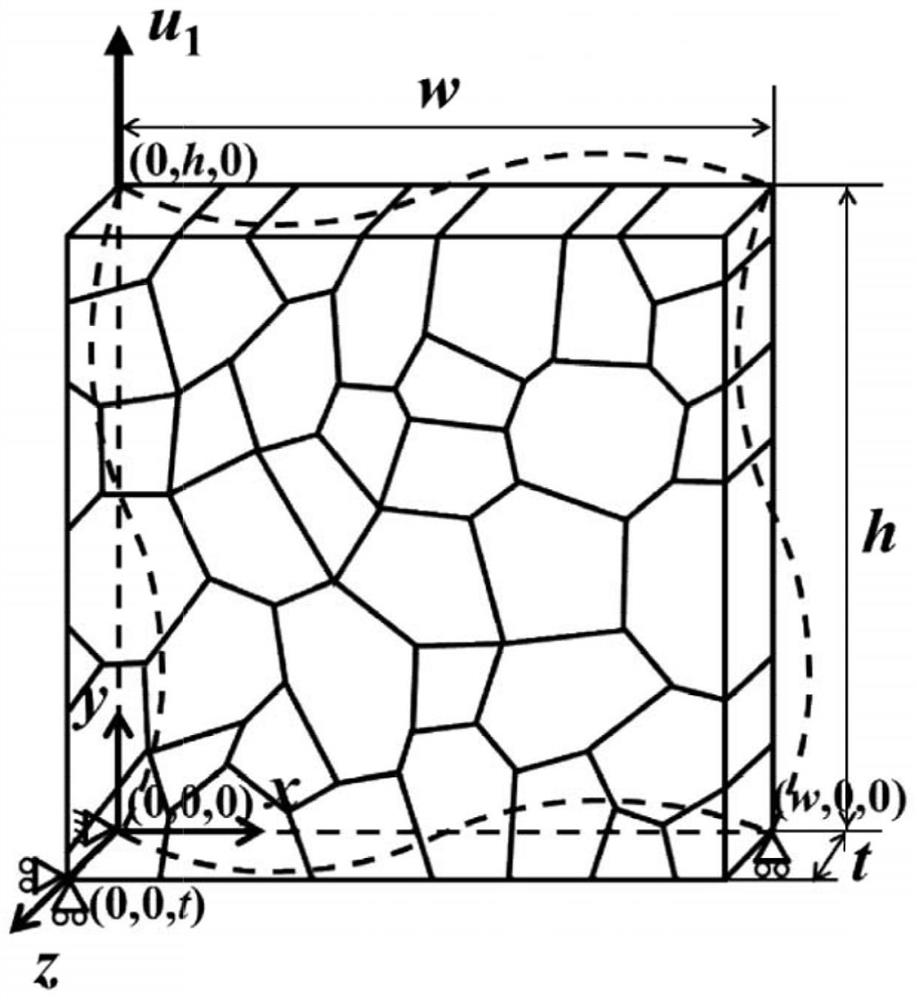

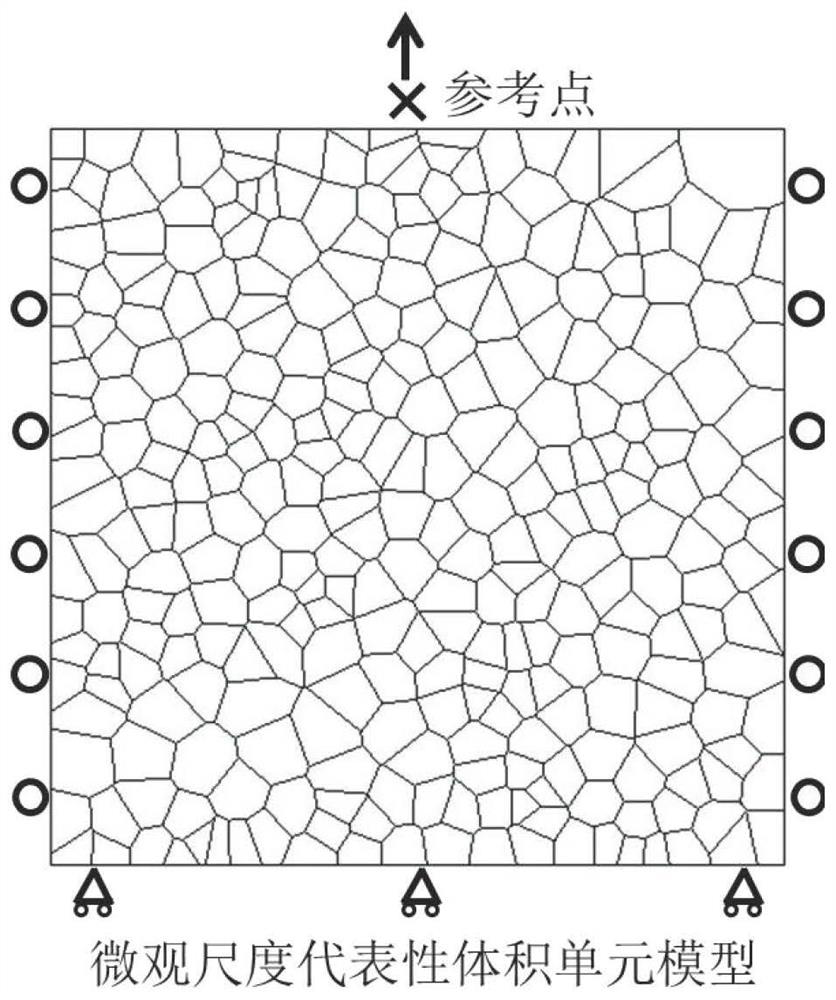

Creep fatigue life prediction method based on crystal plasticity

PendingCN112364535APredicted germination positionDesign optimisation/simulationConstraint-based CADCrystal plasticityCloud atlas

The invention provides a creep fatigue life prediction method based on a crystal plasticity theory. The method comprises the following steps: establishing a representative unit model of ABAQUS based on an electron back scattering diffraction technology; correcting the back stress model and writing the back stress model into a subprogram UMAT to obtain a creep fatigue hysteresis loop; fitting a creep fatigue hysteresis loop through a test parameter method to obtain material parameters; calculating a stress-strain value of each integral point and averaging the stress-strain values to obtain a creep fatigue hysteresis loop and a post-processing cloud atlas; extracting maximum plastic slippage and energy dissipation from the creep fatigue hysteresis loop and the post-processing cloud atlas, analyzing the change rule of the maximum plastic slippage and energy dissipation along with circulation cycles, and providing creep and fatigue indication factors; and predicting the creep fatigue crackinitiation life according to the indication factor. According to the creep fatigue life prediction method, plastic slippage and energy dissipation are used as fatigue and creep indication factors, the creep fatigue damage evolution rule can be better reflected, the crack initiation position can be accurately predicted, and the method has the advantages of being visual, high in applicability and high in accuracy.

