Alkaline-earth heat insulating magnesium alloy for vehicle use and producing method thereof

A magnesium alloy and alkaline earth technology, which is applied in the field of alkaline earth heat-resistant magnesium alloy and its preparation, can solve problems such as increased equipment investment, environmental pollution, and reduced alloy performance, and achieve comprehensive performance improvement, good flame retardancy, and heat resistance. The effect of performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

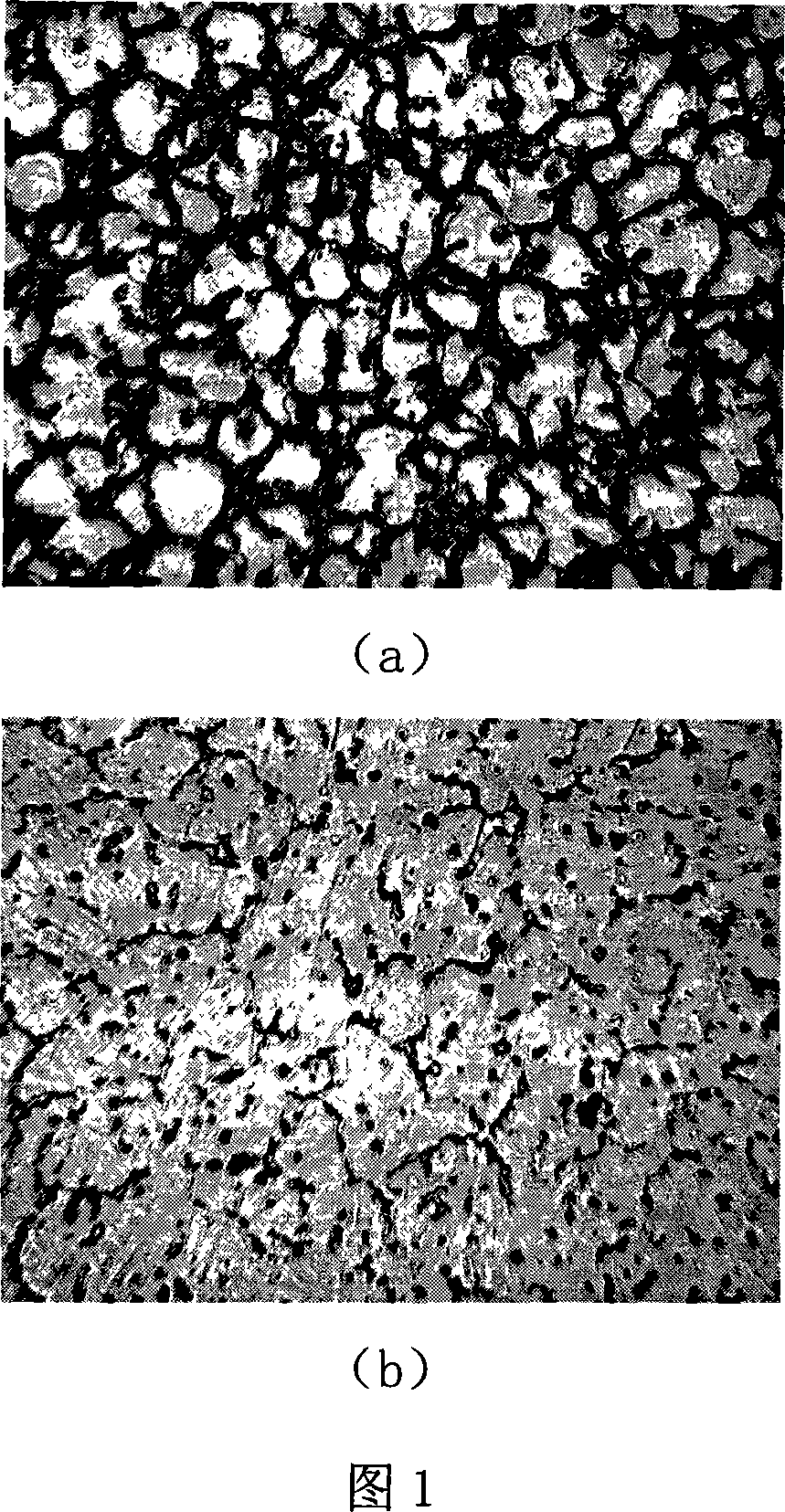

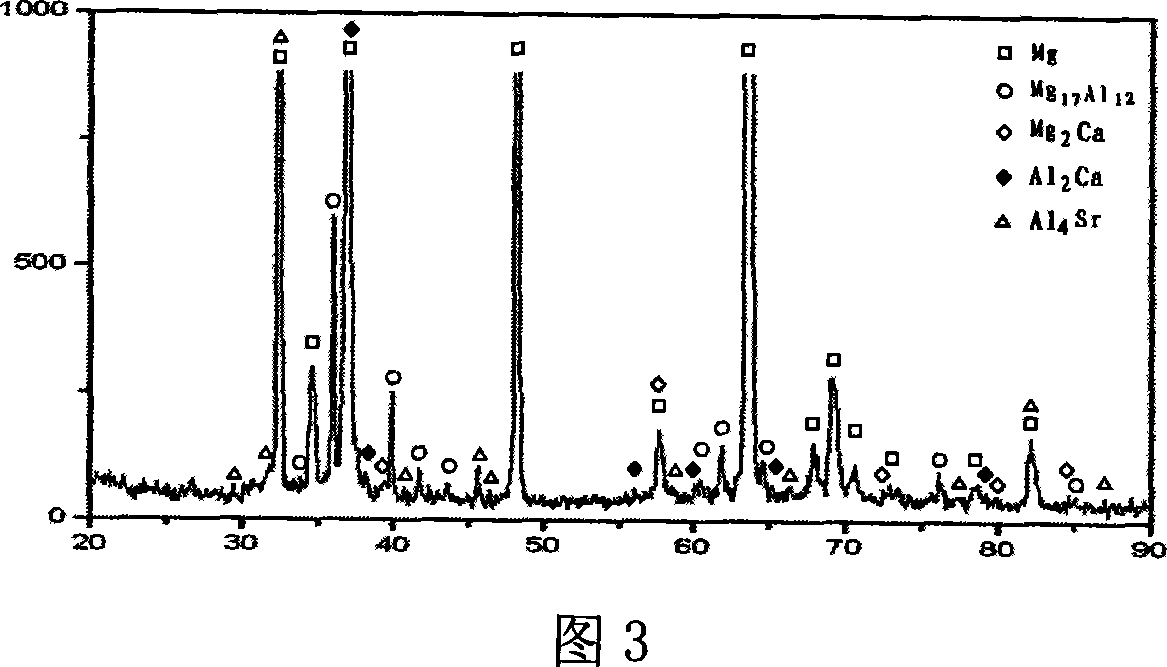

Embodiment 1

[0039] Example 1: The composition of the alloy is (weight percent): 7.5% Al, 1.2% Zn, 0.1% Mn, 1.5% Ca, 0.05% Sr, 89.65% Mg (containing trace unavoidable impurities).

[0040] The present invention smelts in the molten pool of low-carbon steel, and only adds a little RJ2 covering agent in the early stage of smelting, and the raw materials adopted are: magnesium is pure magnesium, with a purity greater than 99.99%; aluminum is pure aluminum, containing at least 99.9%; zinc is commercially available The pure zinc for sale has a purity of 99.8%; manganese is electrolytic flake pure manganese, which should be coated and pressed into the alloy liquid during smelting, and the dissolution time of more than 30 minutes should be guaranteed; calcium is in the form of an intermediate alloy Al-75% Ca When added, it is easy to suspend on the liquid surface and oxidize rapidly. When added, it should be coated and pressed into the alloy liquid; strontium is added in the form of master alloy A...

Embodiment 2

