Method and apparatus for preparing material coating by laser inductive composite melt-coating

A laser induction and cladding technology, applied in metal material coating process, laser welding equipment, coatings, etc., can solve the problems of easy cracking in the cladding layer, heavy cladding preparation work, and low laser cladding efficiency. , to achieve the effect of improving the utilization rate of laser energy, avoiding damage to important components, and avoiding low cladding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

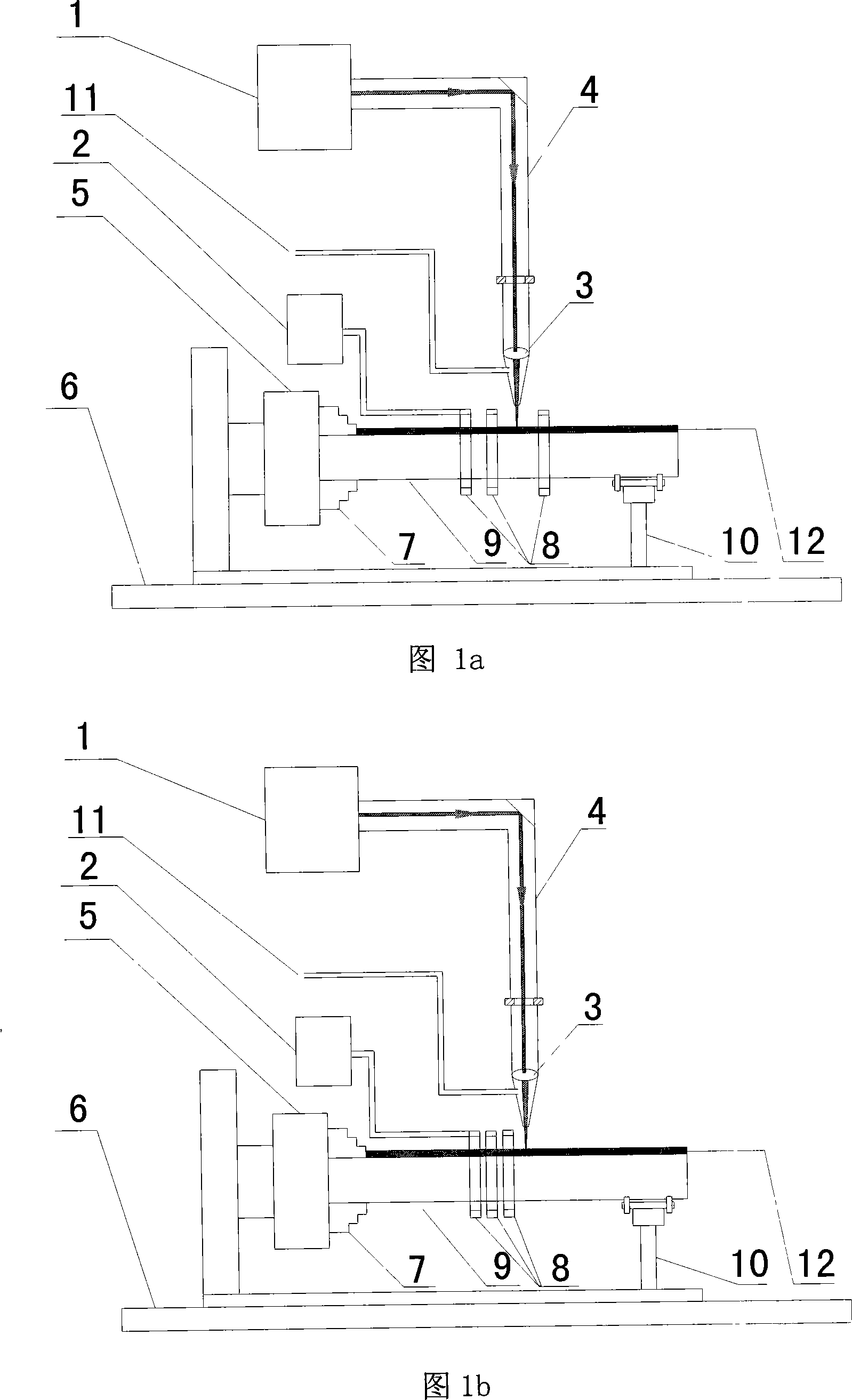

[0050] Select continuous CO 2 Laser, using the device shown in Figure 1a to perform laser induction composite cladding on the outer surface of a tubular metal part with an outer diameter of 110 mm and a wall thickness of 10 mm.

[0051] (1) Sand blasting is carried out to the outer surface of the tubular metal parts;

[0052] (2) Use thermal spraying or cold spraying technology to spray a coating with a thickness of 0.1 mm on the outer surface. The coating material can choose wear-resistant, corrosion-resistant or high-temperature-resistant iron-based, nickel-based or cobalt-based alloy powders, or cermet composite powders composed of the above alloy powders and ceramic particles such as tungsten carbide, titanium carbide, and silicon carbide.