Owner:EAST CHINA UNIV OF SCI & TECH

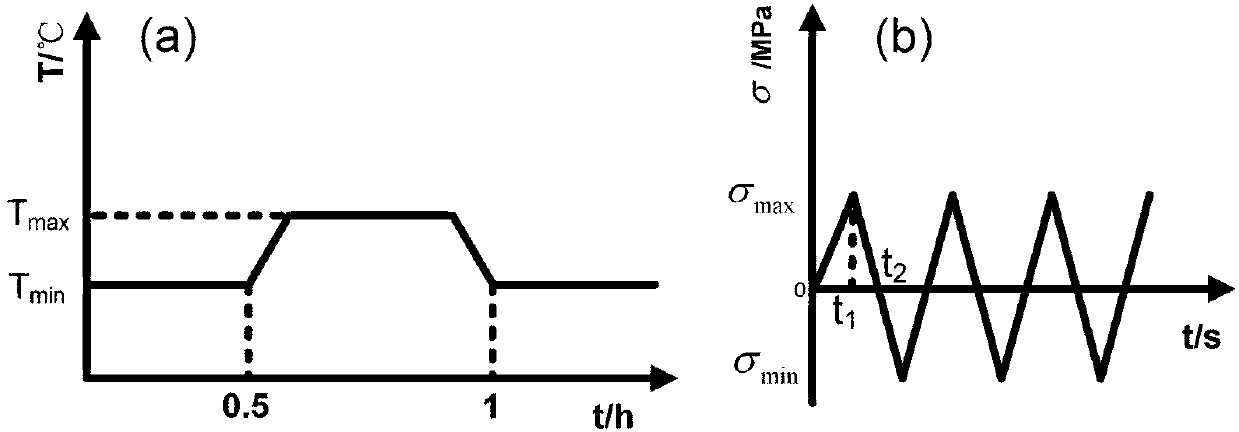

Life prediction method suitable for various cyclic loads

ActiveCN111428361APredicted Cycle LifePrediction is simpleSustainable transportationDesign optimisation/simulationStructural engineeringTest material

The invention discloses a life prediction method suitable for various cyclic loads, which comprises the following steps: carrying out any cyclic load test on a to-be-tested material, such as a strain-controlled pure fatigue test, a strain-controlled creep fatigue test or a stress-strain hybrid-controlled creep fatigue test; calculating fatigue dynamic viscosity and creep dynamic viscosity according to the test input parameters and the hysteresis curve of the half-life cycle; calculating the total energy absorbed in the cycle process according to the hysteresis curve of the half-life cycle; andfinally, establishing a life prediction equation by utilizing the relationship that the accumulated dynamic viscosity related to the fatigue dynamic viscosity and the creep dynamic viscosity is equalto the absorbed total energy, and predicting the cycle life of the to-be-tested material under the rest two cyclic load tests. According to the method, the cycle life under various cyclic loads can be simultaneously predicted by using the same group of parameters, and the method is widely applied to different materials to be tested.

