Creep fatigue life prediction method based on crystal plasticity

A technology for fatigue life prediction and crystal plasticity, applied in constraint-based CAD, special data processing applications, design optimization/simulation, etc., can solve problems such as failure to describe the evolution of stress-strain response damage mechanism at the micro-level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Below, according to the drawings, preferred embodiments of the present invention are given and described in detail, so that the functions and features of the present invention can be better understood.

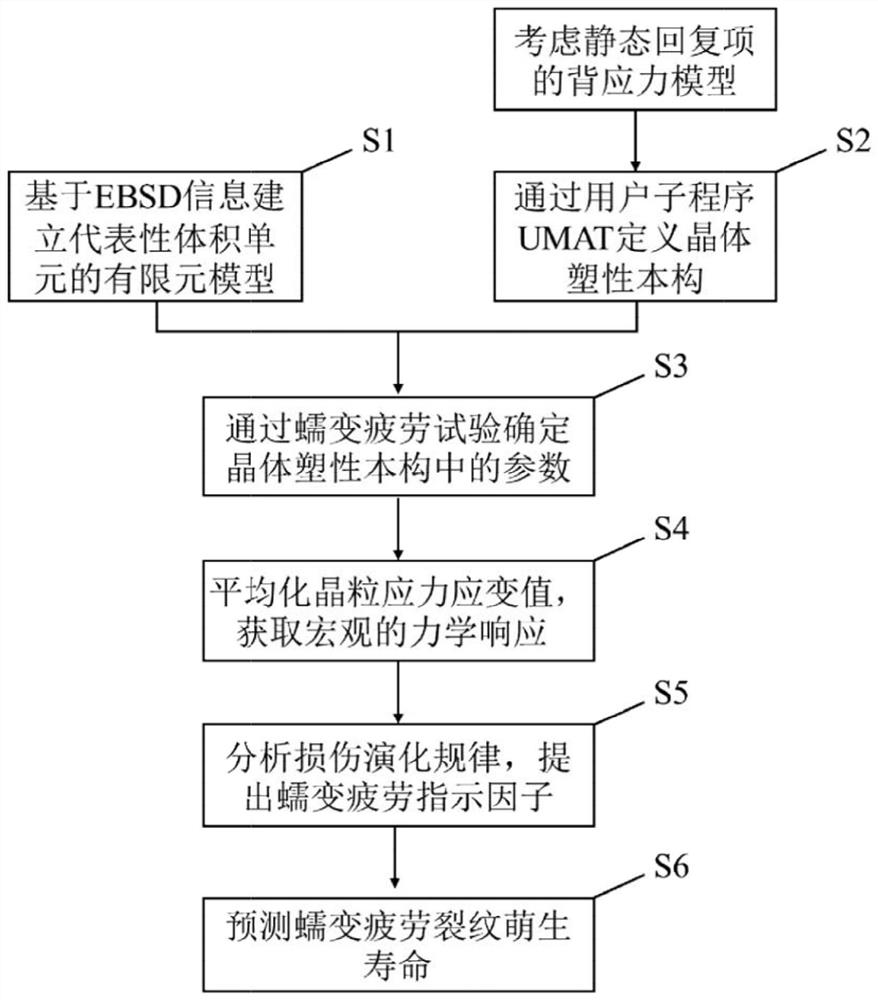

[0065] see figure 1 A method for predicting creep fatigue life based on crystal plasticity disclosed by the present invention comprises the following steps:

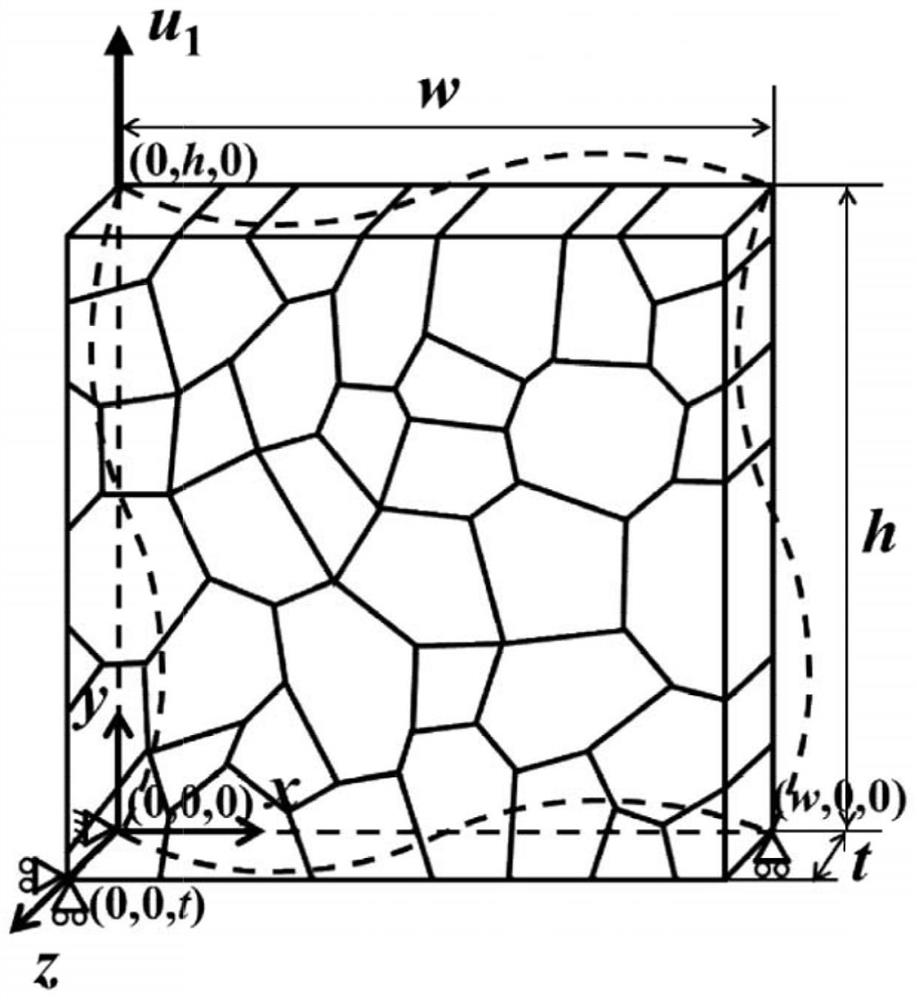

[0066] S1: Obtain the EBSD (Electron Backscatter Diffraction) information of the original material through the backscattered electron diffraction technique. The EBSD information mainly includes crystal orientation and crystal structure information, and the ABAQUS representative unit model is established based on the EBSD information of the material;

[0067] Among them, S1 specifically includes:

[0068] S11: Convert the EBSD information of the material into the nodes and units in the input file readable by ABAQUS and the corresponding grain orientation file through matlab language, where the orientation paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com