[0053] (3) The distance between the coating on the outer surface of the tubular metal part and the induction heating coil is adjusted to 1 mm, the number of turns of the induction heating coil is 3 turns, and an electric current is pa...

example 2

[0057] Choose a diode laser, and use the device shown in Figure 1b to perform laser induction composite cladding on the outer surface of a tubular metal part with an outer diameter of 300 mm and a wall thickness of 15 mm.

[0058] (1) Sand blasting is carried out to the outer surface of the tubular metal parts;

[0059] (2) Use thermal spraying, cold spraying technology or supersonic flame spraying technology to spray a coating with a thickness of 3.0 mm on the outer surface. The coating material can choose wear-resistant, corrosion-resistant or high-temperature-resistant iron-based, nickel-based or cobalt-based alloy powders, or cermet composite powders composed of the above alloy powders and ceramic particles such as tungsten carbide, titanium carbide, and silicon carbide.

[0060] (3) The distance between the coating on the outer surface of the tubular metal part and the induction heating coil is adjusted to 10 mm, the number of turns of the induction heating coil is 3 turn...

example 3

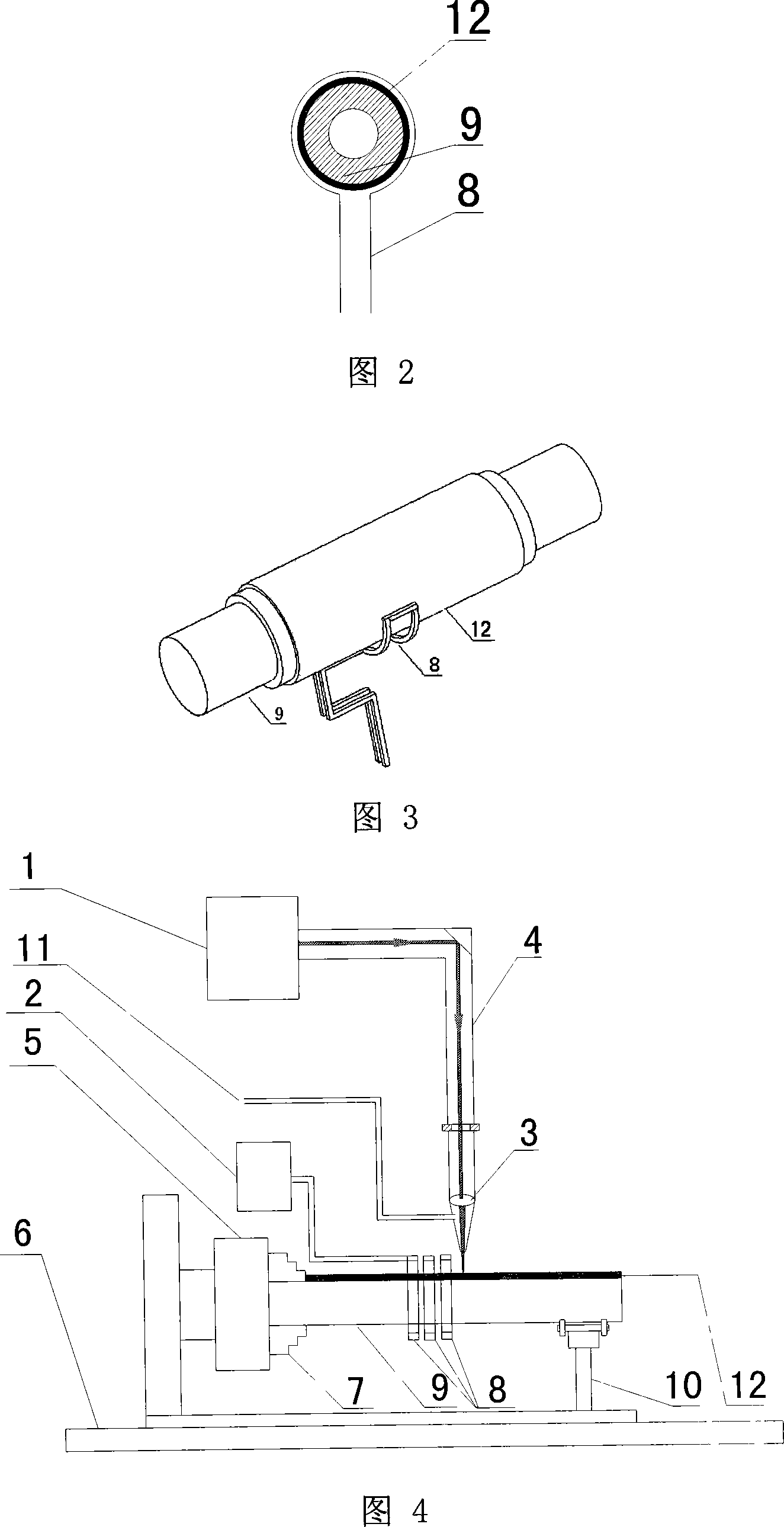

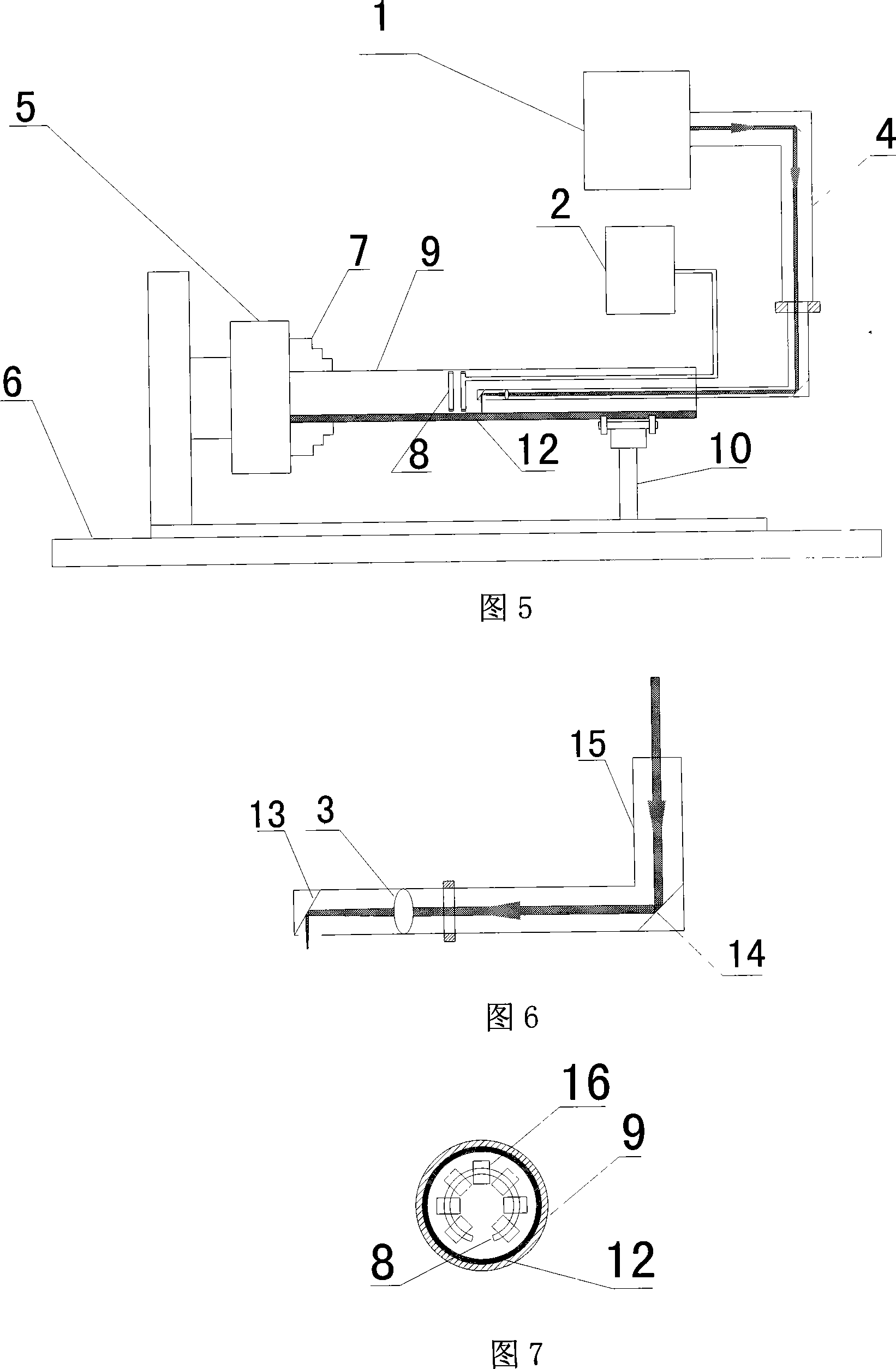

[0064] Select continuous CO 2 Laser, use the device shown in Figure 4 to perform laser induction composite cladding on the surface of the roll with a diameter of D = 600 mm, and this device is also suitable for solid parts such as crankshafts and oil drill pipes.

[0065](1) Sandblasting the surface of the roll first;

[0066] (2) Use thermal spraying, cold spraying technology or supersonic flame spraying technology to spray a coating with a thickness of 1 mm on the surface of the roll. The coating material can choose wear-resistant, corrosion-resistant or high-temperature-resistant iron-based, nickel-based or cobalt-based alloy powders, or cermet composite powders composed of the above alloy powders and ceramic particles such as tungsten carbide, titanium carbide, and silicon carbide.

[0067] (3) The distance between the coating on the surface of the metal parts of the roll and the induction heating coil is adjusted to 5 millimeters, the number of turns of the induction hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com