Owner:NANJING UNIV OF TECH

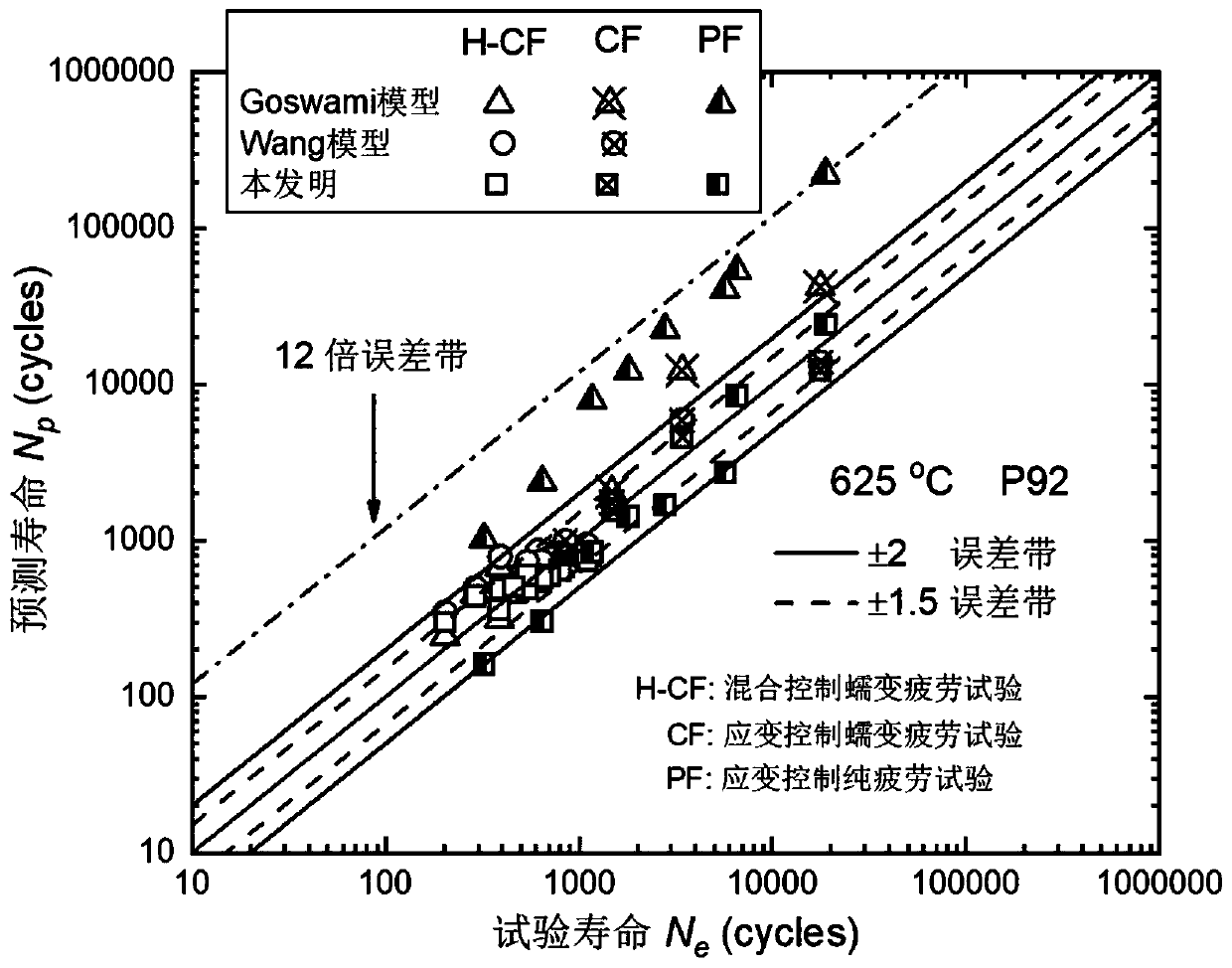

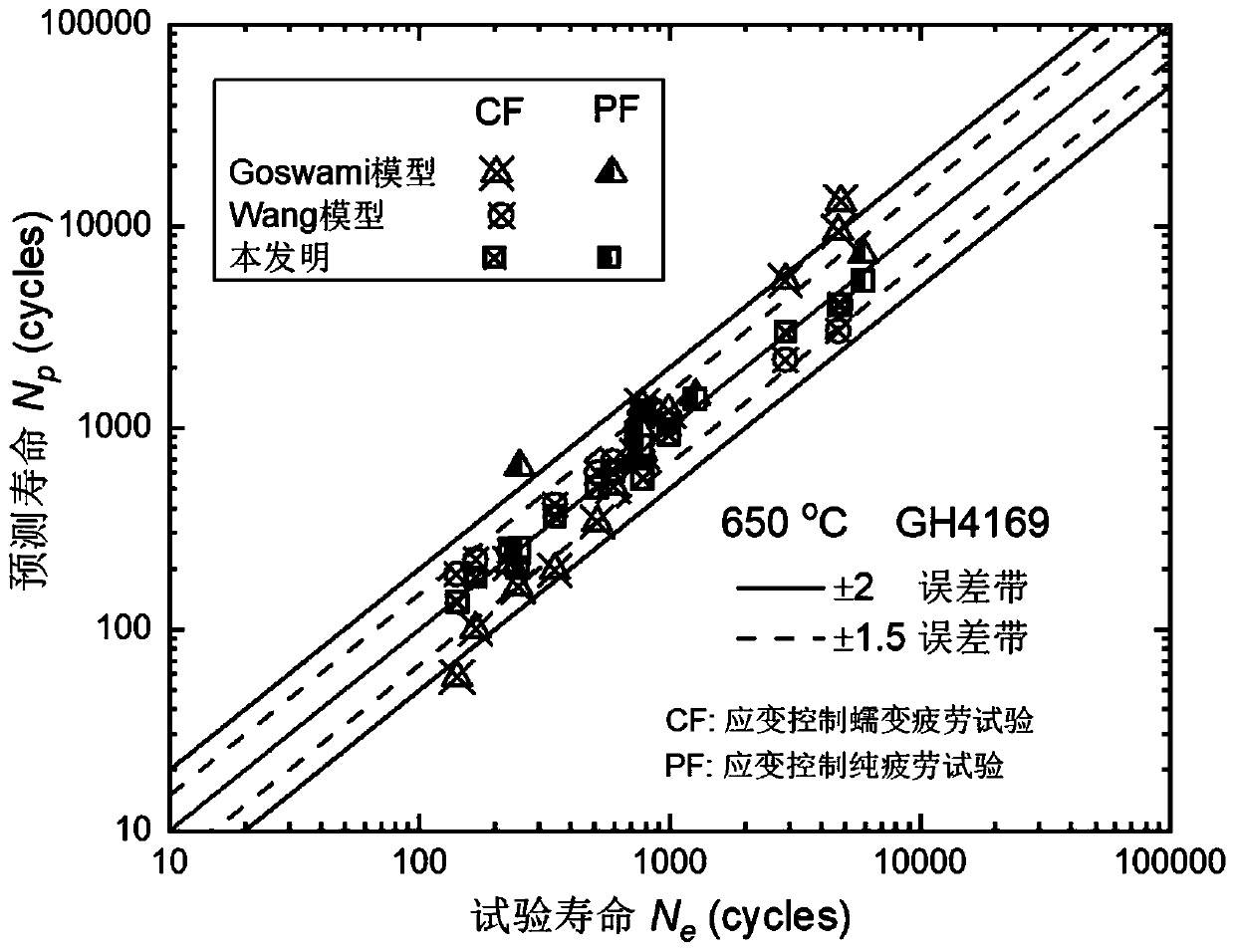

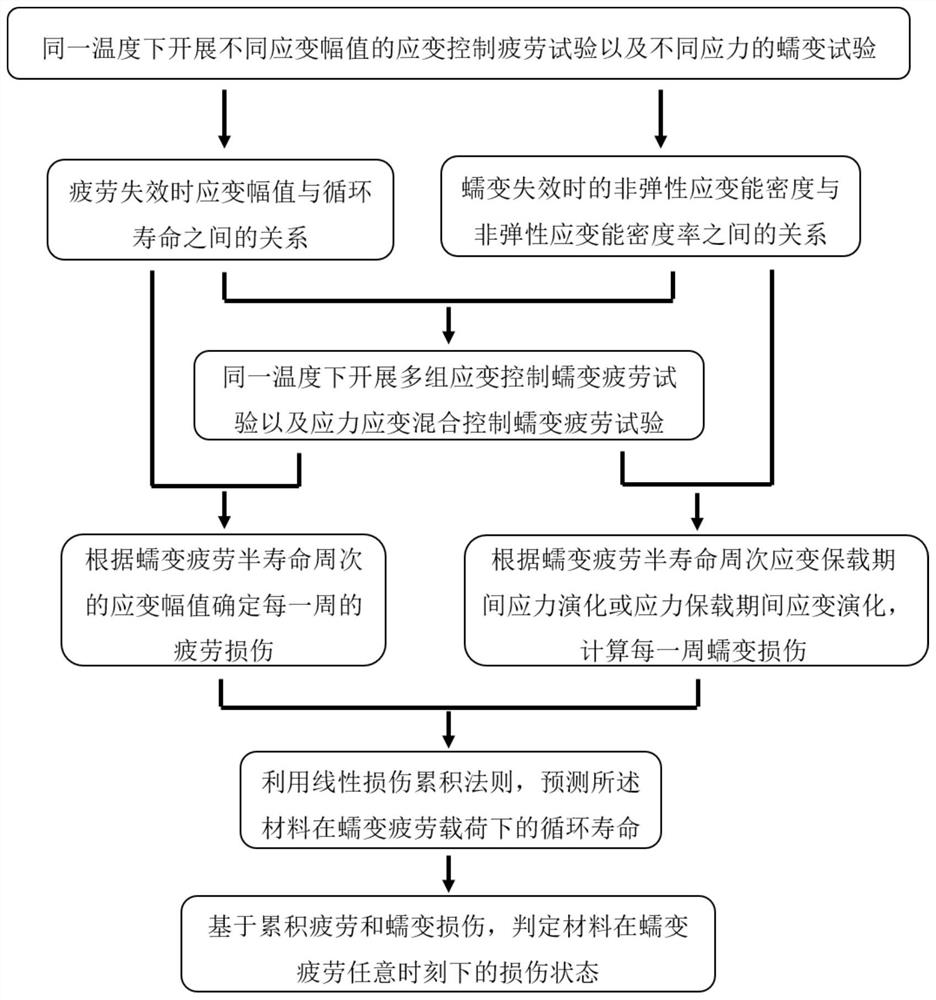

Universal method suitable for judging stress-strain hybrid creep-controlled fatigue damage state

ActiveCN113514350AAccurately Predict Cycle LifeEasy to operateMaterial strength using repeated/pulsating forcesFatigue damageStrain energy

The invention discloses a universal method suitable for judging a stress-strain mixed creep-controlled fatigue damage state. The method comprises the following steps: firstly, carrying out multiple groups of different strain-controlled pure fatigue tests and creep tests at the same temperature; then determining the relationship between the strain amplitude and the service life and the relationship between the inelastic strain energy density and the inelastic strain energy density rate; then carrying out a plurality of groups of strain control and stress-strain mixed control creep fatigue tests; further determining fatigue damage of each week according to the strain amplitude, and determining creep damage of each week according to stress evolution or strain evolution during load holding; predicting the service life of the material under the creep fatigue load based on the damage; and finally, judging the damage state of the sample at any moment according to the accumulated fatigue and creep damage of the sample and a bilinear damage criterion specified by the American ASME III-NH standard. According to the invention, the service life of the material under strain control and mixed control creep fatigue loads can be well predicted, and the damage state of the sample at any moment can be judged.

