Preparation method of biologically active nanometer composite layer on medical-use metal surface

A bioactive and nanocomposite technology is applied in the field of preparing bioactive composite layers with nanostructures, and achieves the effects of simple procedure, strong operability and short time period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

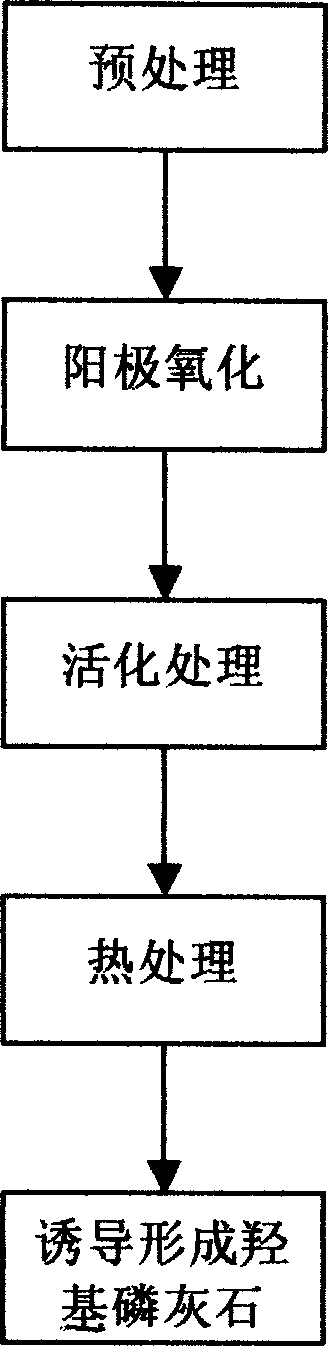

[0023] Such as figure 1 Shown, the present invention provides a kind of medical metal surface bioactive nanocomposite layer preparation method, and it comprises the steps:

[0024] Pretreatment step, put the medical pure titanium or titanium alloy substrate into the diluted acid solution for erosion treatment;

[0025] In the anodic oxidation step, the pretreated titanium or titanium alloy substrate is used as the anode, placed in a polytetrafluoroethylene beaker containing an electrolyte solution, and the stainless steel or platinum sheet is used as the cathode, and anodized for 0.5 to 6 hours to form a dense Titanium dioxide nanotube structure film;

[0026] Activation treatment step, after the anodic oxidation is completed, wash the titanium or titanium alloy substrate with water, and put it into an alkaline solution at 40-80°C for activation treatment for 0.5-3 hours;

[0027] Heat treatment step, the treated titanium or titanium alloy substrate is placed in a temperatur...

experiment example 1

[0037]Put the medical pure titanium TA2 matrix into 3% diluted hydrofluoric acid solution for erosion for 60 seconds, remove the dirt and oxides on the surface, rinse and dry with deionized water; put the pretreated titanium matrix As an anode, put it into a polytetrafluoroethylene beaker containing 0.4% hydrofluoric acid electrolyte, and stainless steel as a cathode, perform anodic oxidation at a DC voltage of 20V and 15°C for 0.5 hours; put the oxidized titanium substrate into a 60 ℃ for 1 hour in a 5mol / L sodium hydroxide solution, rinsed with deionized water, and dried; then put the titanium substrate into a temperature-controlled box-type resistance furnace and raise the temperature to 500°C with a heating rate of 5°C / min, and kept at 500°C for 2 hours, and took it out after cooling to room temperature. After immersing the treated titanium substrate in a pre-prepared simulated body fluid at 36.5°C for 7 days, it was taken out for cleaning and drying. Wherein, each ion c...

experiment example 2

[0039] Put the medical titanium alloy substrate into a mixture containing 2% hydrofluoric acid and 15% nitric acid for 60 seconds to remove dirt and oxides on the surface, rinse and dry with deionized water; The treated titanium alloy substrate is used as an anode, put into a polytetrafluoroethylene beaker containing 0.4% hydrofluoric acid electrolyte, stainless steel is used as a cathode, and anodic oxidation is carried out at a DC voltage of 20V and 25°C for 0.5 hours; the oxidized Put the titanium alloy substrate into a 10mol / L sodium hydroxide solution at 60°C for 30 minutes of activation treatment, rinse with deionized water, and dry; then put the titanium alloy substrate into a temperature-controlled box-type resistance furnace and raise the temperature to 600 °C, the heating rate is 10 °C / min, and it is kept at 600 °C for 1 hour, and it is taken out after cooling to room temperature. After immersing the treated titanium alloy substrate in the pre-prepared simulated body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com