Method for casting aluminium alloy

A technology of aluminum alloy and molten aluminum, applied in the field of aluminum alloy casting, can solve problems such as failure to meet requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

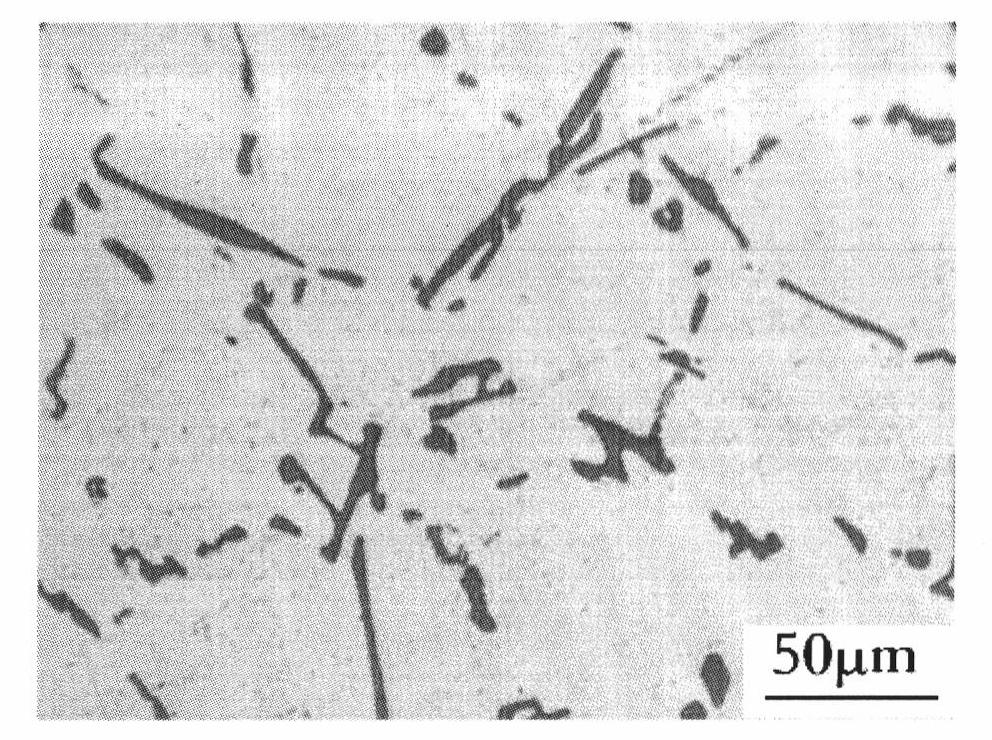

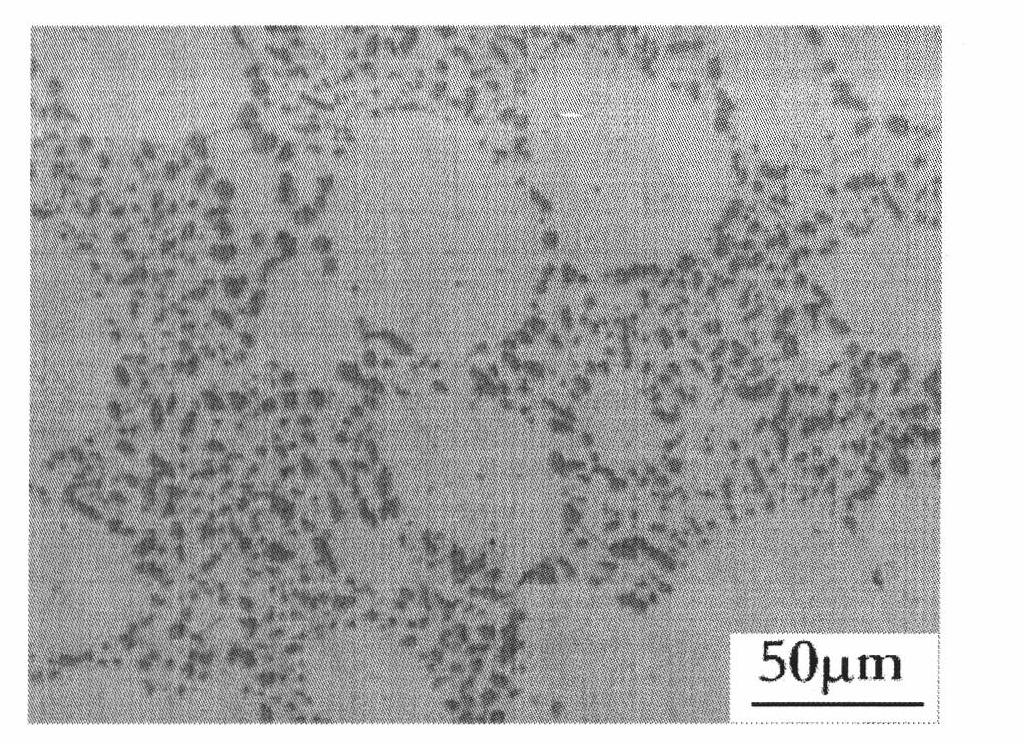

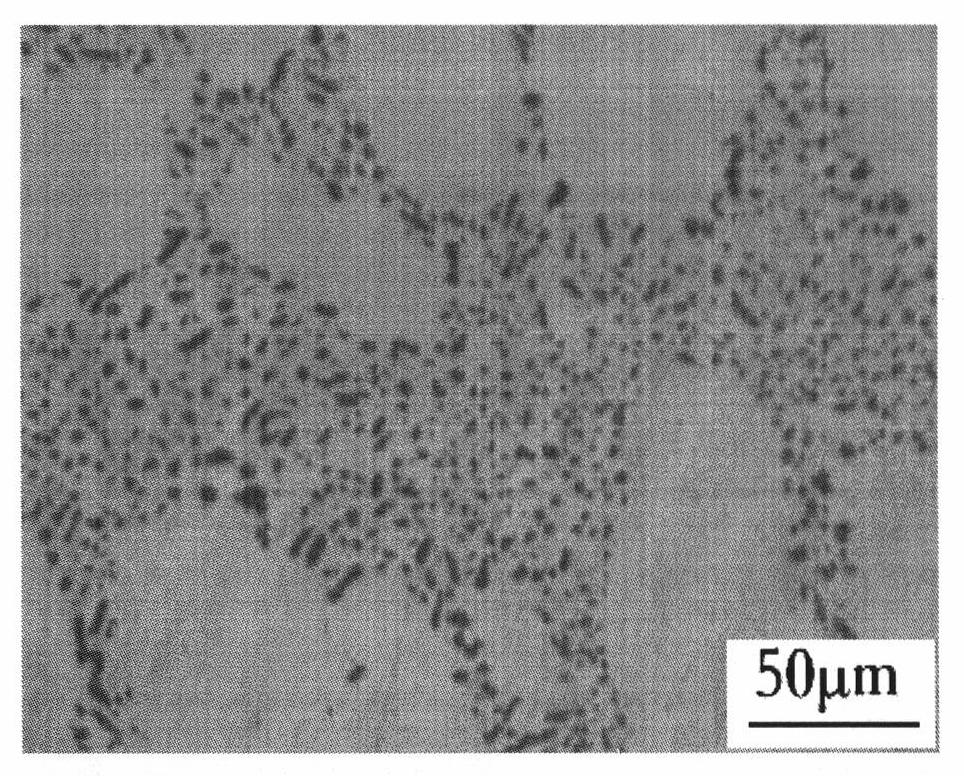

Image

Examples

Embodiment 1

[0031]Smelting: Smelting aluminum ingots, the used aluminum ingots are ZL101, purchased from Baotou Aluminum Company. .08-0.20%, Fe≤0.20%, Mn≤0.01, Cu≤0.01, Zn≤0.01, and the balance is Al. The bell jar, the pouring spoon and the slag scraping tool used in the smelting process are all pre-painted with zinc oxide paint and dried, and the molten aluminum is obtained by smelting.

[0032] Refining: When the temperature of the molten aluminum reaches 710-720 ℃, use a bell jar to press in the dried additives. The additives are purchased from Shanghai Kaiwan Hardware Processing Factory. The product name is WL-1 aluminum alloy pollution-free refining and metamorphic covering agent. 2-5 minutes, do not slag slag, use a rotary blowing device to introduce dry nitrogen, and refine for 15-20 minutes. During the refining process, control the temperature of the molten aluminum at 710-720 ° C to obtain an aluminum melt; the amount of the above additives is aluminum. 1.2% of the liquid mass, ...

Embodiment 2

[0036] Smelting: Smelting aluminum ingots, the used aluminum ingots are ZL101, purchased from Baotou Aluminum Company. .08-0.20%, Fe≤0.20%, Mn≤0.01, Cu≤0.01, Zn≤0.01, and the balance is Al. The bell jar, the pouring spoon and the slag scraping tool used in the smelting process are all pre-painted with zinc oxide paint and dried, and the molten aluminum is obtained by smelting.