Owner:NANJING TECH UNIV

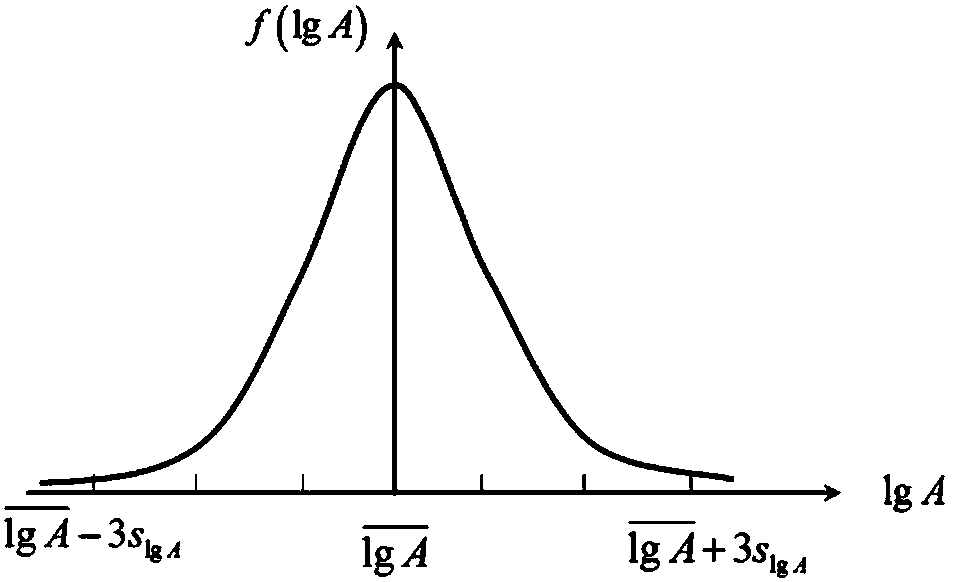

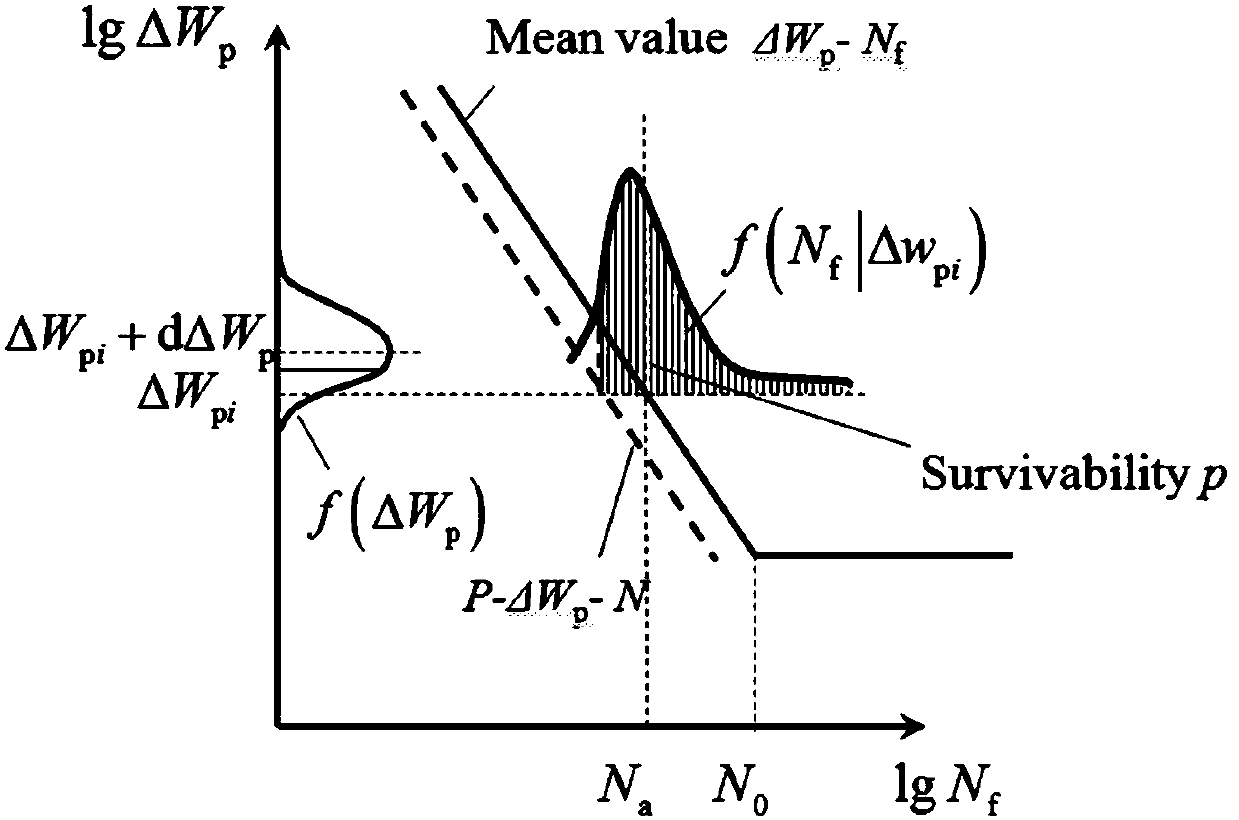

Creep-fatigue life prediction and reliability analysis method for Martensitic steel

InactiveCN107391903AVerify rationalityInformaticsSpecial data processing applicationsLife timeAnalysis method

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

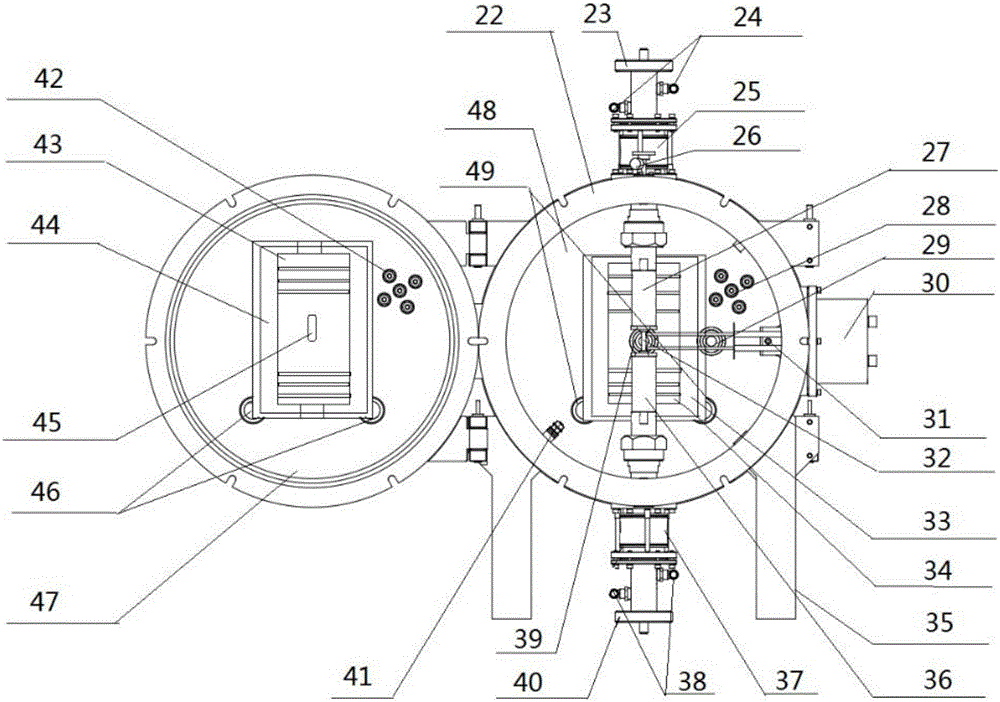

Creep-fatigue interaction test device and load loading and unloading method thereof

ActiveCN102419288AStable forceUndisturbedMaterial strength using repeated/pulsating forcesProgrammable logic controllerElectric machine

The invention provides a creep-fatigue interaction test device, which comprises a lever, wherein one end of the lever is connected with a sample arranged in a high-temperature heating furnace; the other end of the lever is connected with an upper suspender; the upper suspender is connected with a lower suspender; a loading and unloading tray is positioned under a lower weight tray; and the sample is connected with a leveling transmission mechanism through a tie rod. The creep-fatigue interaction test device is characterized in that: the end part, which is connected with the upper suspender, of the lever is connected with displacement sensor which is used for leveling; a programmable logic controller is connected with a variable frequency motor mechanism; and the leveling transmission mechanism and a loading and unloading transmission mechanism are respectively driven by the variable frequency motor mechanism. The invention adopts another technical scheme that: a method adopting the equipment is provided. The creep-fatigue interaction test device is relatively low in cost and easy to realize, and has the advantages of stable power value, reliable change and the like, of a lever type creep lasting tester. In addition, the displacement sensor is adopted to perform lever leveling control, so compared with the prior art in which photoelectric limit switch control technology is adopted, the creep-fatigue interaction test device is higher in control precision.

