Microcomputer control electro-hydraulic servo large bidirectional direct shear apparatus

An electro-hydraulic servo and microcomputer control technology, which is applied to instruments, adopts mechanical devices, and uses stable shear force to test the strength of materials, etc. It can solve the problems of large stress ratio, inability to apply, single detection items, etc., and achieve the degree of automation High, easy to operate, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

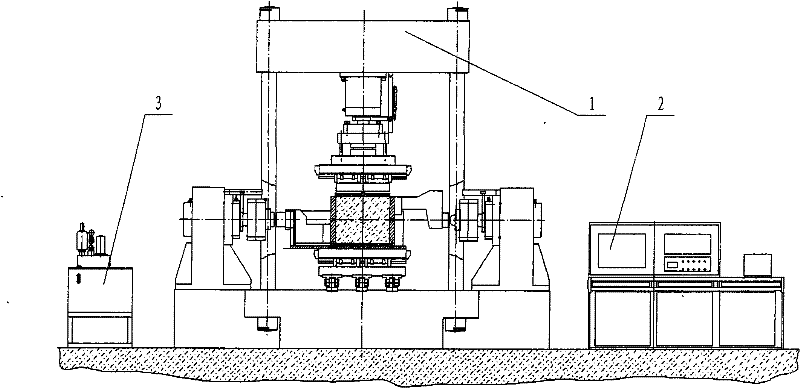

[0021] Such as figure 1 As shown, the present invention is made up of main engine 1, hydraulic system 2, electro-hydraulic servo control system 3.

[0022] Such as figure 2 As shown, the main engine 1 includes a load-bearing beam 101, four columns 102, a load-bearing frame composed of a base 107, and a vertical servo loading cylinder 103 installed on the load-bearing beam 101 at the top of the frame, and the vertical servo load cylinder 103 The upper shear test bench 104 connected by the piston through the load sensor, the two horizontal bearing brackets 106, 106' installed on the upper plane of the lower base 107 of the frame, and the upper center height of the two horizontal bearing brackets 106, 106'. Two horizontal shear servo loading cylinders 105, 110, and the lower shear test bench 108 that enters and exits the test position through the linear guide installed on the machine base 107, and the combined shear box device installed on the lower shear test bench 108 109. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com