[0037] Refining: When the temperature of the molten aluminum reaches 710-720 ℃, use a bell jar to press in the dried additives. The additives are purchased from Shanghai Kaiwan Hardware Processing Factory. The product name is WL-1 aluminum alloy pollution-free refining and metamorphic covering agent. 2-5 minutes, do not slag slag, use a rotary blowing device to introduce dry nitrogen, and refine for 15-20 minutes. During the refining process, control the temperature of the molten aluminum at 710-720 ° C to obtain an aluminum melt; the amount of the above additives is aluminum. 1.0% of the liquid mass,...

Embodiment 3

[0041] Smelting: Smelting aluminum ingots, the used aluminum ingots are ZL101, purchased from Baotou Aluminum Company. .08-0.20%, Fe≤0.20%, Mn≤0.01, Cu≤0.01, Zn≤0.01, and the balance is Al. The bell jar, the pouring spoon and the slag scraping tool used in the smelting process are all pre-painted with zinc oxide paint and dried, and the molten aluminum is obtained by smelting.

[0042] Refining: When the temperature of the molten aluminum reaches 710-720 ℃, use a bell jar to press in the dried additives. The additives are purchased from Shanghai Kaiwan Hardware Processing Factory. The product name is WL-1 aluminum alloy pollution-free refining and metamorphic covering agent. 2-5 minutes, do not slag slag, use a rotary blowing device to introduce dry nitrogen, and refine for 15-20 minutes. During the refining process, control the temperature of the molten aluminum at 710-720 ° C to obtain an aluminum melt; the amount of the above additives is aluminum. 1.3% of the liquid mass,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com