Owner:SHANGHAI POWER EQUIP RES INST

Lead-free solder

InactiveCN102233488ACompatibleImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaMechanical propertySpreadability

The invention discloses a newly developed lead-free solder, and in particular relates to a low-cost and high-performance lead-free solder for microelectronic package. The lead-free solder is characterized by comprising the following components by weight percentage: 0.5-1% of Ag, 0.3-0.7% of Cu, 1-3% of Bi, 0.0002-0.0005% of P, 0.01-1% of Ce, 0.01-0.15% of Ni and the balance of Sn. The lead-free solder meets the dual requirements of the market for no lead and benefit. The lead-free solder provided by the invention has the characteristics of no toxicity, good mechanical properties, good electrical properties, excellent oxidation resistance, excellent corrosion resistance, good creep fatigue resistance, good wettability, good spreadability, high solder joint reliability, low cost, good mechanical properties and the like.

Owner:NINGBO ZHUOCHENG SOLDER TECH

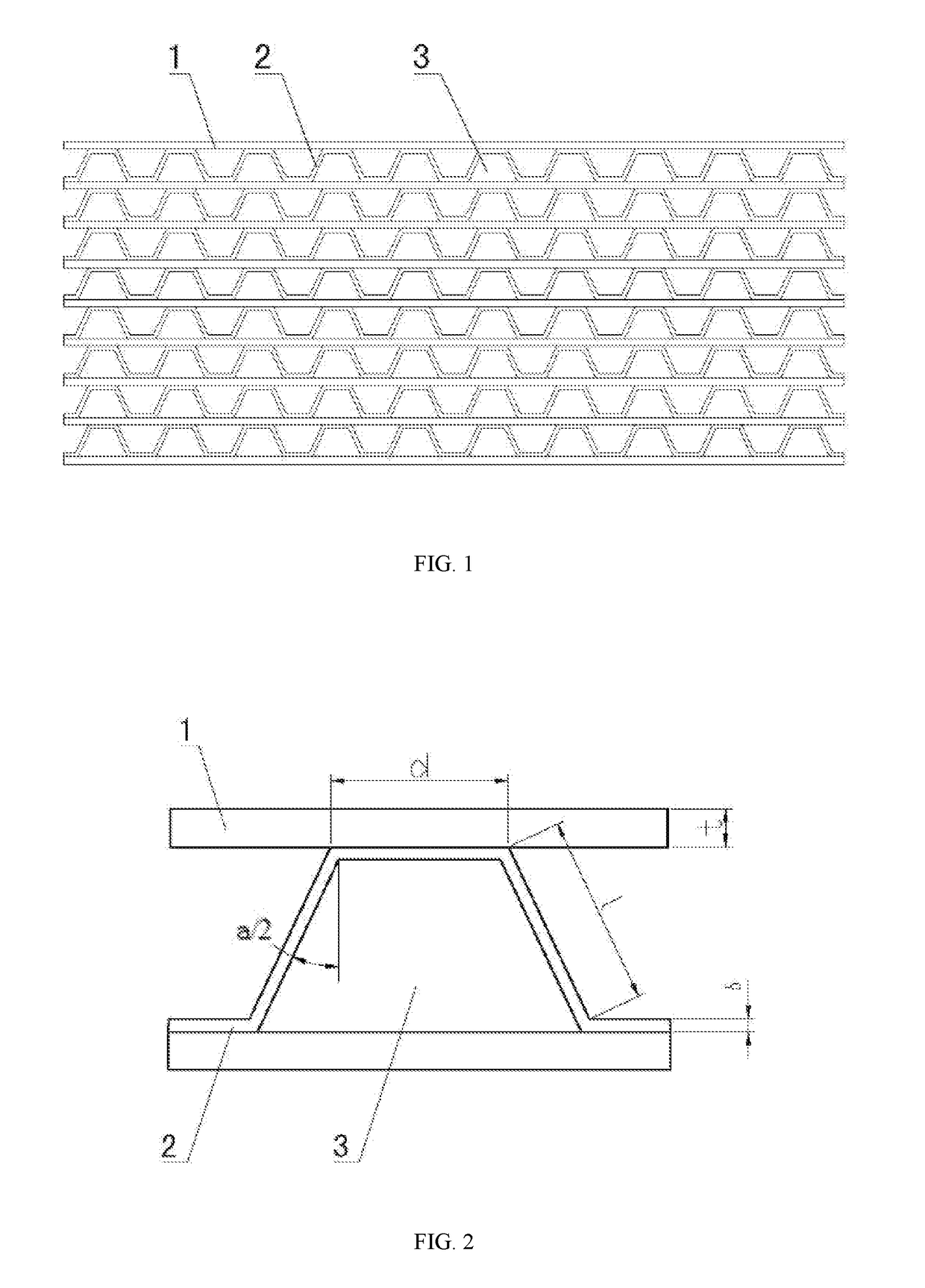

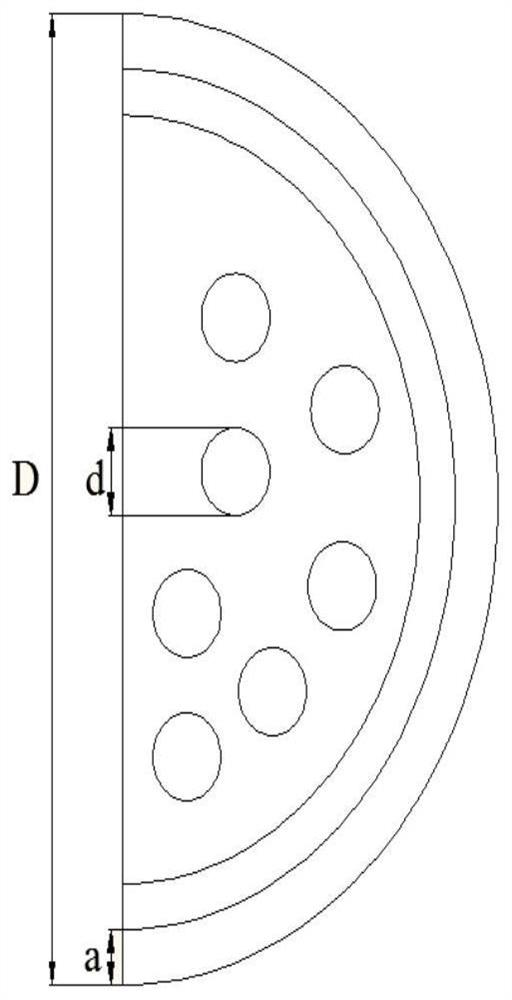

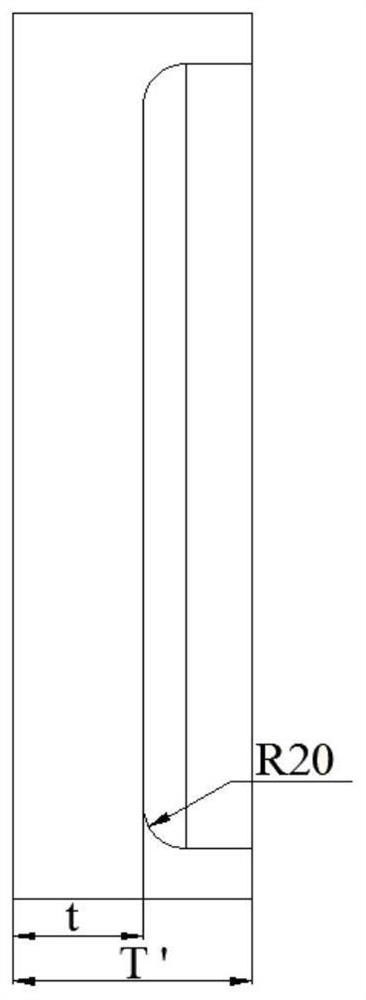

Design method for creep-fatigue strength of plate-fin heat exchanger

ActiveUS20180365356A1Improve design efficiencyEasy to calculateGeometric CADDesign optimisation/simulationThermal fatigueStress assessment

