Ferritic heat-resistant steel

A technology of ferritic and heat-resistant steel, applied in the field of ferritic heat-resistant steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

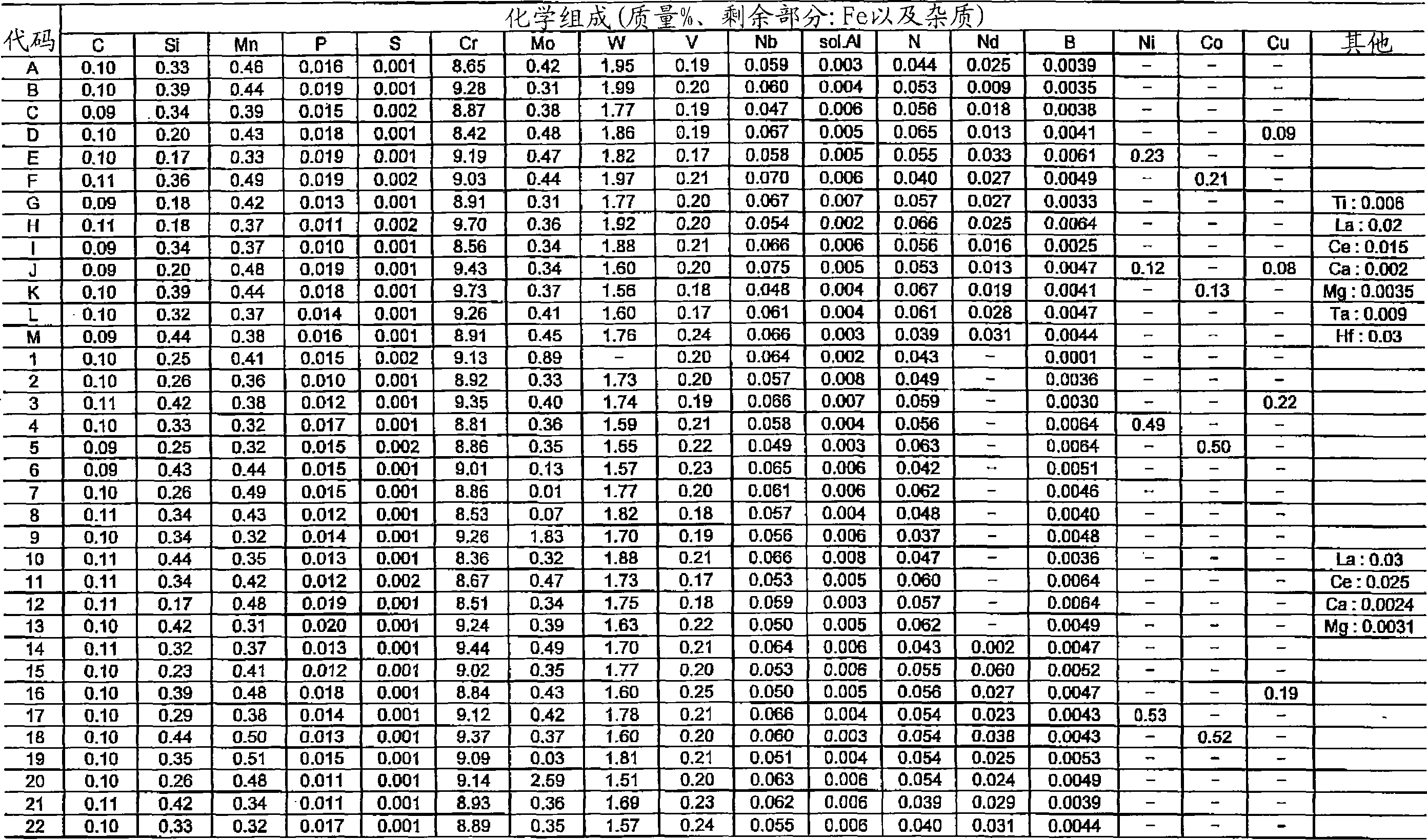

[0105] Steel having the chemical composition shown in Table 1 was melted using a vacuum induction melting furnace to form a 50 kg steel ingot with a diameter of 144 mm. Codes A to M represent steels of the present invention, and codes 1 to 22 represent comparative steels. For steels with codes A to M and steels with codes 15 to 20, Nd is added immediately before casting after sufficiently deoxidizing with C, Si, Mn, and Al. Nd was added to steel code 21 from the start of melting, and Nd was added to steel code 22 after deoxidation by carbon (C) only.

[0106] The above steel ingot was hot forged and hot rolled to form a 20 mm thick plate. Next, after holding at 1050 degreeC temperature for 1 hour, air cooling (AC) was performed. Further, it was kept at 760° C. to 780° C. for 3 hours, and air-cooled (AC) tempering was performed. A sample was selected from the above-mentioned plates, and the longitudinal direction of the sample was oriented in the rolling direction, and a cre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| creep strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com