Creep fatigue damage assessment method for superheater tube plate

A superheater tube, fatigue damage technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problem of not considering non-isothermal conditions or multi-holding creep behavior, unable to predict the history of creep stress relaxation, etc. , to achieve a strong intuitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] Below, according to the drawings, preferred embodiments of the present invention are given and described in detail, so that the functions and features of the present invention can be better understood.

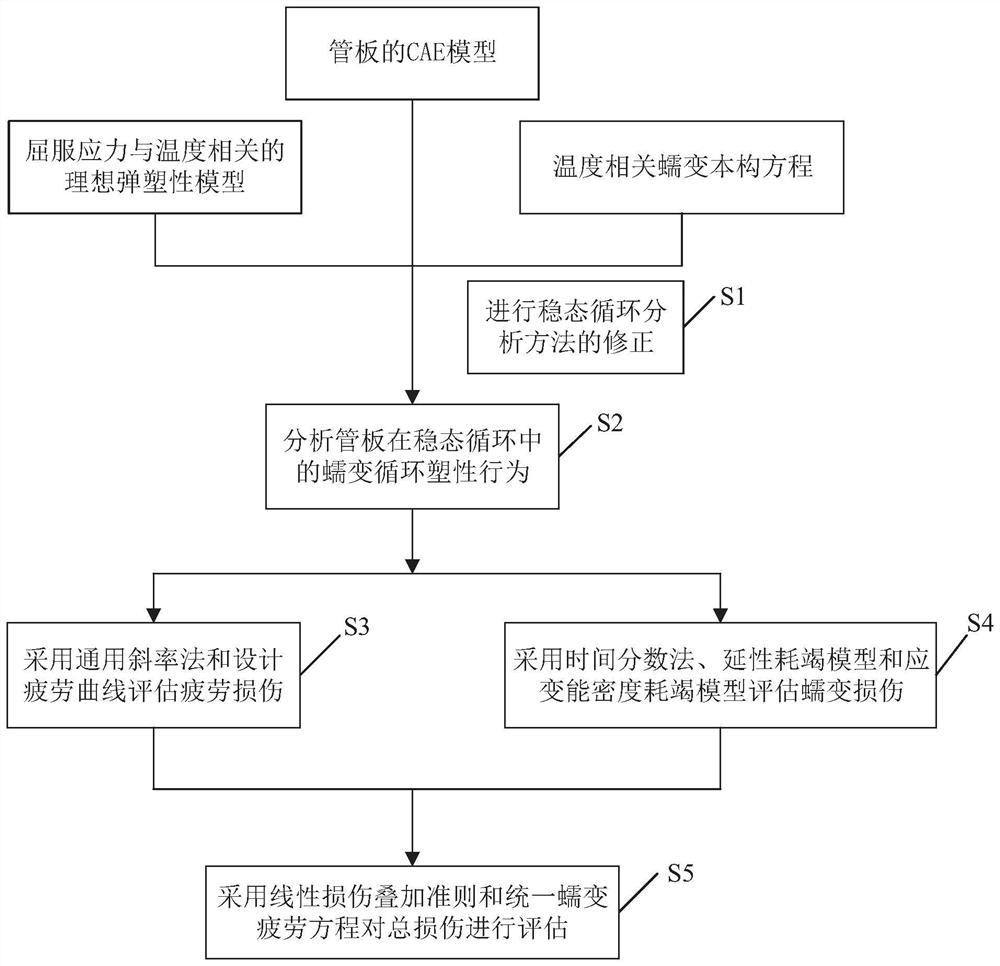

[0089] see figure 1 A creep fatigue damage assessment method for a superheater tube sheet disclosed in the present invention comprises the following steps:

[0090] S1: The steady-state cycle analysis method is modified by considering the three factors of non-isothermal creep, multiple loads and creep relaxation history during the load period.

[0091] Among them, S1 specifically includes:

[0092] S11: Establish a creep strain calculation equation including non-isothermal effects, and the creep strain calculation equation is:

[0093]

[0094] A=A * exp(-Q eng / R gas T) (2);

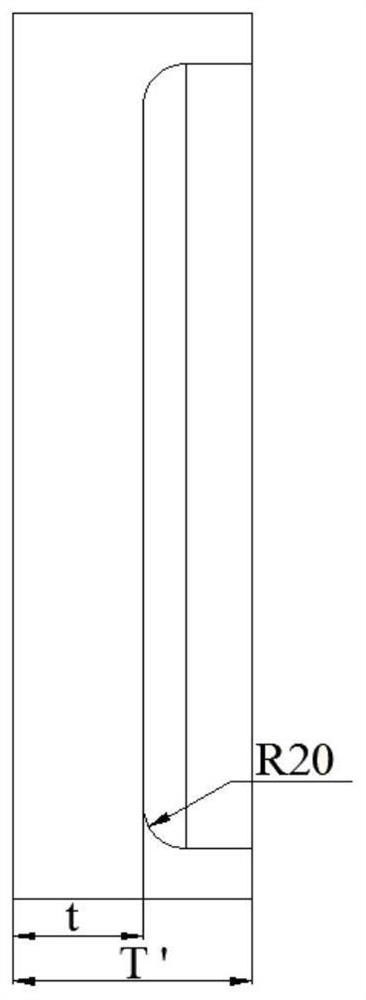

[0095] in, is creep strain rate, A, n, m are creep material constants, σ is stress value, t is holding time, A * is the frequency factor, Q eng is the activation energy, R gas is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com