A design method for creep-fatigue strength of a plate-fin heat exchanger. The method includes preliminarily designing the plate-fin heat exchanger according to its service requirements, making a primary stress assessment for the plate-fin heat exchanger, calculating the equivalent mechanical and thermophysical parameters of the plate-fin heat exchanger core to satisfy the allowable stress requirement, performing a thermal fatigue analysis for the plate-fin heat exchanger based on these parameters and then calculating the fatigue life and creep life of the plate-fin heat exchanger to accomplish the comprehensive design of the plate-fin heat exchanger in the high-temperature service. The design method provides an effective method for the high temperature design of the plate-fin heat exchanger.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for assessing structural integrity of high-temperature and high-pressure welded member

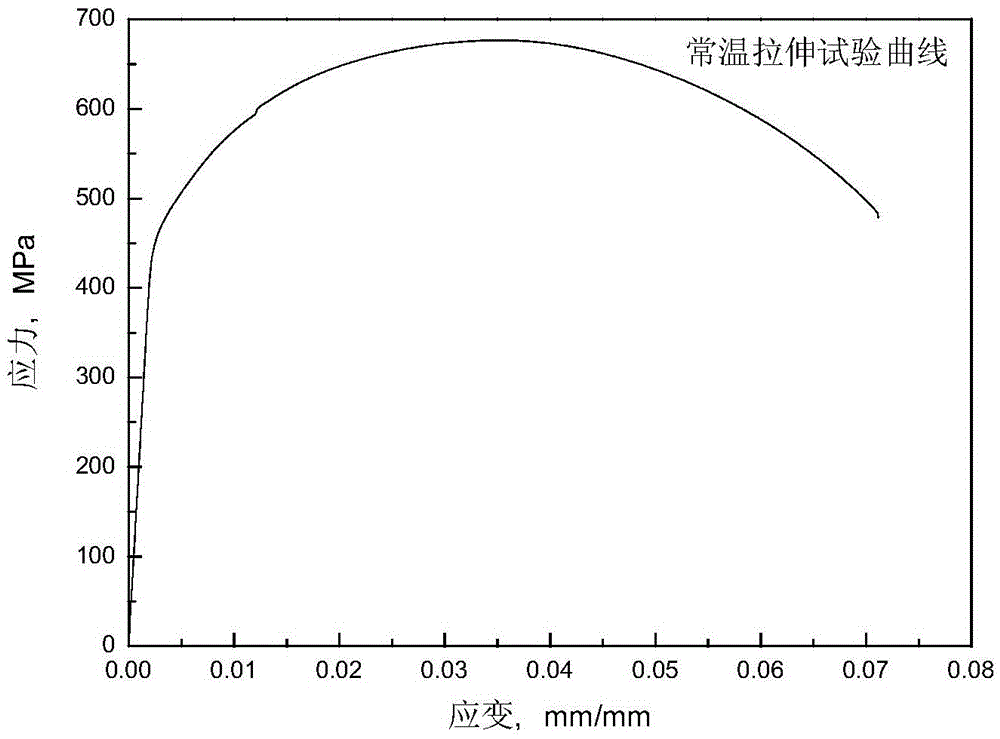

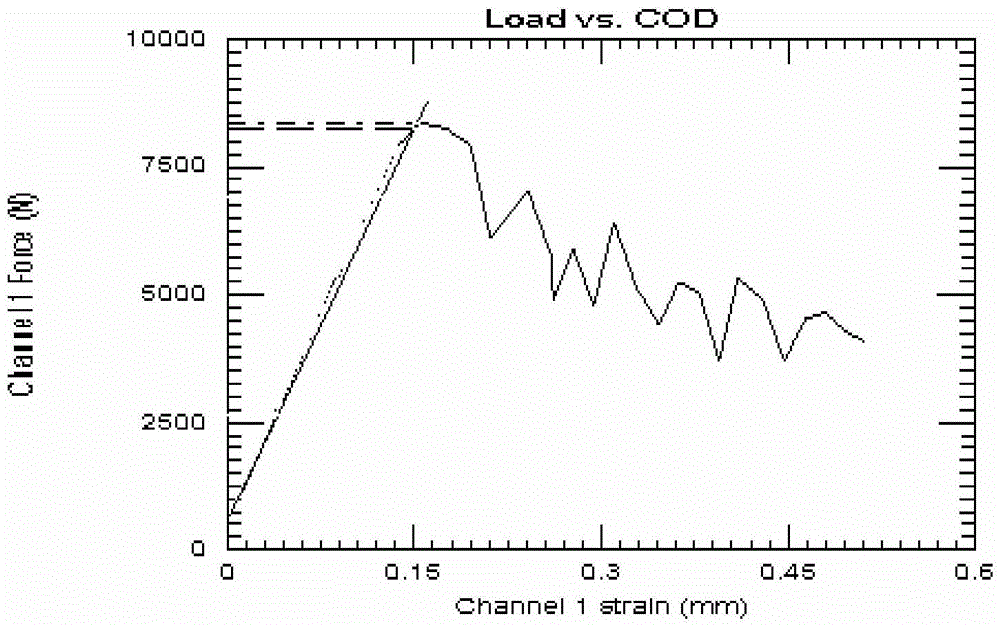

InactiveCN105651606ASafety Assessment ScienceSafety assessment is accurateMaterial analysis by electric/magnetic meansMaterial strength using tensile/compressive forcesFailure assessmentStress–strain curve

The invention relates to a method for assessing the structural integrity of a high-temperature and high-pressure welded member. The method comprises the following steps that (a) mechanical performance testing is conducted on a joint material of the welded member at normal temperature and high temperature; (b) crack propagation rate testing under the creep-fatigue and fatigue-creep interaction effect is conducted on the joint of the welded member in a high-temperature temperature to obtain crack propagation characteristics represented by high-temperature breakage parameters; (c) SEM is adopted to analyze the fracture of the joint of the welded member so as to determine a failure mode of a test sample and select corresponding high-temperature breakage parameters; (d) an isochronous stress-strain curve of the joint of the welded member is established; (e) the ratio value of a stress intensity factor to fracture toughness serves as a vertical coordinate and the ratio value of an applied load to a plastic collapse load serves as a horizontal ordinate to establish a failure assessment curve about the correlation between the joint material of the welded member and time, and an assessment area of the failure assessment curve is divided into a safety area and a failure area to perform structural safety assessment. Therefore, the obtained safety evaluation is more scientific and accurate.