[0042] Embodiment 2: The alloy composition adopted is (by weight): 9% Al, 0.8% Zn, 0.8% Mn, 0.8% Ca, 0.15% Sr, 88.45% Mg (containing trace unavoidable impurities). Select the appropriate proportion of raw materials according to the above proportions. Under the protection of a small amount of covering agent, first add the preheated pure magnesium into the crucible. After it is completely melted, add pure aluminum and pure zinc respectively at about 650 ° C. Finally, pure manganese, Al-Sr, and Al-Ca master alloys are coated and pressed into the liquid surface to prevent suspension on the liquid surface and oxidation. After the alloy is completely melted, stir and mix evenly and raise the temperature to 720°C. After 20 minutes of refining, it can be seen that the magnesium liquid has a silver-white mirror surface, and the surface is covered with a very thin layer of solvent. Let it stand for 30 minutes before pouring. The temperature of the permanent mold is 150°C, the liquid flo...

Embodiment 3

[0043] Example 3: The alloy composition used is (by weight): 8% Al, 1% Zn, 0.45% Mn, 1.1% Ca, 0.1% Sr, 89.35% Mg (containing trace unavoidable impurities). Configure alloy raw materials according to the above ingredients, add preheated Mg into the cleaned electric heating crucible, and sprinkle a small amount of RJ2 covering agent on the magnesium and the bottom of the crucible; after the pure magnesium is completely melted, add Al and Zn respectively After the melting is complete, wrap the intermediate alloy of Mn, Ca, and Sr with aluminum foil, press it under the liquid surface, and after it is completely melted, raise the temperature to 720°C, and stir the alloy liquid vigorously with a stirring spoon for 10 minutes. After completion, the magnesium liquid can be seen as a silver-white mirror. , non-stick stirring tool, the liquid surface is covered with a very thin layer of solvent. After standing still for 30 minutes, pour it into a steel mold with a temperature of 150°C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ultimate tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com