Owner:SUZHOU NUCLEAR POWER RES INST +2

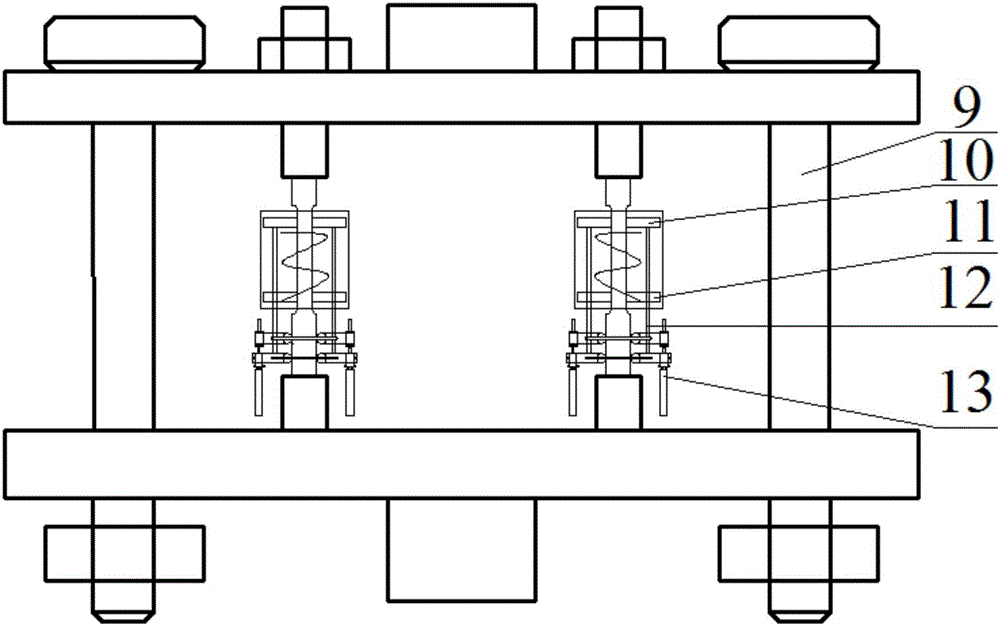

Experiment device and testing method of uniaxial BREE solution

InactiveCN105738223AFacilitate experimental researchThe result is objectiveMaterial strength using tensile/compressive forcesTemperature controlUniaxial load

The invention discloses an experiment device and testing method of a uniaxial BREE solution. The experiment device mainly comprises a high temperature creep fatigue testing machine, an upper beam, a lower beam, sample clamps, a first rod sample, a second rod sample, a heating furnace, a high temperature displacement sensor, a temperature controller and a measurement system. The upper beam and the lower beam are fixed to the high temperature creep fatigue testing machine, the two parallel sample clamps are arranged between the upper beam and the lower beam, and the first rod sample and the second rod sample are fixed to the two sample clamps; the first rod sample and the second rod sample are provided with the heating furnace and the high temperature displacement sensor, the temperature controller is connected with the first rod sample and the second rod sample, and the measurement system is connected with the high temperature creep fatigue testing machine. The testing method includes the steps that the high temperature displacement sensor tests displacement deformation of the rod samples, and the relation between plastic stress and the cycle times is obtained, so that the structural stability limit is obtained. The experiment device and testing method can be used for testing and evaluating of the structural stability limit under the condition of uniaxial load and similar working conditions.

Owner:江西铭源电气有限公司

Method for predicting dual-scale creep fatigue life of discontinuous structure

PendingCN112966347AAccurate prediction of creep fatigue lifeGeometric CADDesign optimisation/simulationCrystal plasticityElement model

The invention relates to a method for predicting the dual-scale creep fatigue life of a discontinuous structure. The method comprises the following steps: extracting a displacement field of a finite element model of the discontinuous structure; obtaining crystal plasticity model parameters, and establishing a crystal plasticity finite element model at the dangerous position of the discontinuous structure; taking a displacement field of the finite element model of the discontinuous structure as a boundary condition of a crystal plasticity finite element model, and constructing a dual-scale finite element model of the discontinuous structure; acquiring a creep indication factor and a critical value thereof, and a fatigue indication factor and a critical value thereof; and predicting the creep fatigue life of the discontinuous structure. According to the method, the stress condition of the discontinuous structure on the macro scale can be reflected, the damage evolution of the discontinuous structure on the micro scale can be revealed, the dangerous position of creep fatigue crack initiation can be effectively obtained, and therefore the creep fatigue life of the discontinuous structure can be accurately predicted; and theoretical support is provided for premature failure prevention and life extension of the discontinuous structure.

Owner:EAST CHINA UNIV OF SCI & TECH

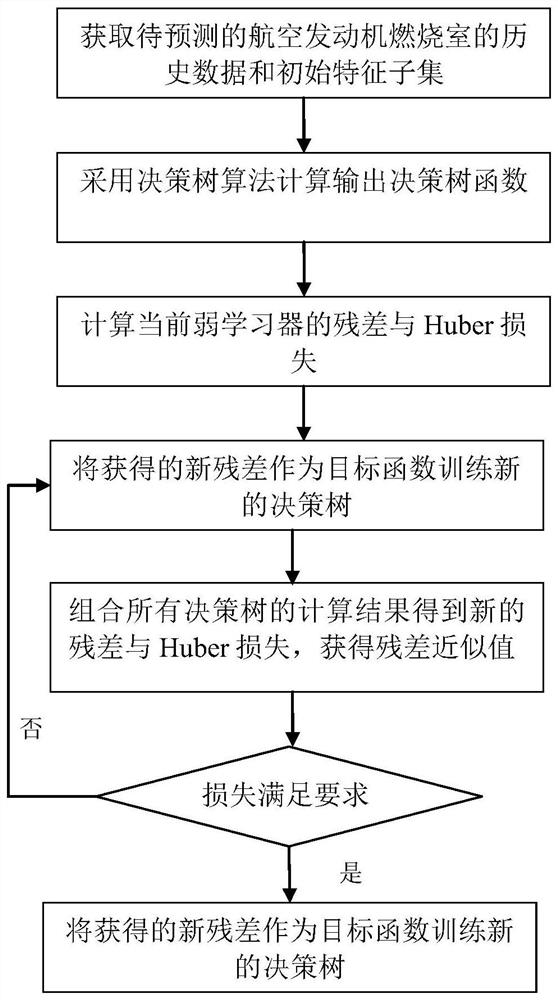

Aero-engine combustion chamber creep fatigue life prediction method

PendingCN113569504ALife expectancyForecastingDesign optimisation/simulationCombustion chamberAlgorithm

The invention discloses an aero-engine combustion chamber creep fatigue life prediction method. The method comprises: obtaining historical data and an initial feature subset of a to-be-predicted aero-engine combustion chamber; training the extracted initial feature subset by adopting an iterative decision tree algorithm to obtain a creep fatigue life prediction model of the aero-engine combustion chamber, and predicting the creep fatigue life of the aero-engine combustion chamber by utilizing the creep fatigue life prediction model of the aero-engine combustion chamber obtained in the step 2; and performing model calculation by taking the aero-engine combustion chamber load spectrum obtained in the step 1 as an input quantity of a prediction model so as to predict the creep fatigue residual life of the aero-engine combustion chamber. The invention further discloses a system for predicting the creep fatigue life of the aero-engine combustion chamber.

Owner:天津内燃机研究所(天津摩托车技术中心)

High-precision creep fatigue crack propagation testing machine

InactiveCN111060406AImplement crack growth testMaterial strength using tensile/compressive forcesOptically investigating flaws/contaminationTemperature controlControl system

The invention discloses a high-precision creep fatigue crack propagation testing machine which comprises a direct-current bias power supply, a voltage instrument and a testing host. The testing host comprises a high-temperature CT stretching tool, a high-temperature furnace observation window, a split high-temperature furnace (1200 DEG C), a high-temperature furnace rotating bracket, an electronicuniversal test host, a CCD camera rotating bracket, a CCD camera, a temperature control box, a temperature control system, a test control system and software. A crack propagation test of a high-temperature alloy material in a high-temperature environment is realized by improving a conventional static electronic universal testing machine and adding software and hardware.

Owner:珠海市三思泰捷电气设备有限公司

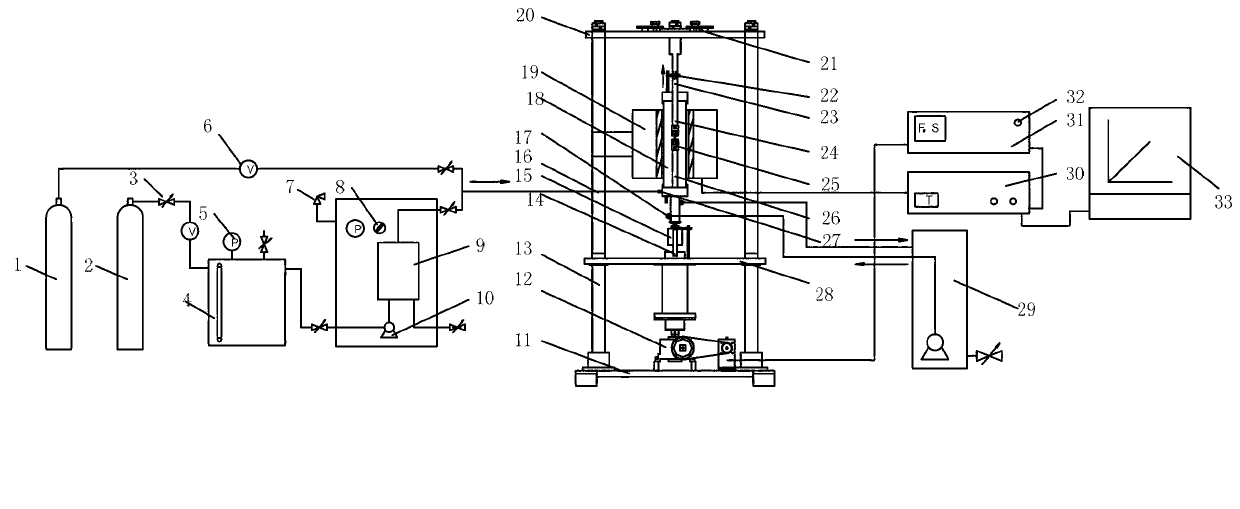

Creep-fatigue property testing system with controllable oxygen partial pressure

ActiveCN105973693AMeet the requirements of creep fatigue performance testingMulti-level controllable oxygen partial pressureMaterial strength using repeated/pulsating forcesEngineeringProcess engineering

The invention relates to a creep-fatigue property testing system with a controllable oxygen partial pressure. The creep-fatigue property testing system comprises a mixed gas inflating subsystem, a mechanical loading main unit, an inflating high-temperature furnace and a circular water cooling subsystem, wherein the mixed gas inflating subsystem comprises a premixed inflating tank, an oxygen source and an argon source; the oxygen source and the argon source are respectively connected with the premixed inflating tank through mass flowmeters; the mass flowmeters control the oxygen source and the argon source to provide oxygen and argon with preset proportions to the premixed inflating tank according to the preset proportions provided by a computer industrial control subsystem; the inflating high-temperature furnace is arranged between a cabinet of the main unit and a cross beam of the main unit; the circular water cooling subsystem is connected with the inflating high-temperature furnace. The testing system disclosed by the invention is integrally redesigned, and is additionally provided with the mixed gas inflating subsystem, and all key parts are improved by aiming at an application occasion of an oxygenating environment, so that the testing system can meet the demand of a creep-fatigue property test with the controllable oxygen partial pressure, is high in testing precision and stable and safe in operation; the oxygen partial pressure is controllable in multiple stages.

Owner:EAST CHINA UNIV OF SCI & TECH +1

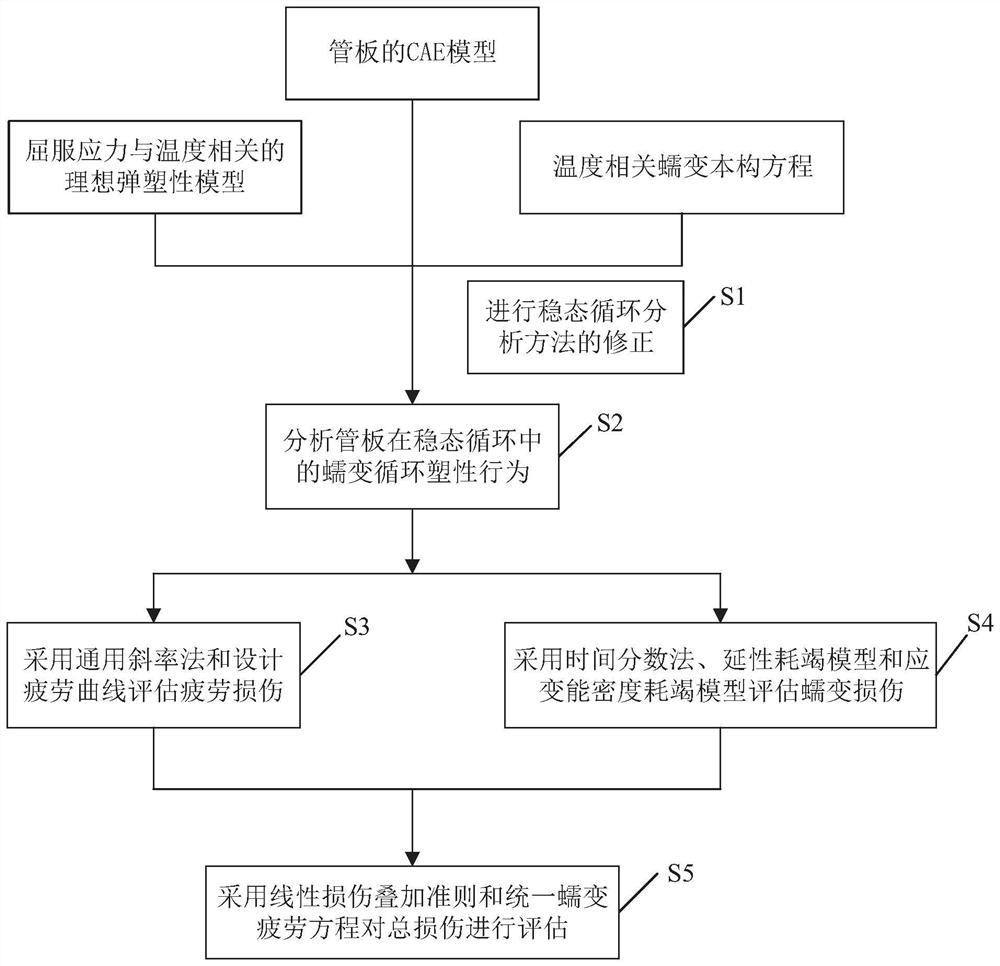

Creep fatigue damage assessment method for superheater tube plate

ActiveCN113049376AEffective assessmentIdentify key factors of injuryMaterial strength using tensile/compressive forcesFatigue damageStrain energy

The invention provides a creep fatigue damage assessment method for a superheater tube plate. The creep fatigue damage assessment method comprises the steps of correcting a steady-state cyclic analysis method; combining a CAE model, a yield stress and temperature related ideal elastic-plastic model and a temperature related creep constitutive equation, and analyzing the creep cycle plasticity behavior of the tube plate in the steady-state cycle; designing a fatigue curve to evaluate fatigue damage by adopting a general slope method; evaluating creep damage by adopting a time fraction method, a ductility depletion model or a strain energy density depletion model; and evaluating the creep fatigue damage according to a linear damage superposition criterion or a unified creep fatigue equation. According to the creep fatigue damage assessment method for the superheater tube plate, the non-isothermal creep effect, the multiple load holding periods and the stress-strain relaxation history in the load holding periods are considered, creep fatigue total damage assessment can be conducted on the superheater tube plate, and the creep fatigue damage assessment method has the advantages of being visual, high in applicability and high in accuracy.

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com